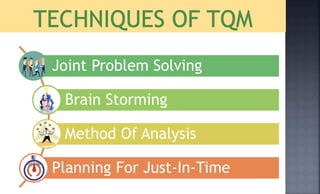

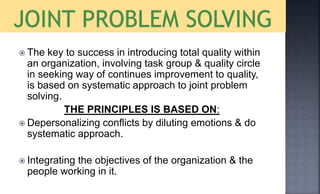

Total Quality Management (TQM) emphasizes long-term success through customer satisfaction by involving all organization members in continuous improvement processes. It relies on eight principles, including fact-based decision-making and total employee involvement, to enhance quality and productivity. Just-In-Time (JIT) is a compatible strategy under TQM that focuses on reducing waste and delivering the correct quantities of materials at the right time.