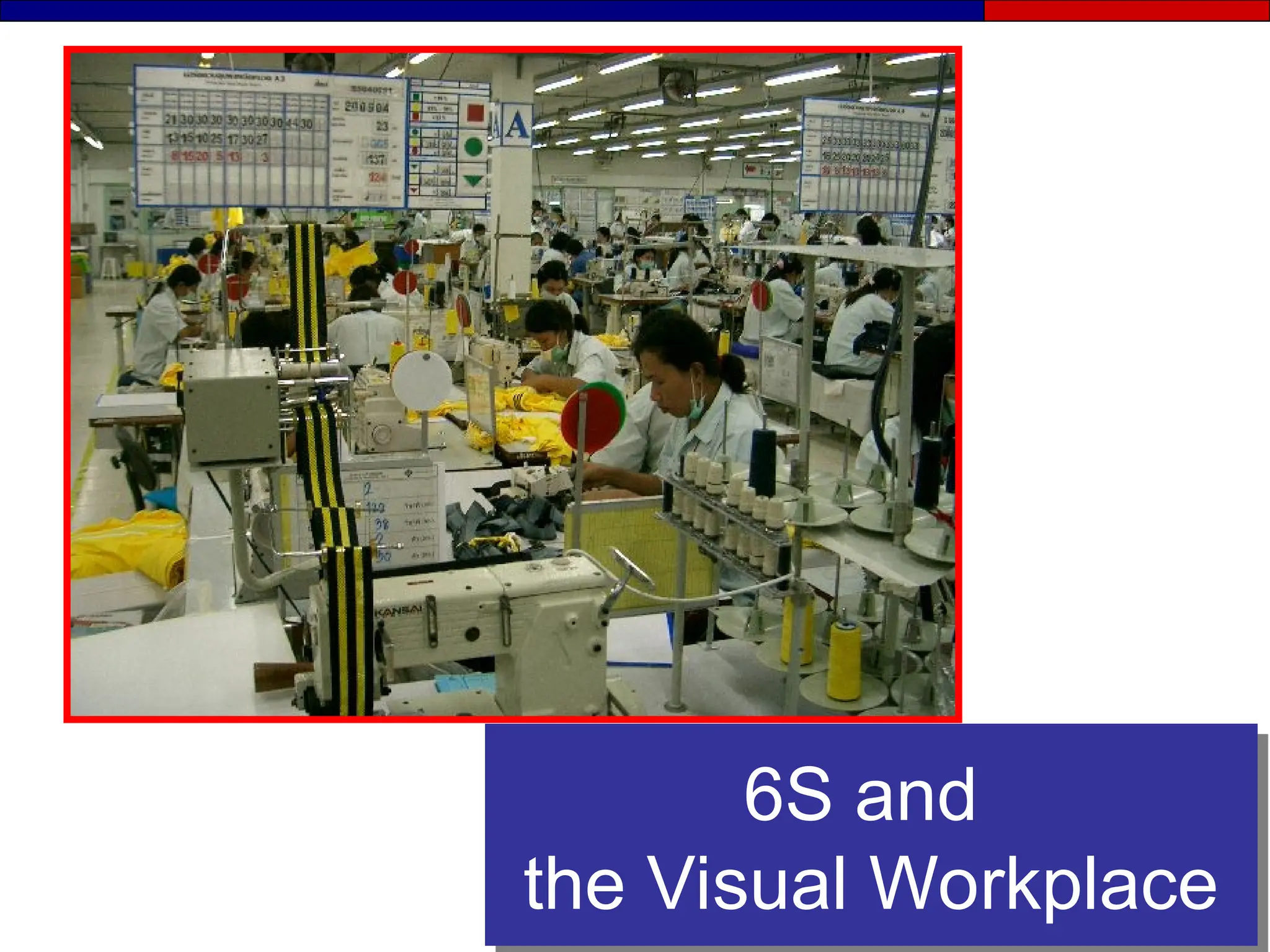

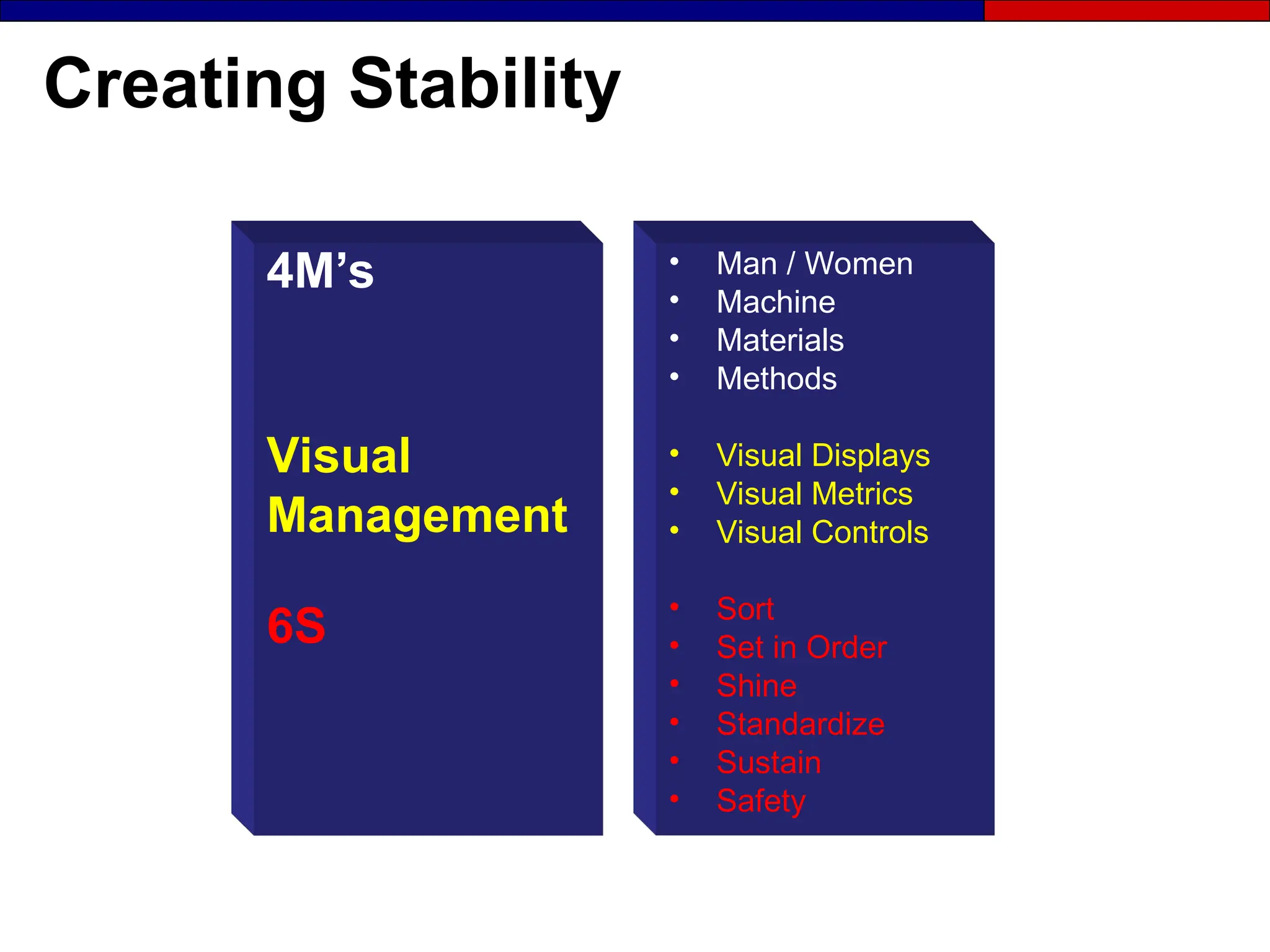

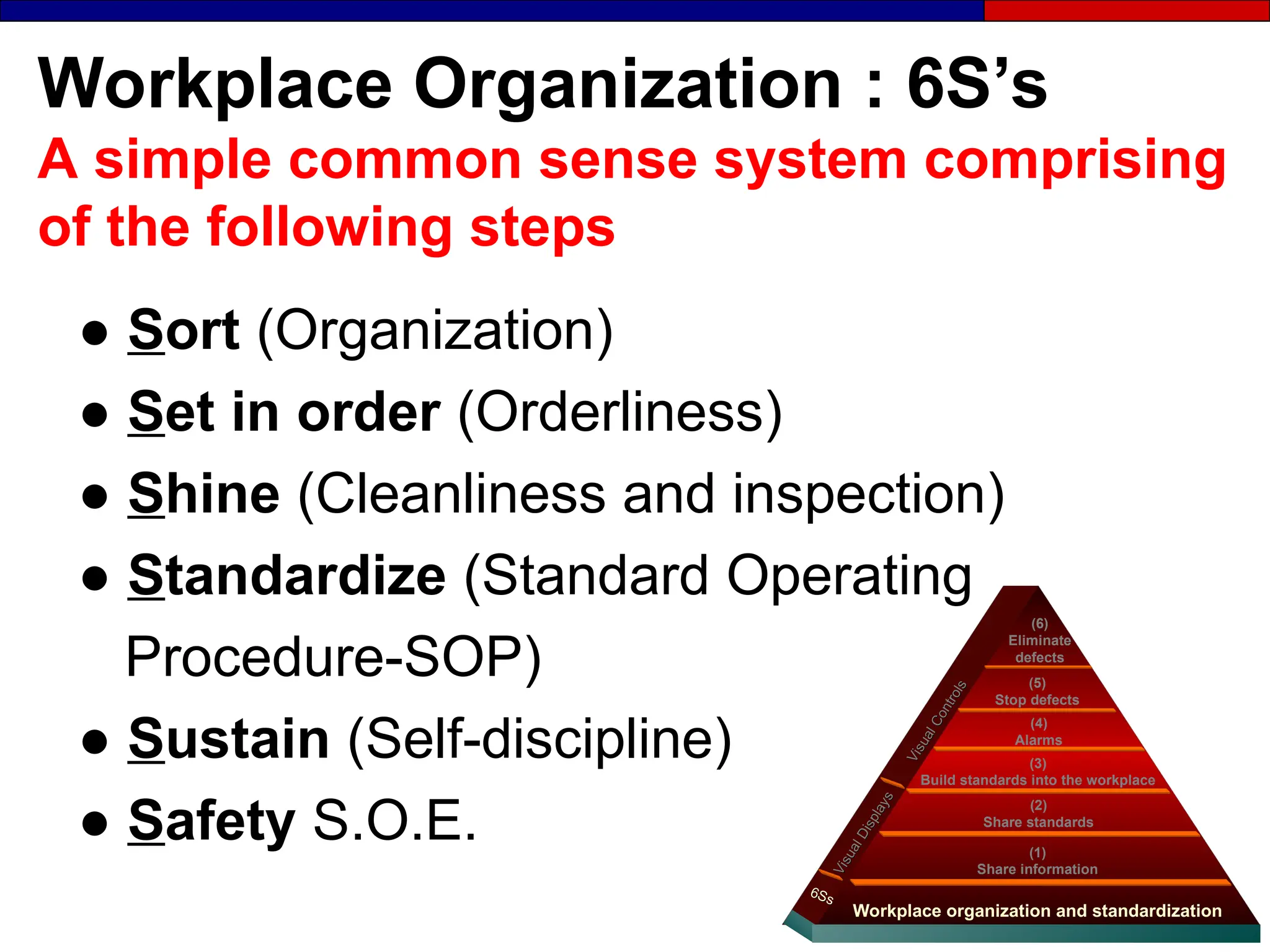

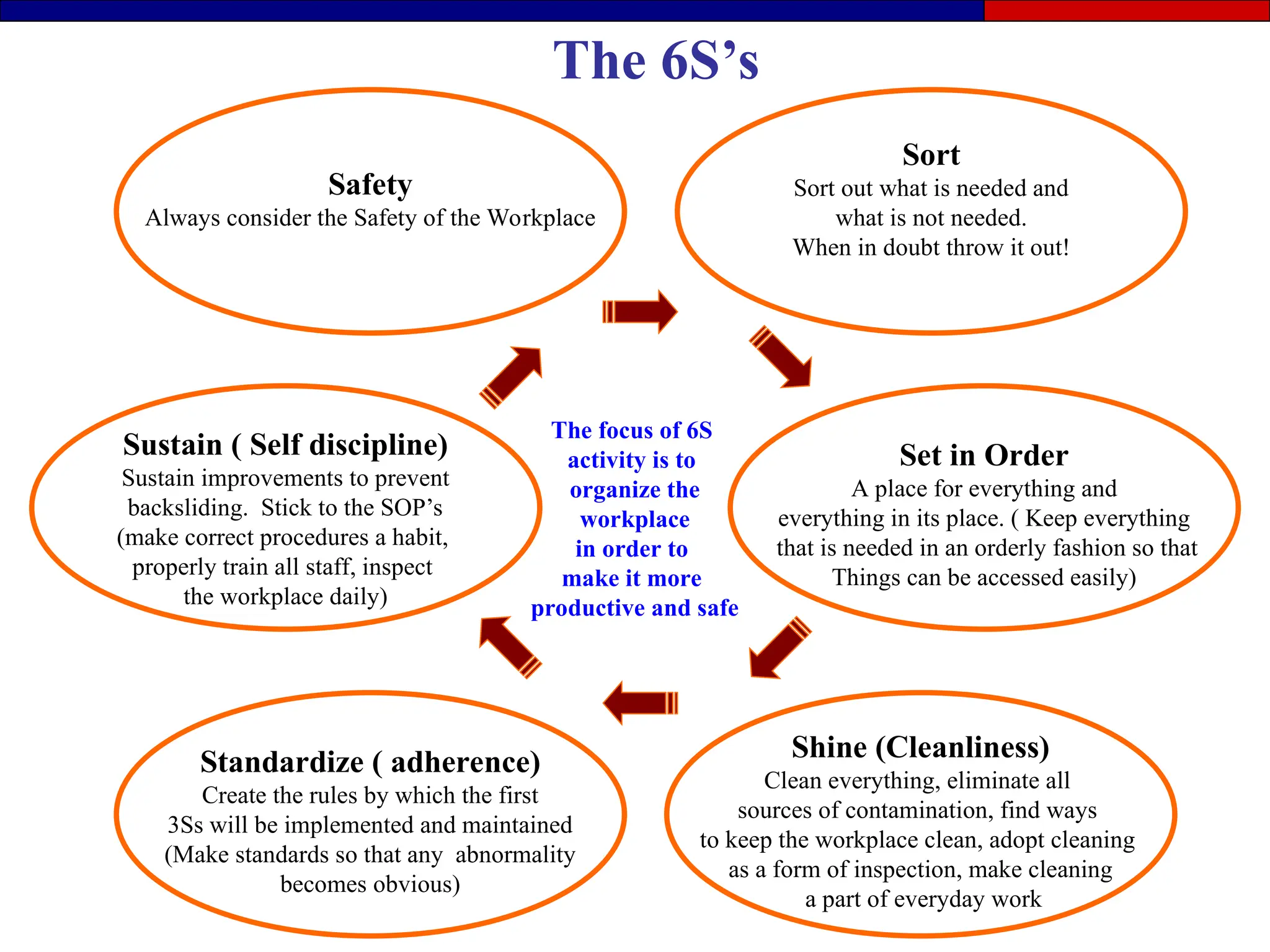

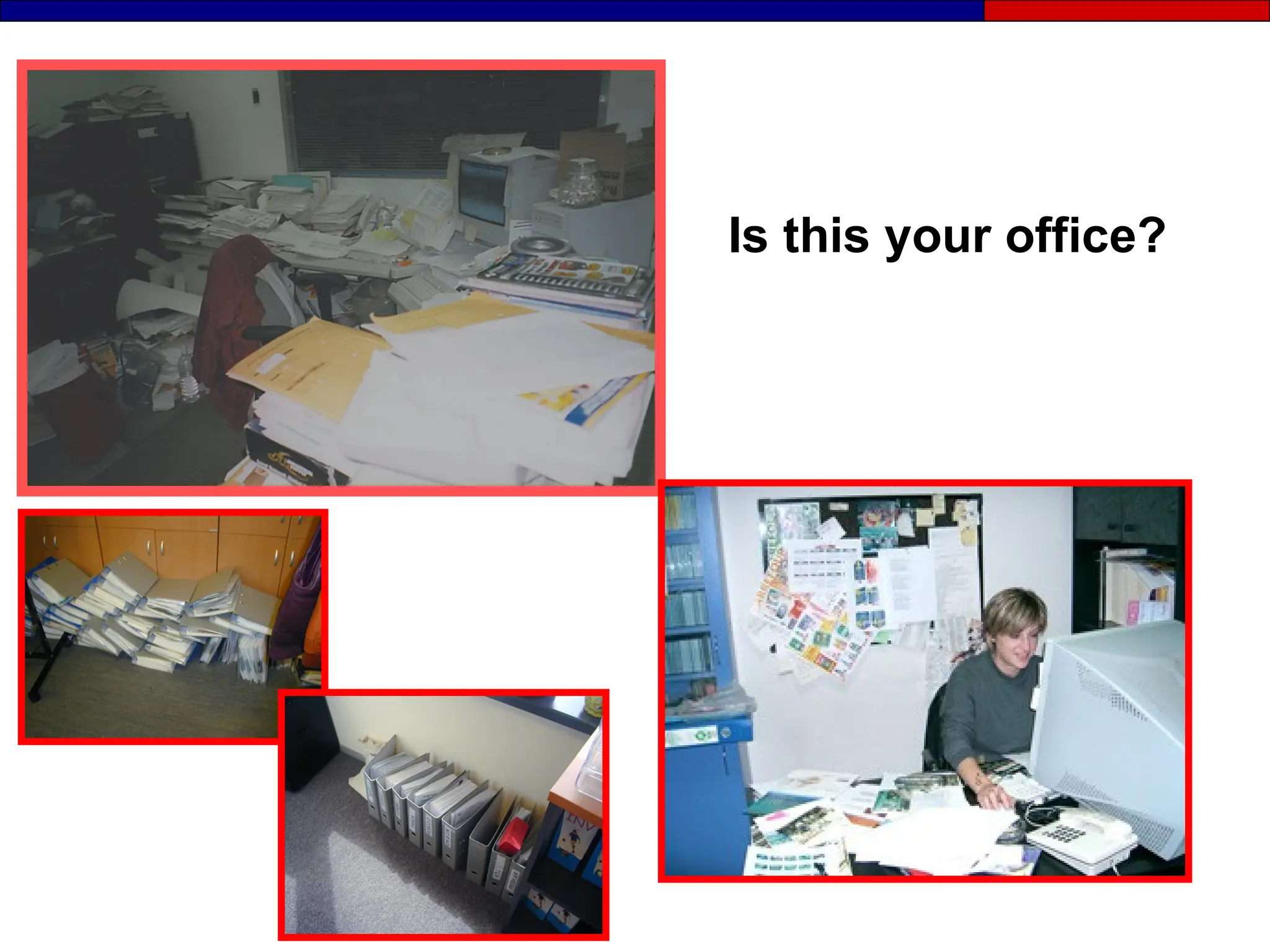

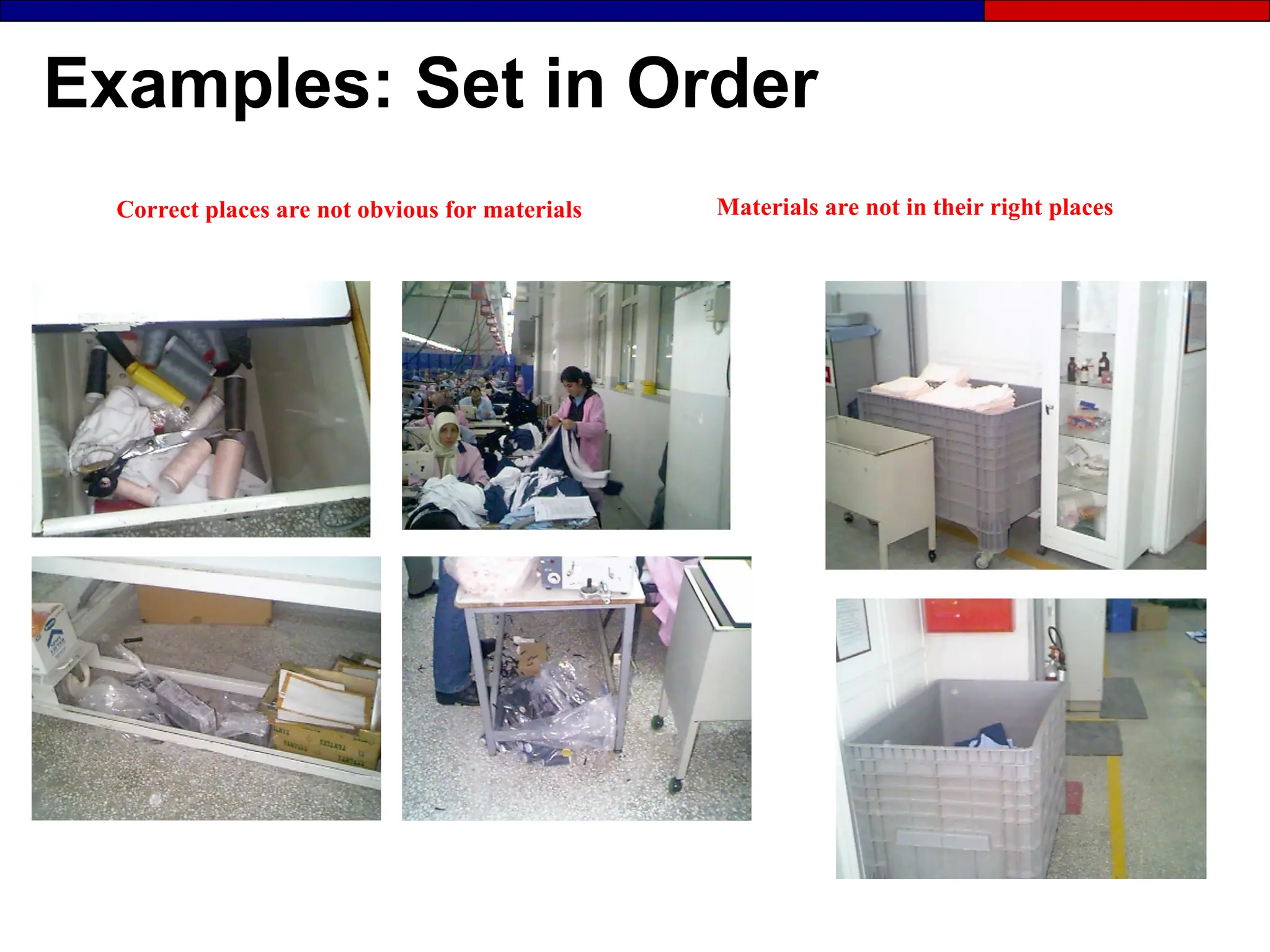

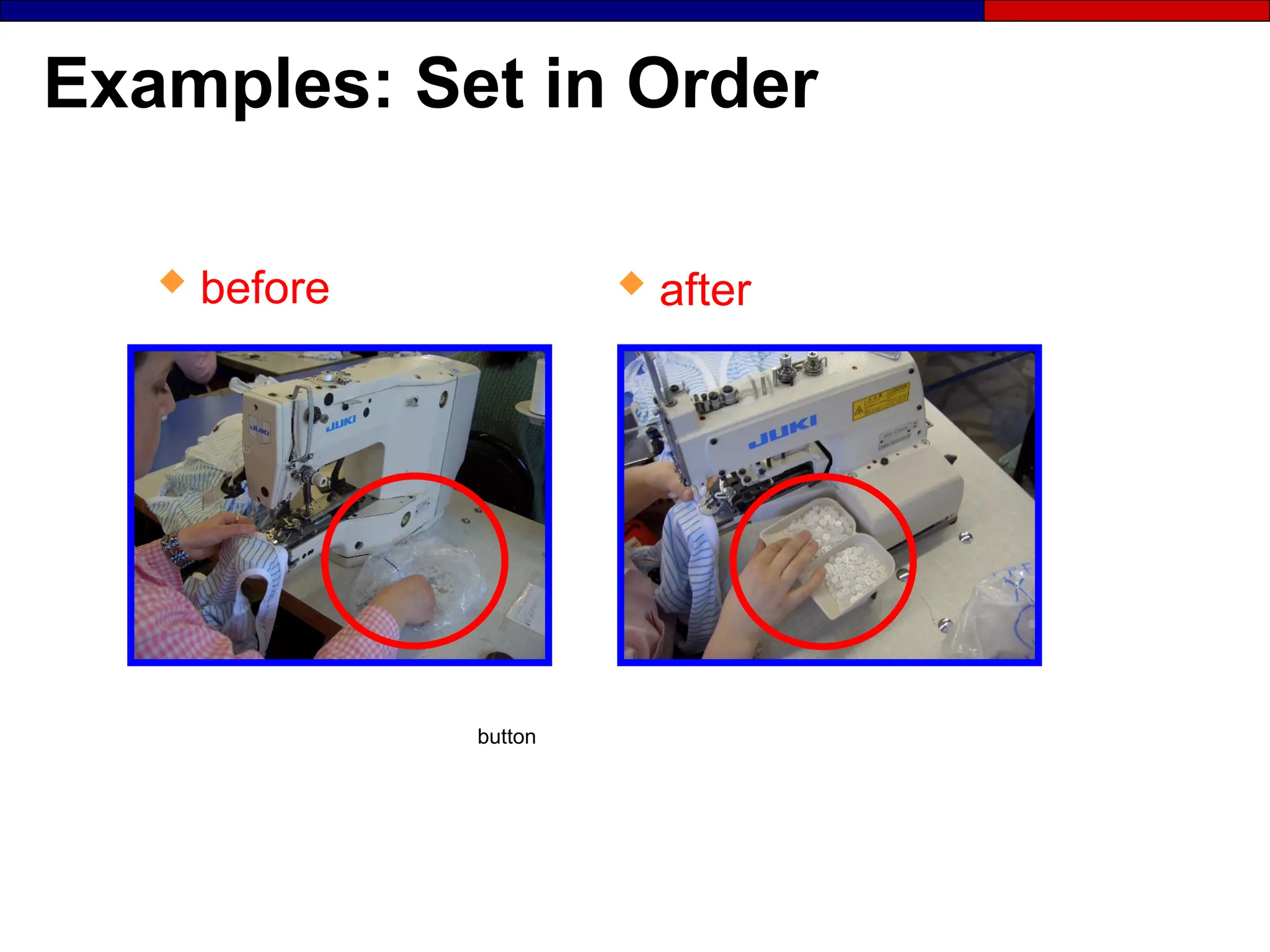

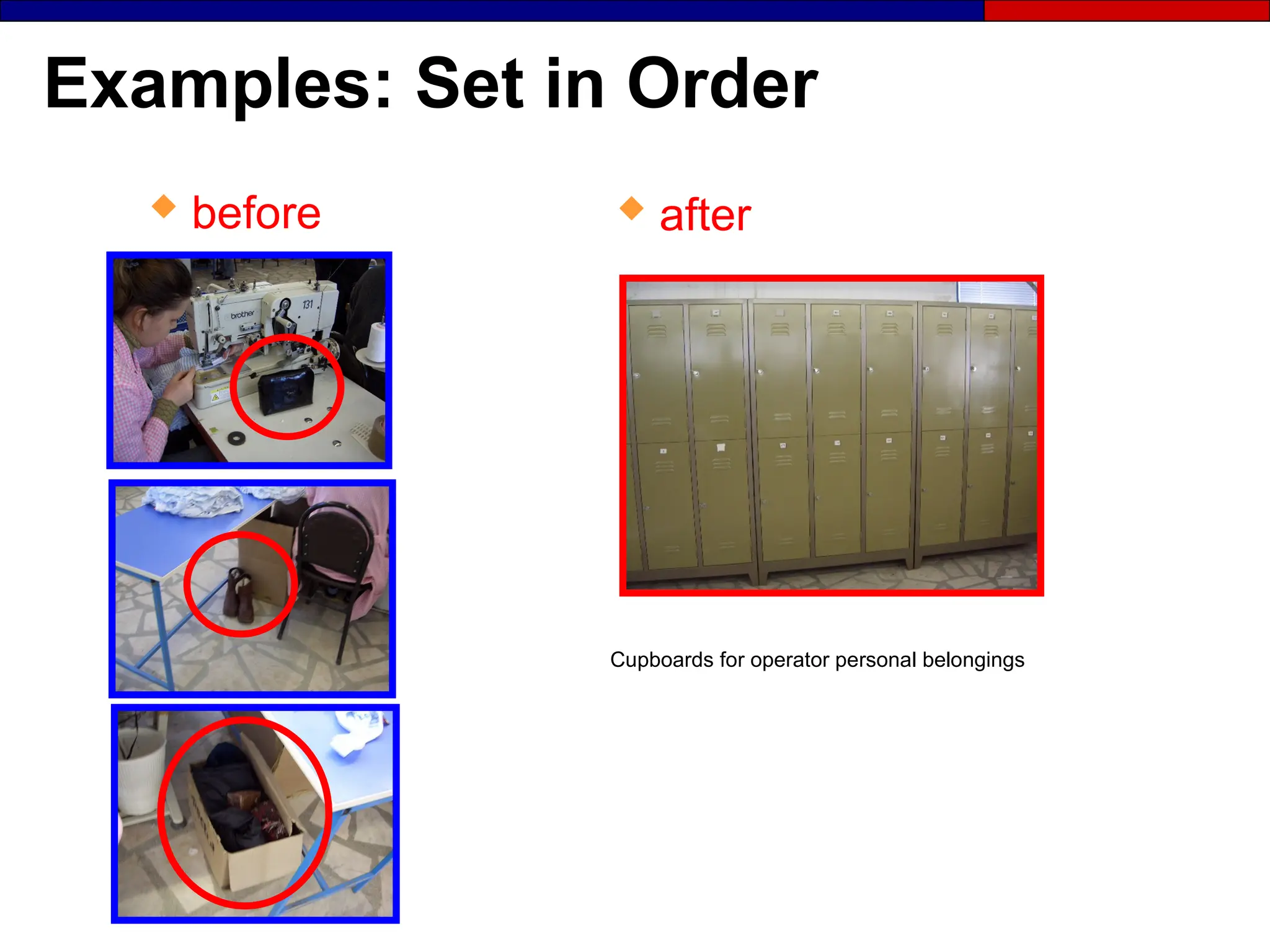

