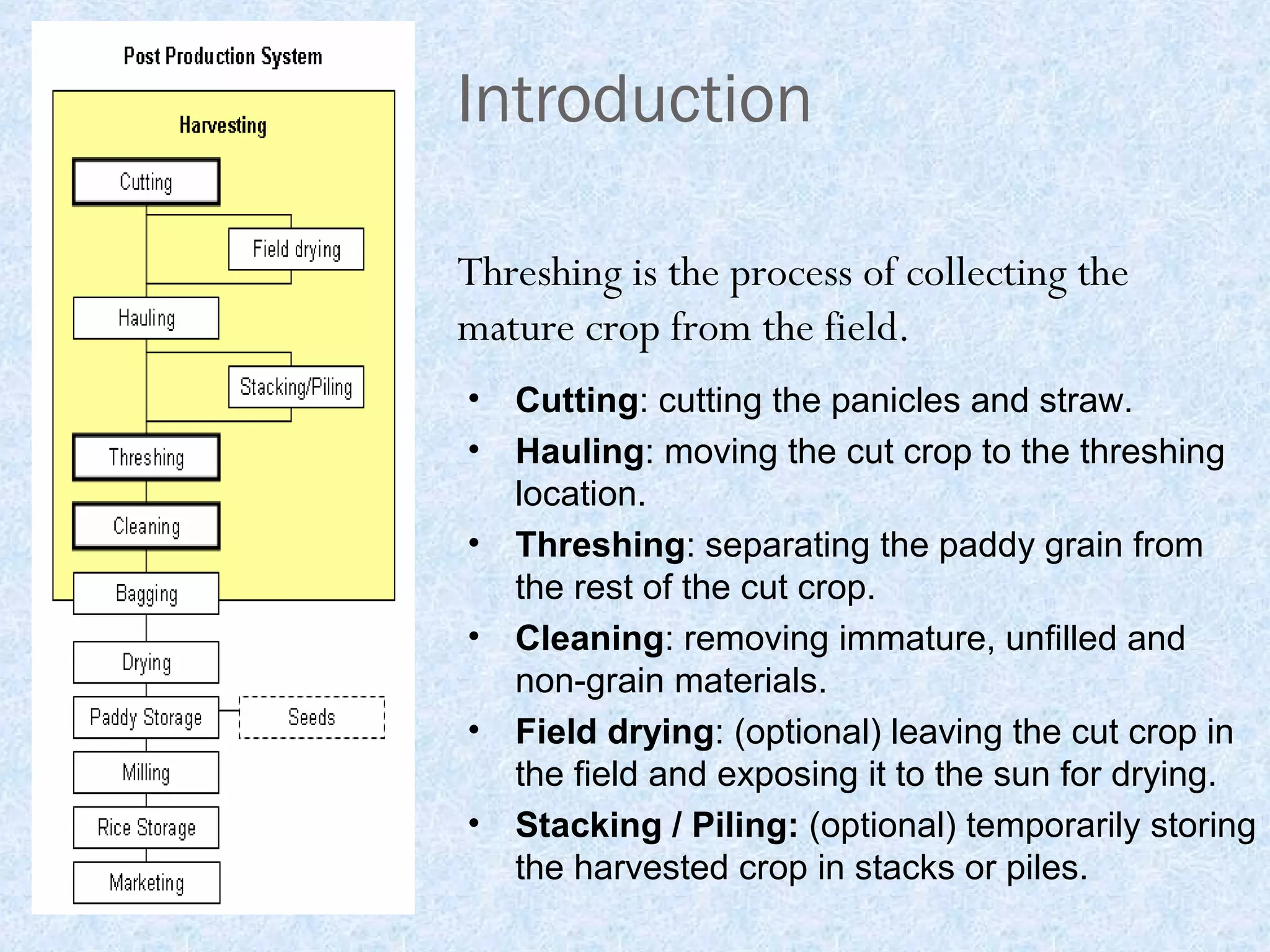

This document provides information about threshing processes and a Super