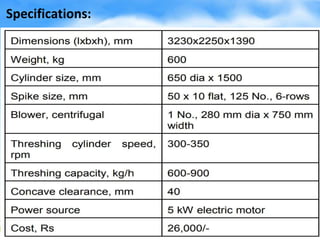

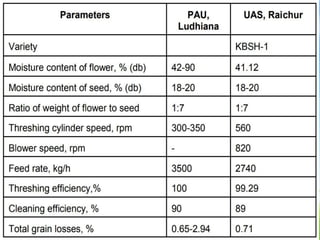

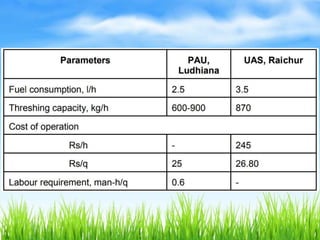

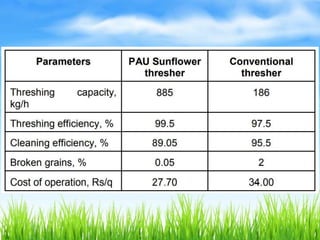

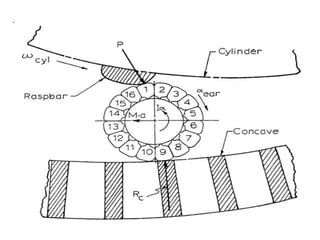

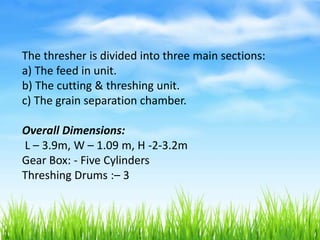

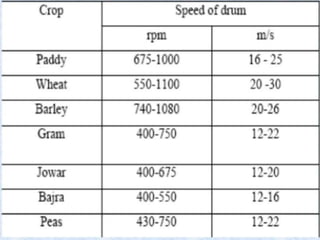

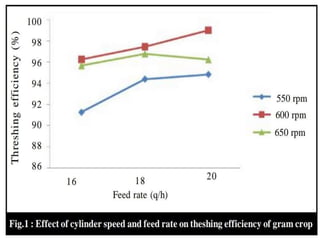

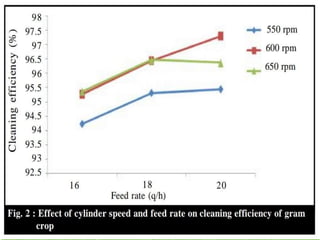

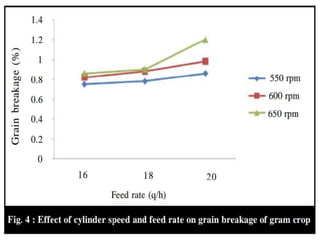

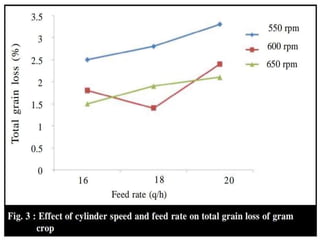

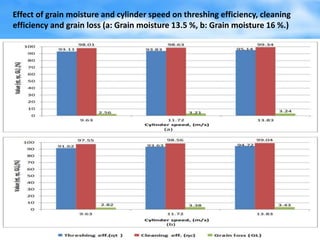

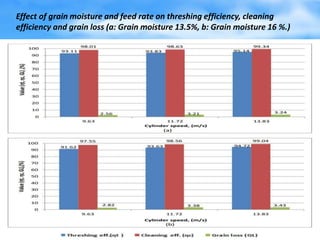

This document provides specifications for several agricultural threshing machines. It describes a paddy thresher that consists of a feeding chute, threshing cylinder, blower, and grain and straw outlets. It is made of steel and powered by a 5 hp engine. It also describes a sunflower thresher with a 65 cm diameter threshing cylinder and cleaning system. Further, it provides details on a maize dehusker-cum sheller that uses staggered pegs and sieves to separate husks from shelled maize. Charts are also included showing the effects of cylinder speed, grain moisture, and feed rate on threshing efficiency and grain loss.