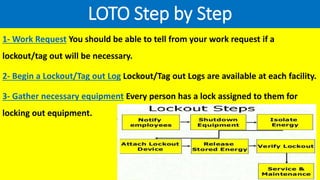

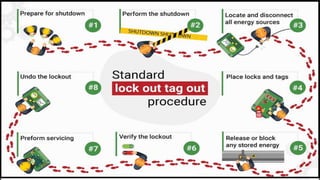

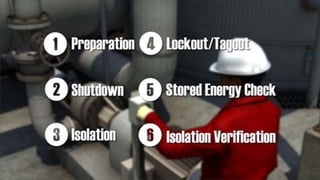

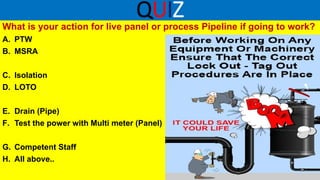

The correct action for working on a live panel or process pipeline is to follow all the steps listed:

A. Permit to Work

B. Manage System Risk Assessment

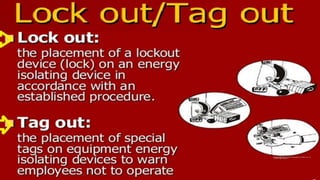

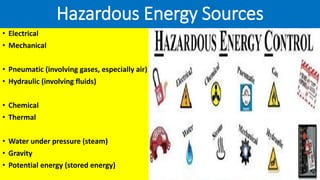

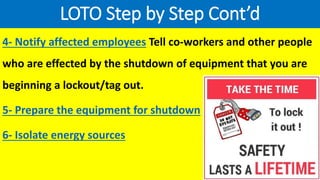

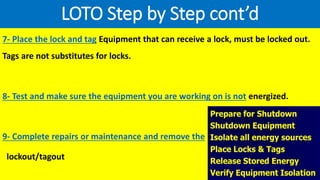

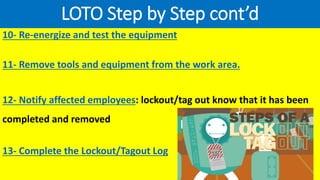

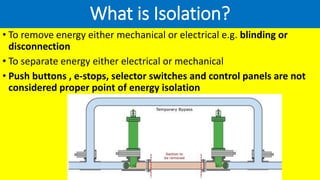

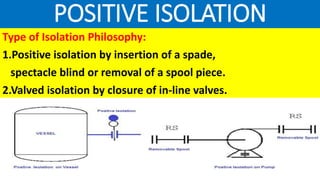

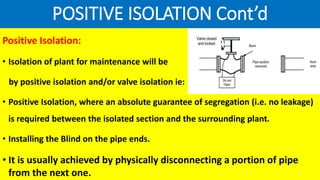

C. Isolate the energy sources

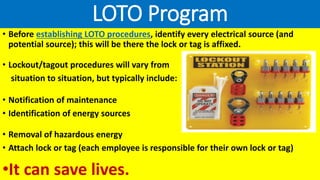

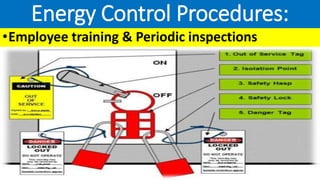

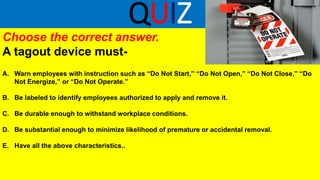

D. Lockout/Tagout the energy isolating devices

E. Drain the pipeline if required

F. Test that the power/energy is isolated using a multimeter for panels

G. Ensure only competent and authorized staff perform the work

H. All of the above steps should be followed to safely isolate, control and verify isolation of hazardous energy sources.