Jet multicrop thresher. It discusses:

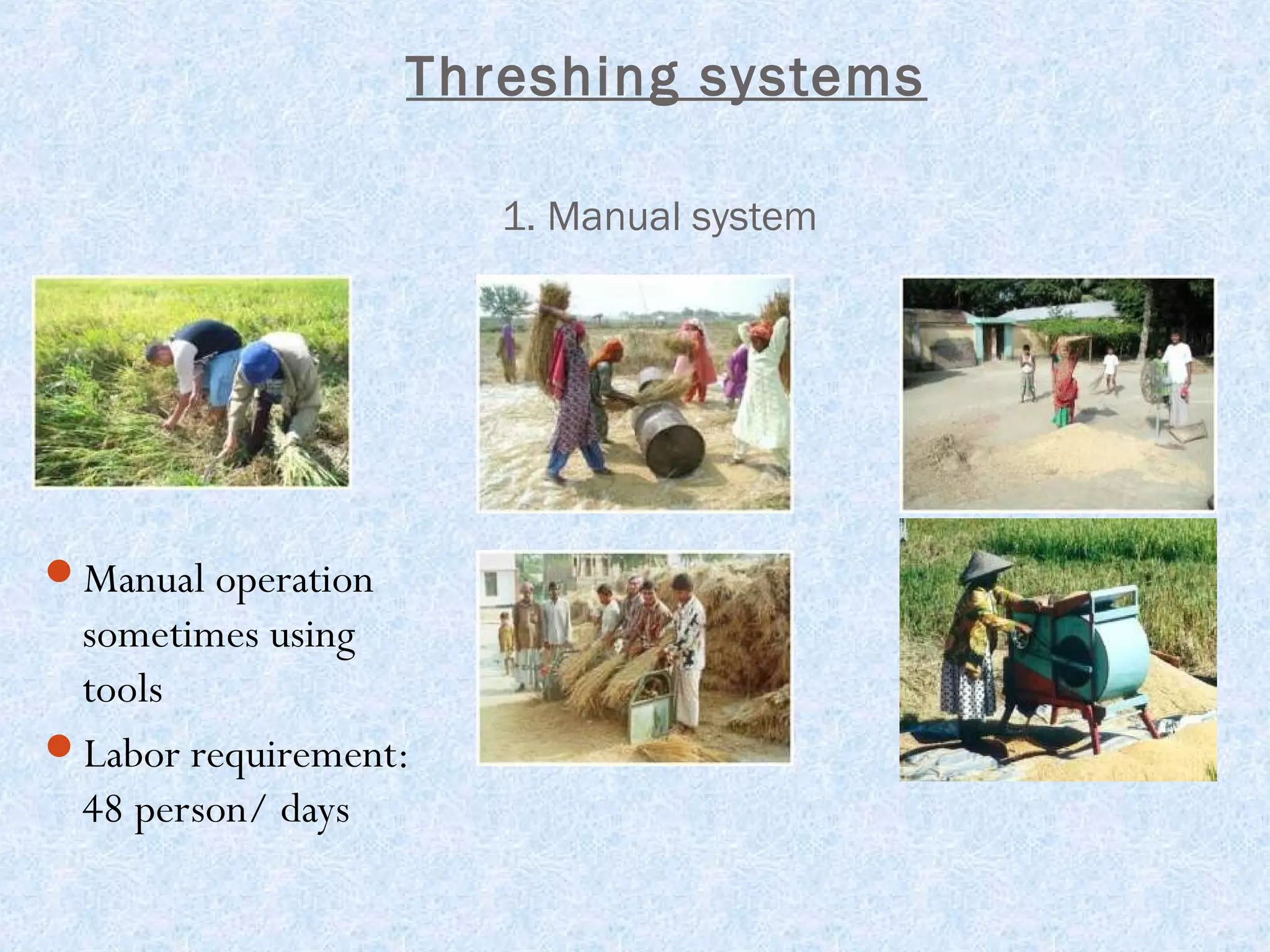

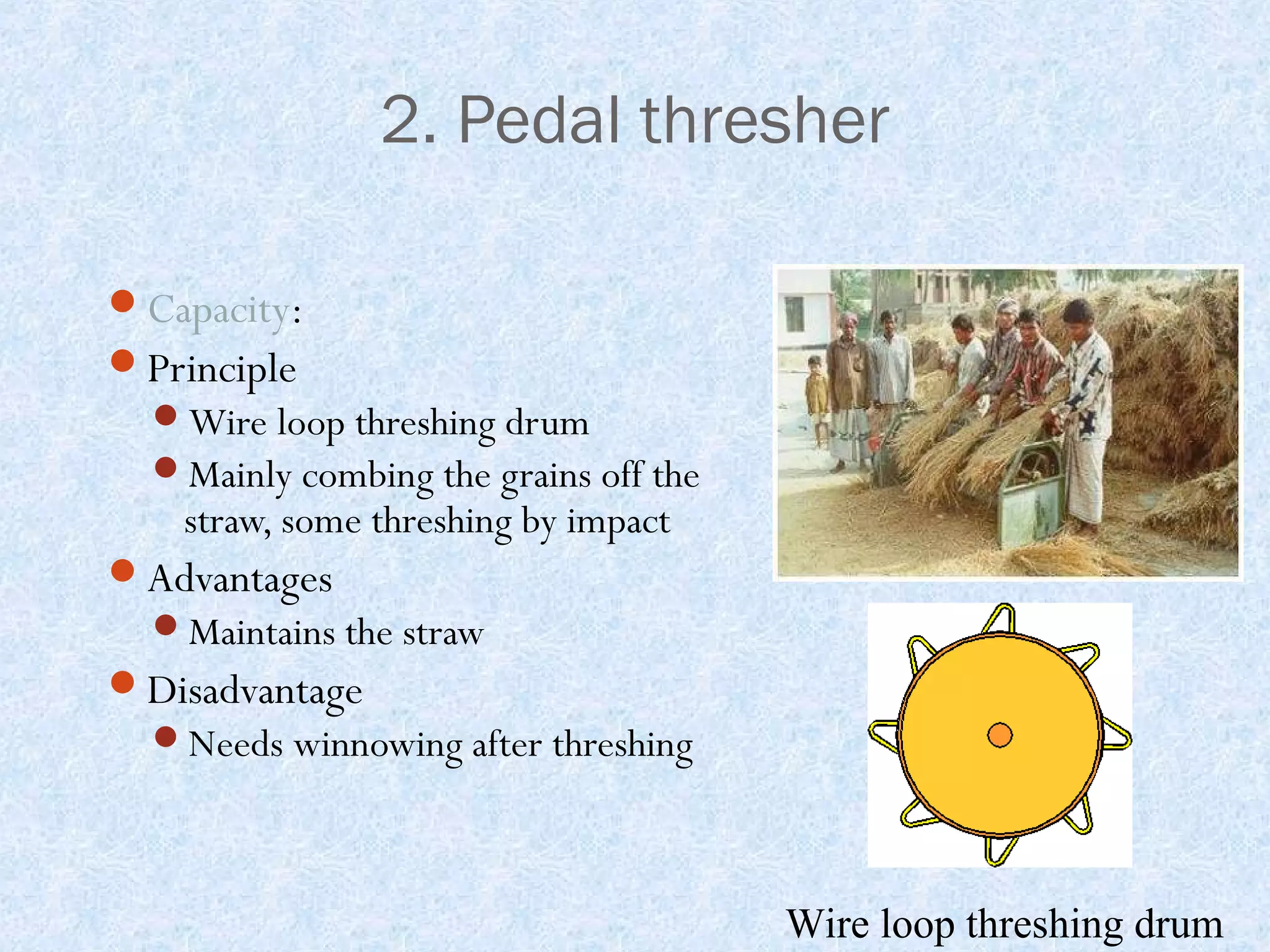