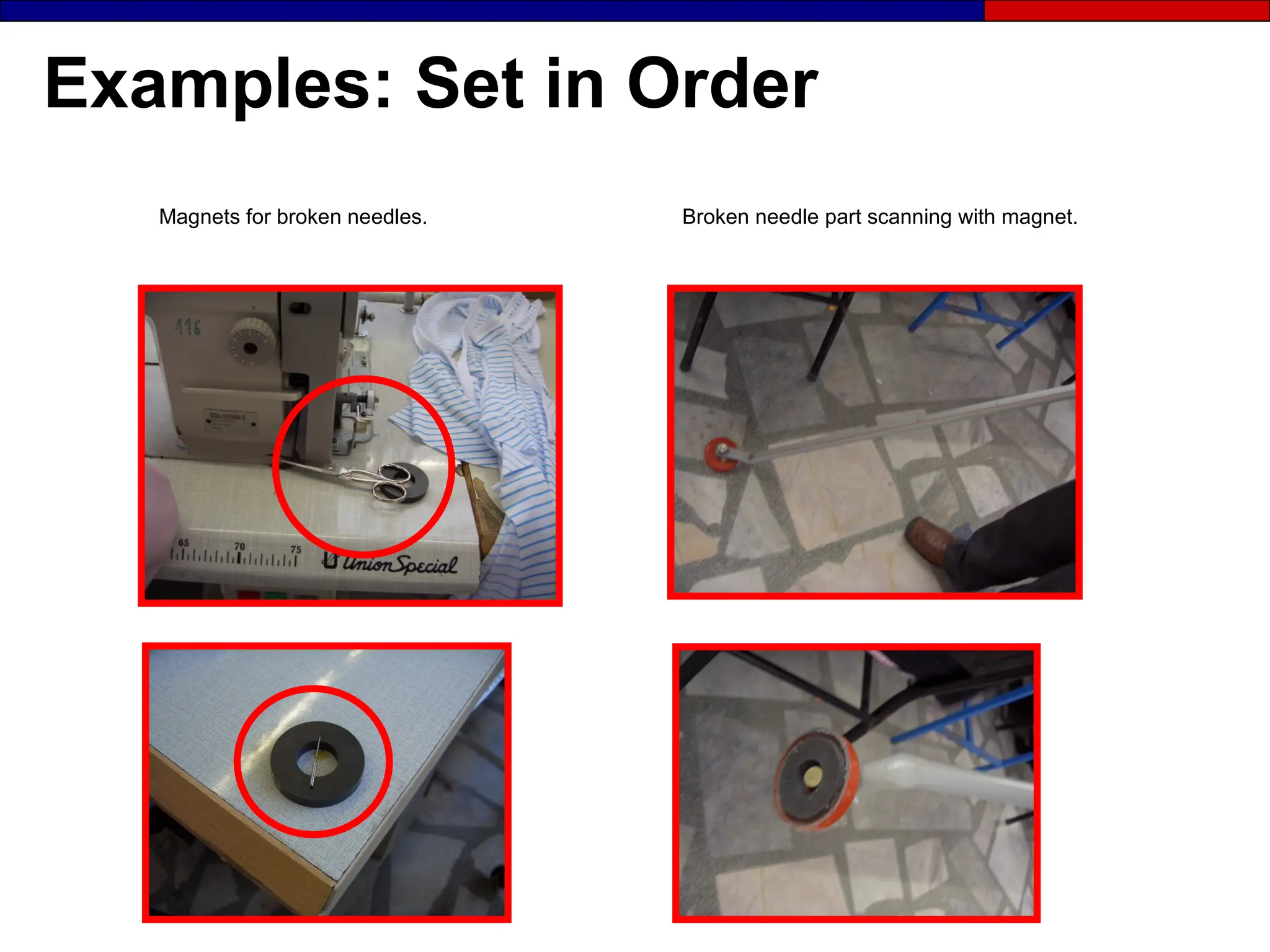

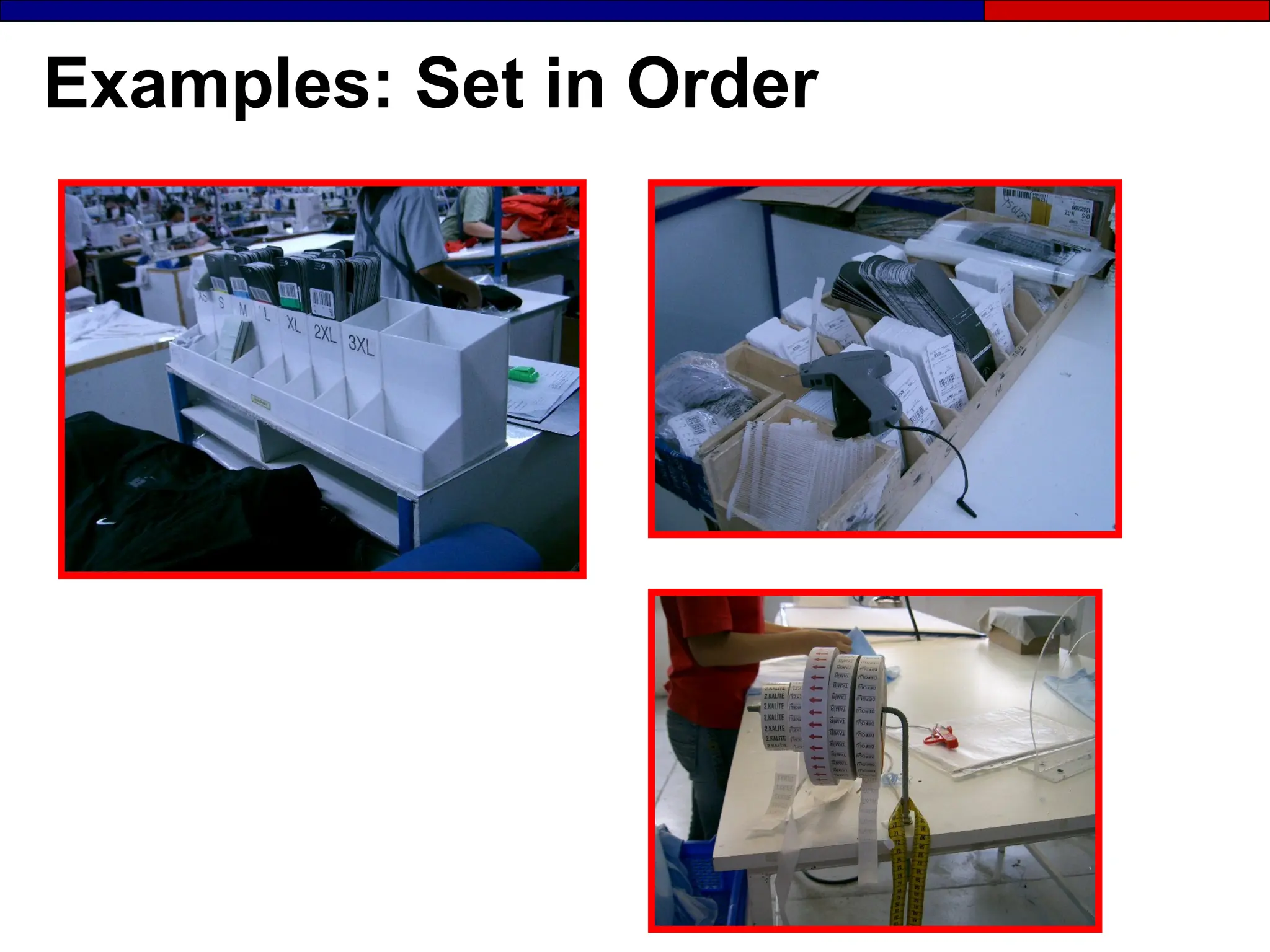

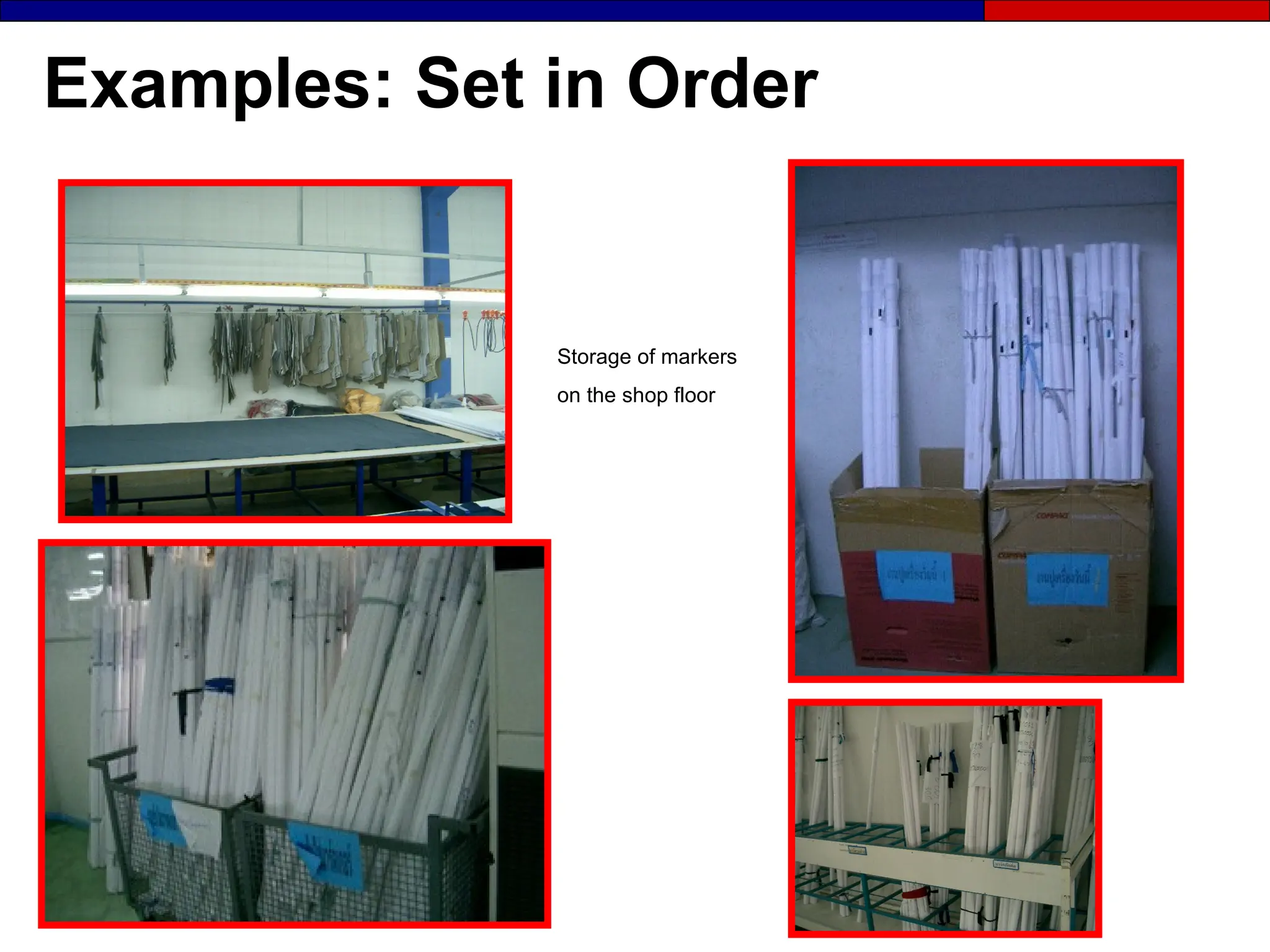

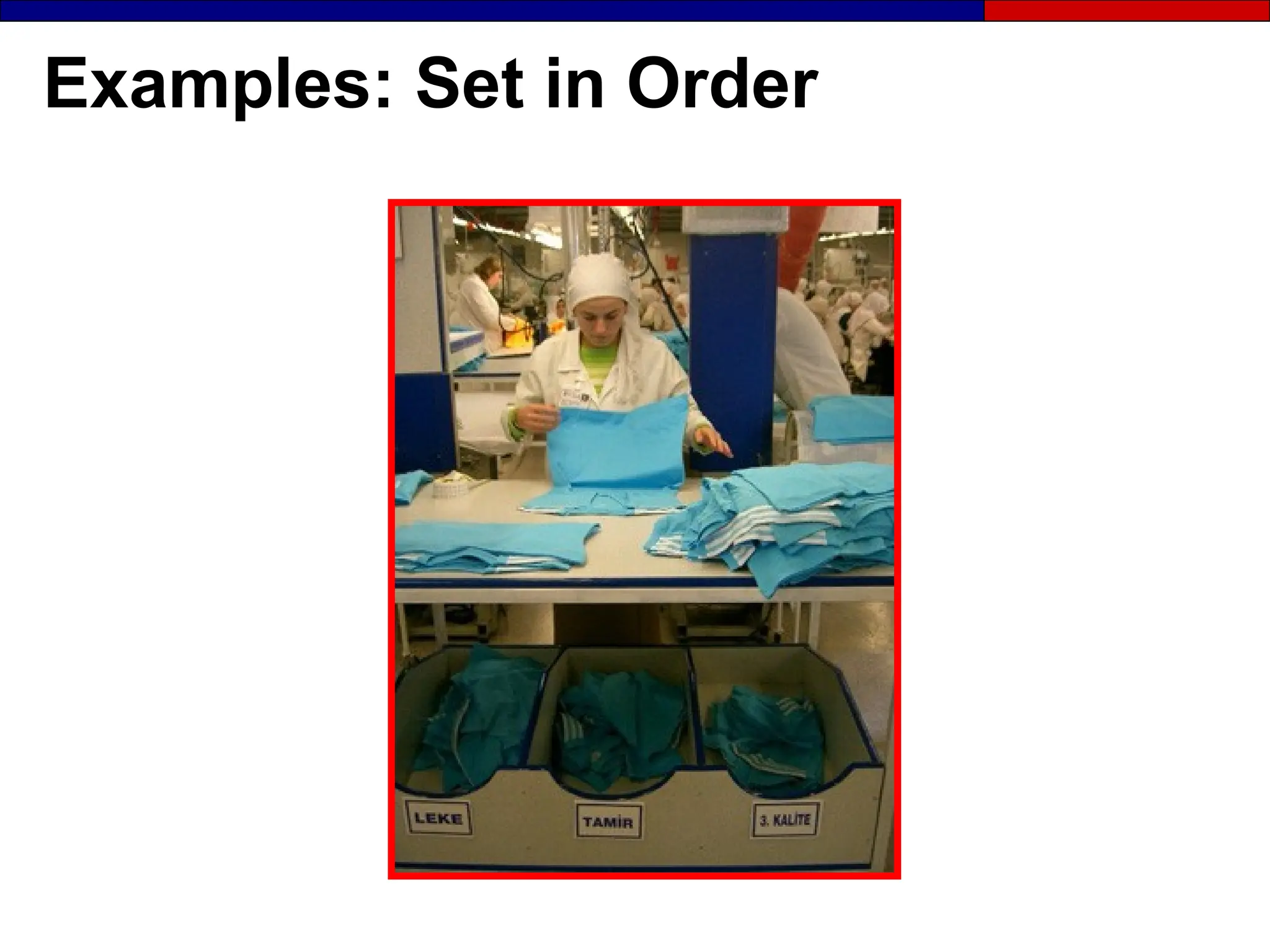

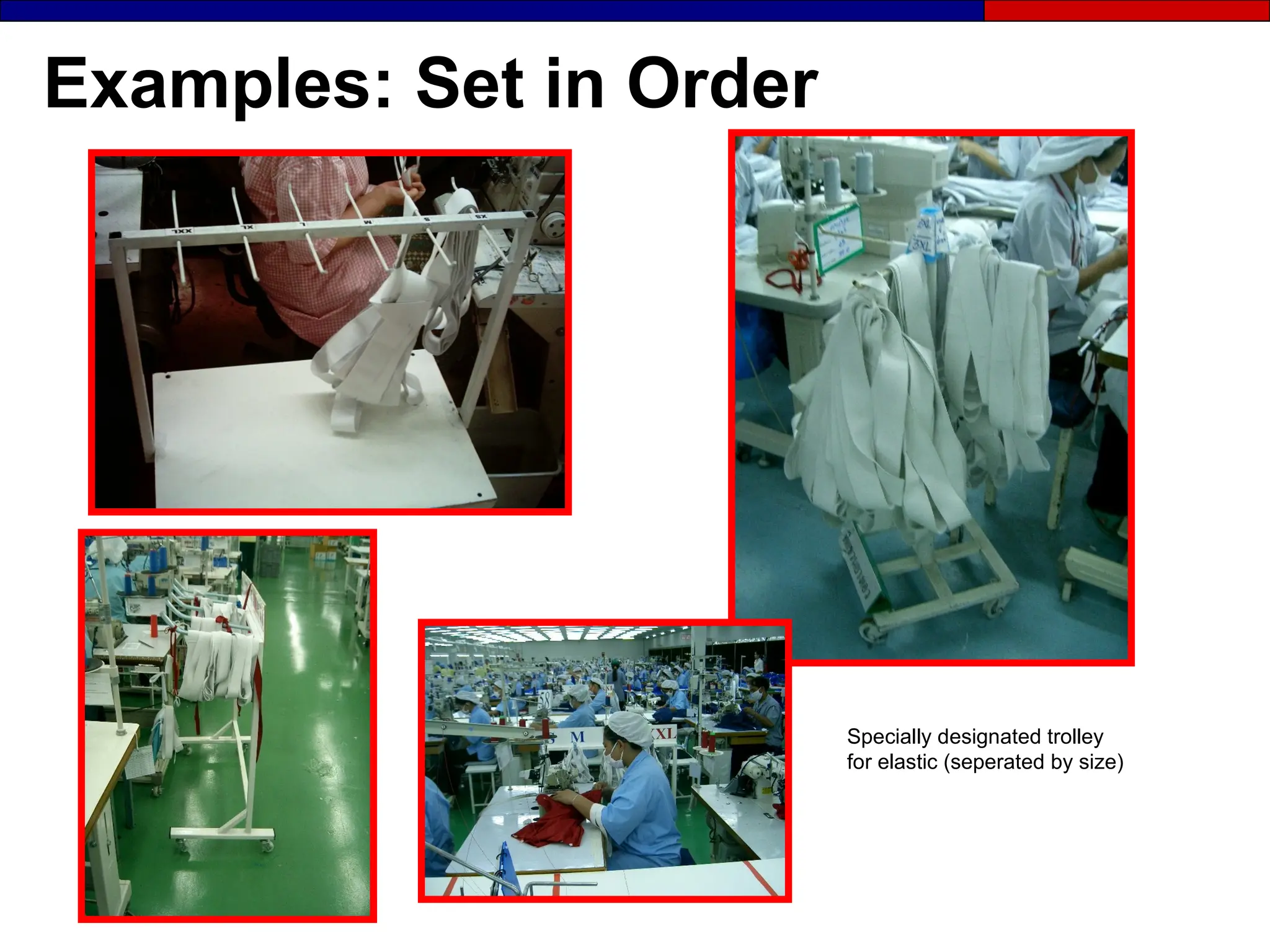

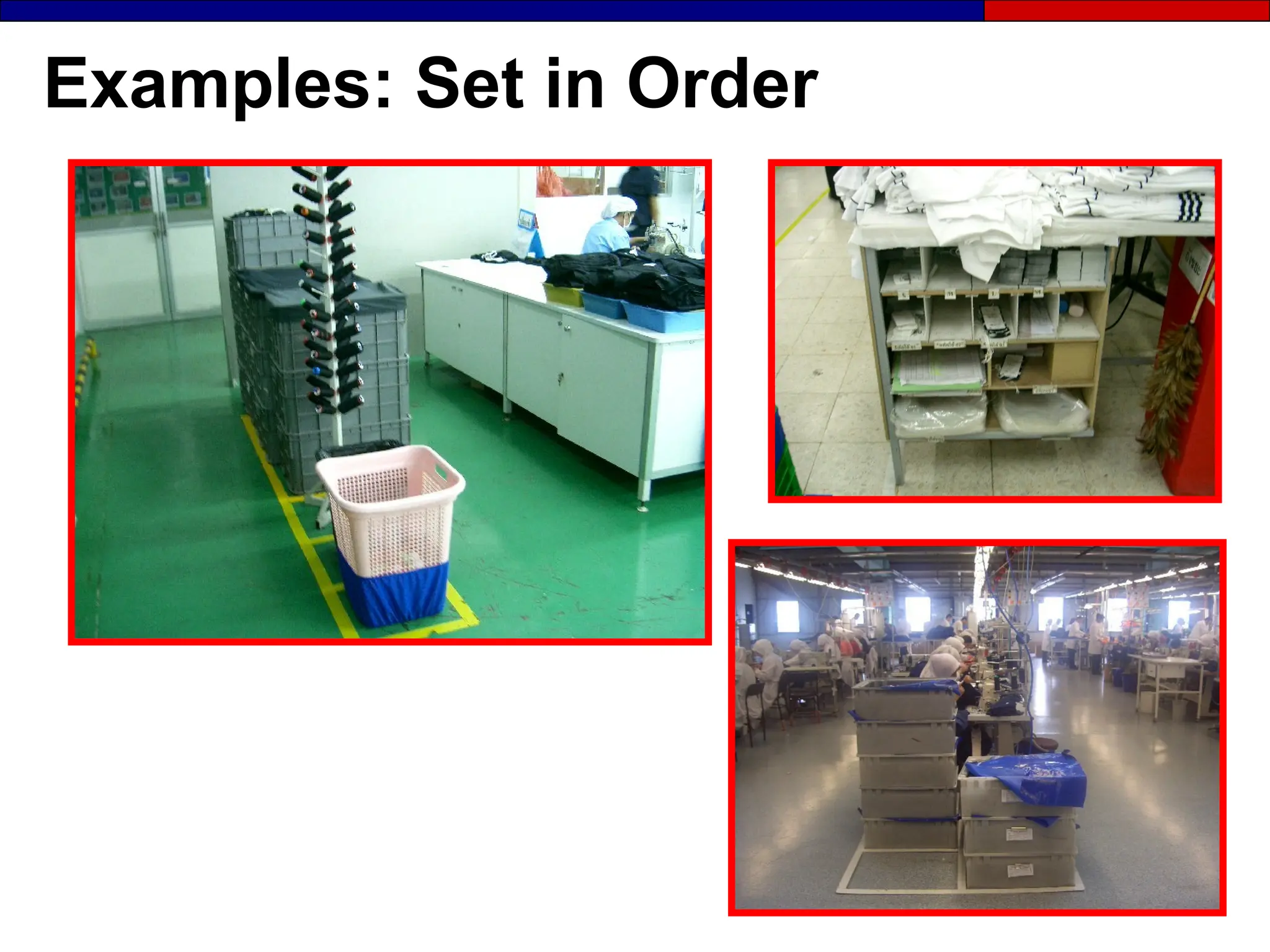

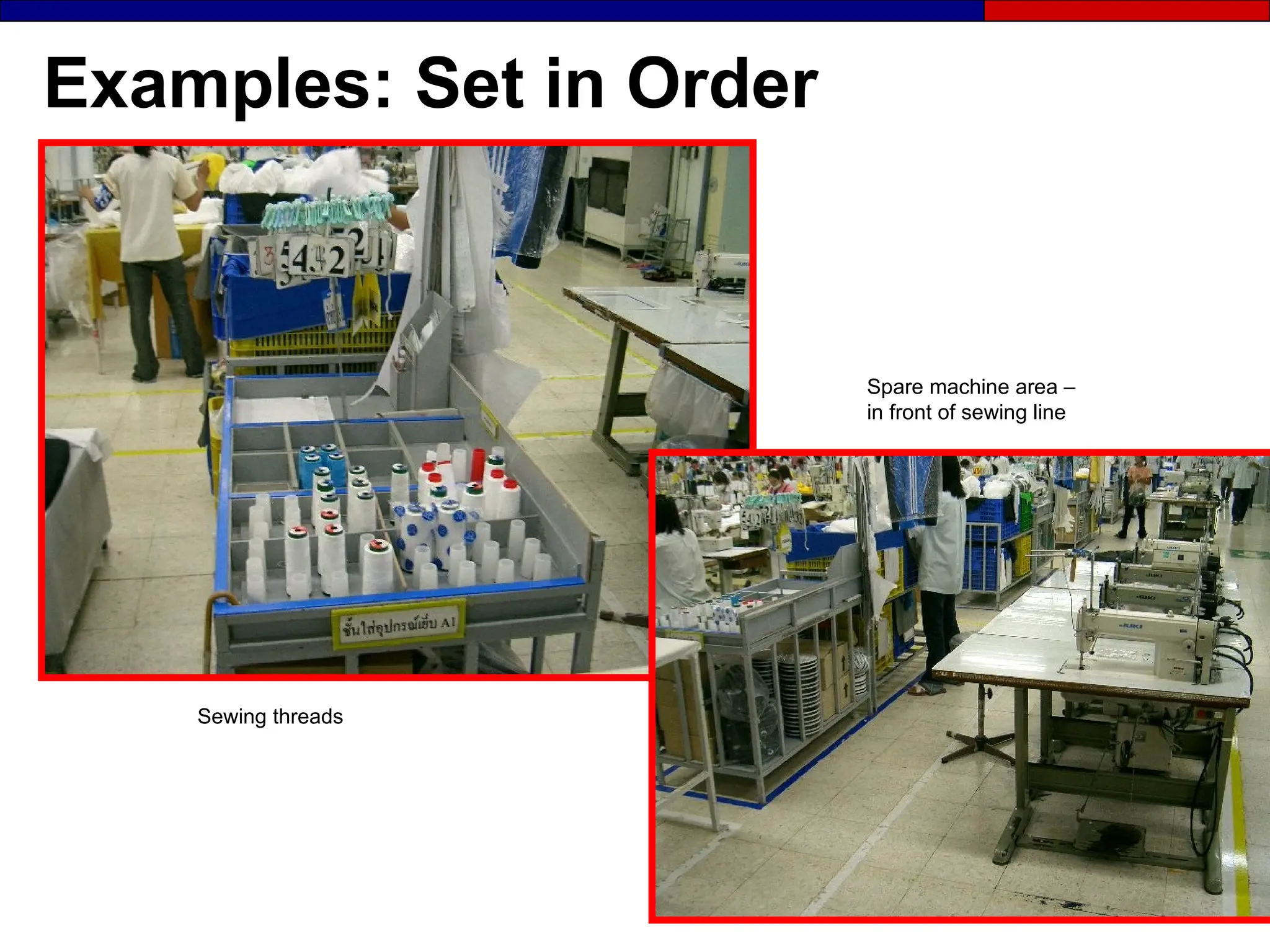

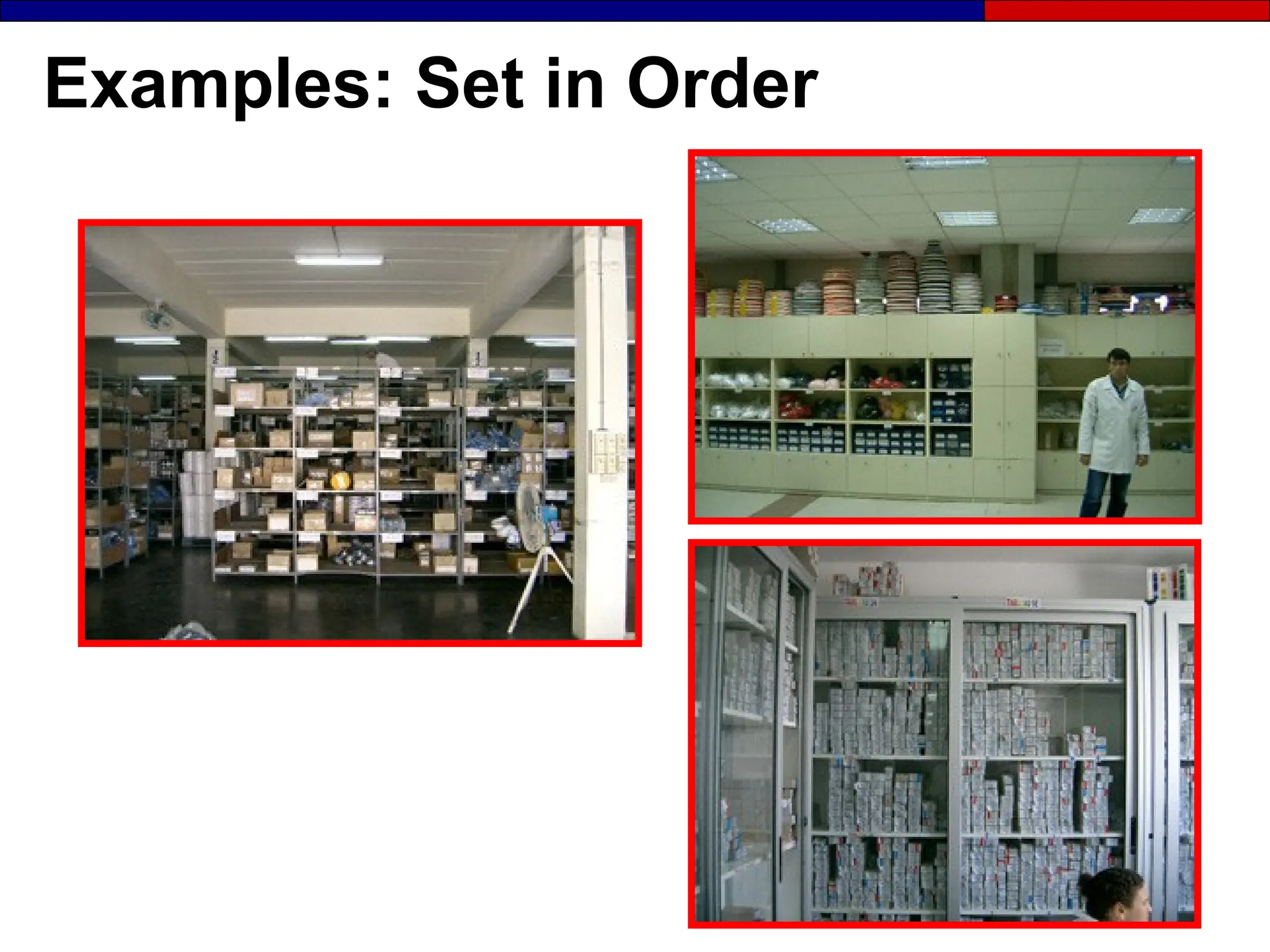

