A f2445 swing bolt calc

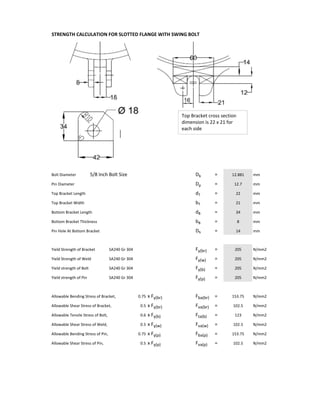

- 1. STRENGTH CALCULATION FOR SLOTTED FLANGE WITH SWING BOLT Bolt Diameter 5/8 Inch Bolt Size Db = mm Pin Diameter Dp = mm Top Bracket Length dT = mm Top Bracket Width bT = mm Bottom Bracket Length dB = mm Bottom Bracket Thickness bB = mm Pin Hole At Bottom Bracket Dh = mm Yield Strength of Bracket SA240 Gr 304 Fy(br) = N/mm2 Yield Strength of Weld SA240 Gr 304 Fy(w) = N/mm2 Yield strength of Bolt SA240 Gr 304 Fy(b) = N/mm2 Yield strength of Pin SA240 Gr 304 Fy(p) = N/mm2 Allowable Bending Stress of Bracket, x Fy(br) Fba(br) = N/mm2 Allowable Shear Stress of Bracket, x Fy(br) Fva(br) = N/mm2 Allowable Tensile Stress of Bolt, x Fy(b) Fta(b) = N/mm2 Allowable Shear Stress of Weld, x Fy(w) Fva(w) = N/mm2 Allowable Bending Stress of Pin, x Fy(p) Fba(p) = N/mm2 Allowable Shear Stress of Pin, x Fy(p) Fva(p) = N/mm2 153.75 102.5 21 34 8 14 123 12.881 12.7 205 205 205 102.5 153.75 205 22 102.50.5 0.75 0.5 0.6 0.5 0.75 Top Bracket cross section dimension is 22 x 21 for each side 14

- 2. A) Shear Stress For Weld Attachment of Bracket/Shell Total Operating Bolt Load, WM1 (Read from PV Elite) WM1 = N Total Number of Bracket & Bolts N(b) = Operating Bolt Load Per Bracket & Bolt, F(b)=WM1/N(b) F(b) = N Top Bracket Total Weld Length Per Set of Bracket L(wtbr) = mm Fillet Weld Leg Size of Bracket F(wtbr) = mm Weld Shear Area, A(wtbr)=L(wtbr) xF(wtbr) A(wtbr) = mm2 Shear Stress (Max), Sv(wtbr)=F(b)/A(wtbr) OK Sv(wtbr) = N/mm2 Bottom Bracket Total Weld Length Per Set of Bracket L(wbbr) = mm Fillet Weld Leg Size of Bracket F(wbbr) = mm Weld Shear Area, A(wbbr)=L(wbbr) xF(wbbr) A(wbbr) = mm2 Shear Stress (Max), Sv(wbbr)=F(b)/A(wbbr) OK Sv(wbbr) = N/mm2 B) Bending Stress & Moment For Brackets (Per Set) Moment Arm For Bracket At Full Bolt Load L(m) = mm Top Bracket Neutral Axis For The Set of Bracket y(tbr) = mm 2nd Moment of Area per Set of Bracket, I(tbr)=(bd3 )/12 I(tbr) = mm4 Bending Moment (Max), M(tbr)=F(b) x L(m) M(tbr) = N‐mm Bending Stress (Max), Sb(tbr)=M(tbr)/[I(tbr)/y(tbr)] OK Sb(tbr) = N/mm2 Bottom Bracket Neutral Axis For The Set of Bracket y(bbr) = mm 2nd Moment of Area per Set of Bracket, I(bbr)=(bd 3 )/12 I(bbr) = mm4 Bending Moment (Max), M(bbr)=F(b) x L(m) M(bbr) = N‐mm Bending Stress (Max), Sb(bbr)=M(bbr)/[I(bbr)/y(bbr)] OK Sb(bbr) = N/mm2 C) Shear Stress For The Bottom Bracket Due To Load At Point of Pin Contact Operating Bolt Load Per Bracket & Bolt, F(b)=WM1/N(b) F(b) = N Top Bracket Shear Area For The Bracket, A(tbr) = mm2 Shear Stress (Max), Sv(tbr)=F(b)/A(tbr) OK Sv(tbr) = N/mm2 Bottom Bracket Shear Area For The Bracket, A(bbr) = mm2 Shear Stress (Max), Sv(bbr)=F(b)/A(bbr) OK Sv(bbr) = N/mm2 924 7.85 136 2 272 26.67 10 10666.67 108830.83 102.03 29021.555 4 7255.39 0 0 0 32.12 544 7255.39 13.34 0.00 15 108830.83 37268.00 11

- 3. D) Bending Moment, Bending Stress & Shear Stress For Pin Insert Through Bottom Bracket F1 = F2 = y= mm R1 = R2 = Max Bending Moment, M(p) = F x L M(p) = N‐mm Neutral Axis For The Pin y = mm 2nd Moment of Area, I(p)=πd 4 /64 I(p) = mm4 Max Bending Stress, Sb(p) = M/(I/y) OK Sb(p) = N/mm2 Shear Stress At Point Of Contact Between Pin And Bracket Cross section Area of Pin A(p) = mm2 Shear Stress (Max), Sv(p)=F(R1)/[SF x A(p)] SF= 0.5 OK Sv(p) = N/mm2 E) Axial Tension Of Bolt Root Area of Bolt A(b) = mm2 Shear Stress (Max), St(b)=F(b)/A(b) OK St(b) = N/mm2 F) Load Combination Top Bracket OK LC(tbr) = Bottom Bracket OK LC(bbr) = Pin OK LC(p) = 0.882 55.68 0.794 46.17 6.35 59.66 2.560 2.560 Bracket(bot) Width 0.286 130.313 3627.69 3627.69 1276.98 3627.69 3627.69 6.35 121.610 9285.08 18

- 4. 14