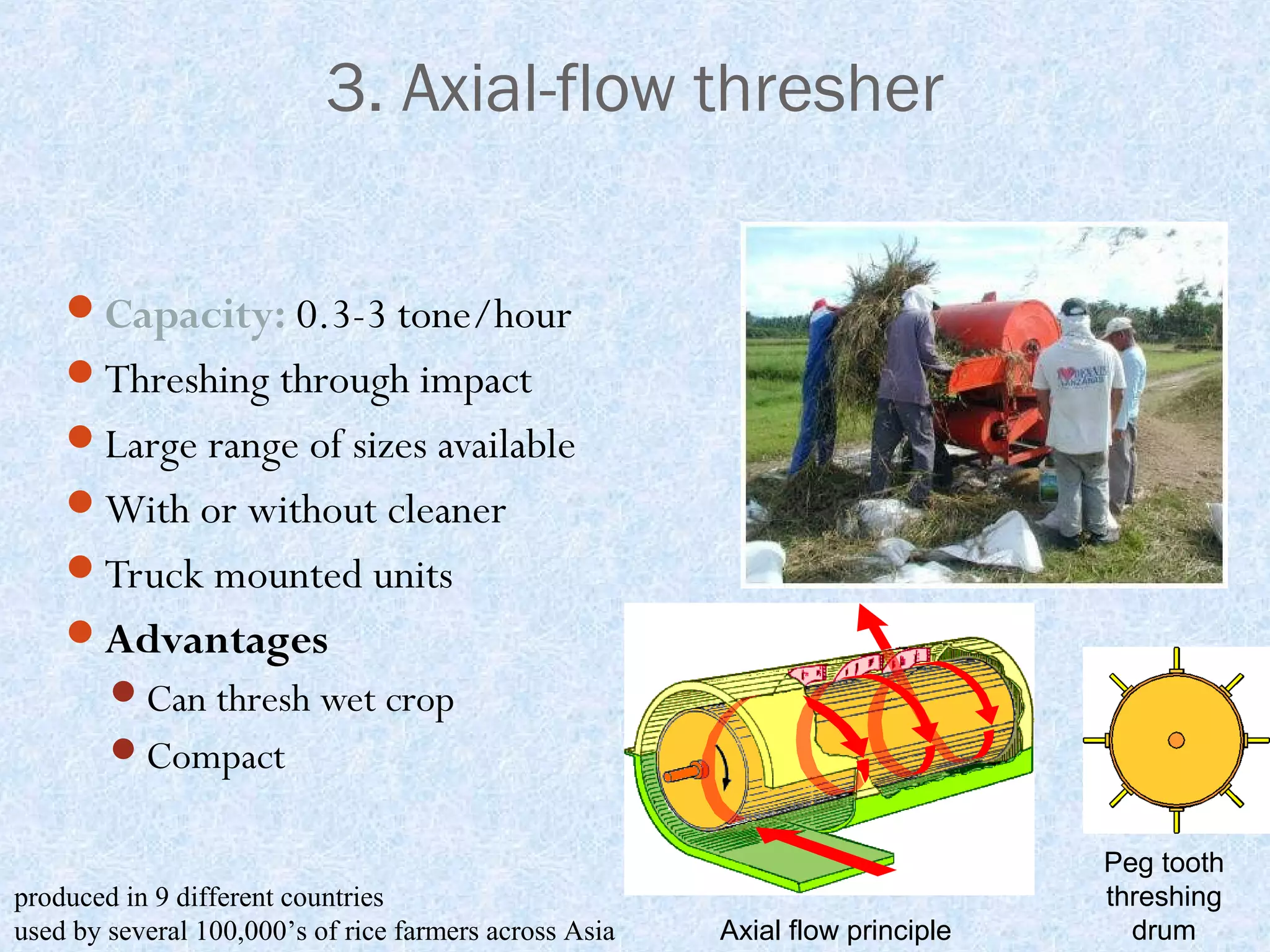

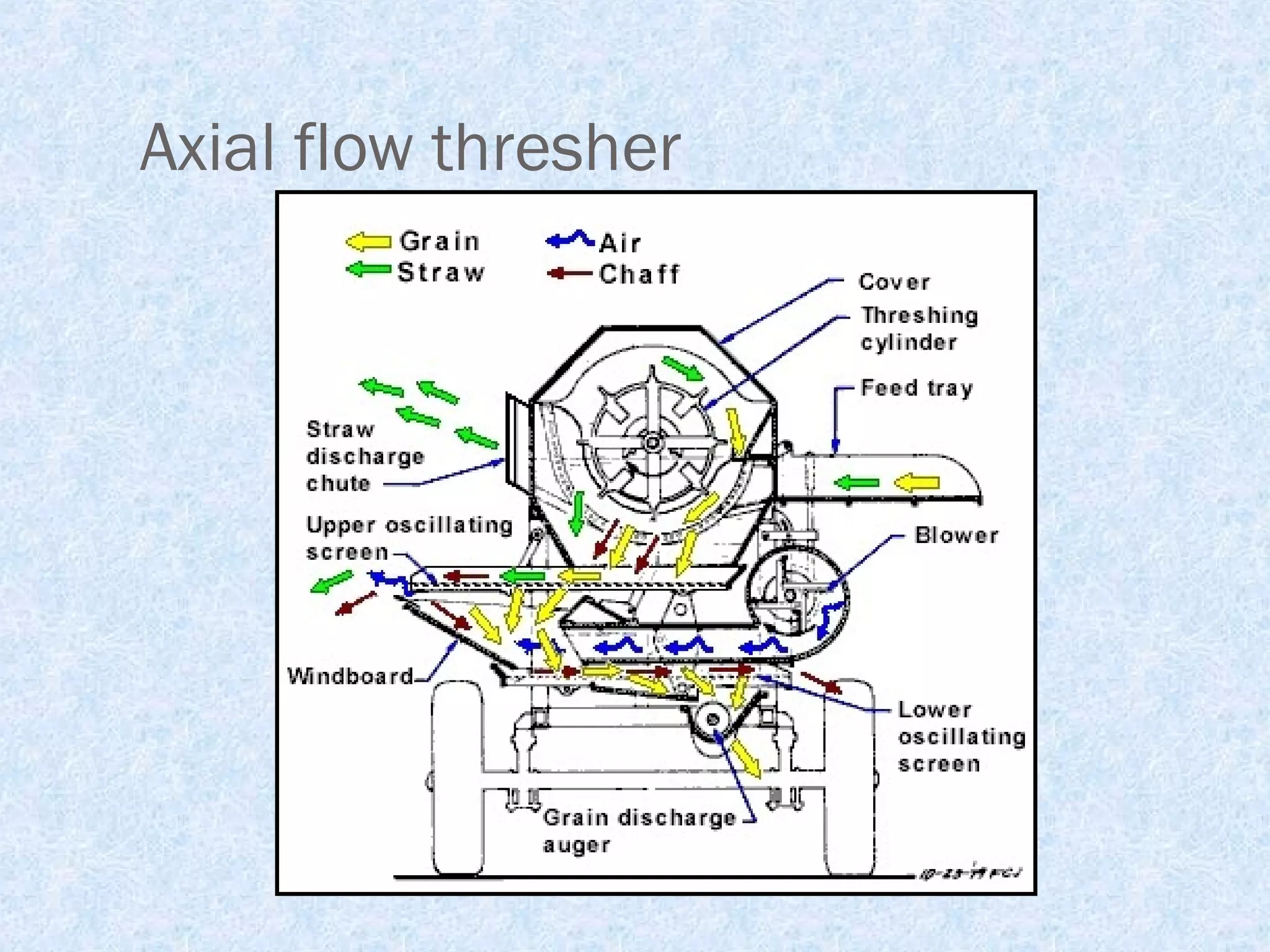