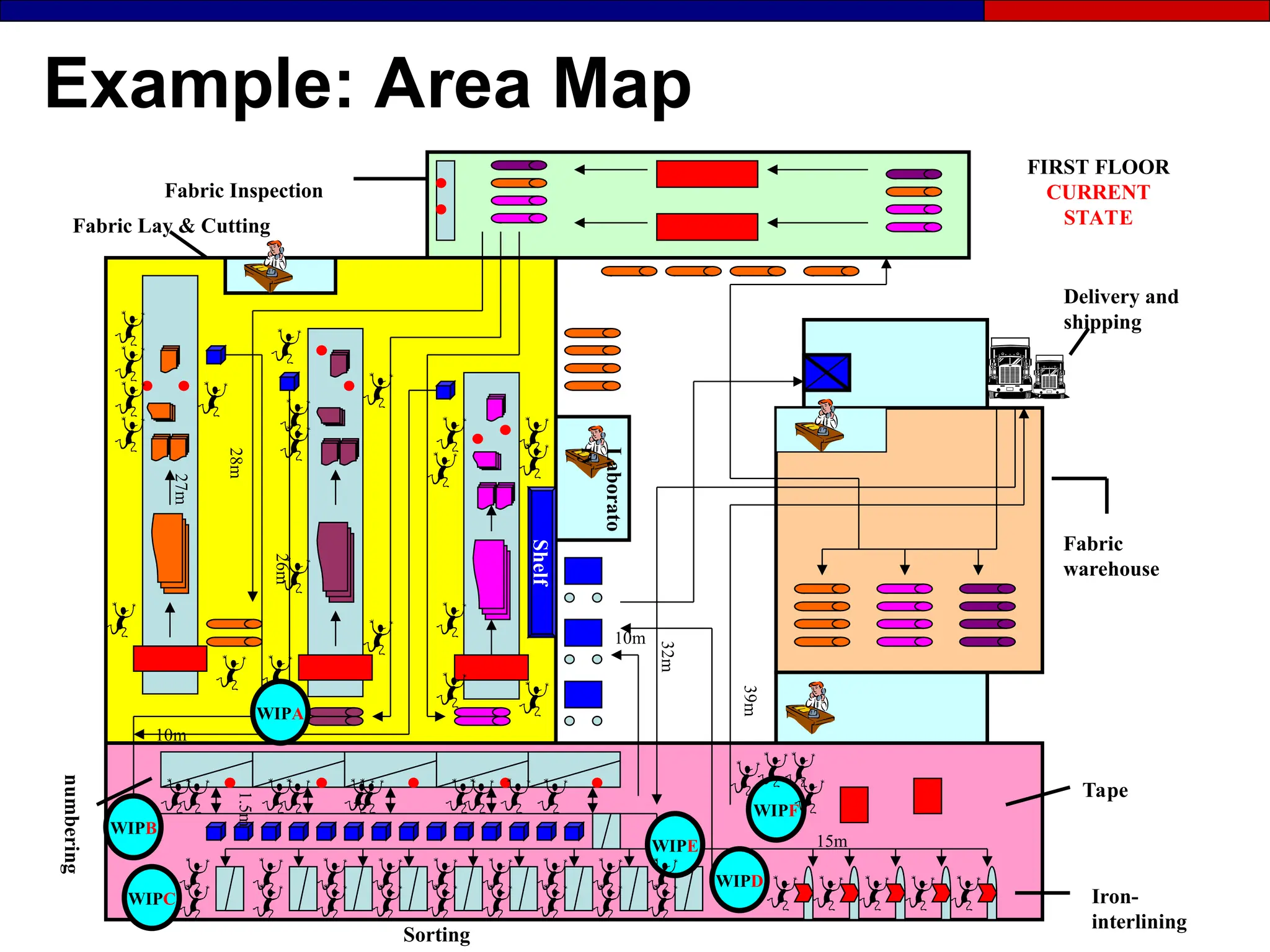

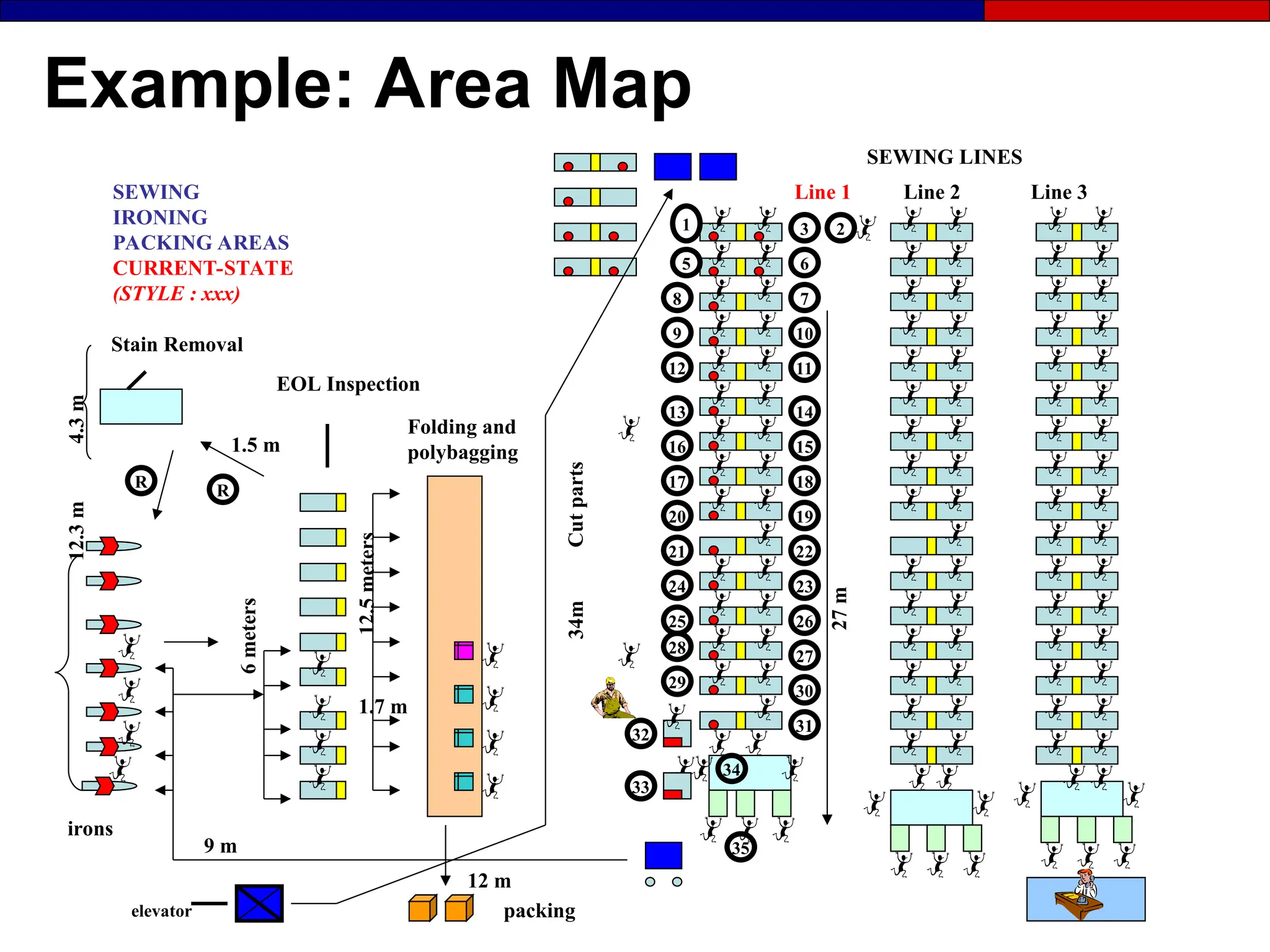

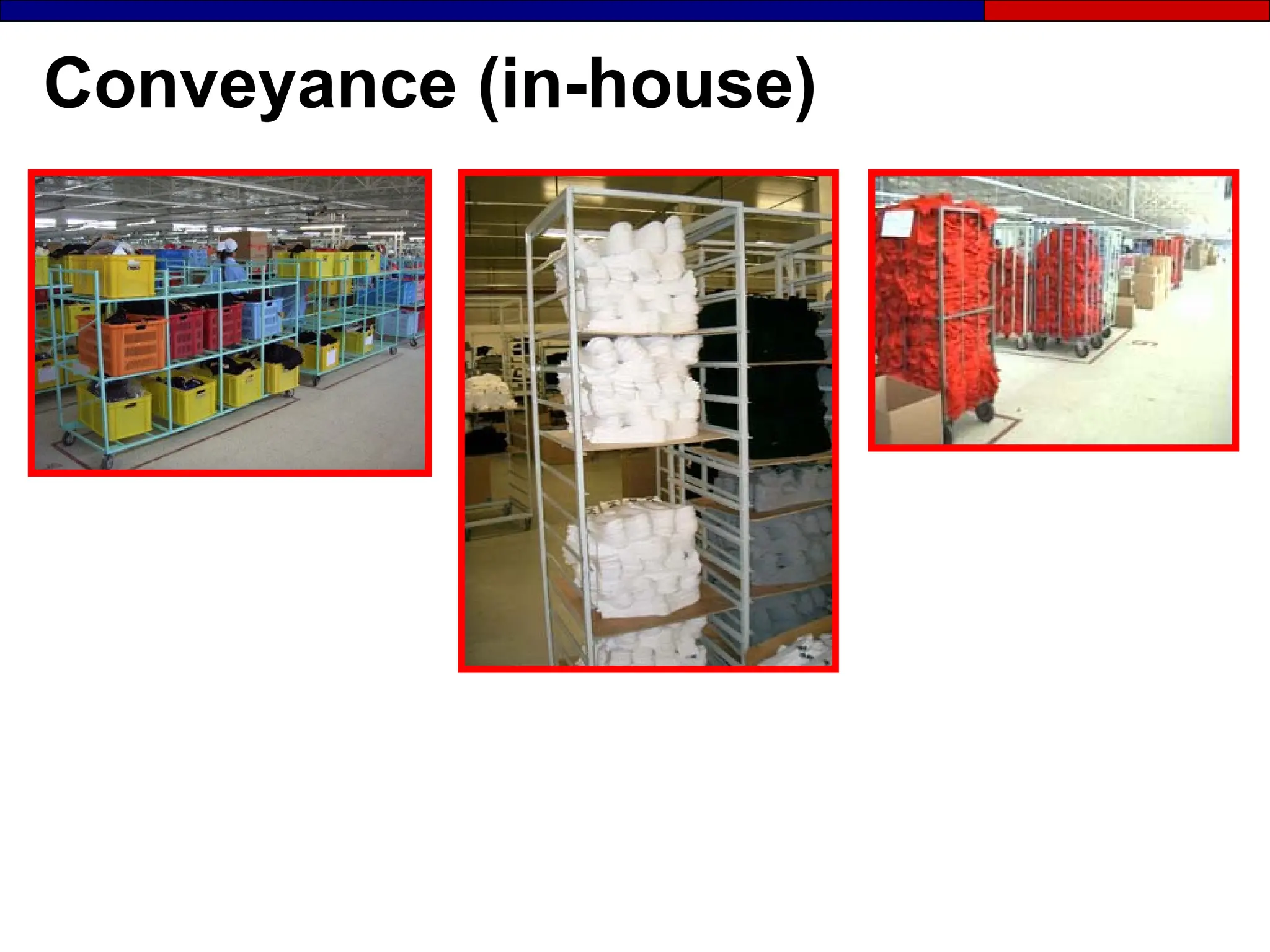

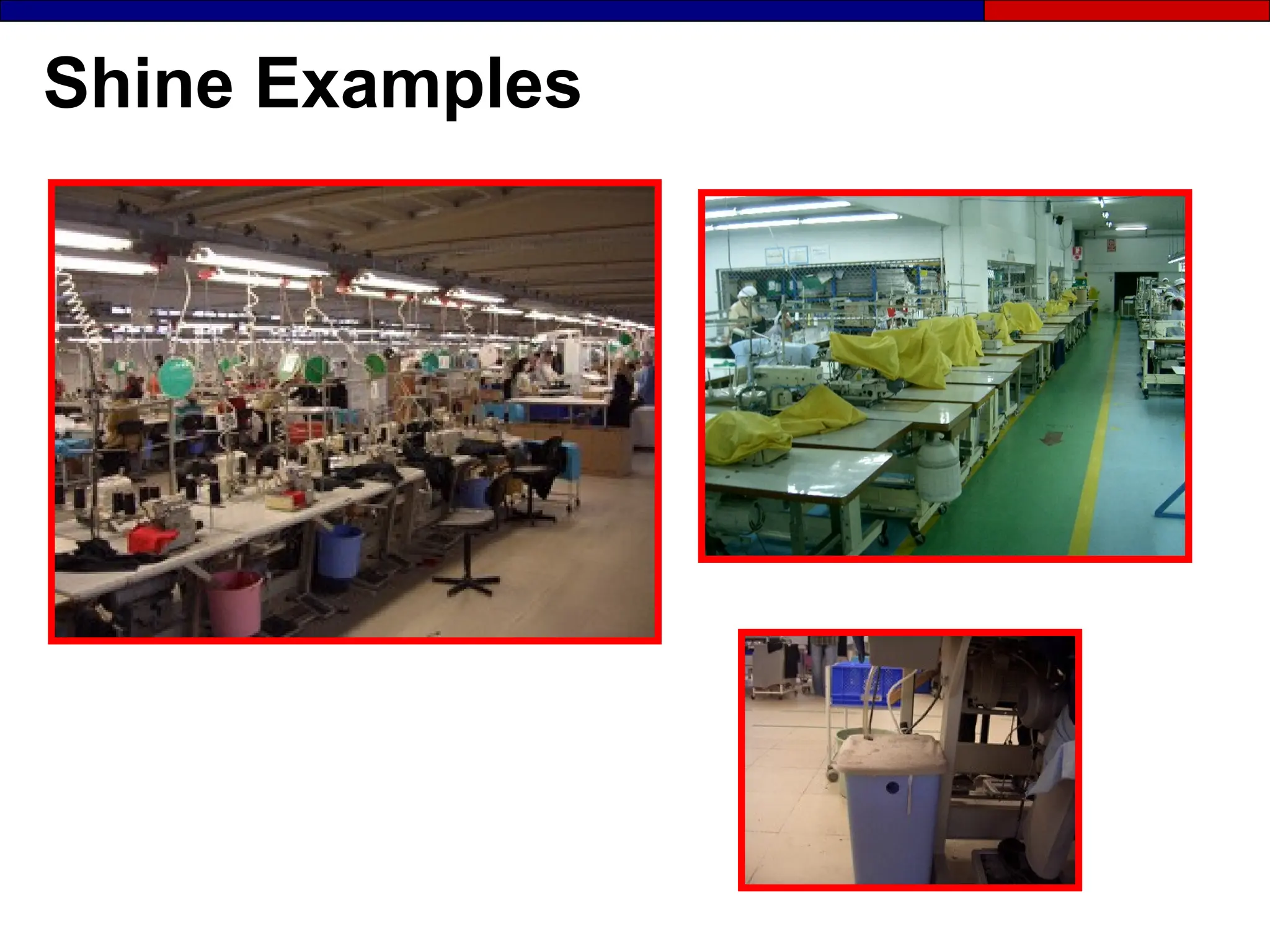

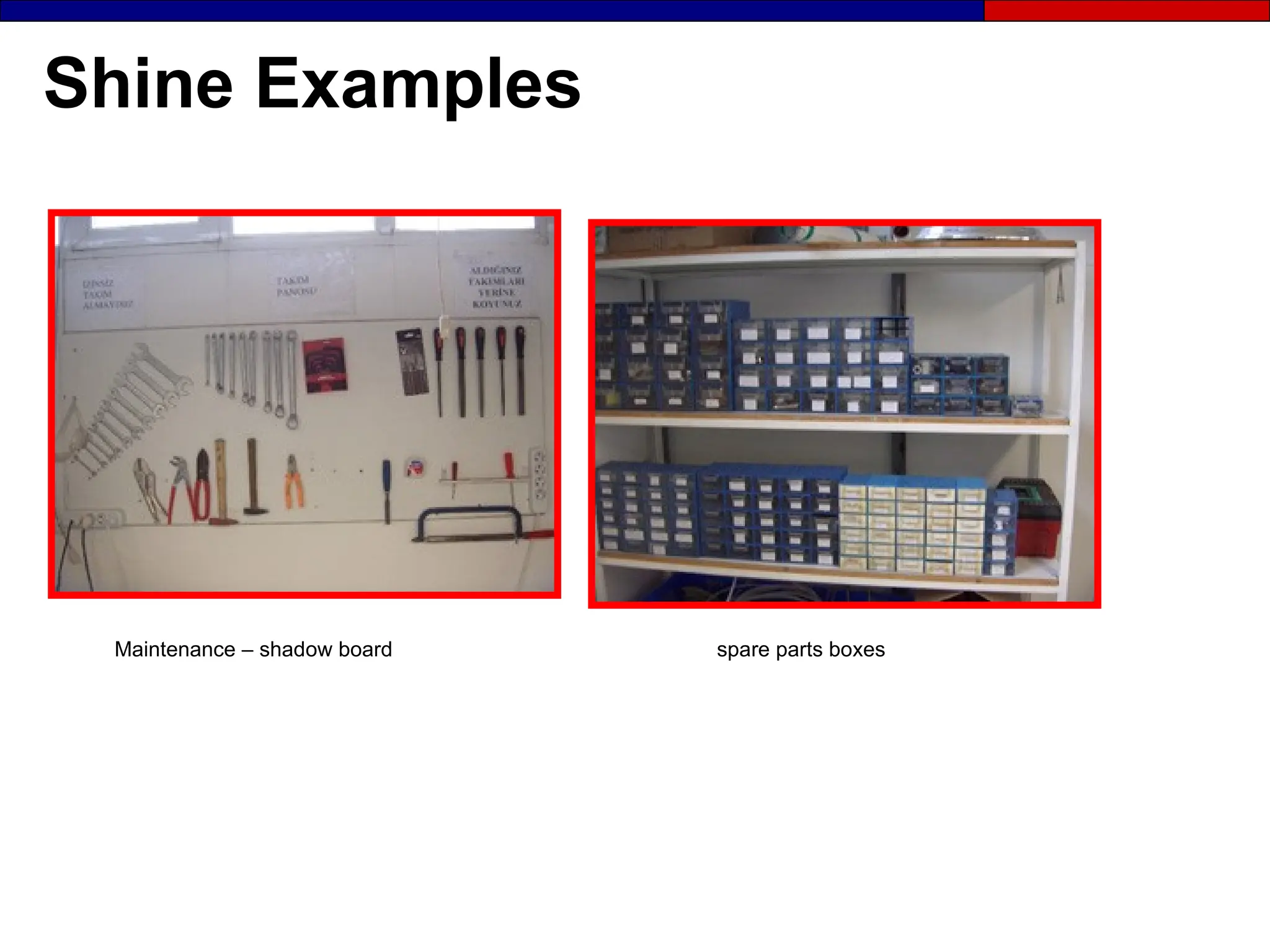

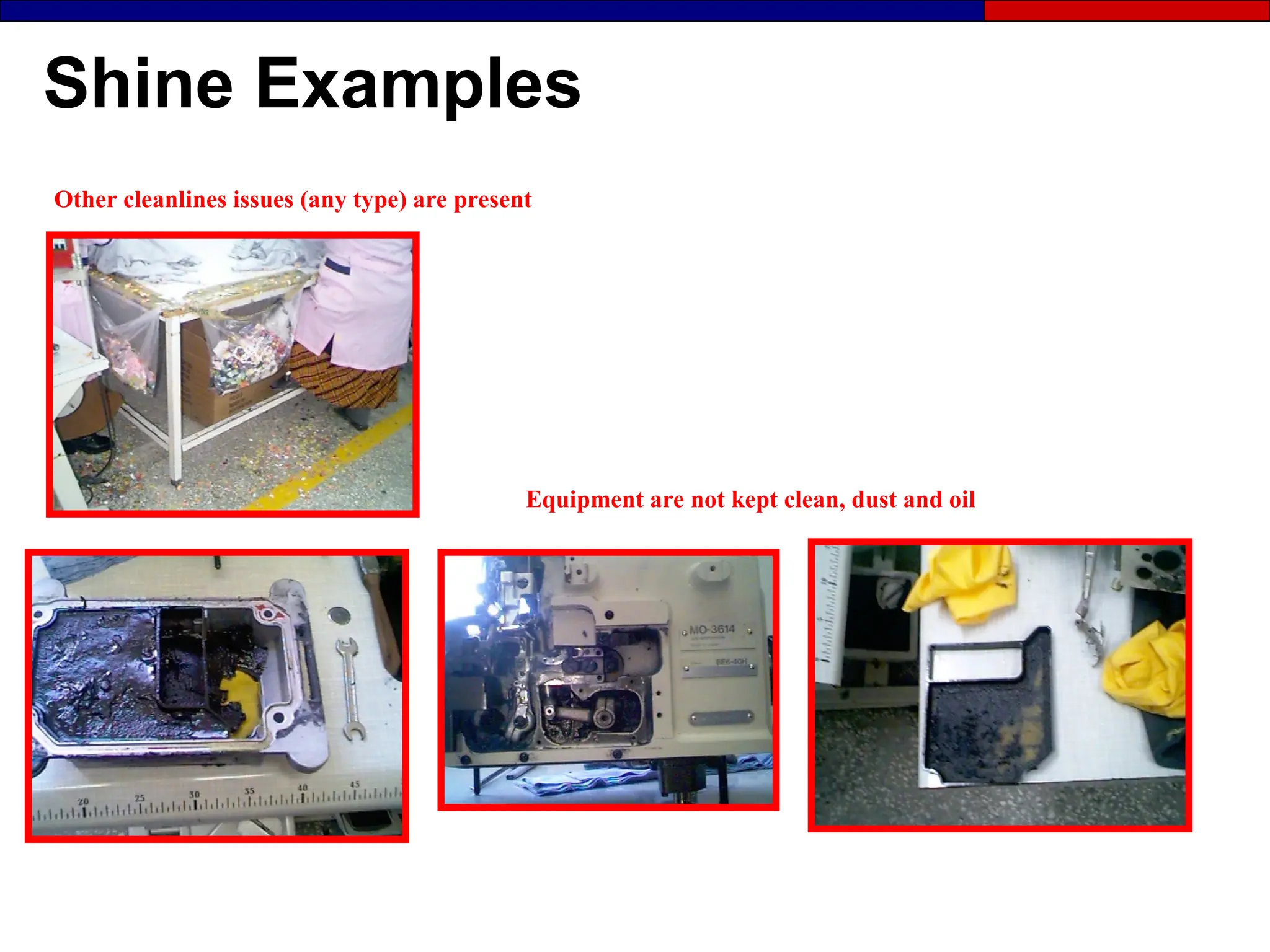

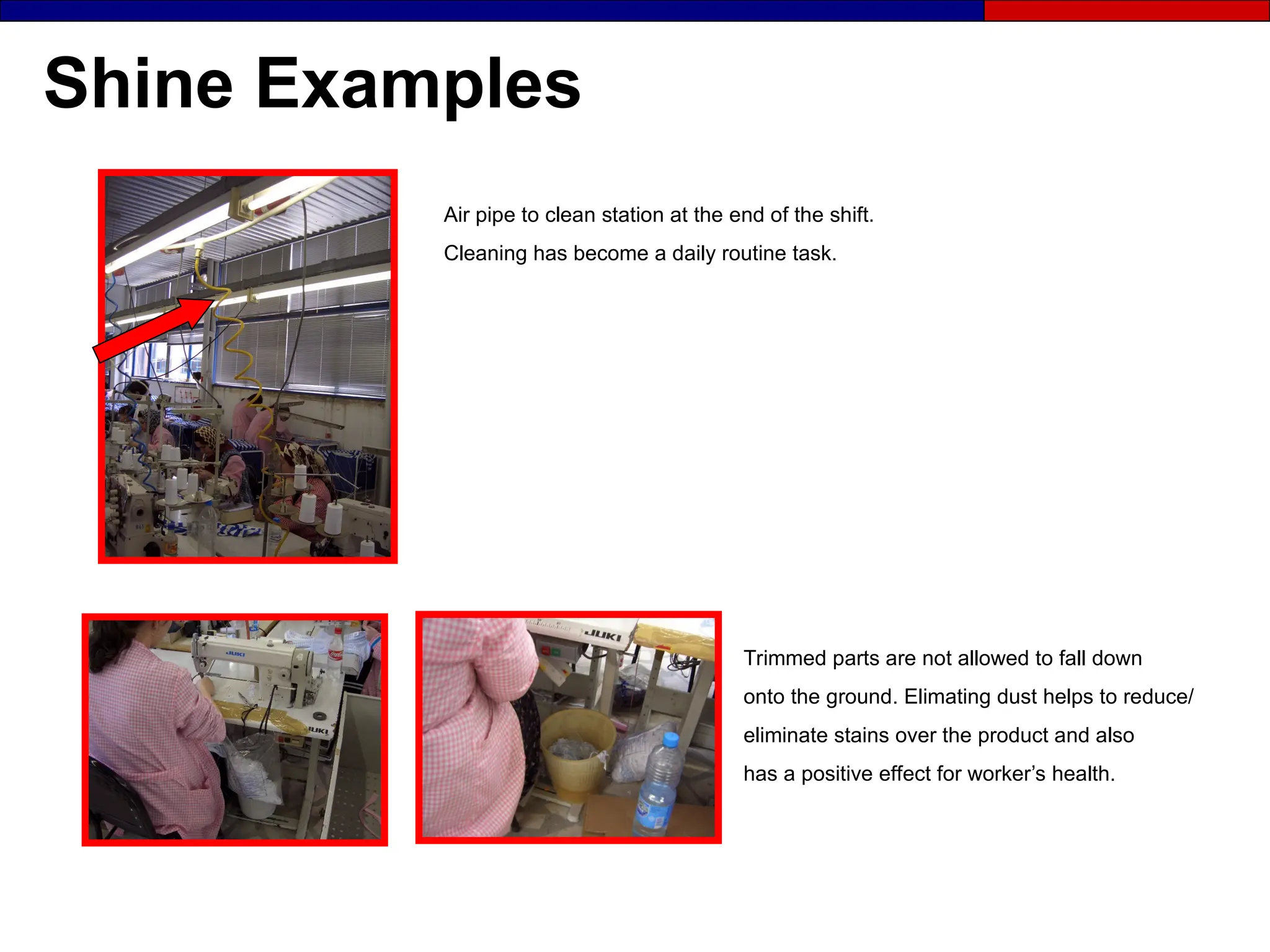

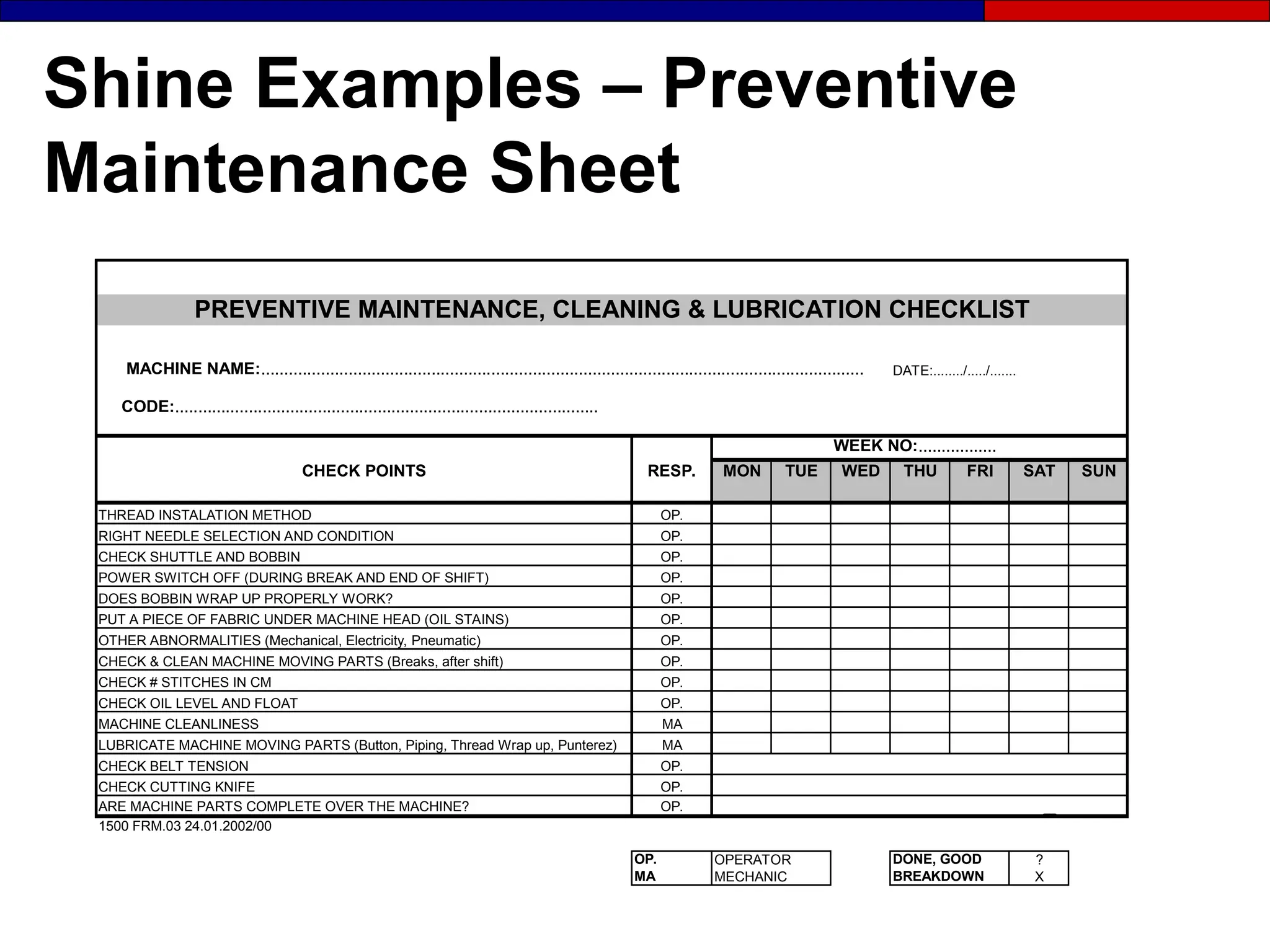

