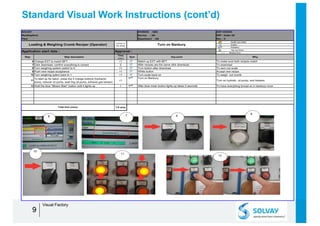

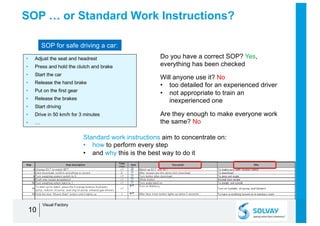

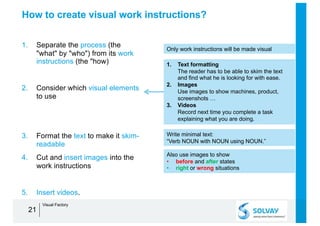

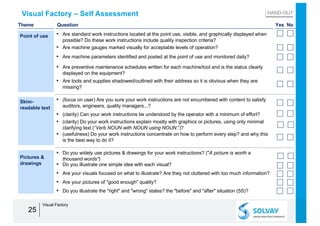

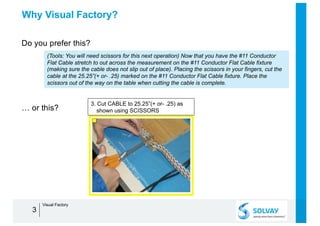

The document outlines the concept of a visual factory, emphasizing the importance of visual communication in work environments to enhance knowledge transfer and efficiency. It describes how visual work instructions, local signage, and checklists can reduce injuries, training time, and variability in operations. Additionally, the text provides guidance on creating effective visual work tools and assessing their clarity and usability.

![What means Visual Factory?

• Visual Factory is a concept focused on the visual perception.

• Purpose = replace texts by communicating via “visual signals”:

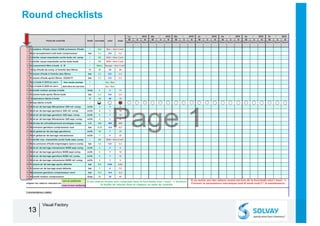

- in work instructions and checklists (pictures of the equipment with control

points)

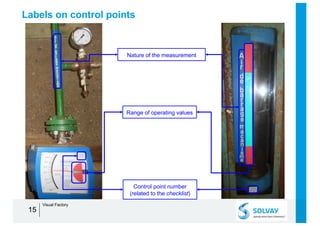

- with local signage: tags, labels (what to measure, range, …), pictures

• Benefits:

- quick and easy instructions

- reductions in injuries and strain

- increased efficiency and reactivity

- reduction of the variability and the non-conformity rate

- decreased training time…

• Scope: HSE, production, maintenance, QC, …

5

Testimony

Gilles B., Producer Manager:

“Regarding the number of measurements to read, the Visual Management makes the

use of the checklist simple and efficient [...] however, the labels on the measurement

tools are essential for the understanding of all technicians.”

Visual Factory](https://image.slidesharecdn.com/2-190505105827/85/Manufacturing-Excellence-Visual-Factory-5-320.jpg)