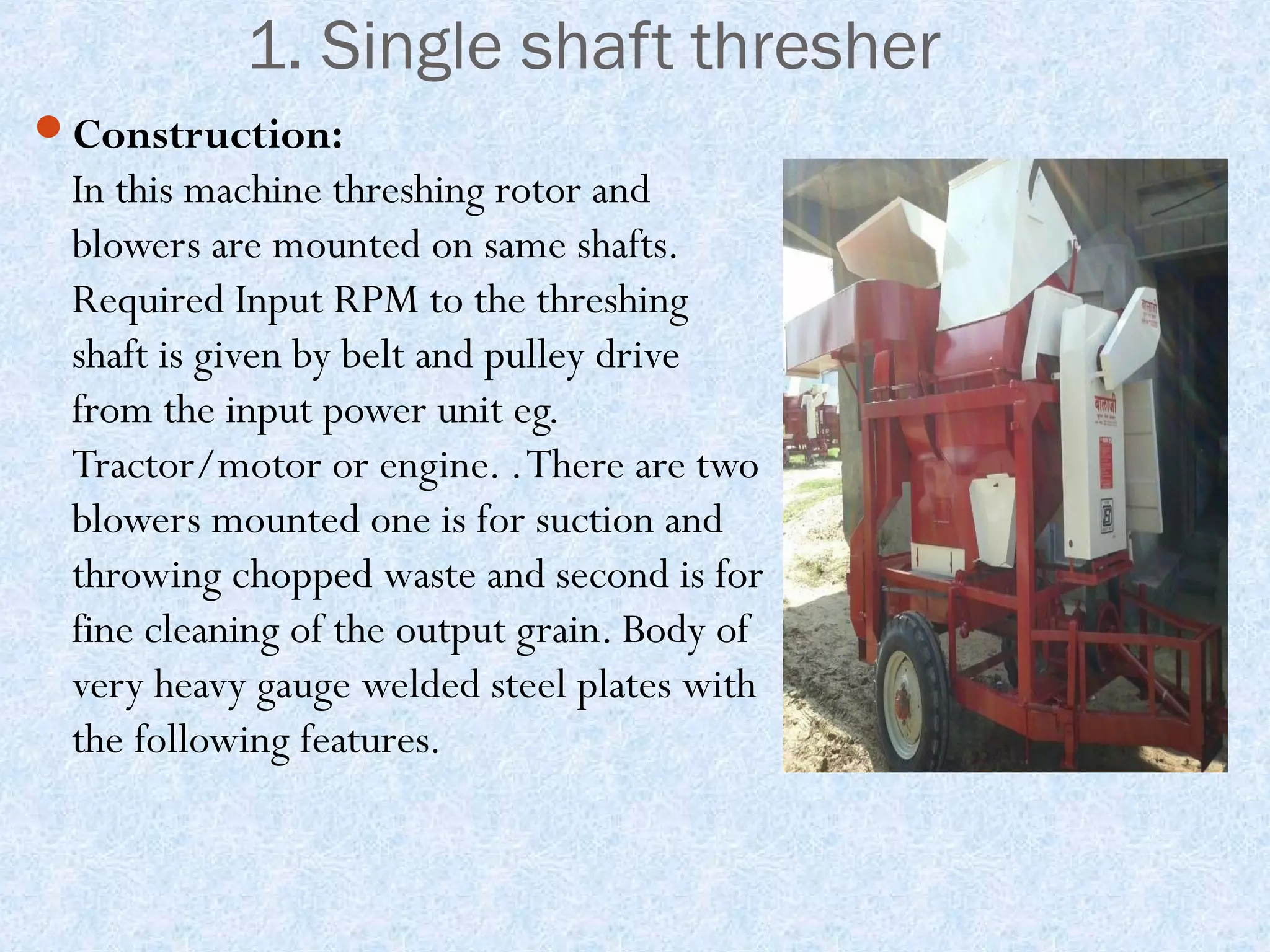

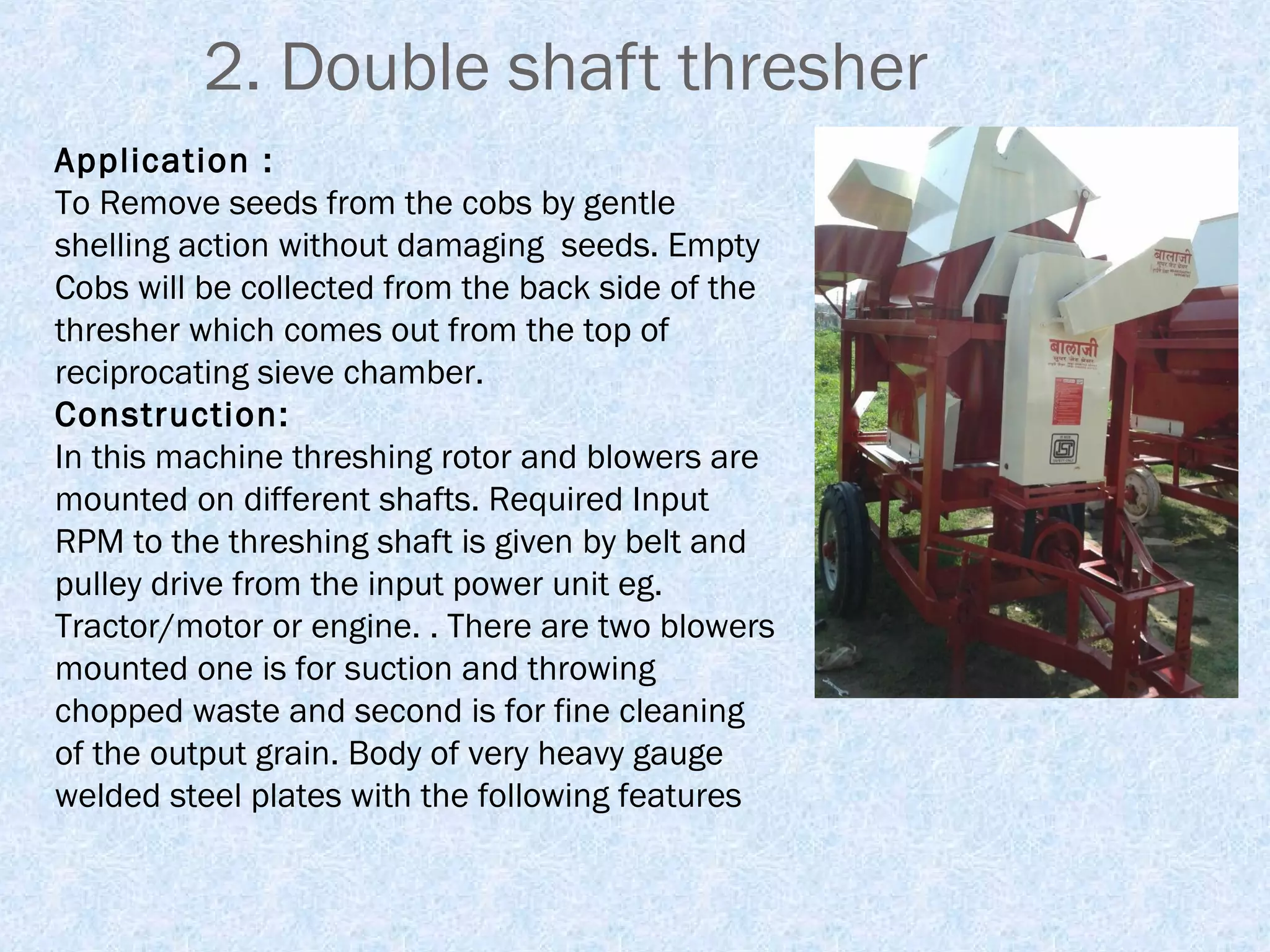

1) Types of threshing systems including