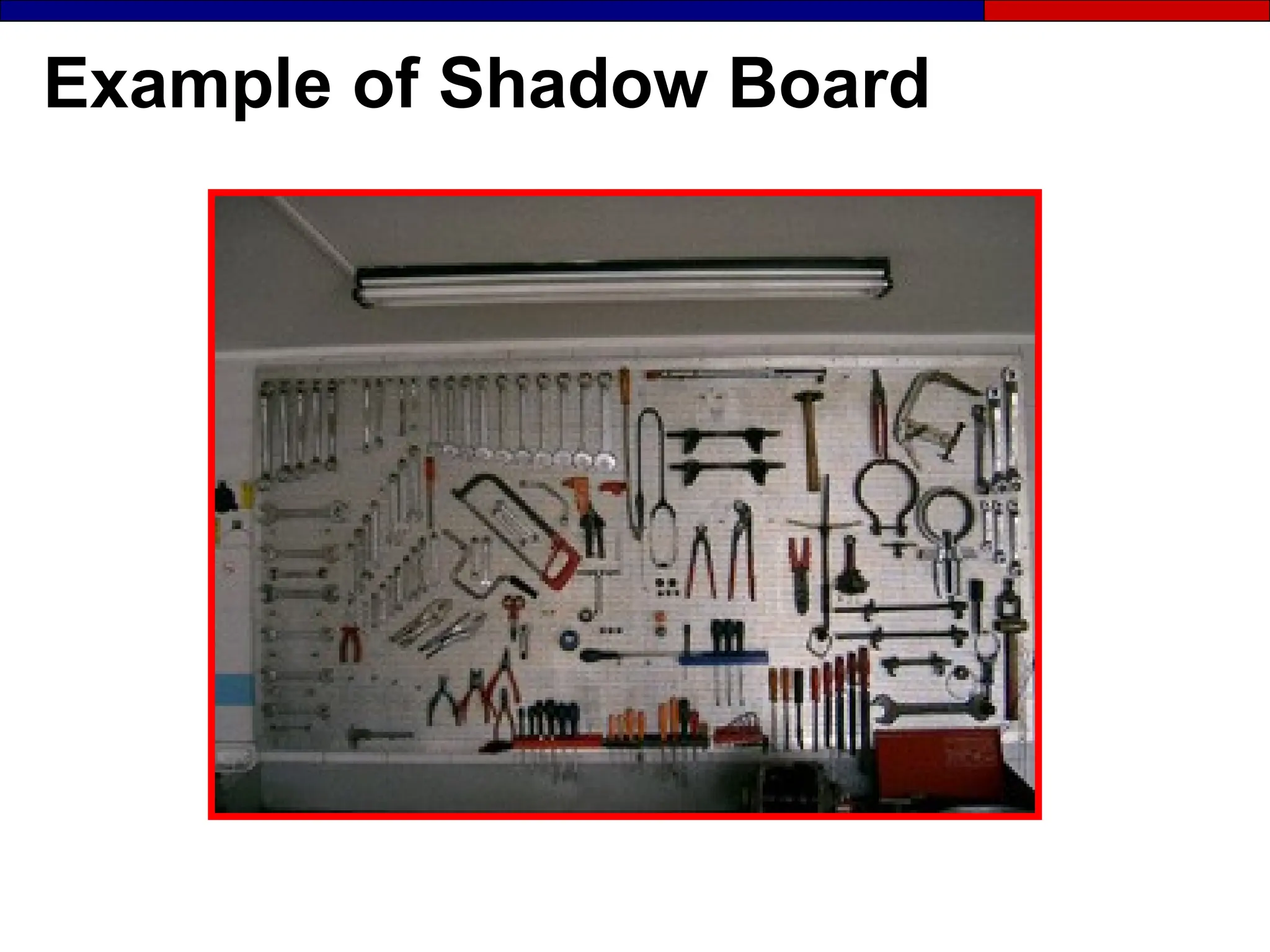

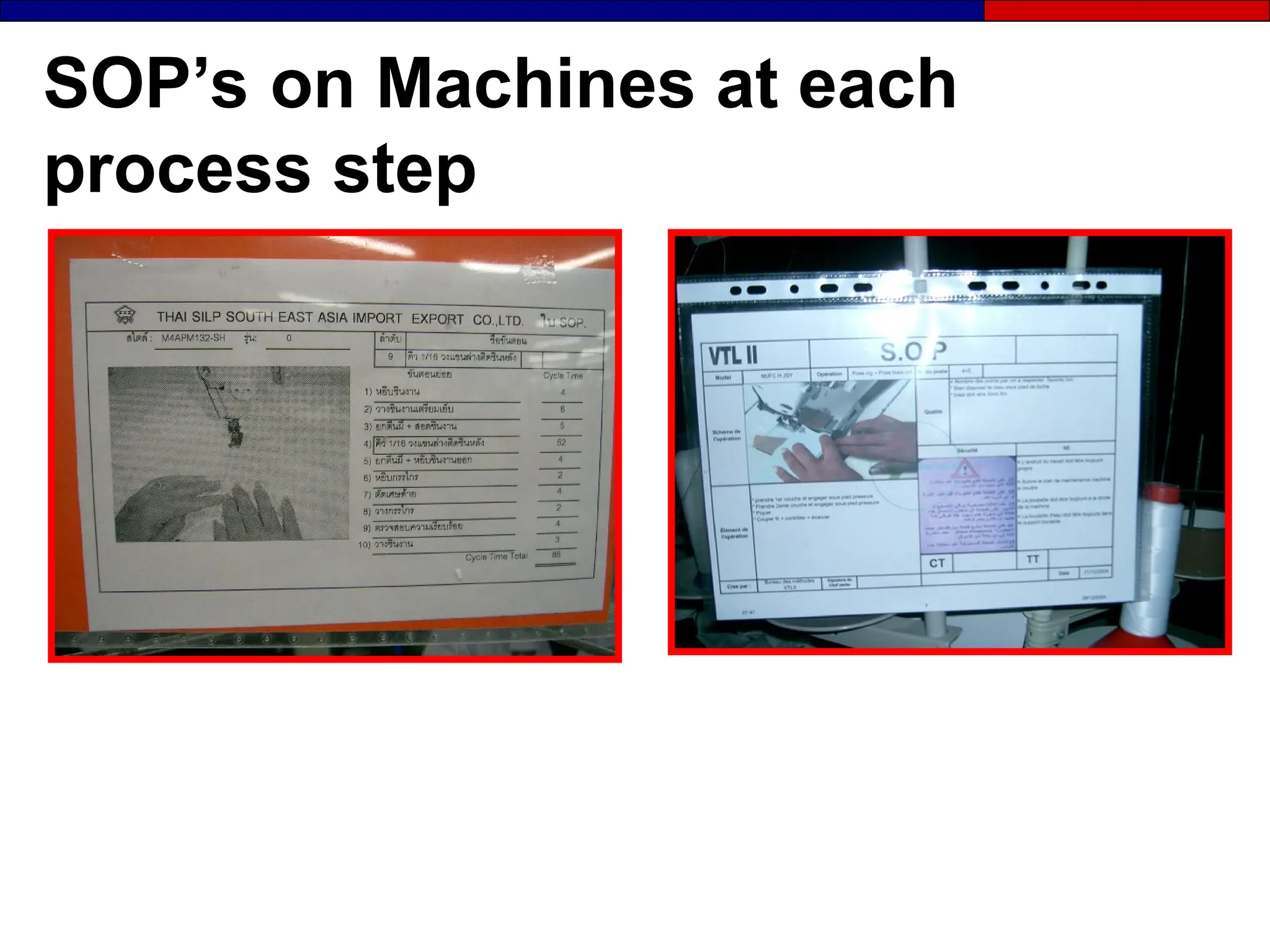

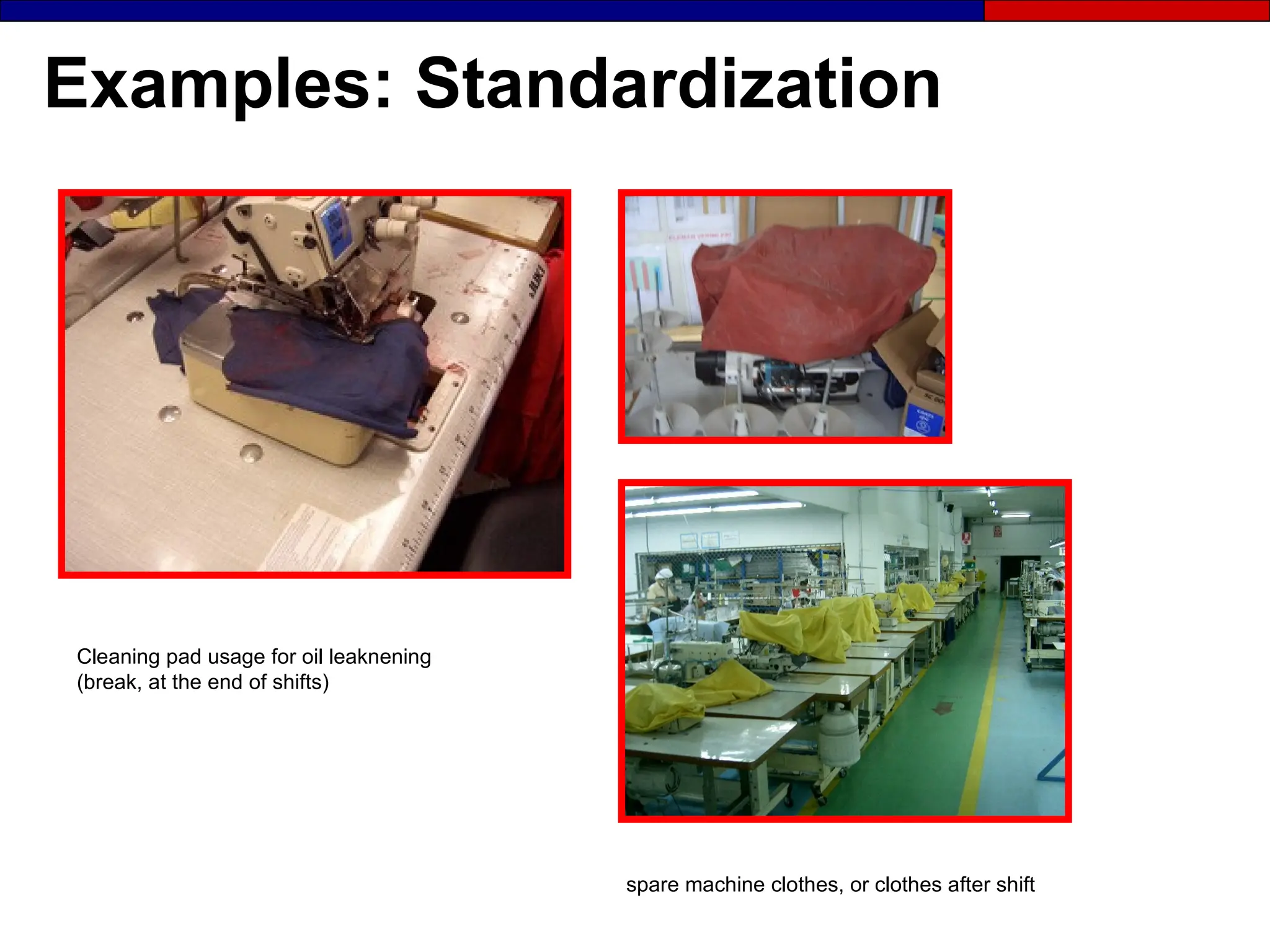

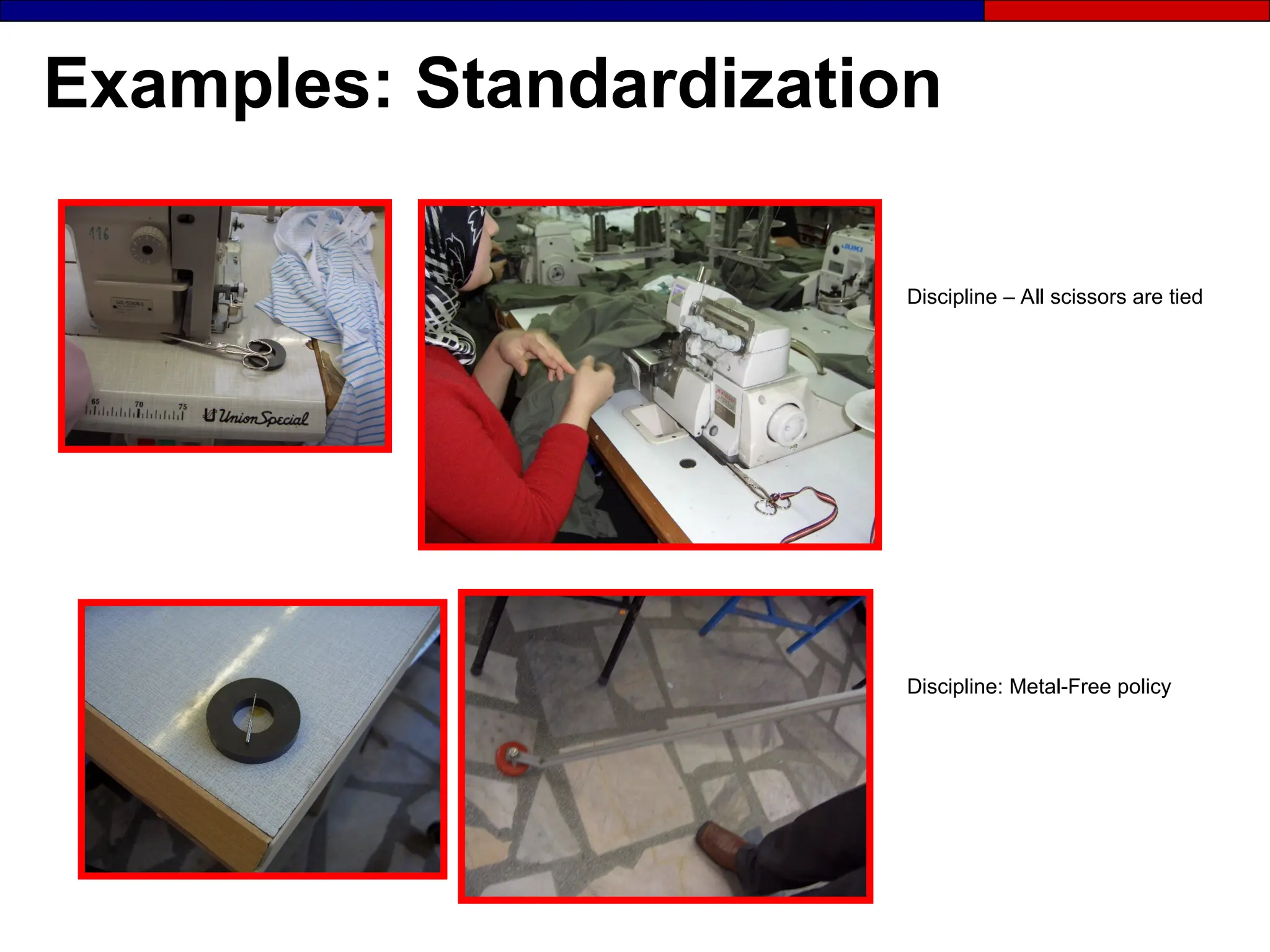

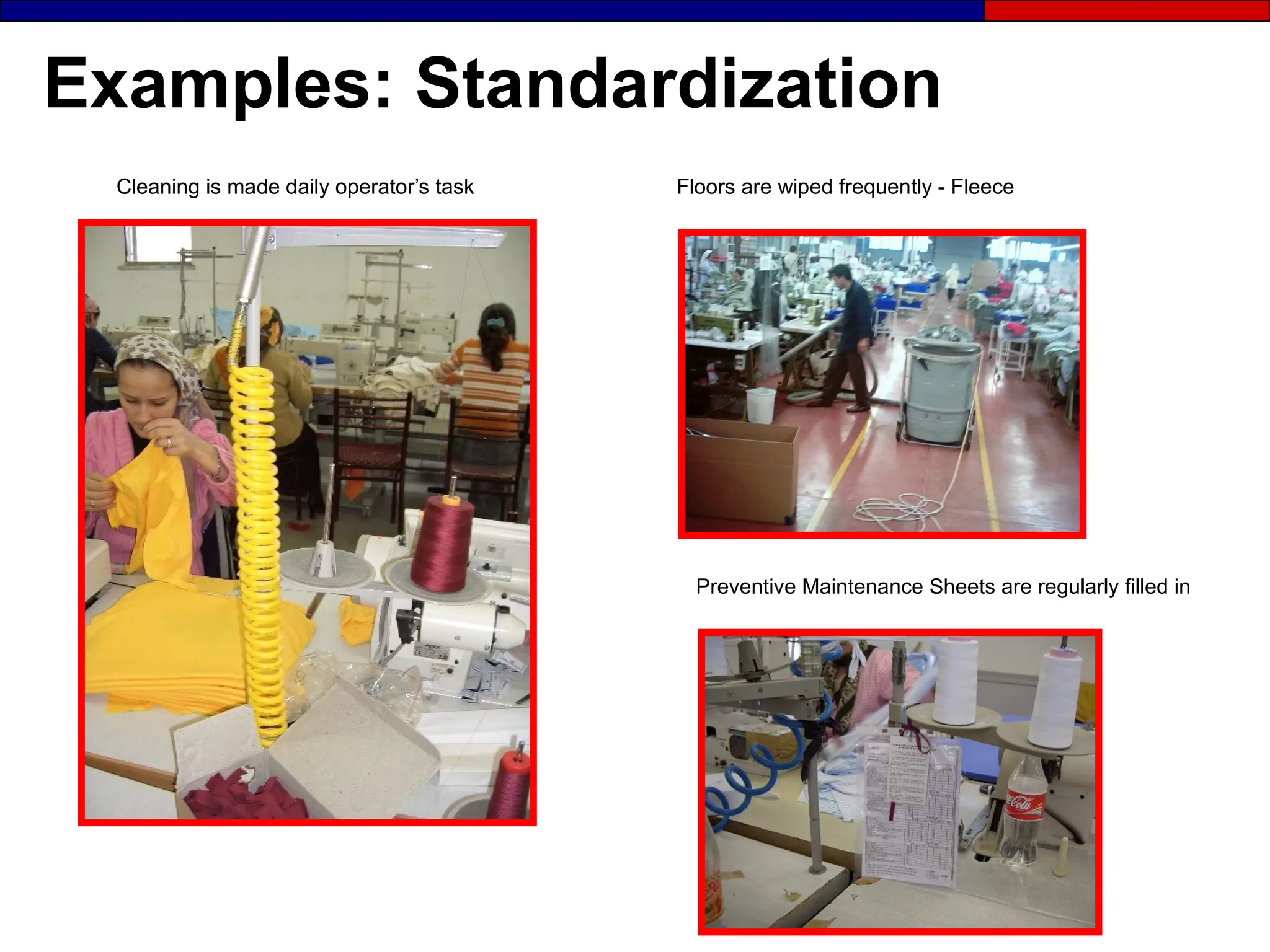

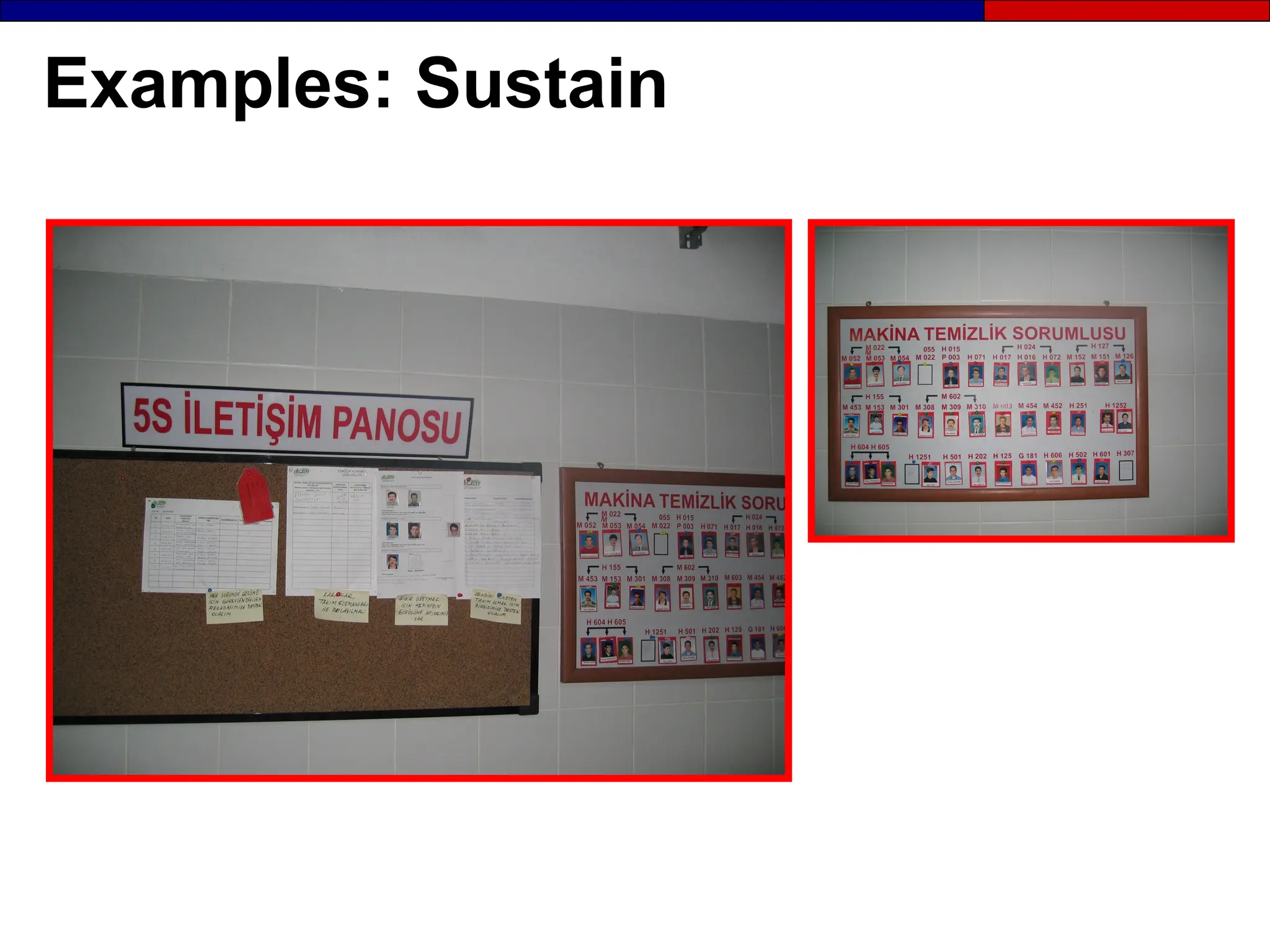

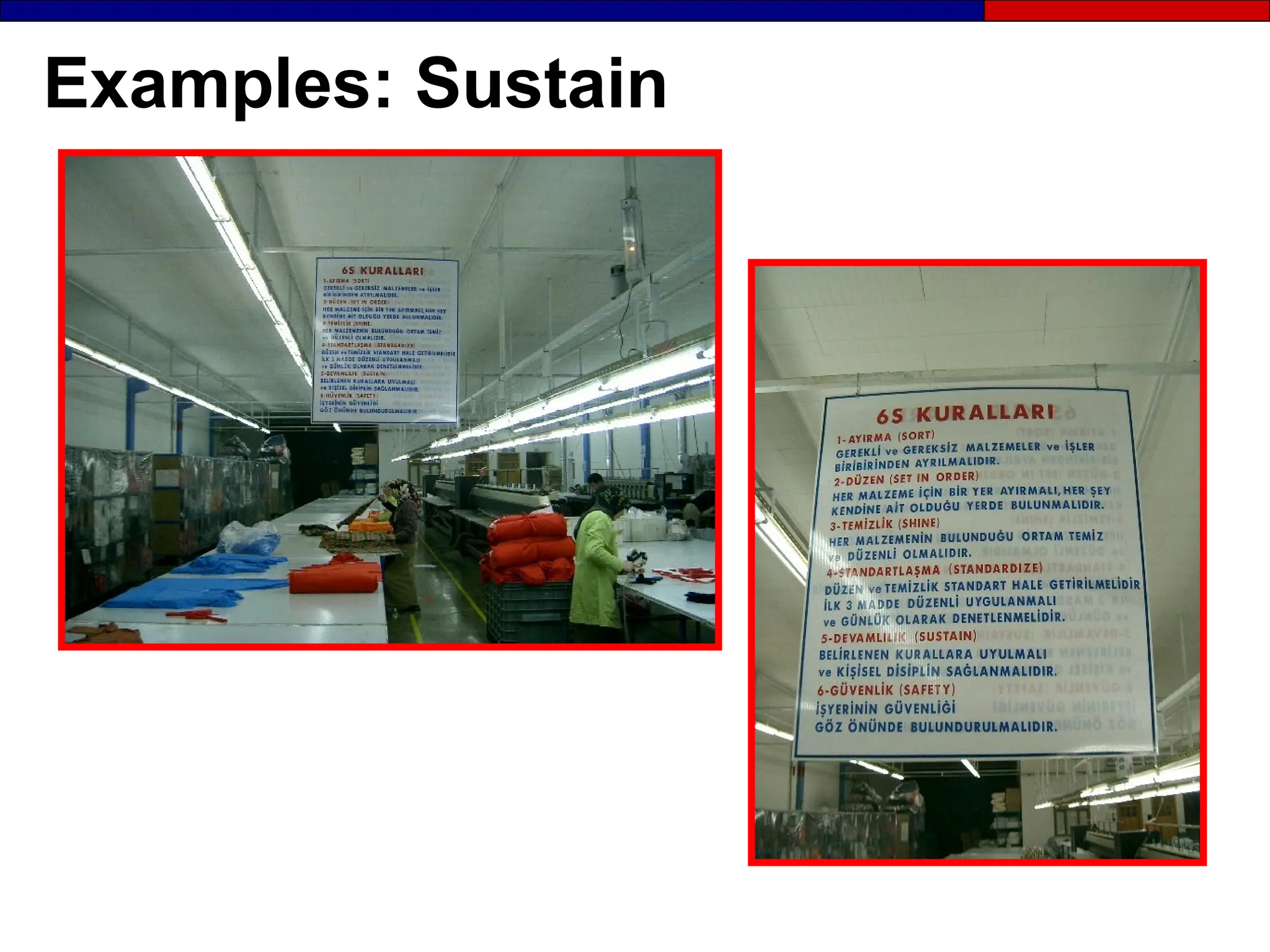

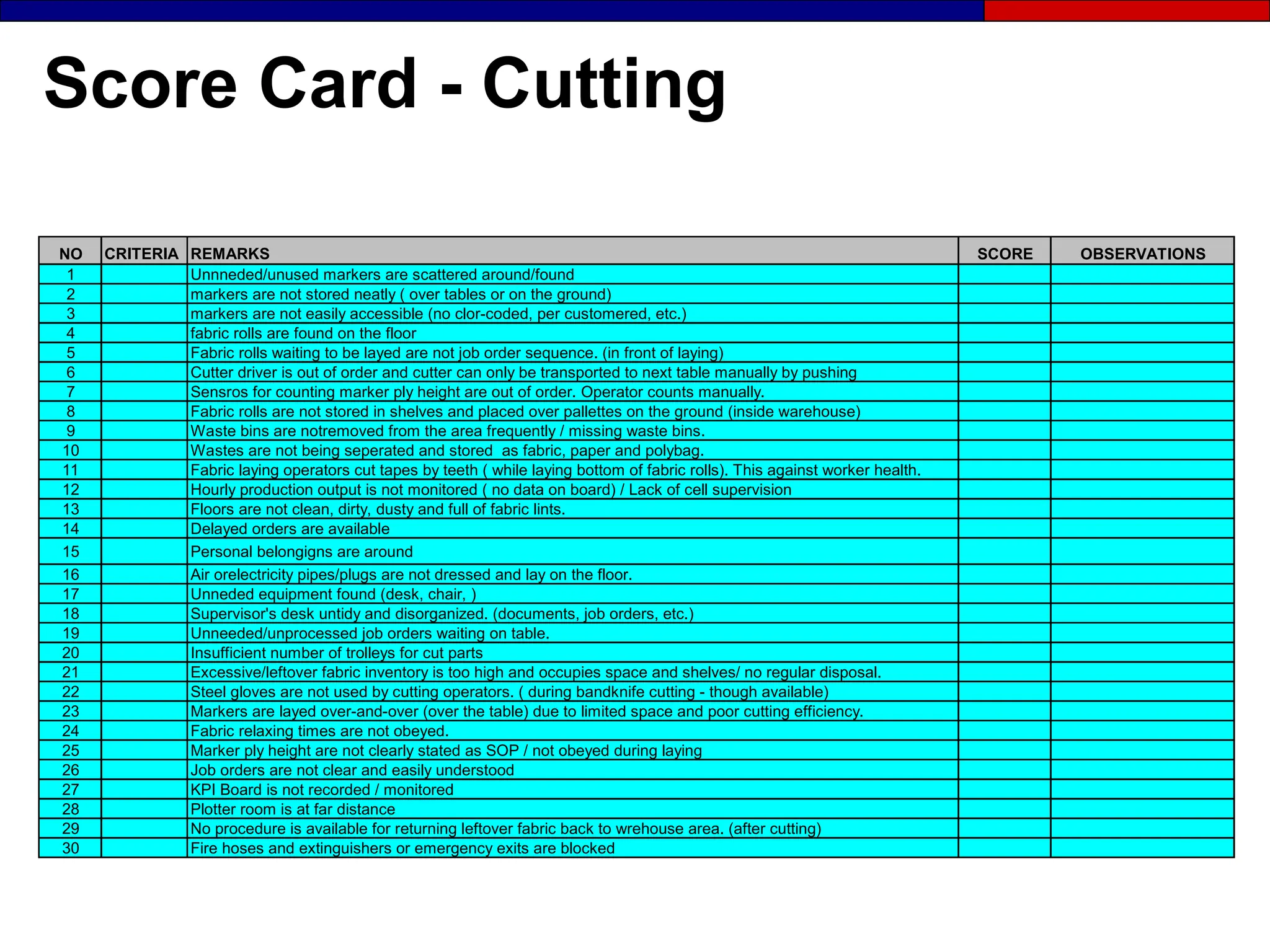

