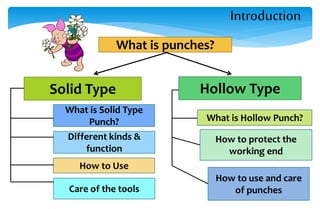

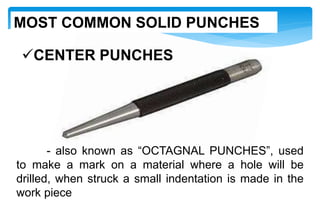

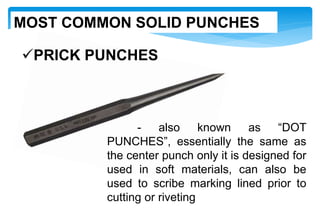

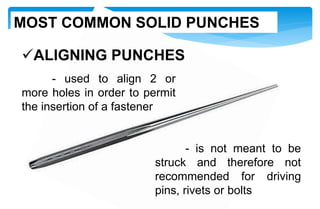

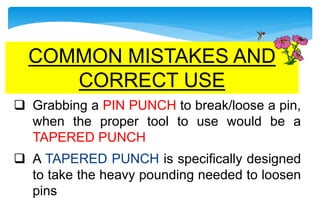

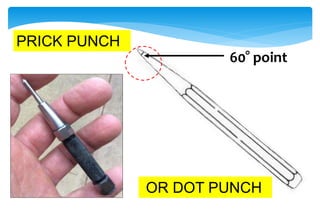

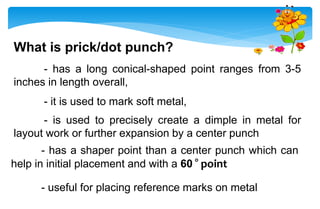

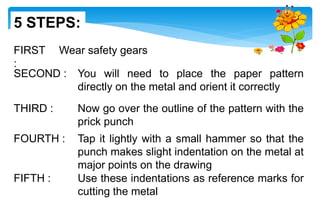

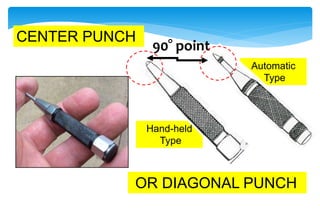

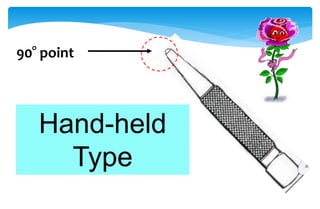

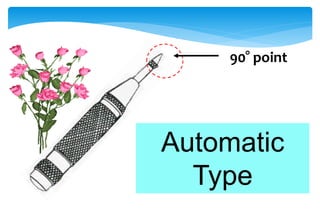

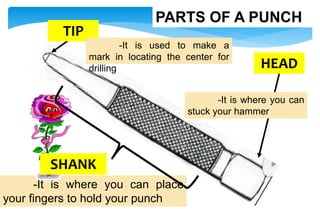

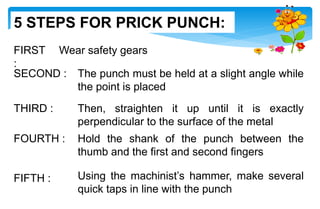

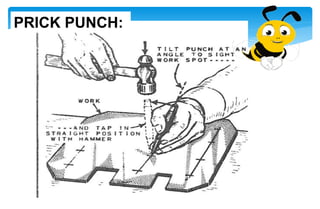

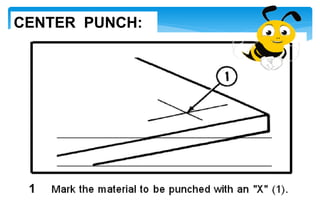

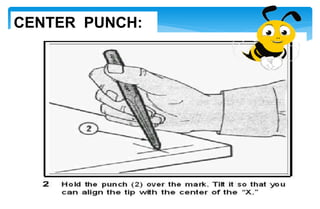

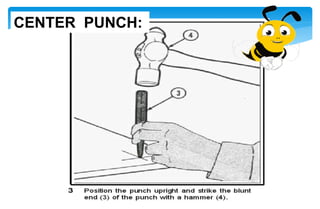

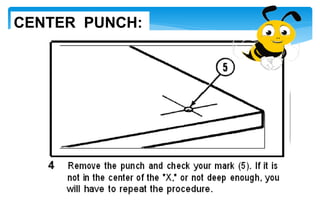

This document provides information on different types of punches used in metalworking, including solid and hollow punches. It discusses common solid punches like pin punches, pilot punches, taper punches, center punches, and prick punches. Center punches are available in hand-held or automatic types and are used to mark metal for drilling. Prick punches have a sharp point and are used to precisely mark soft metals. The document outlines how to properly use punches, including placing a board under the workpiece, and emphasizes taking light taps to avoid damage. It also stresses the importance of using the correct punch for the task and proper care of punch tools.