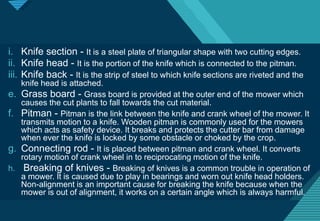

Harvesting and threshing equipment are important for removing crops from fields. Sickles are manually operated tools used to harvest crops like rice. Mowers cut herbage crops using cylinders, reciprocating blades, or rotary knives. Self-propelled harvesters reduce labor needs and increase coverage area for harvesting rice. Combine harvesters integrate harvesting, threshing, cleaning, and collection in a single machine to process multiple crops. Threshers separate grains from harvested crops using cylinders fitted with spikes, hammers, or wire loops along with concaves and sieves to minimize loss.