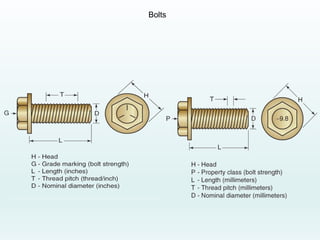

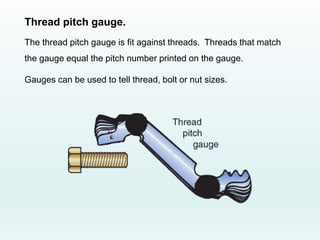

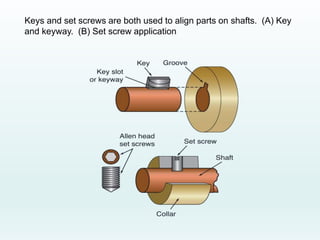

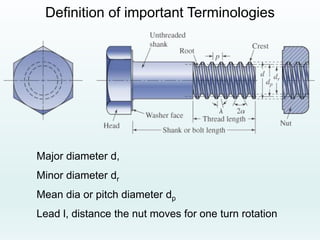

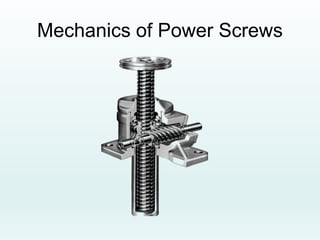

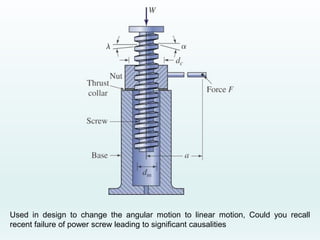

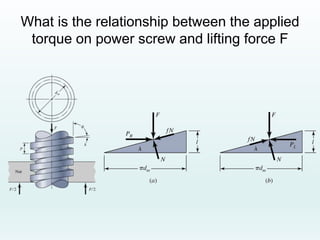

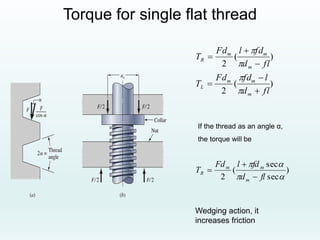

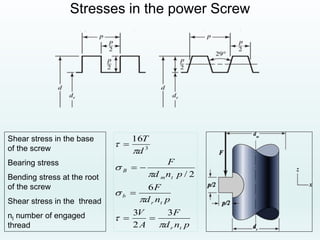

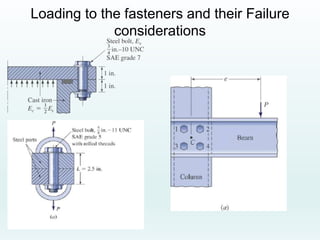

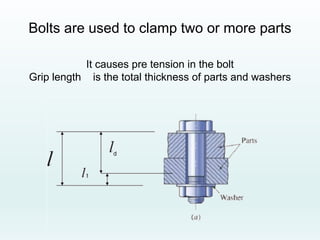

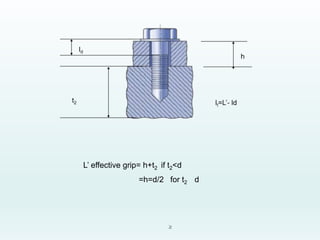

Fasteners like bolts, nuts, and screws are essential components that hold vehicles together. Bolts transmit axial forces and are made of different materials with varying strengths depending on the application. Power screws can transmit rotational motion into linear motion or produce large axial forces, and are designed to reduce stresses from these forces. Proper selection and installation of fasteners is important for safety and performance.