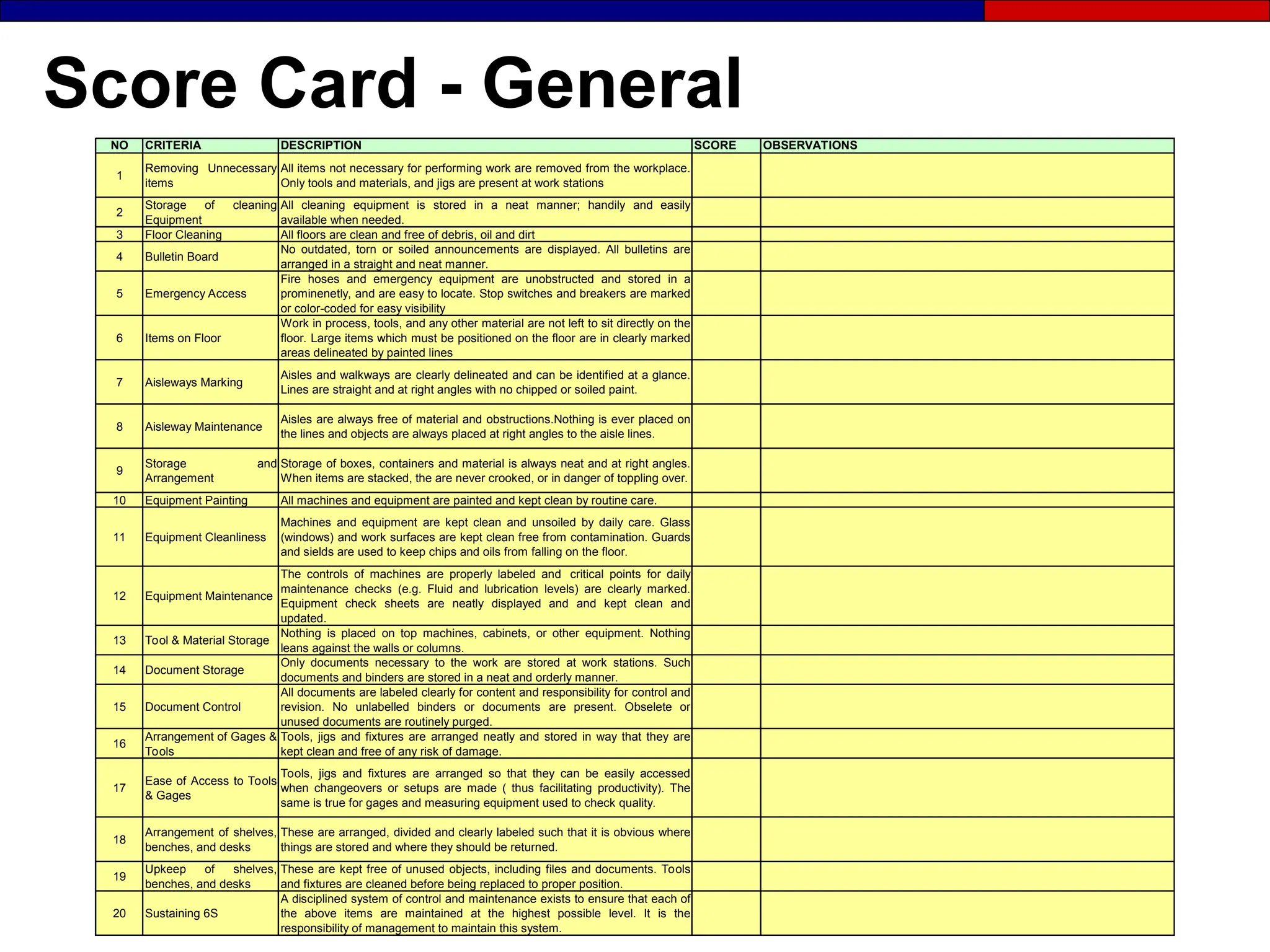

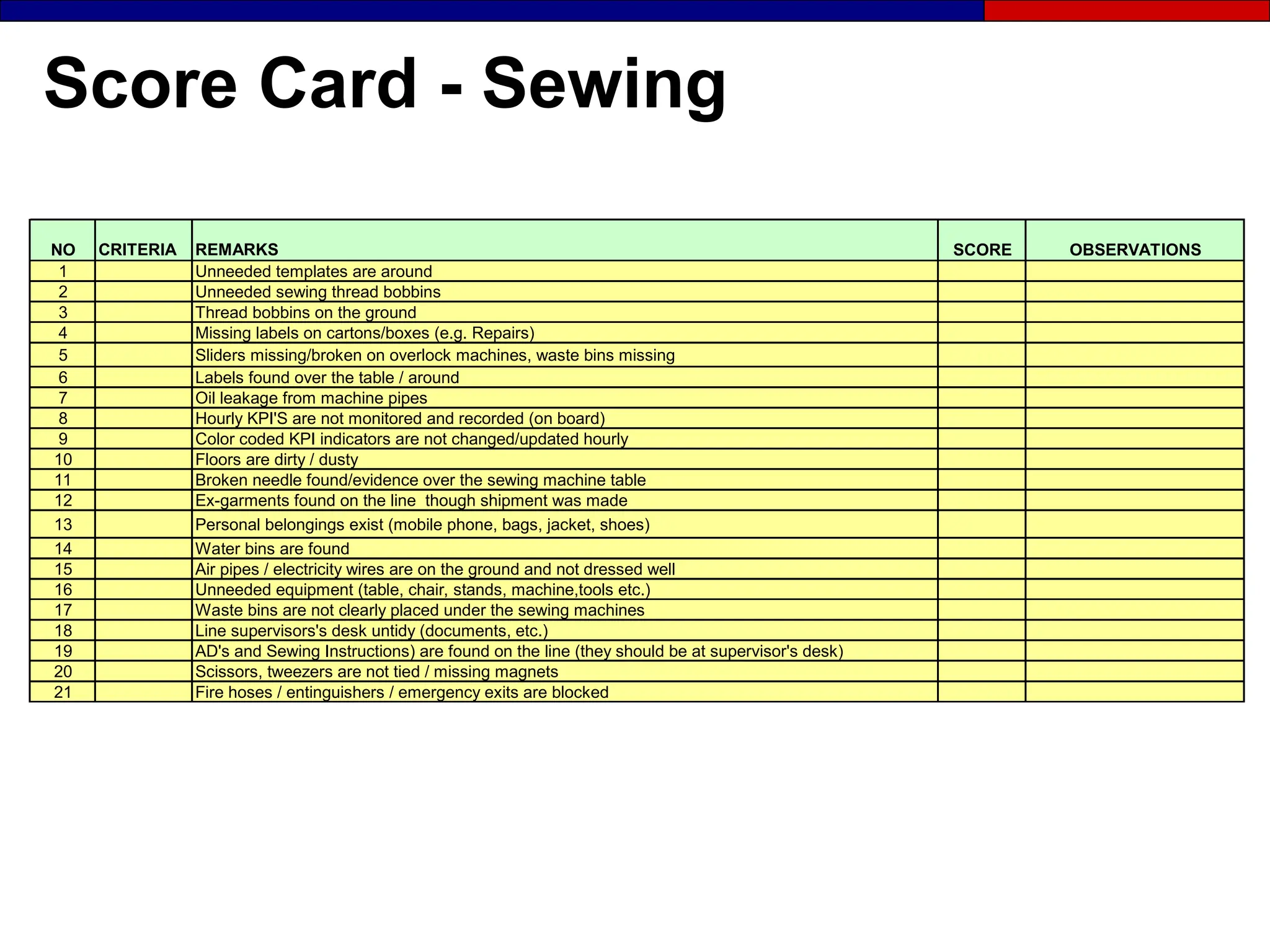

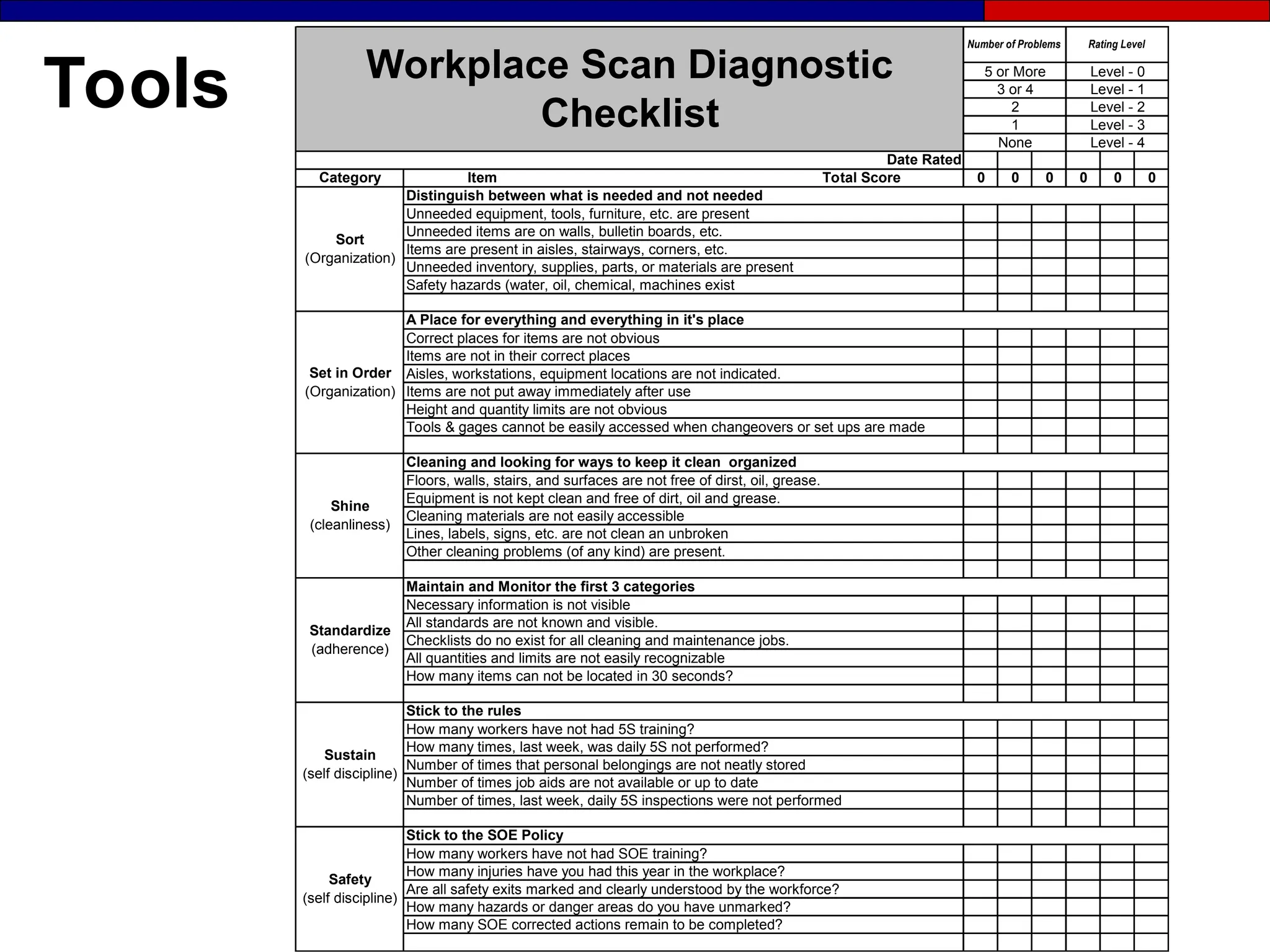

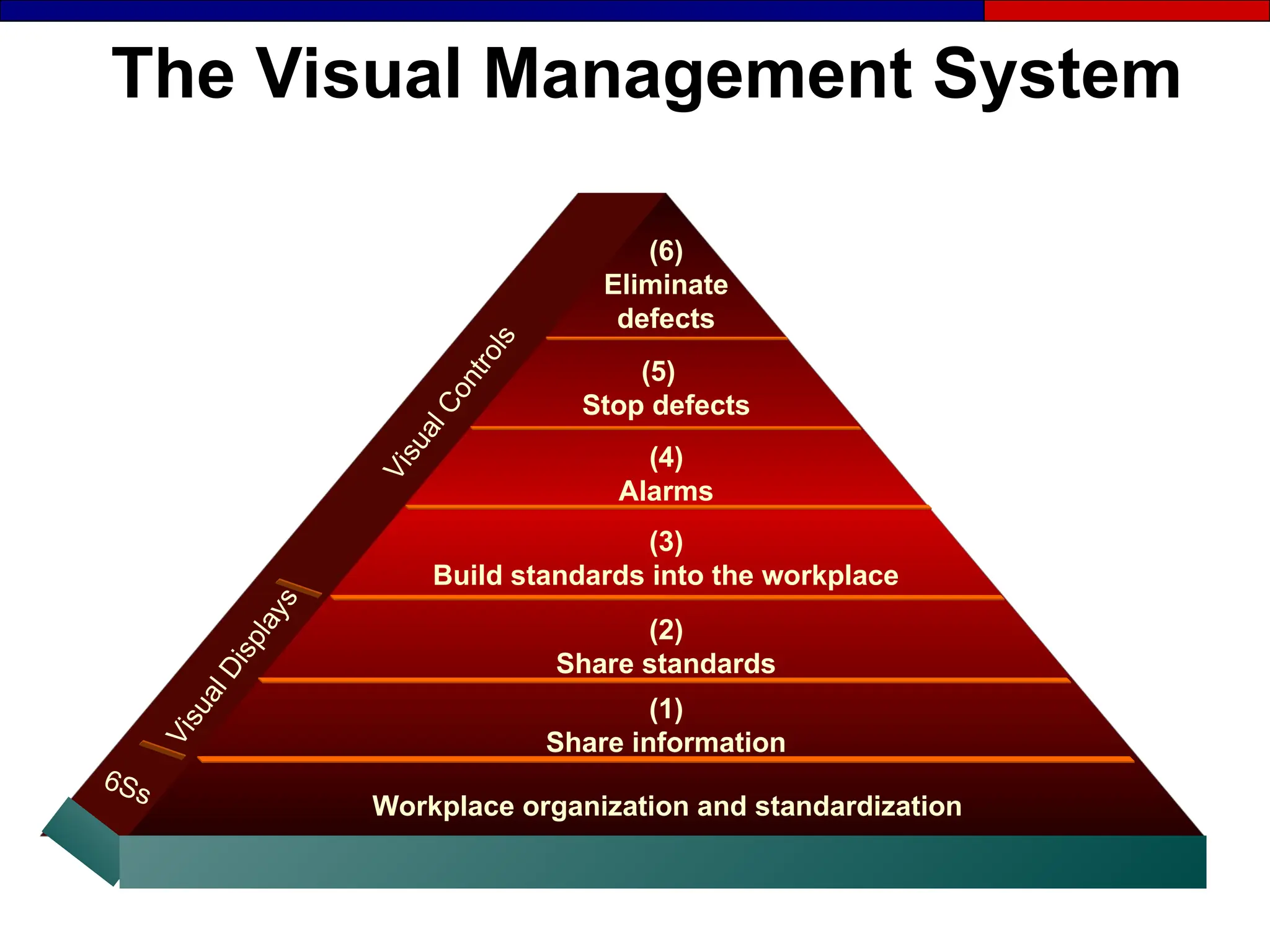

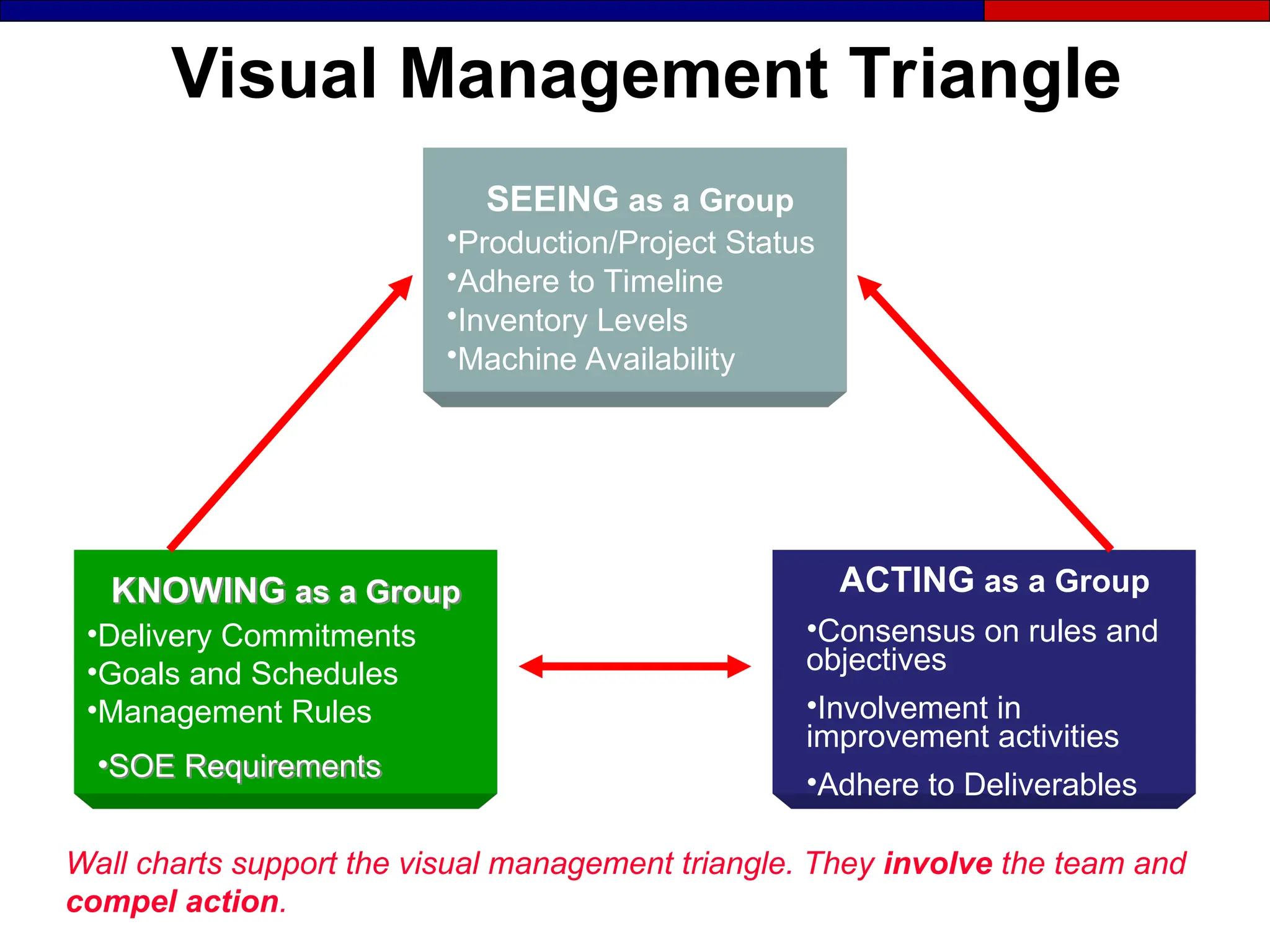

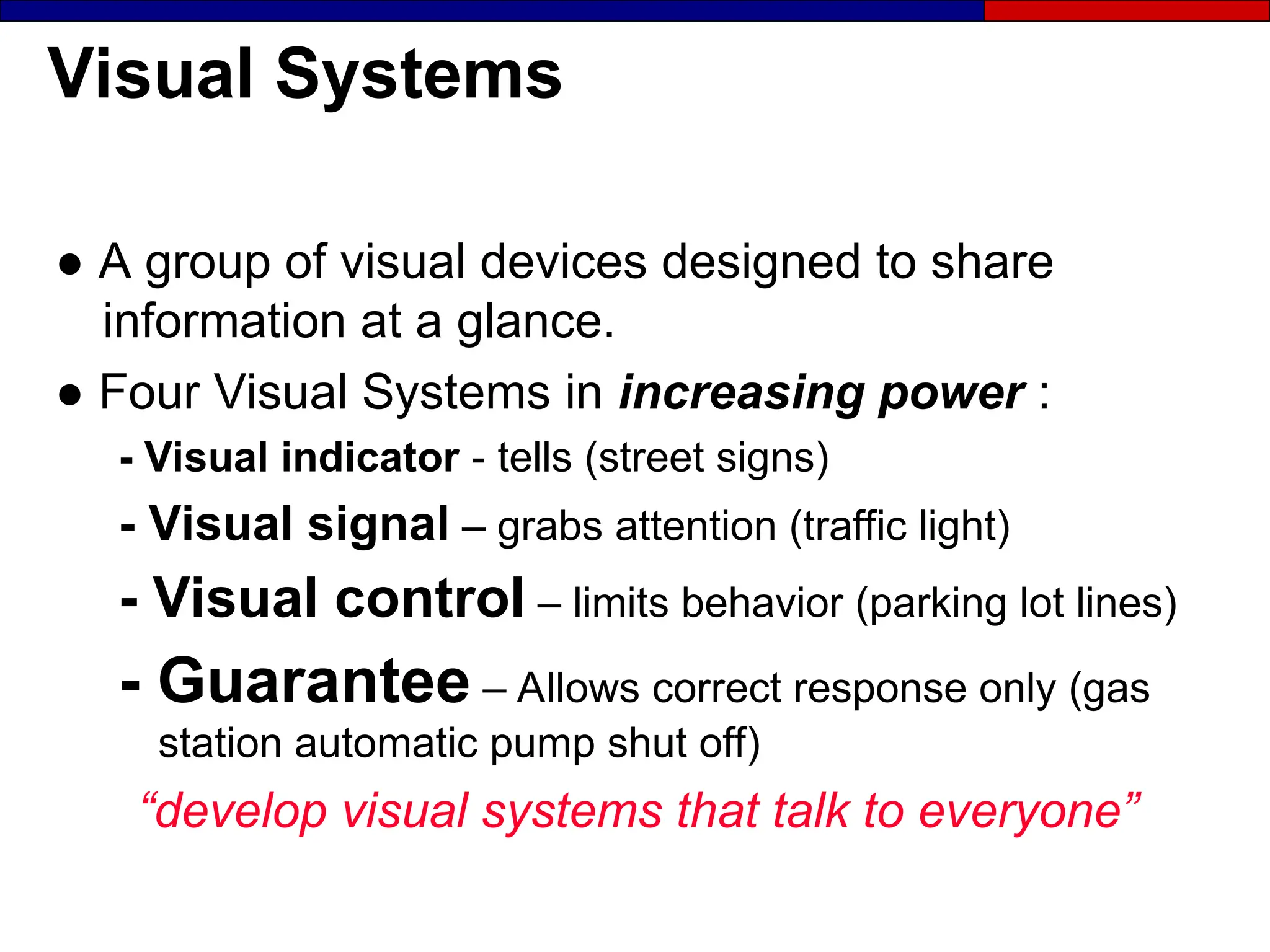

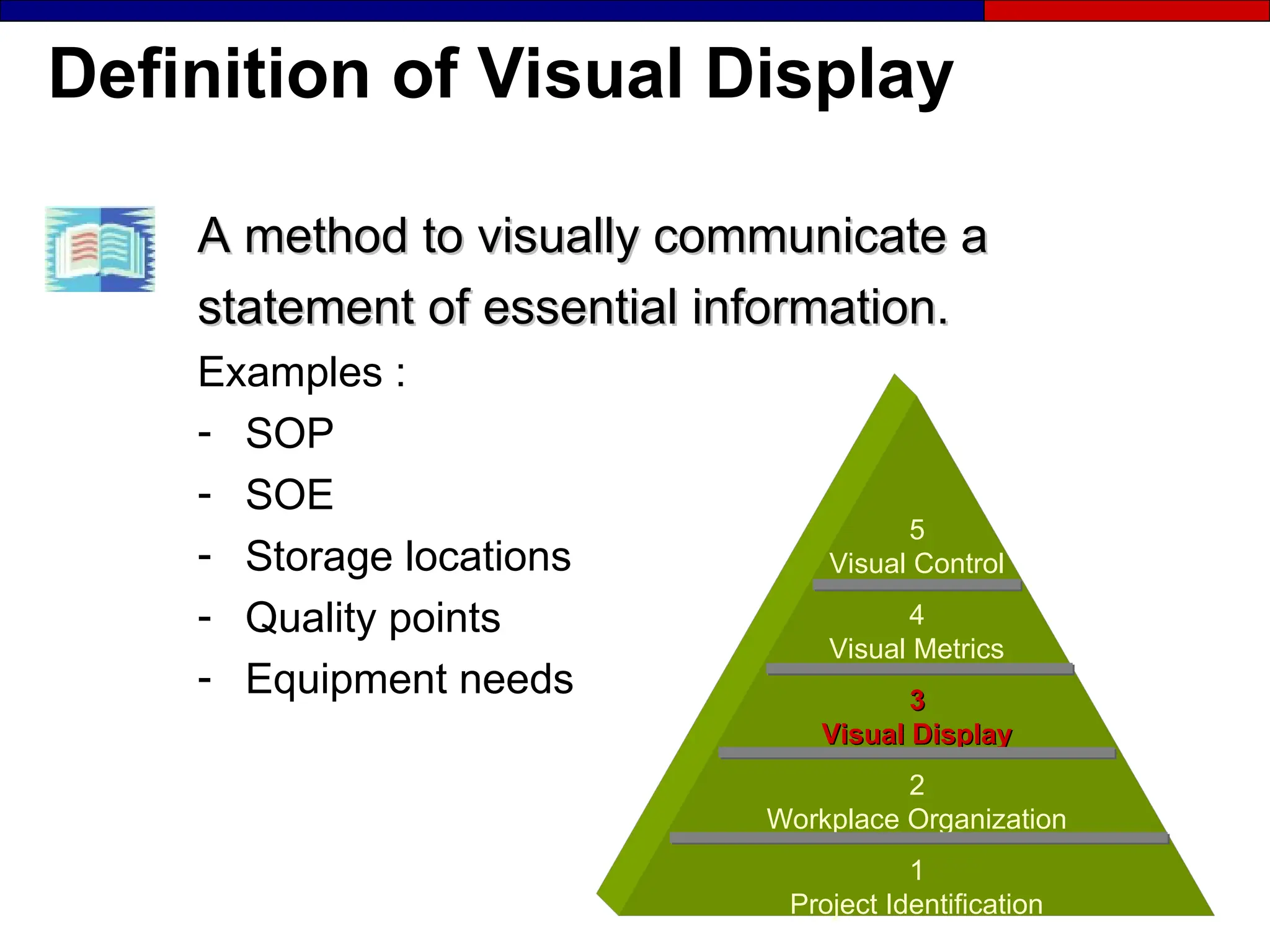

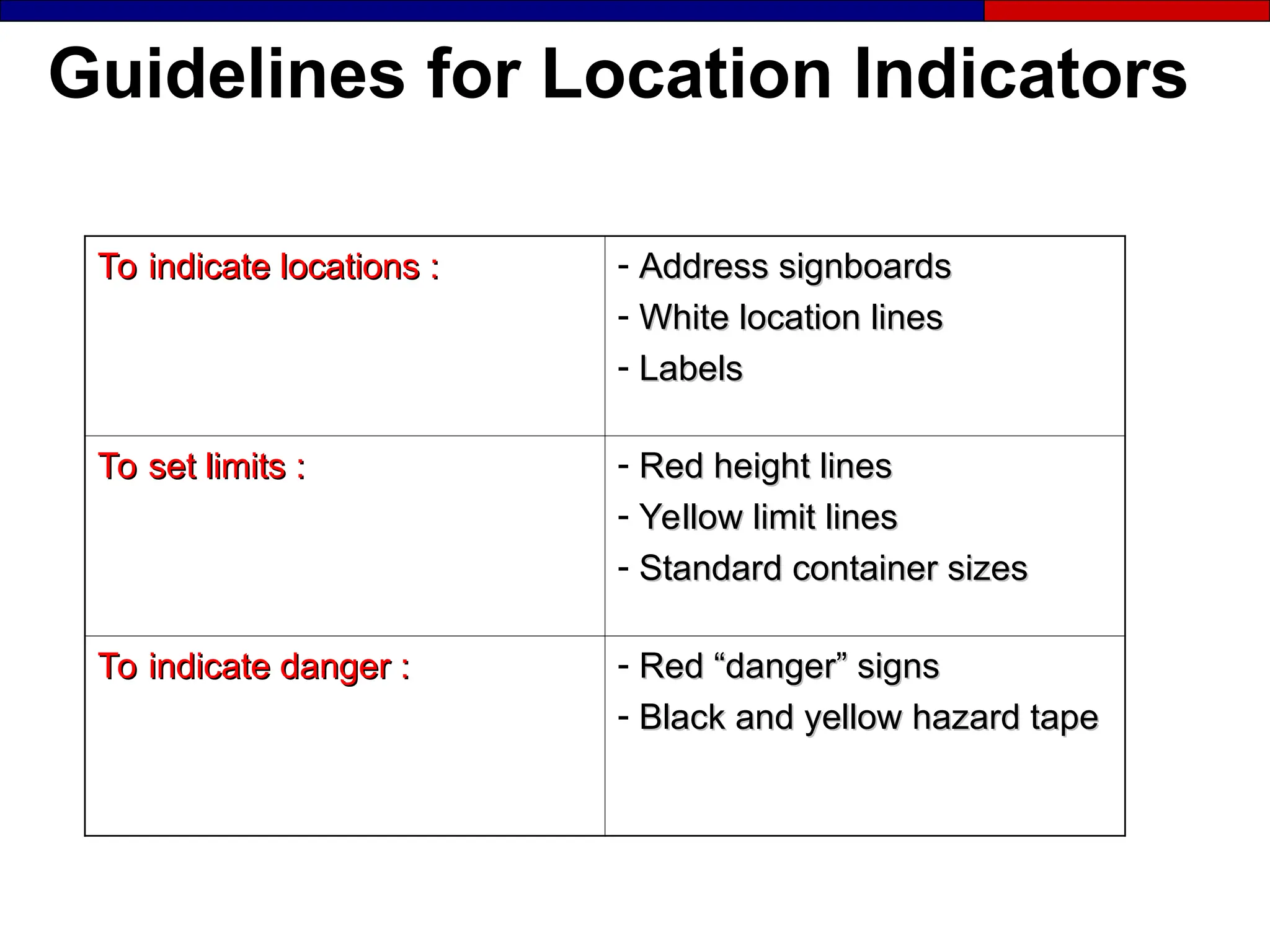

