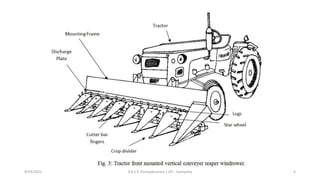

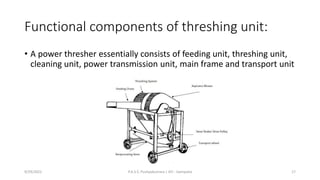

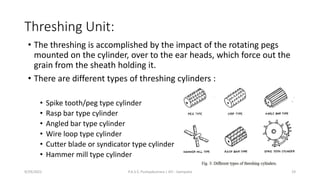

The document discusses various agricultural machinery used in harvesting and processing crops. It describes reapers, which can be animal-drawn, engine-powered, or tractor-mounted. It also describes combine harvesters, which both reap and thresh grains crops in a single pass. Threshers are discussed as machines that separate seeds from stalks using a rotating drum and concave. The document provides details on components and principles of operation for reapers, combines, threshers, and machinery used in rice milling and parboiling.