manual, pedal, axial-flow, and Super Jet multicrop threshers. The Super Jet comes in single shaft, double shaft, and autofeeder models.

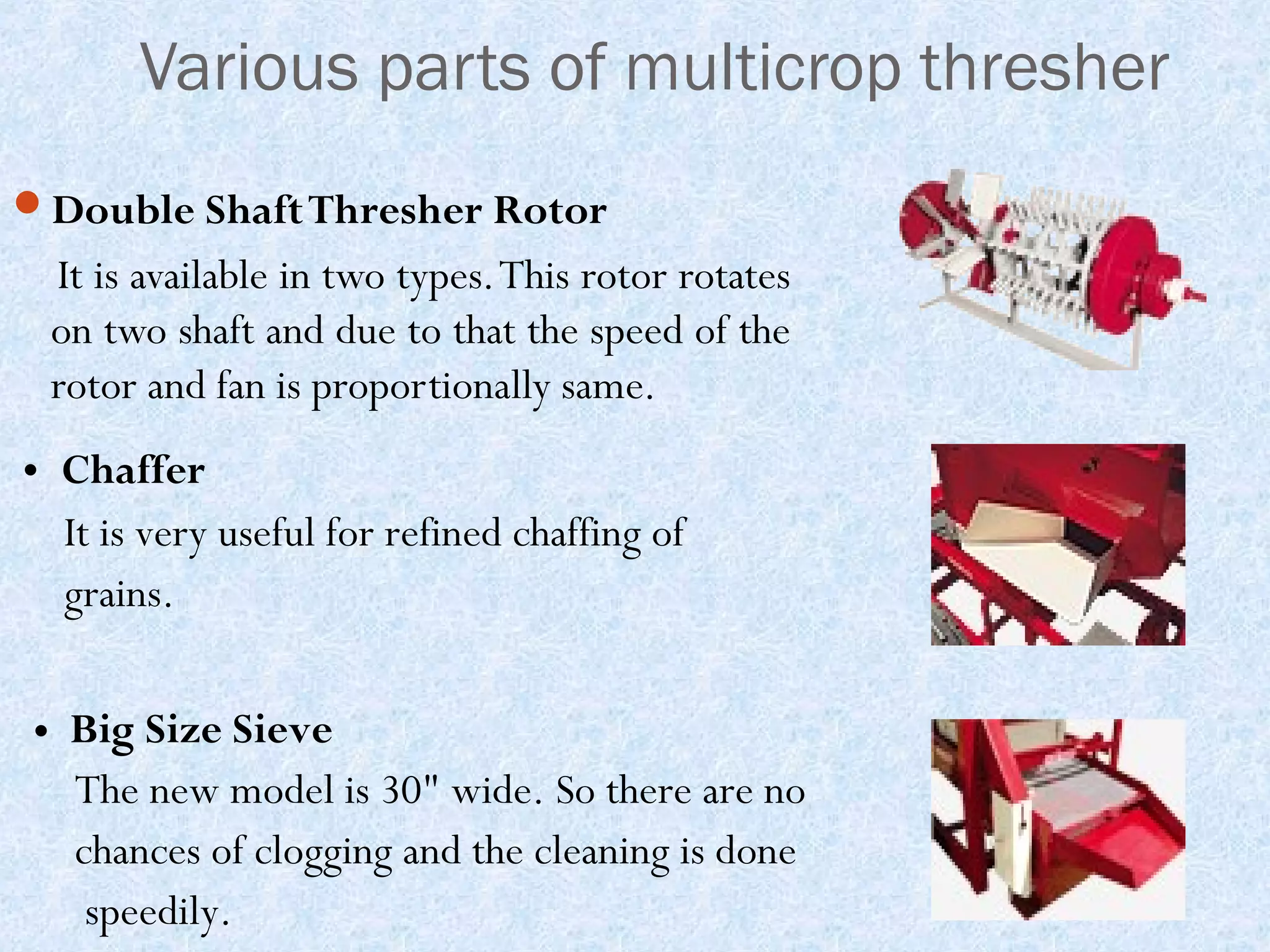

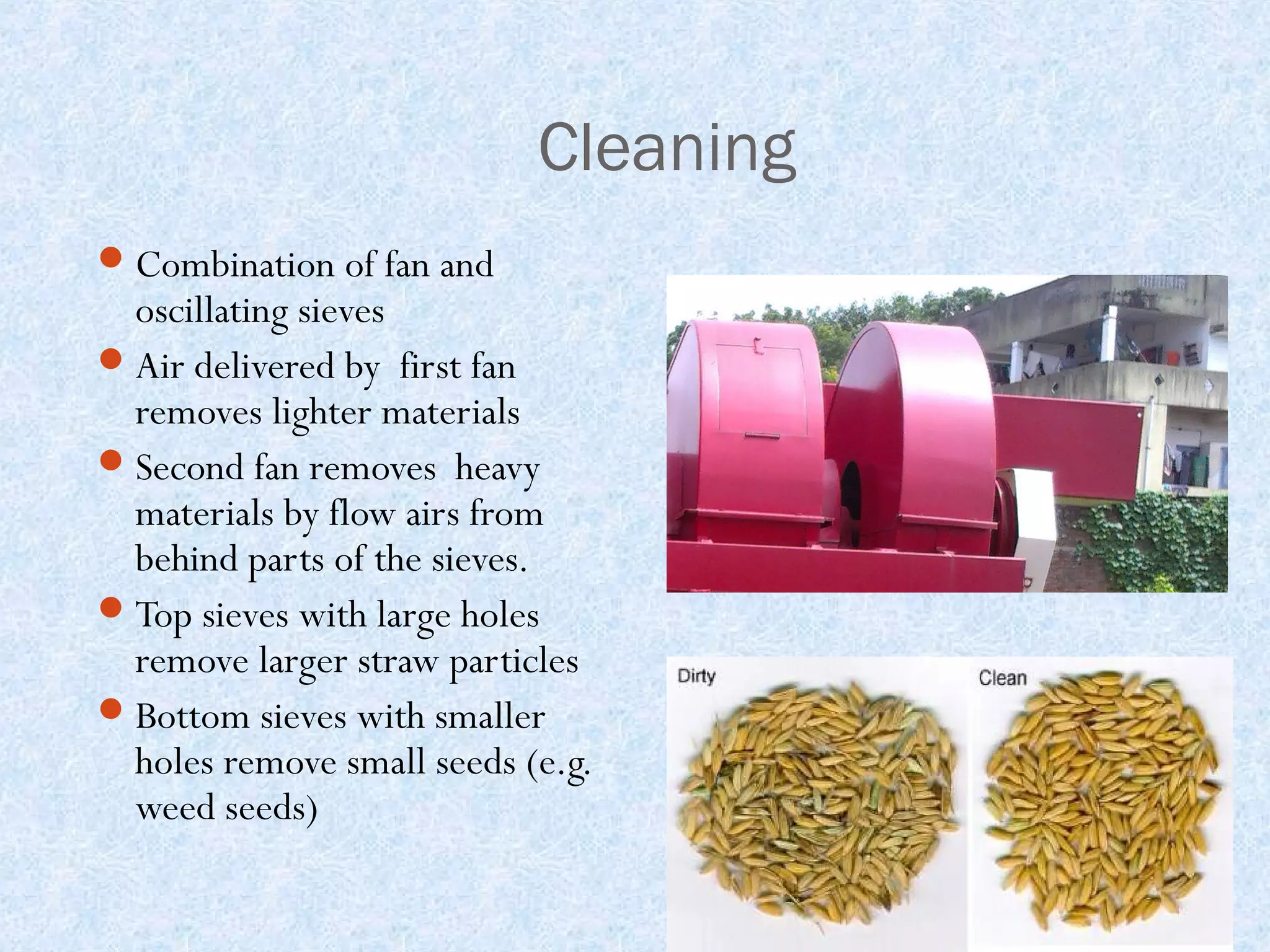

2) Parts of the Super Jet thresher including the threshing rotor, chaffer, sieves, table, blowers, gearbox, and auto-feeder hopper.