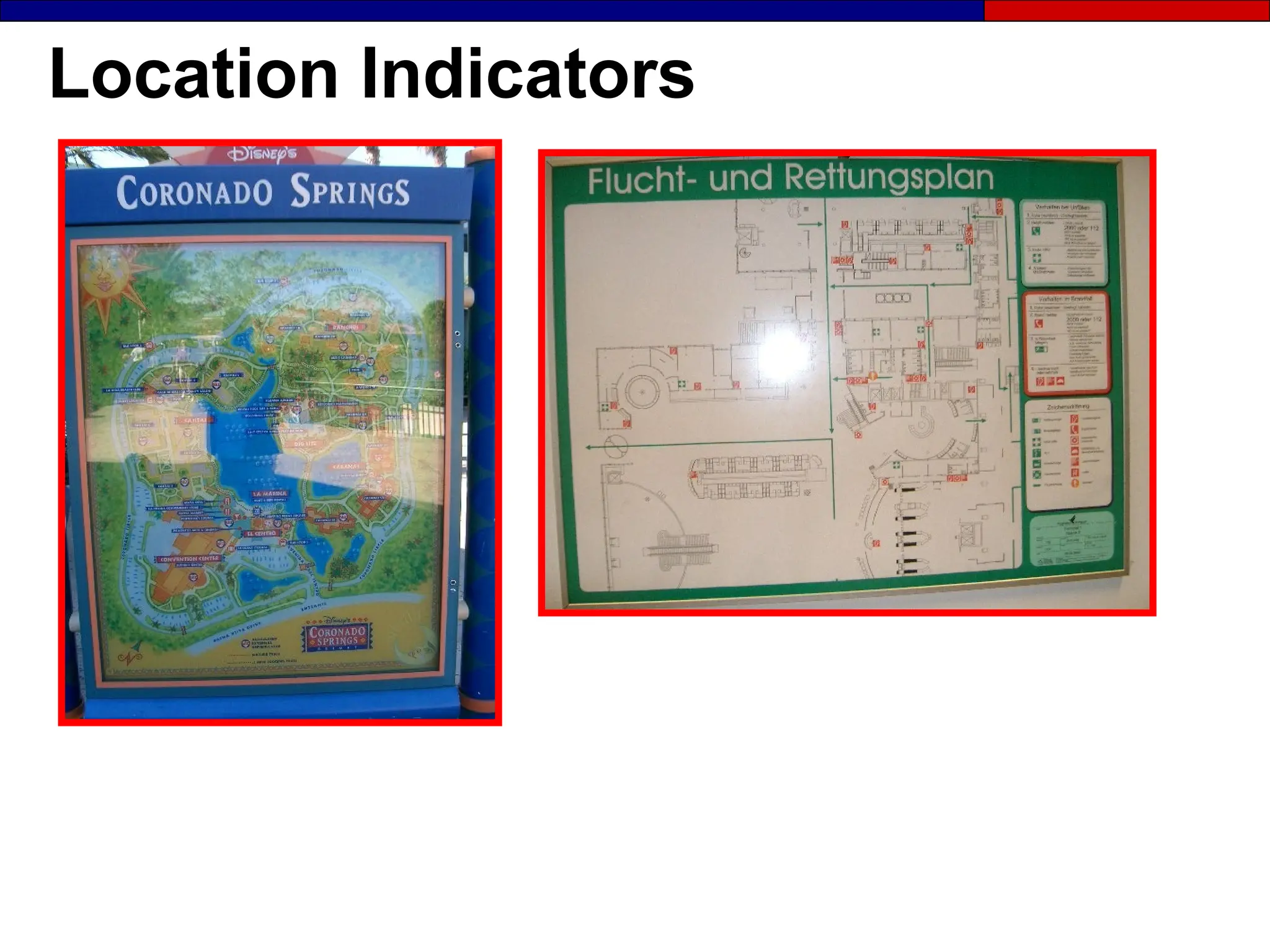

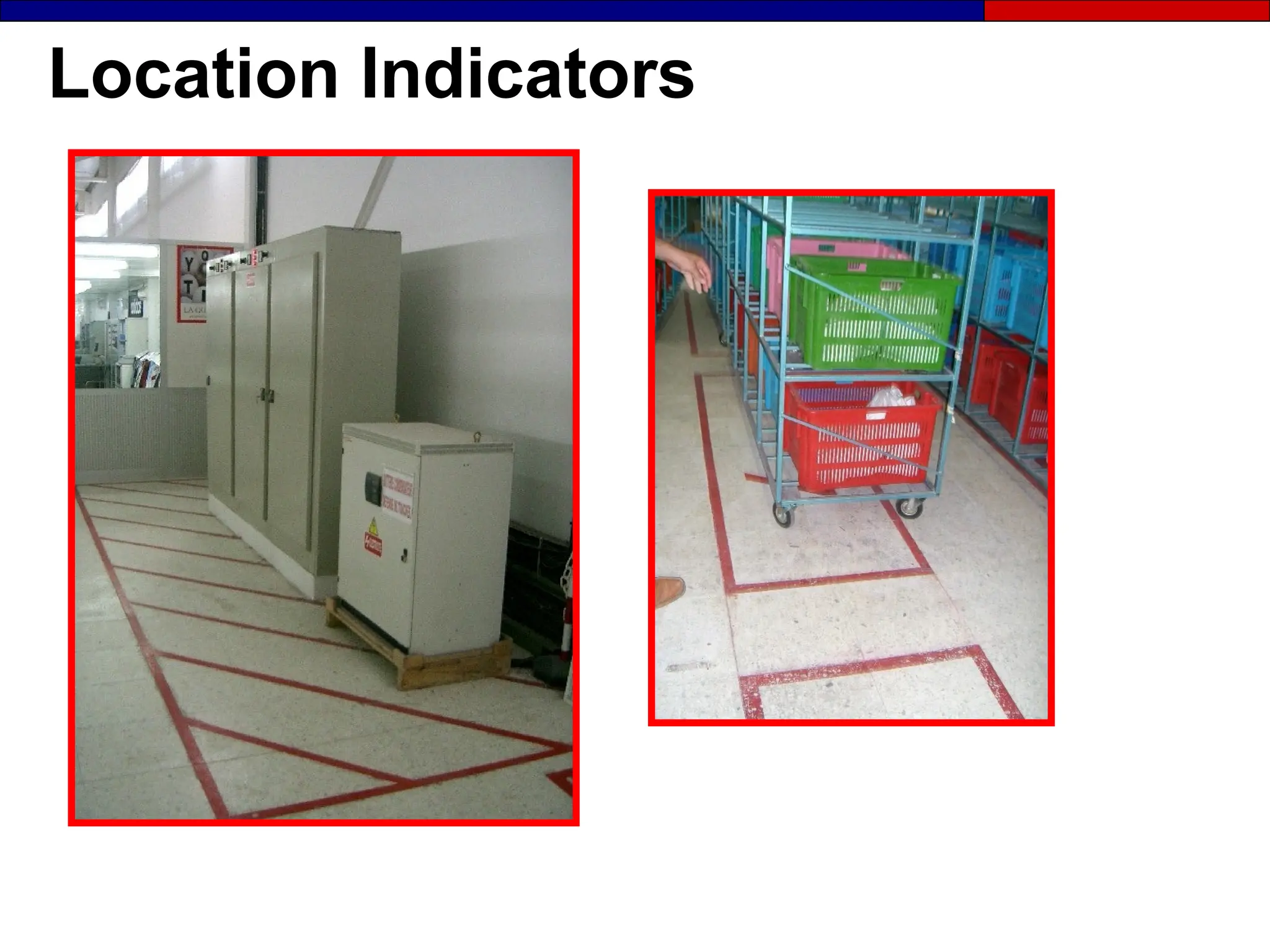

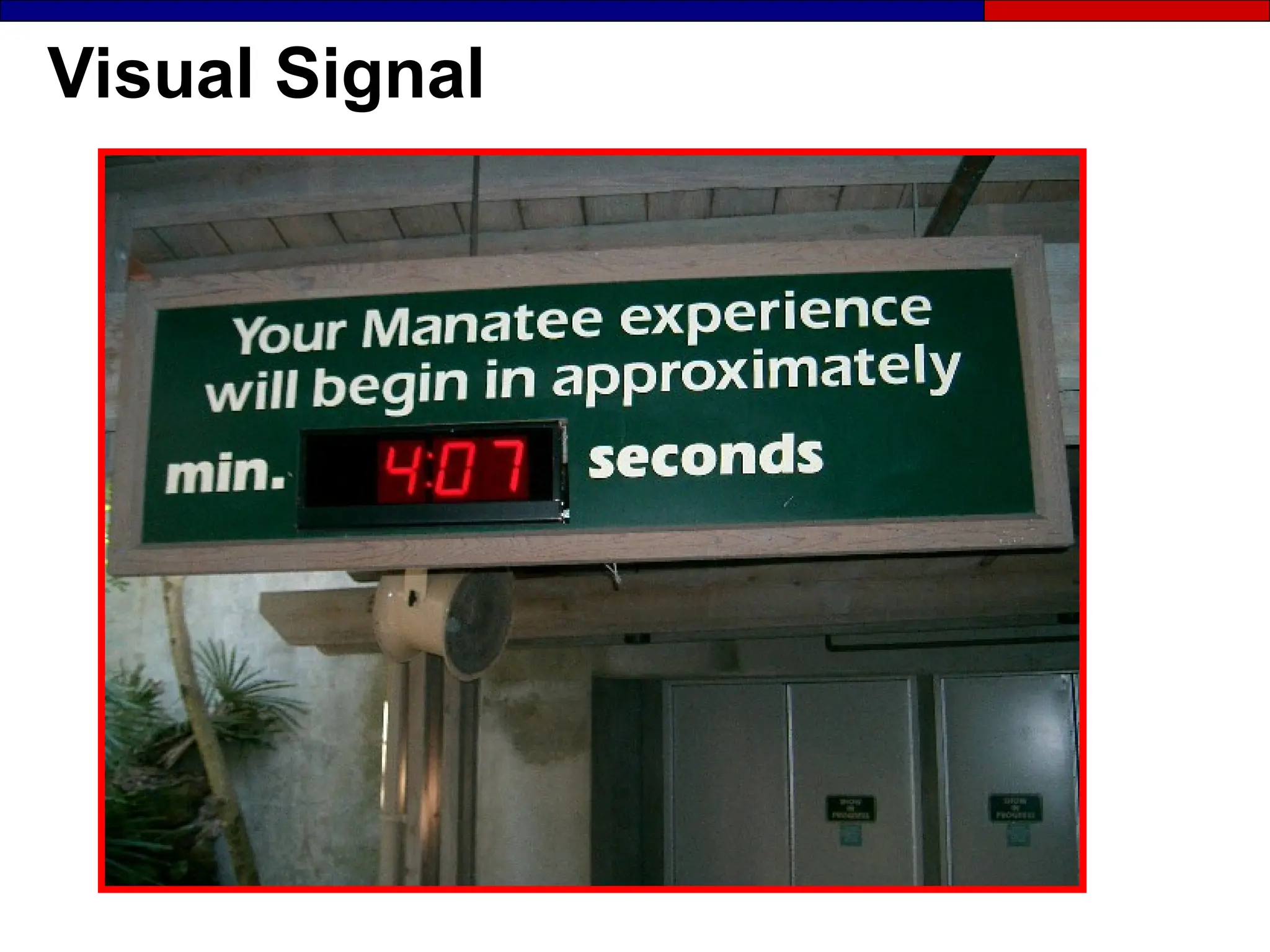

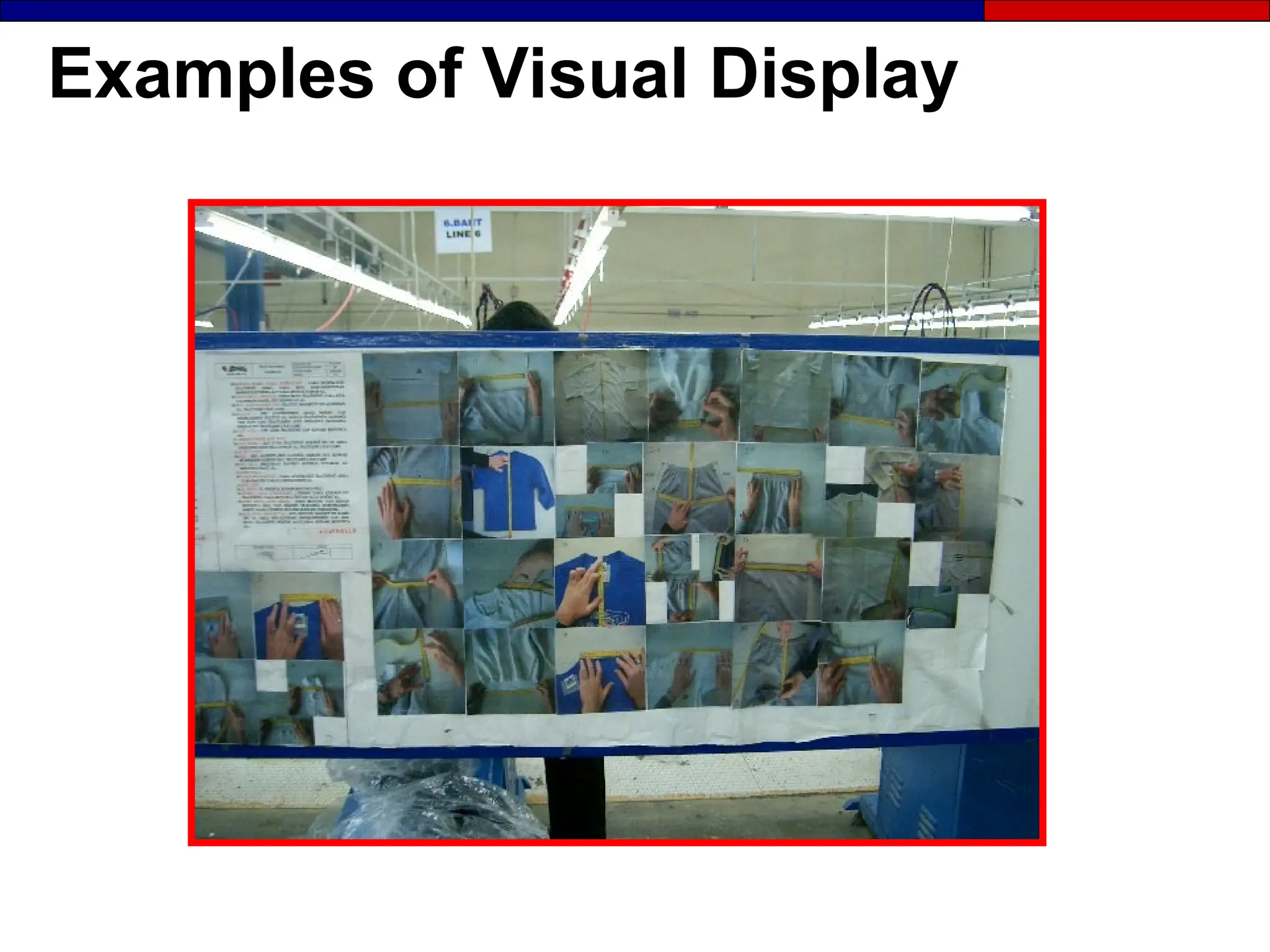

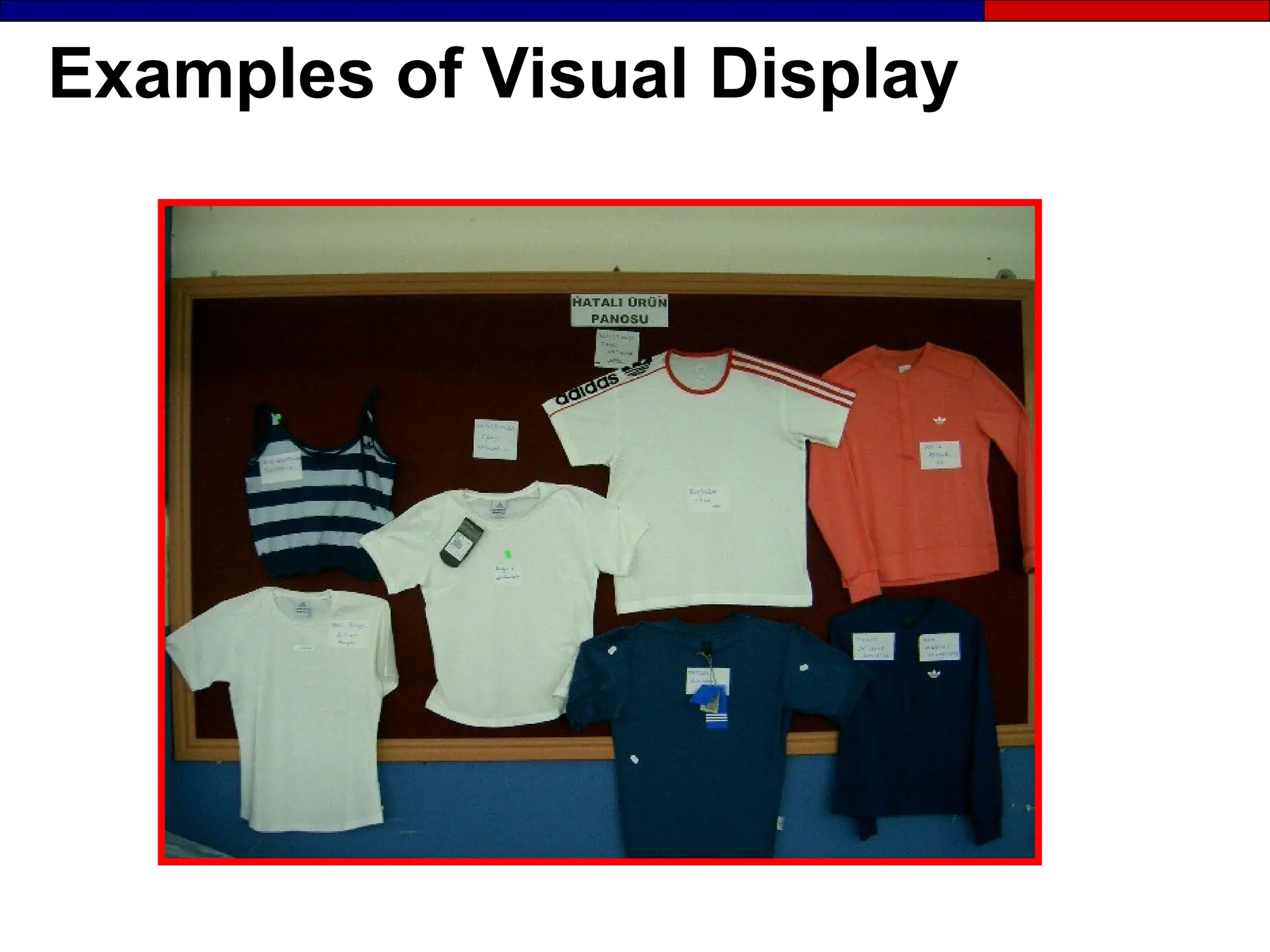

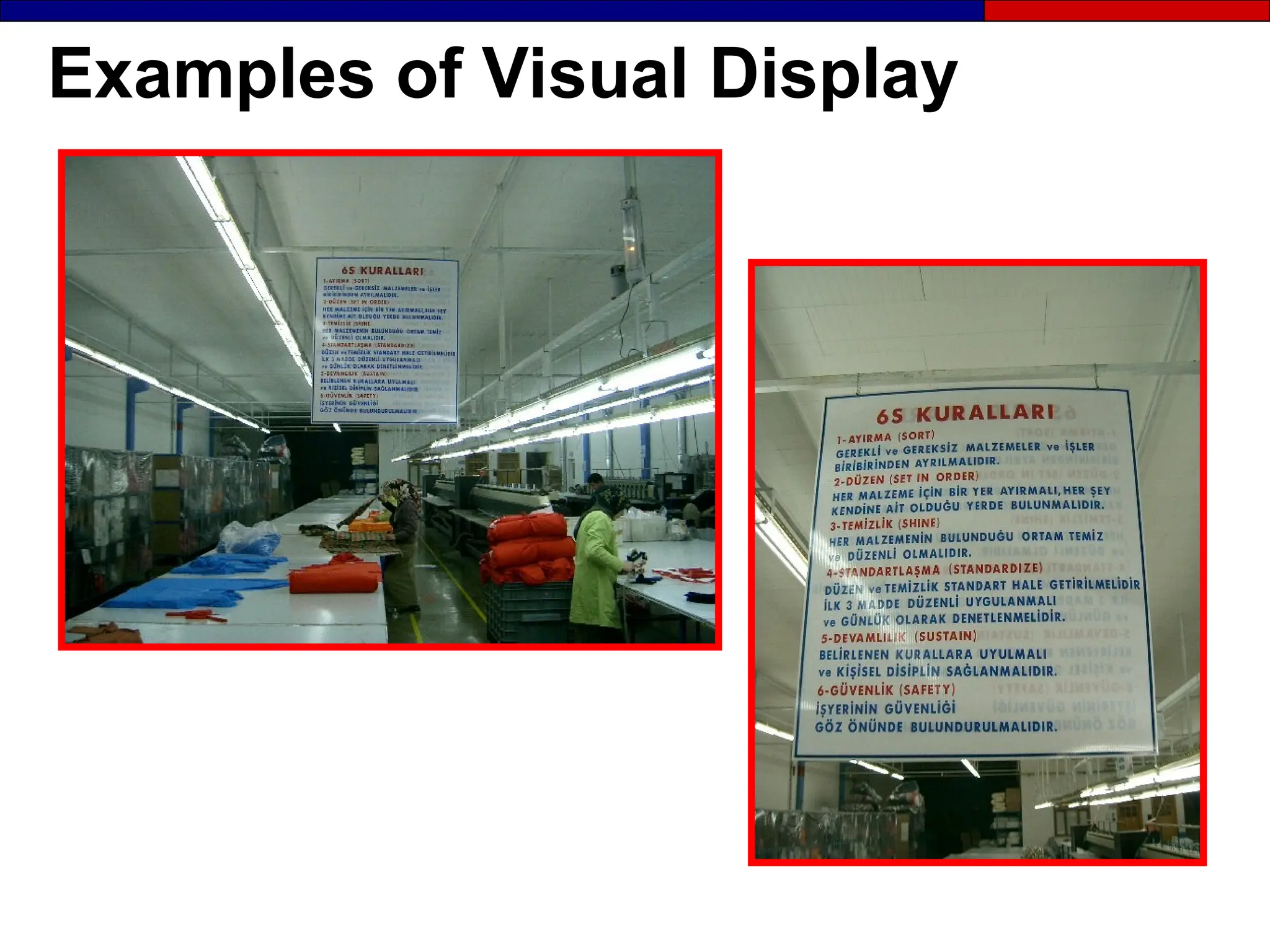

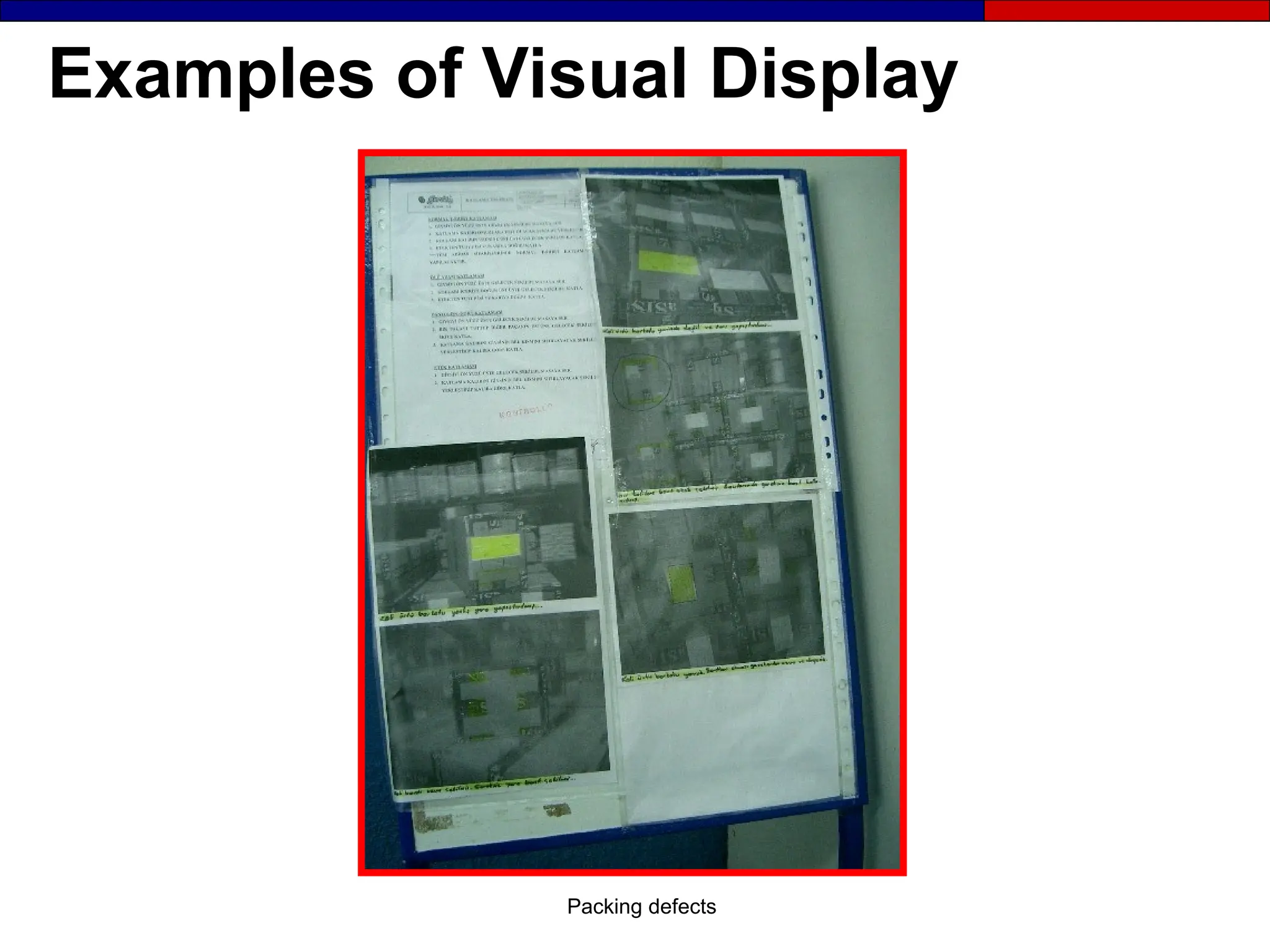

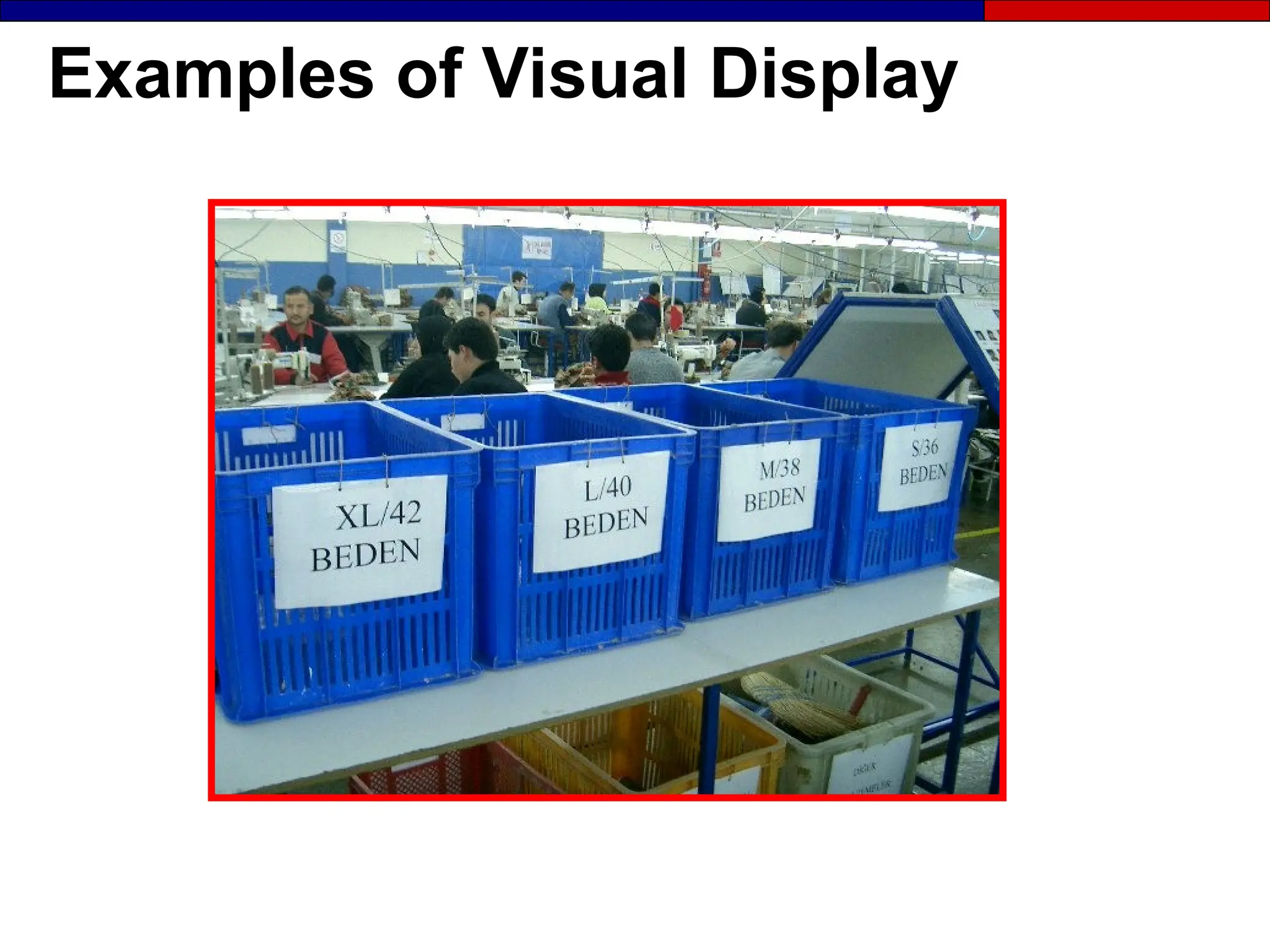

