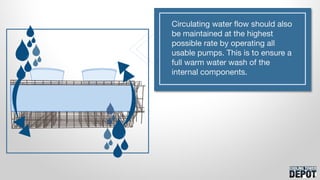

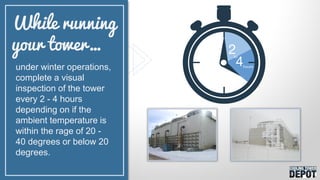

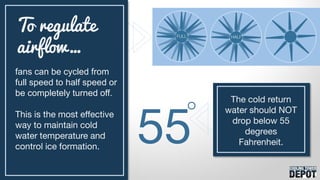

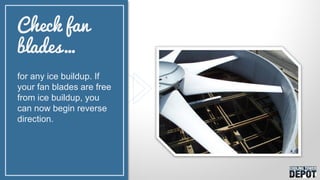

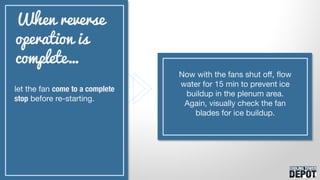

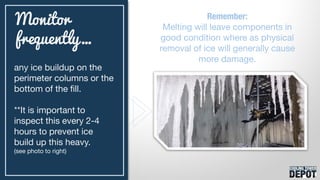

The document outlines 12 key operational rules for cooling towers during the winter to prevent icing issues. These rules include conducting inspections, protecting air inlets, maintaining water circulation, and managing airflow effectively. It emphasizes the importance of regular monitoring and precautions against ice removal to avoid damage to the cooling tower structure.