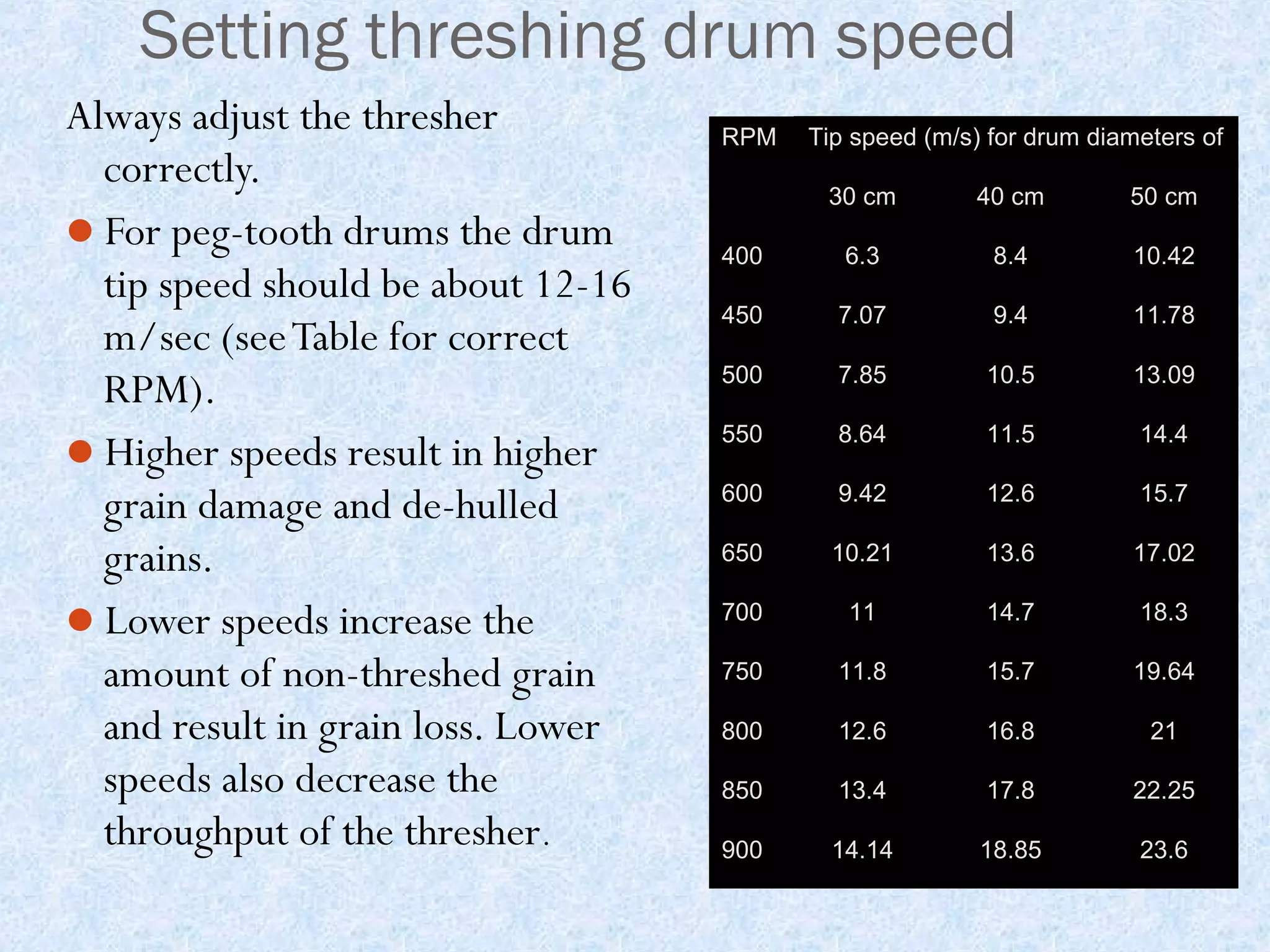

3) Recommendations for optimizing threshing such as using the proper machine settings and timing threshing based on crop moisture content. Tips are provided for both manual and machine threshing.