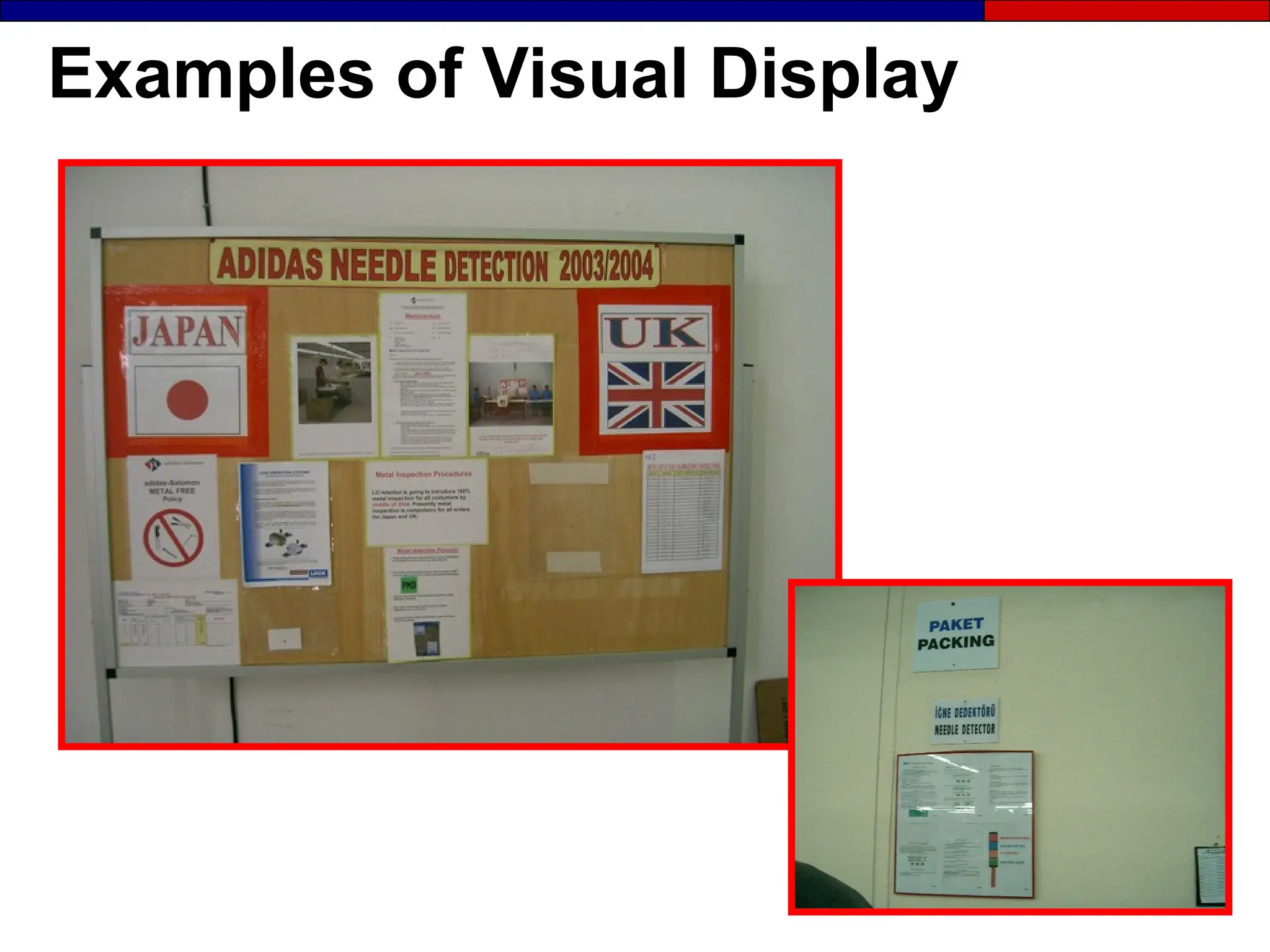

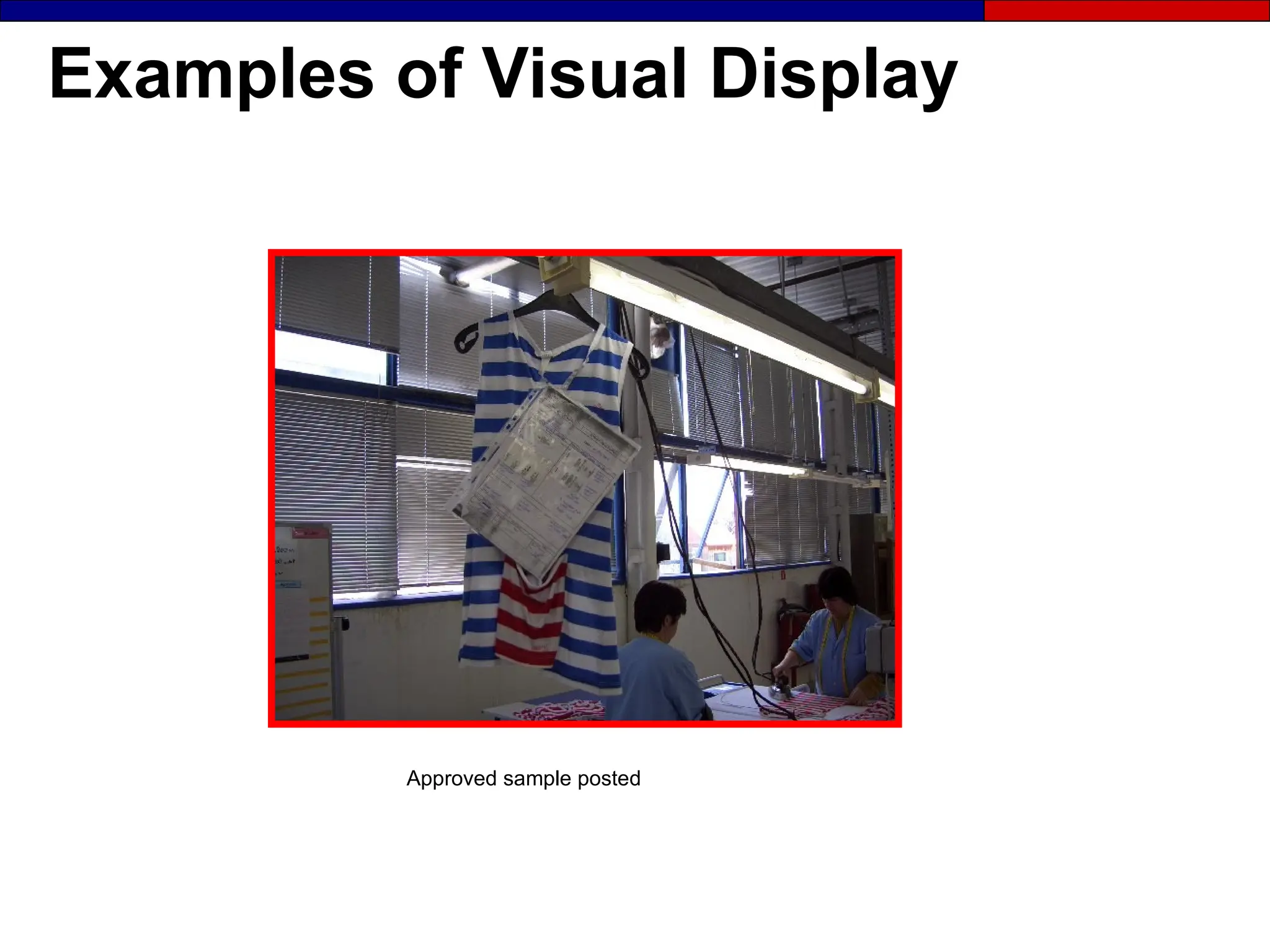

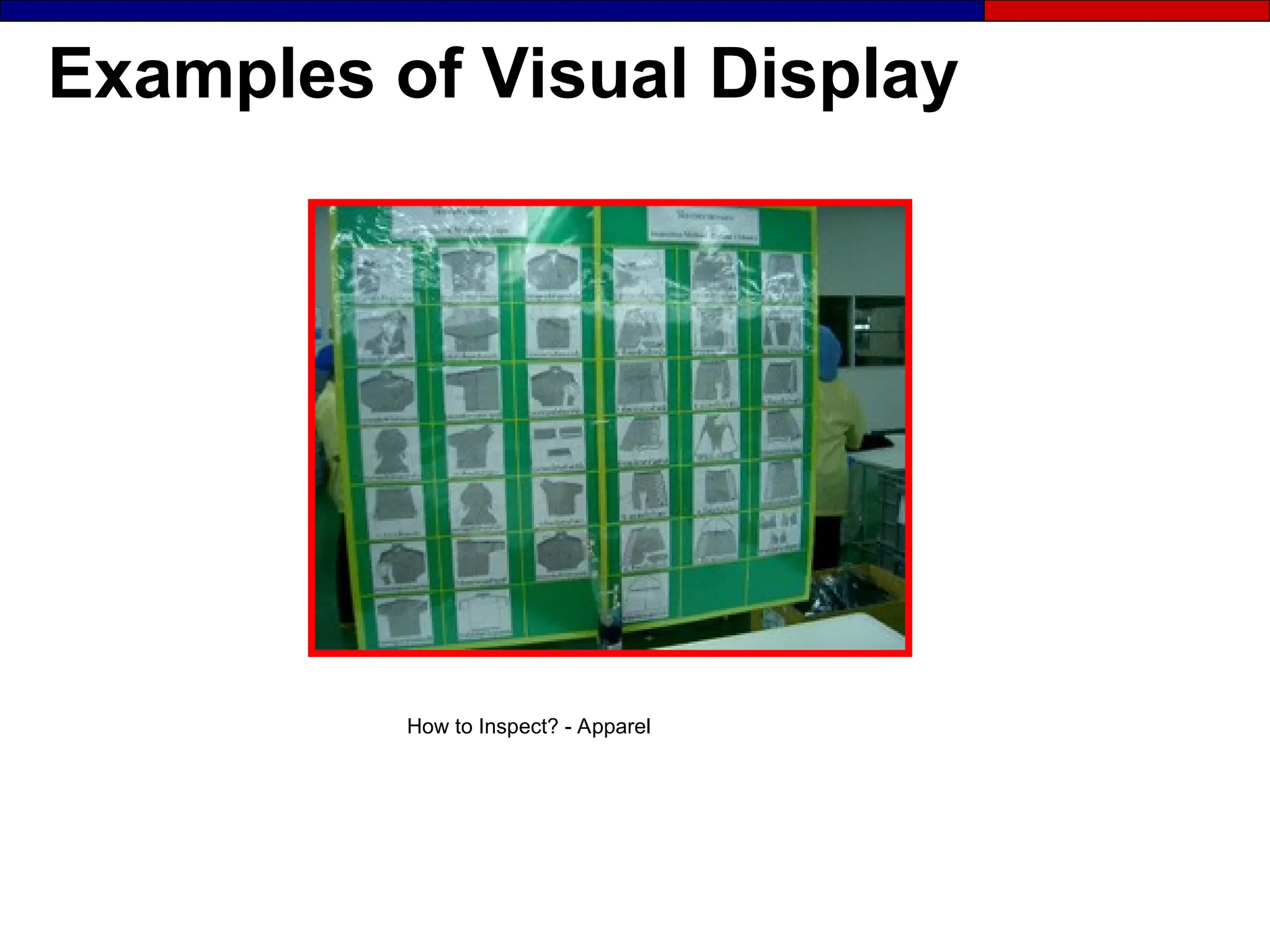

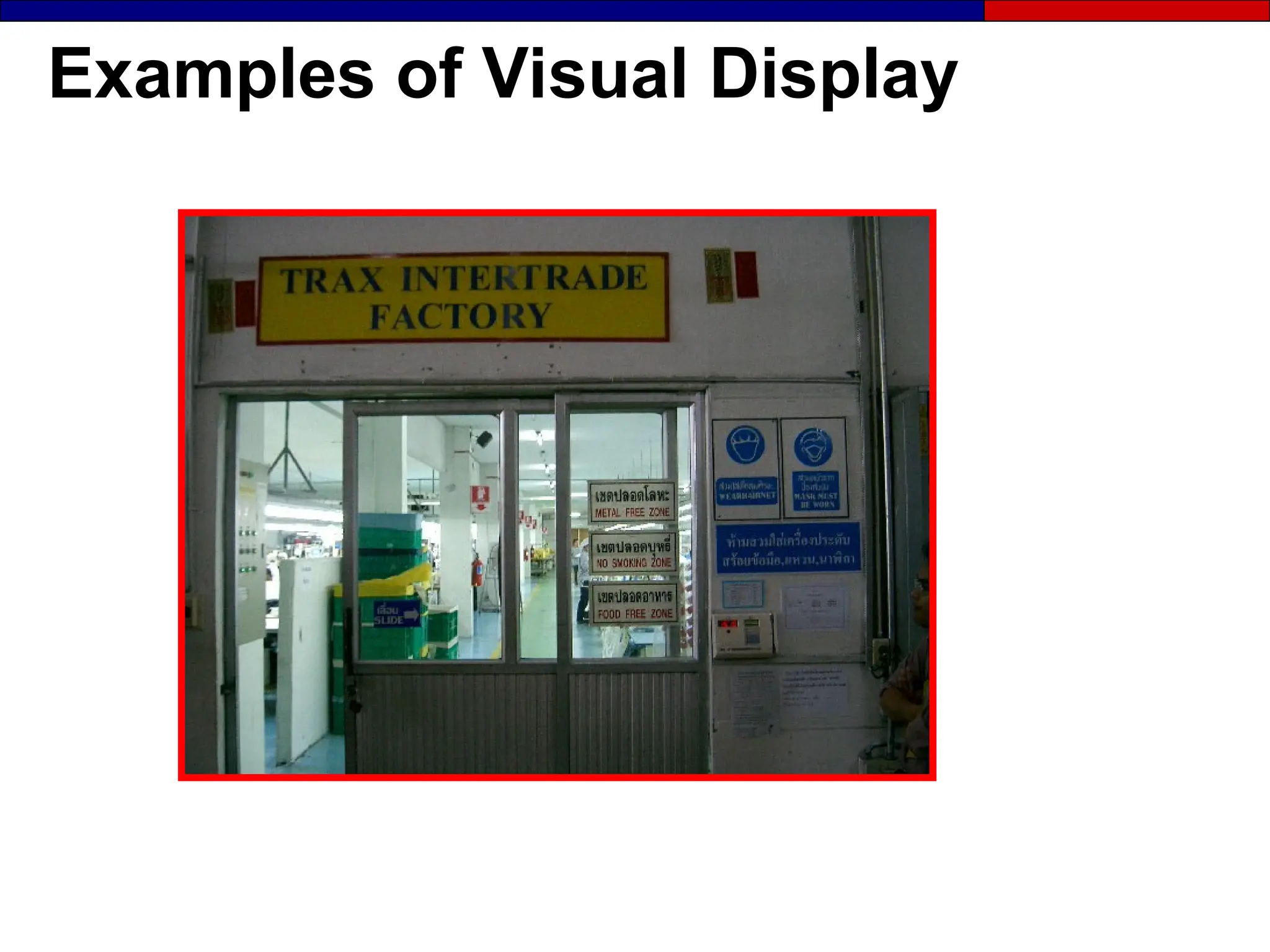

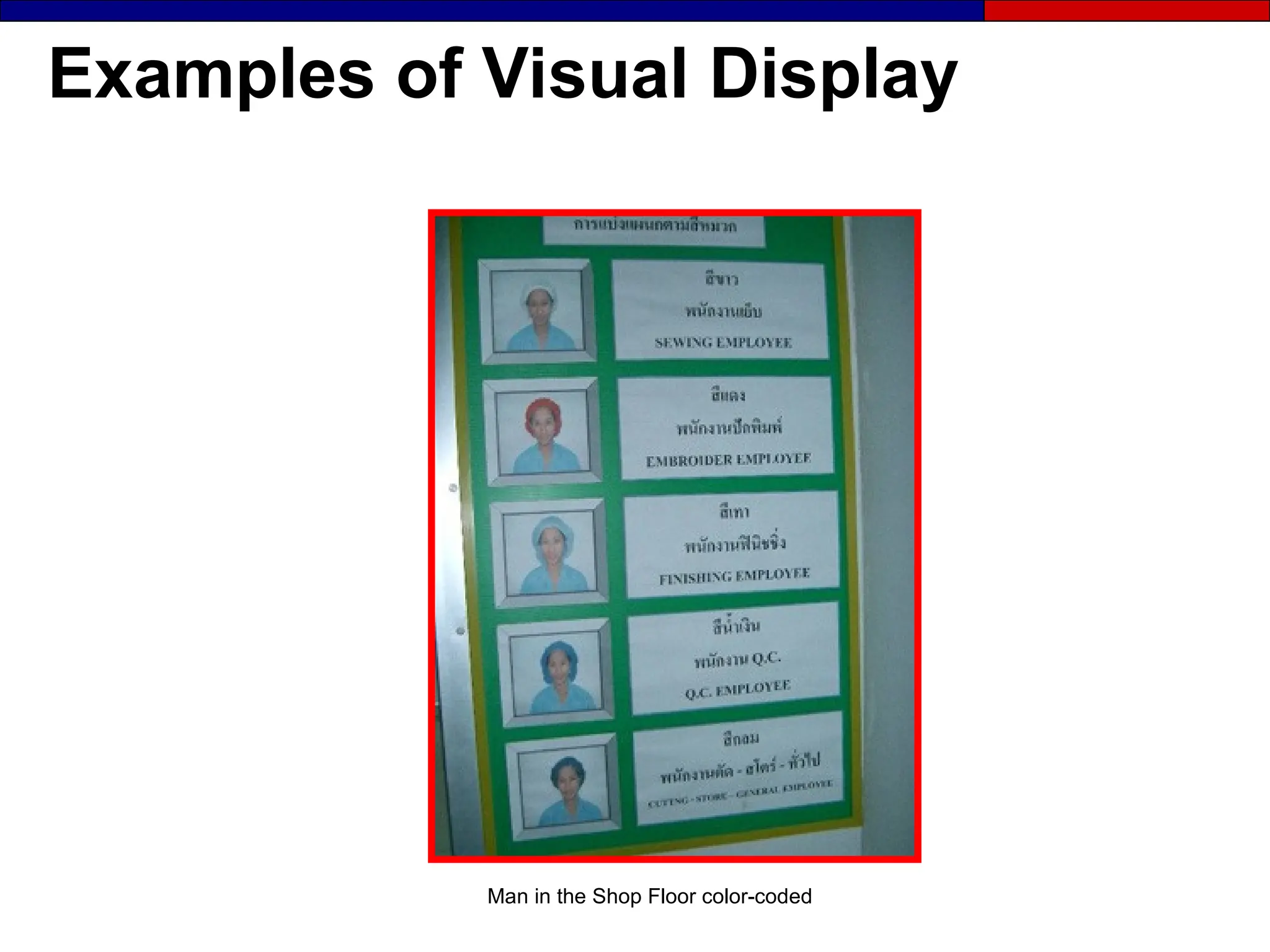

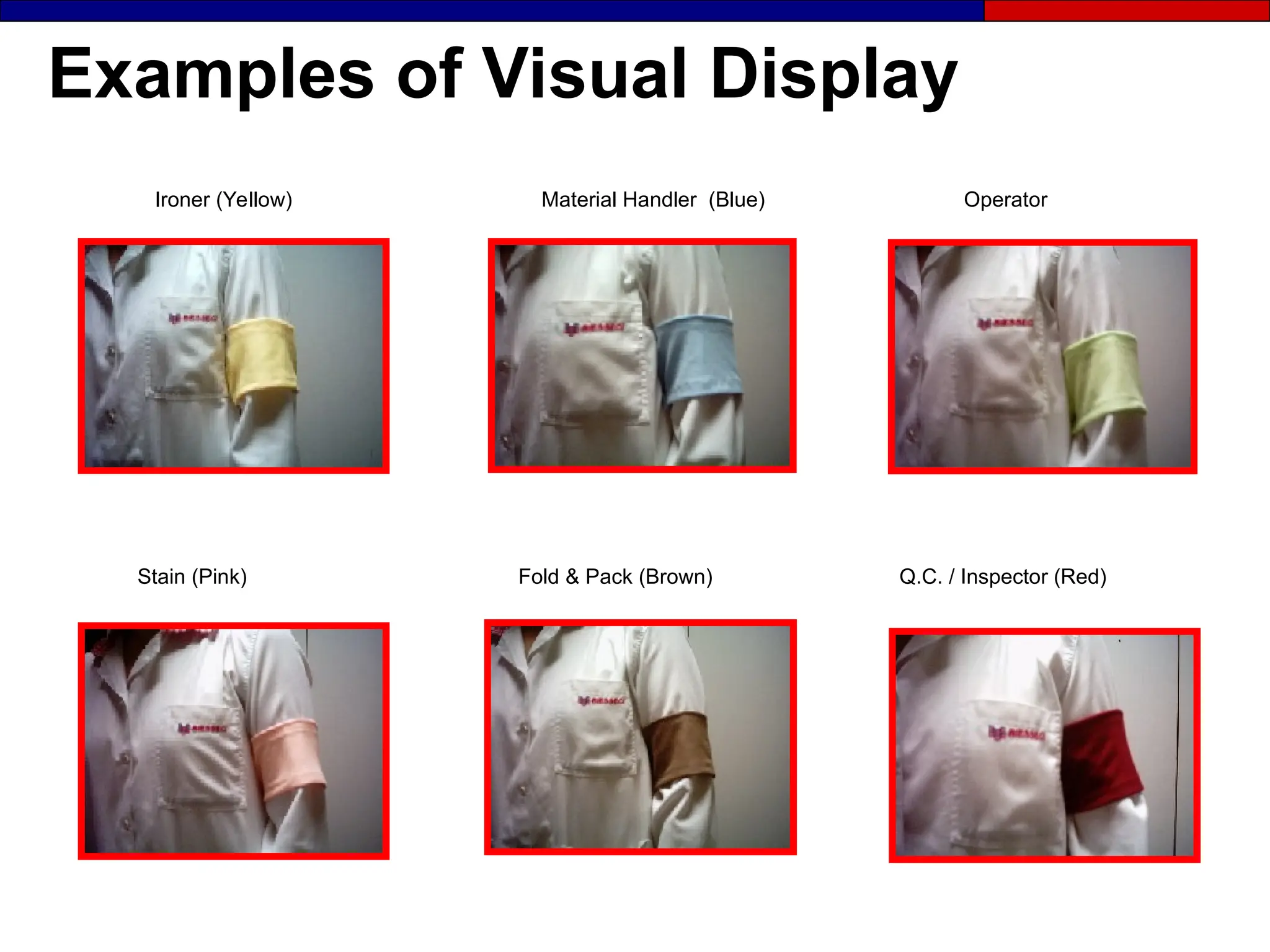

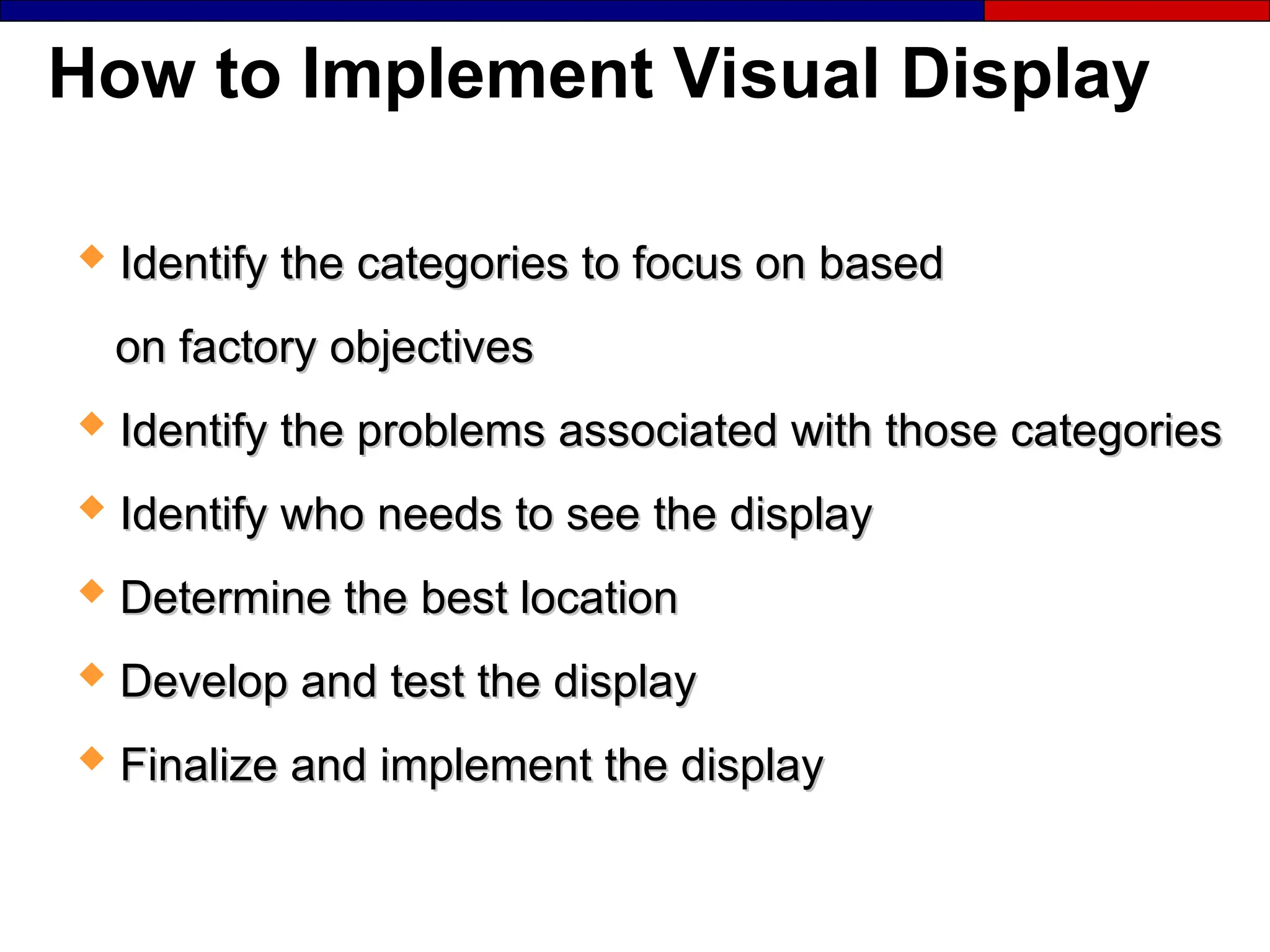

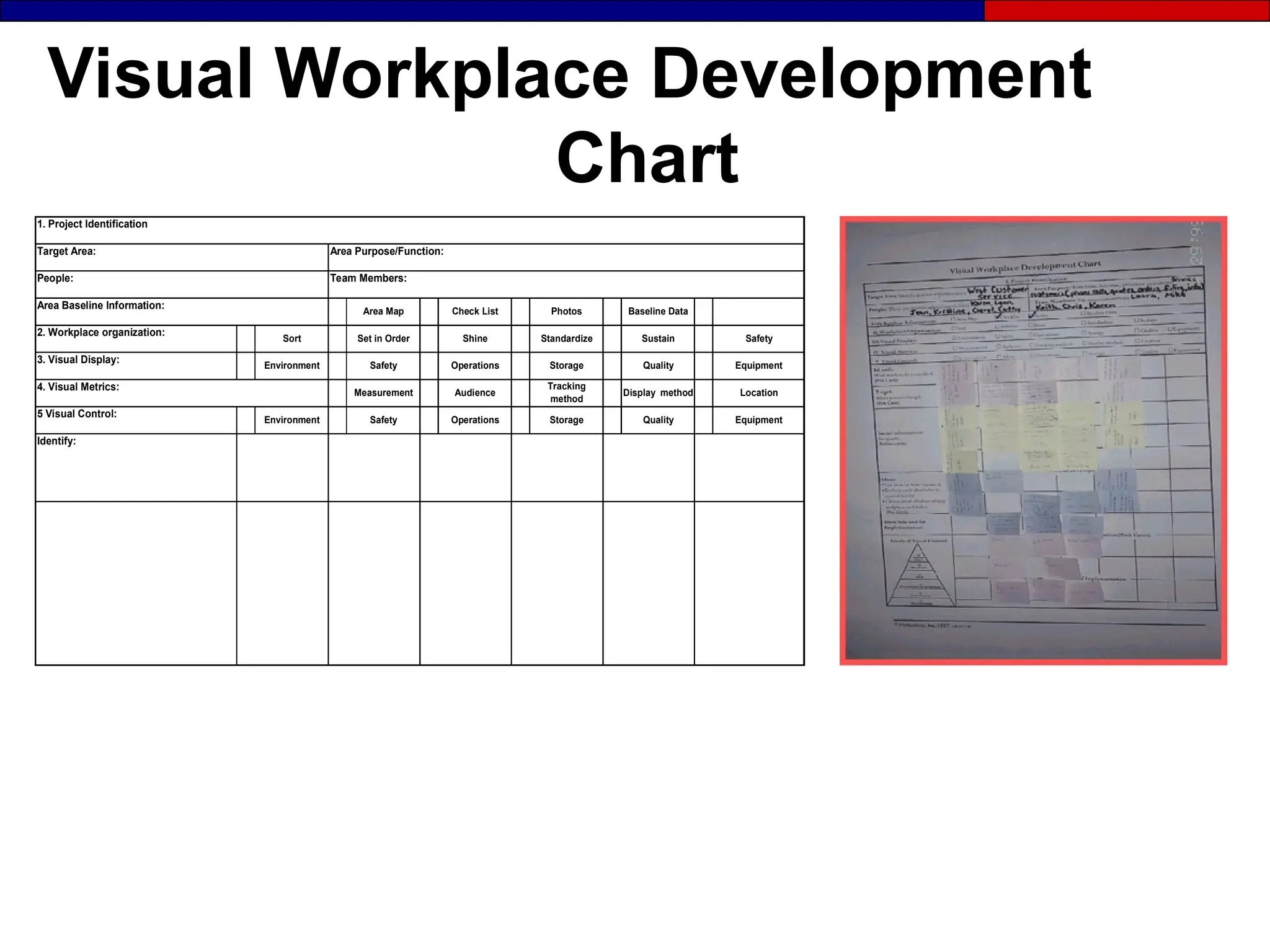

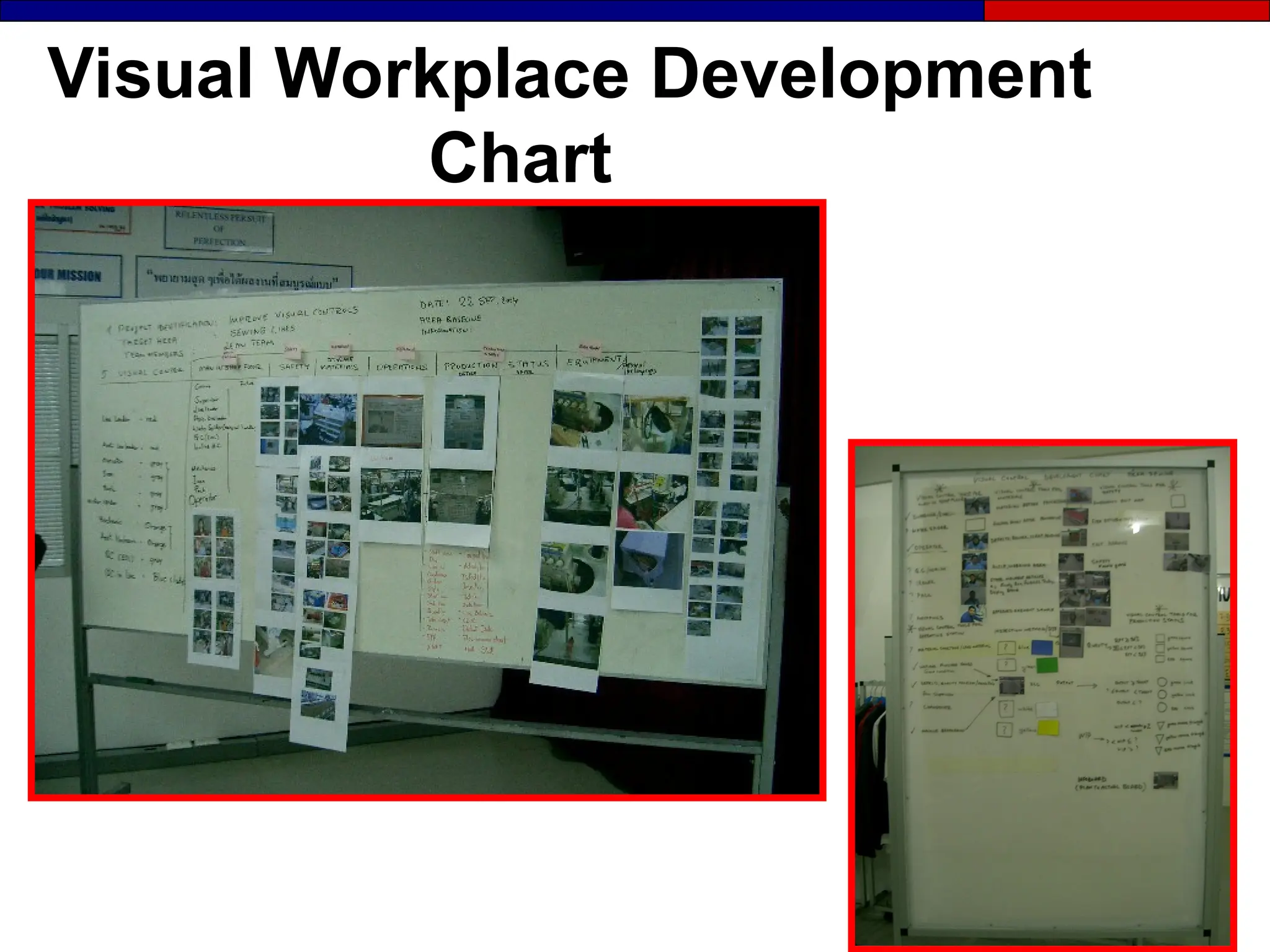

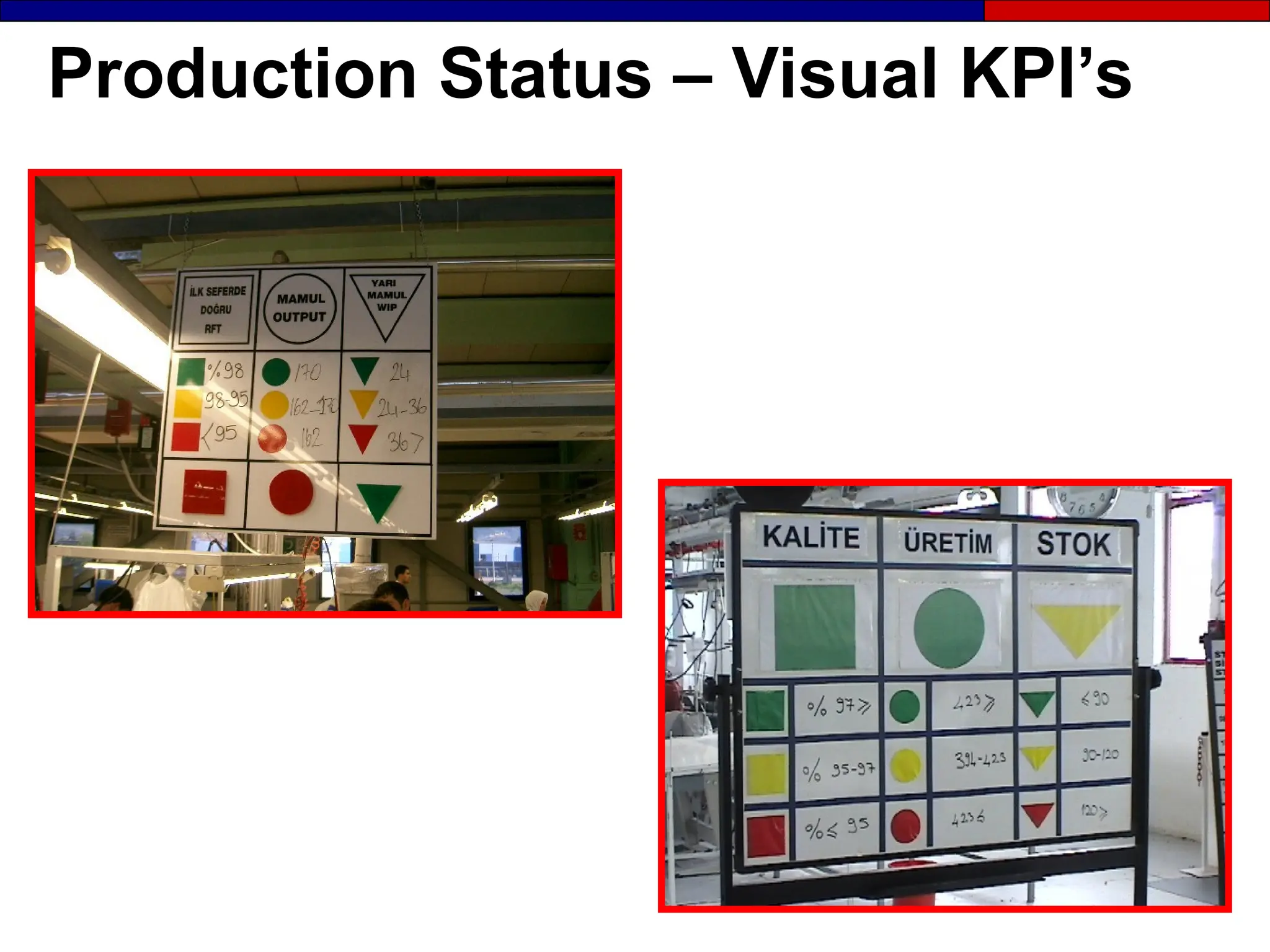

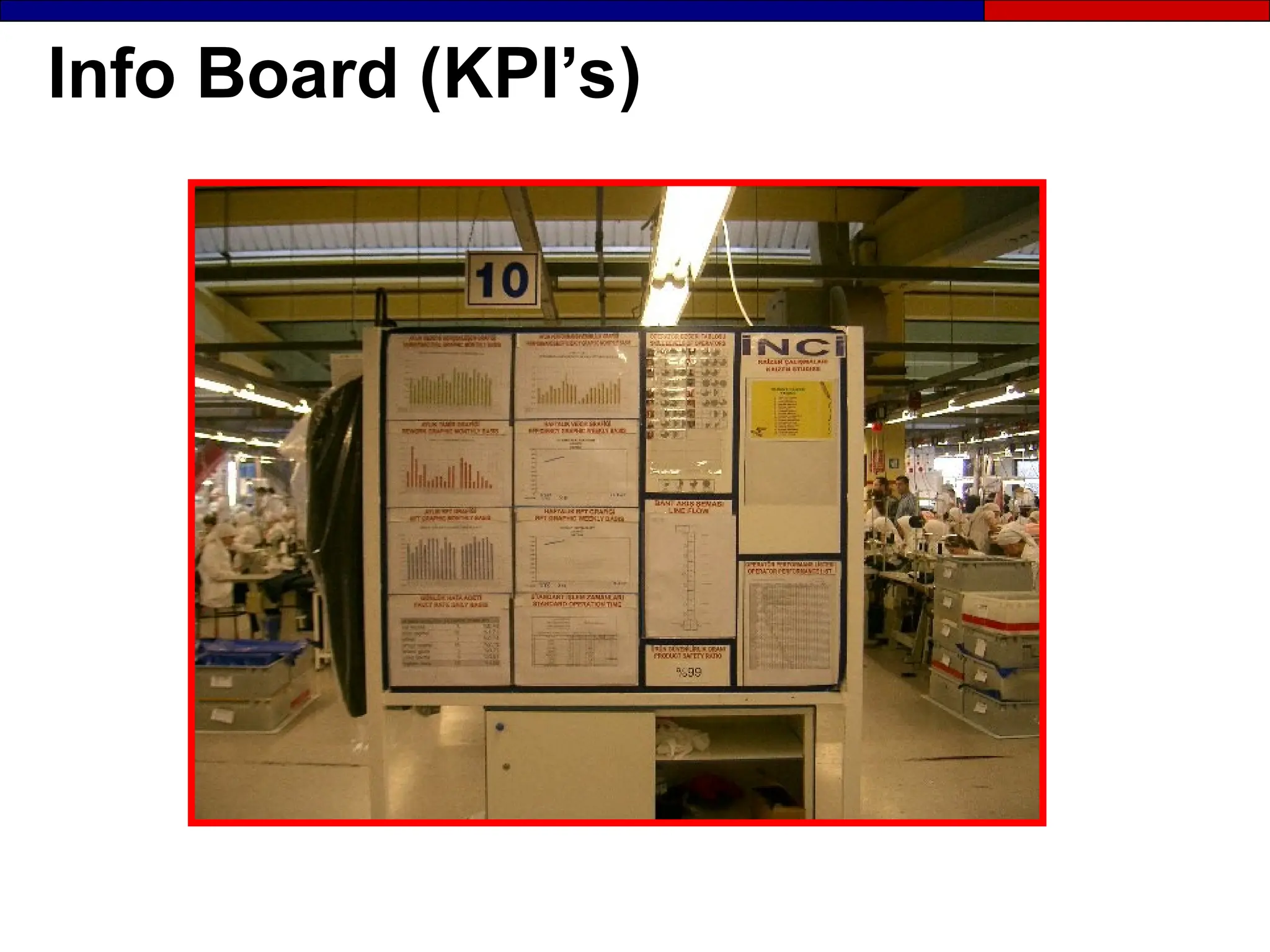

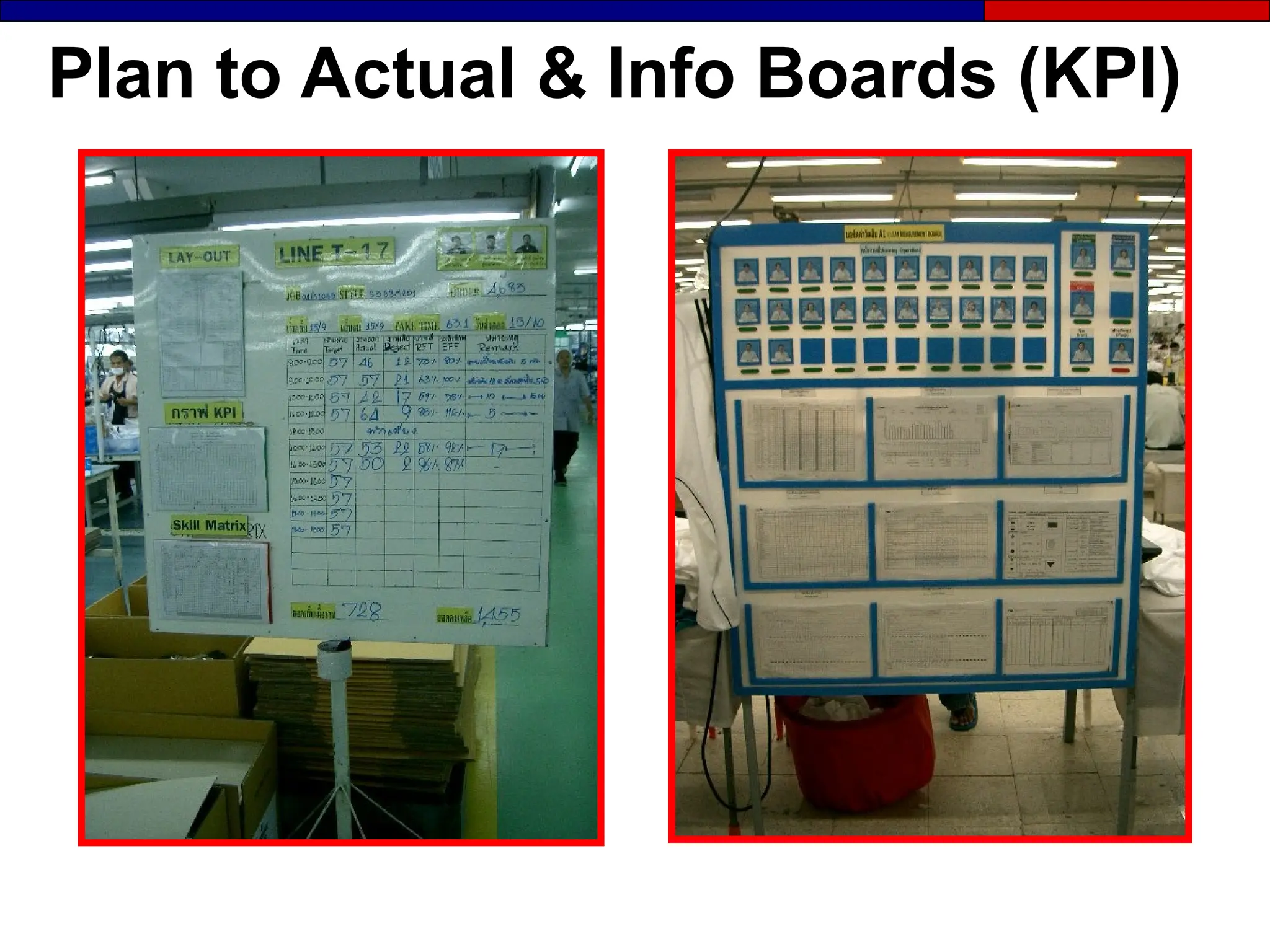

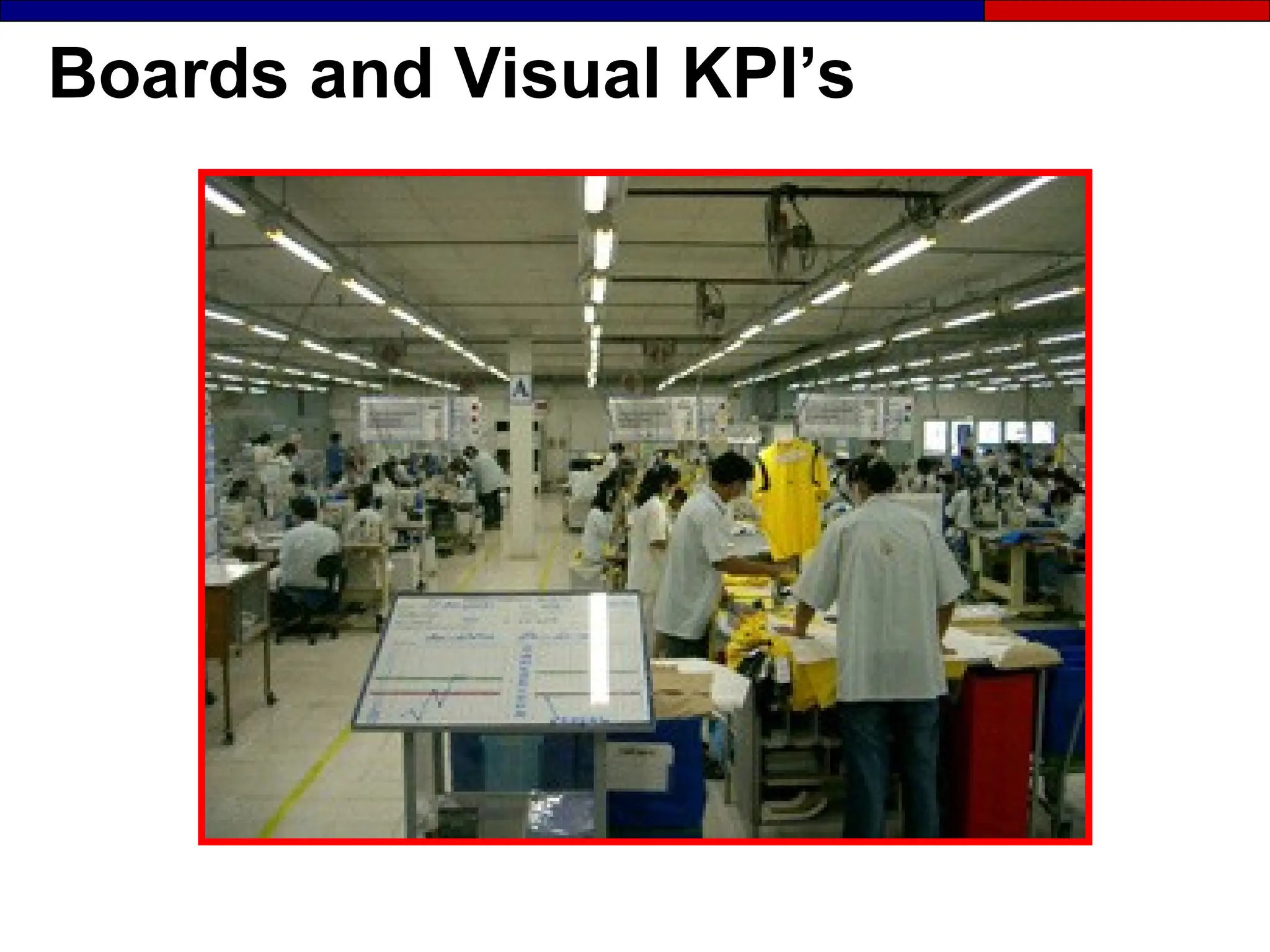

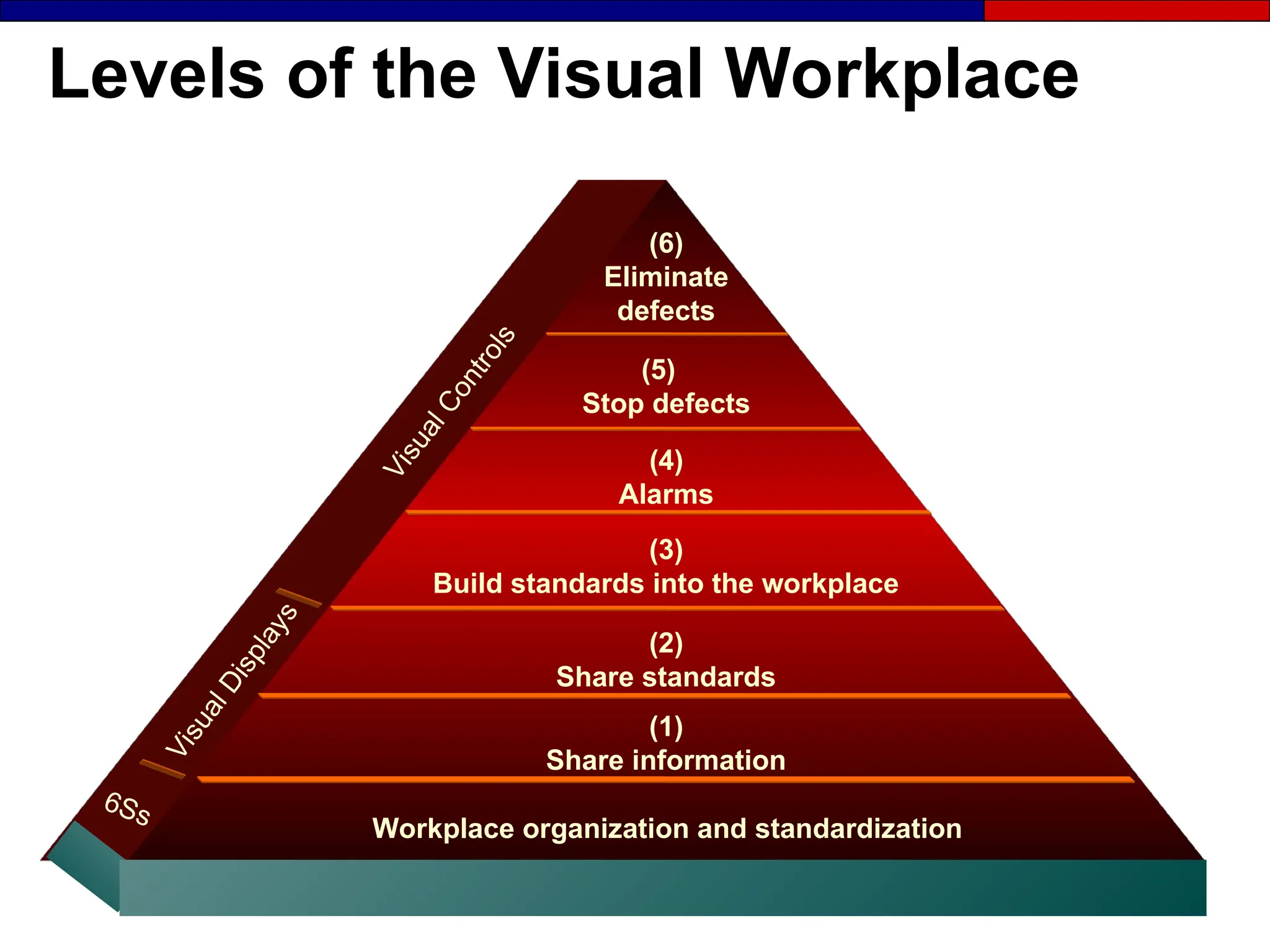

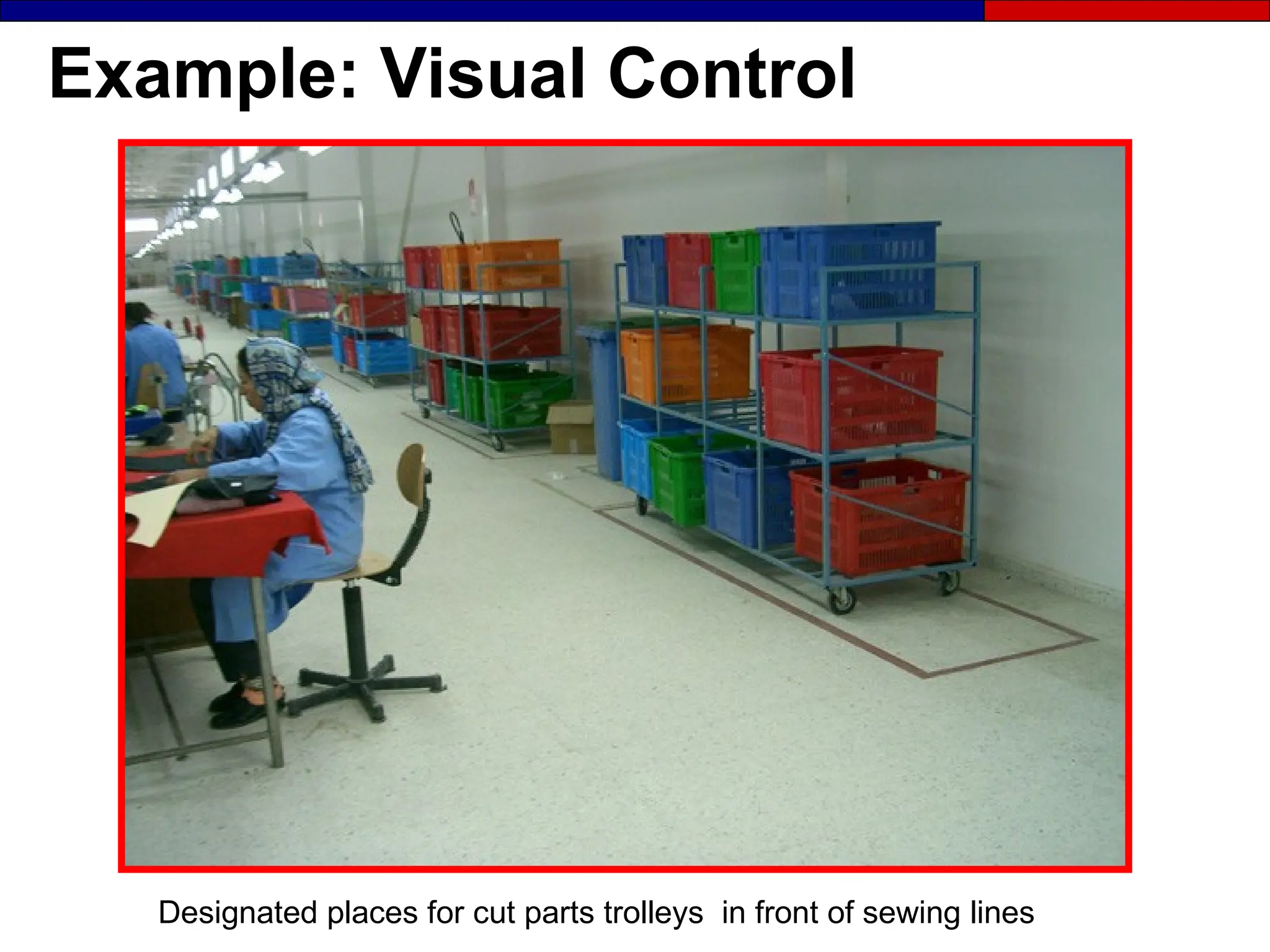

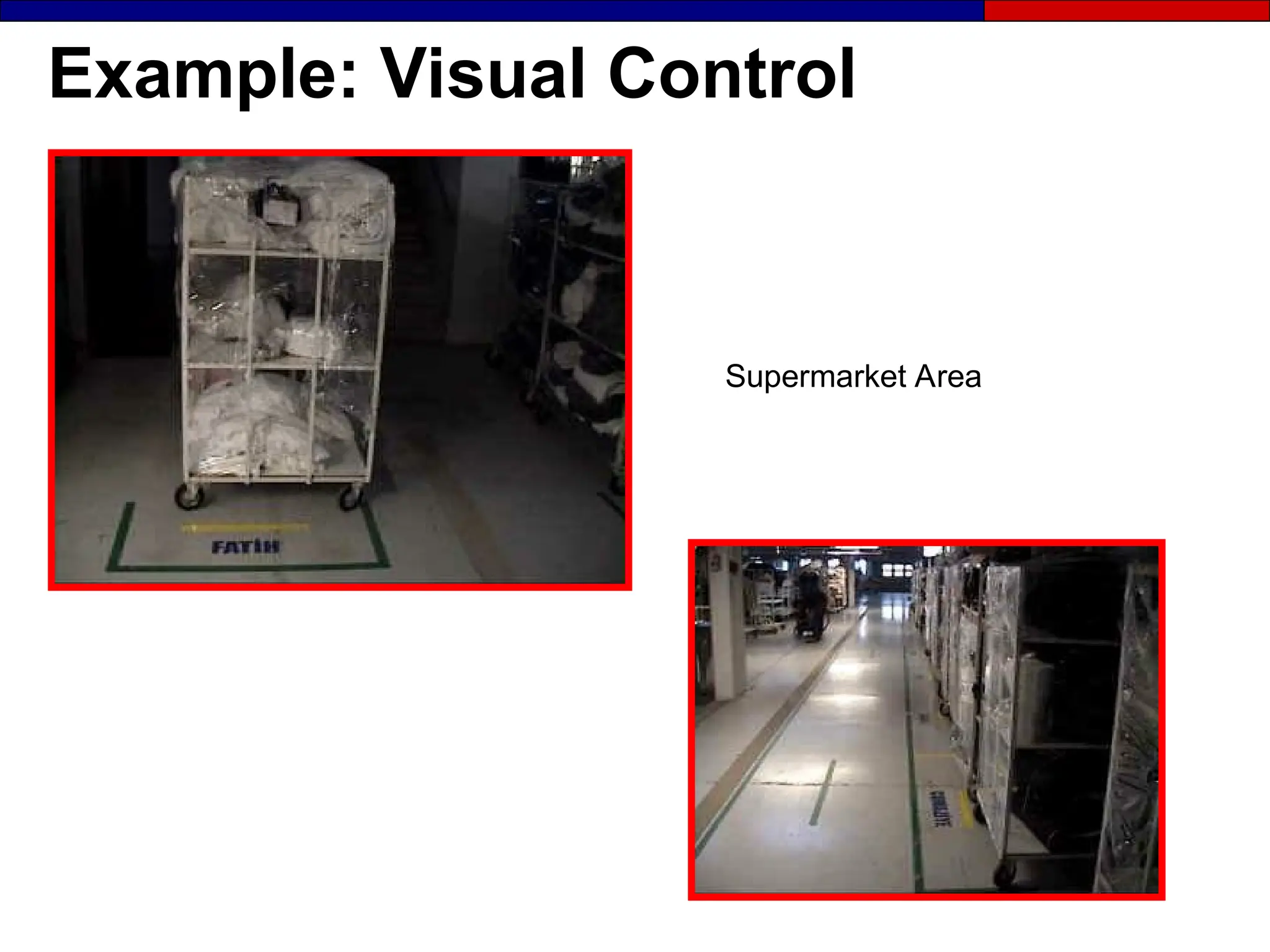

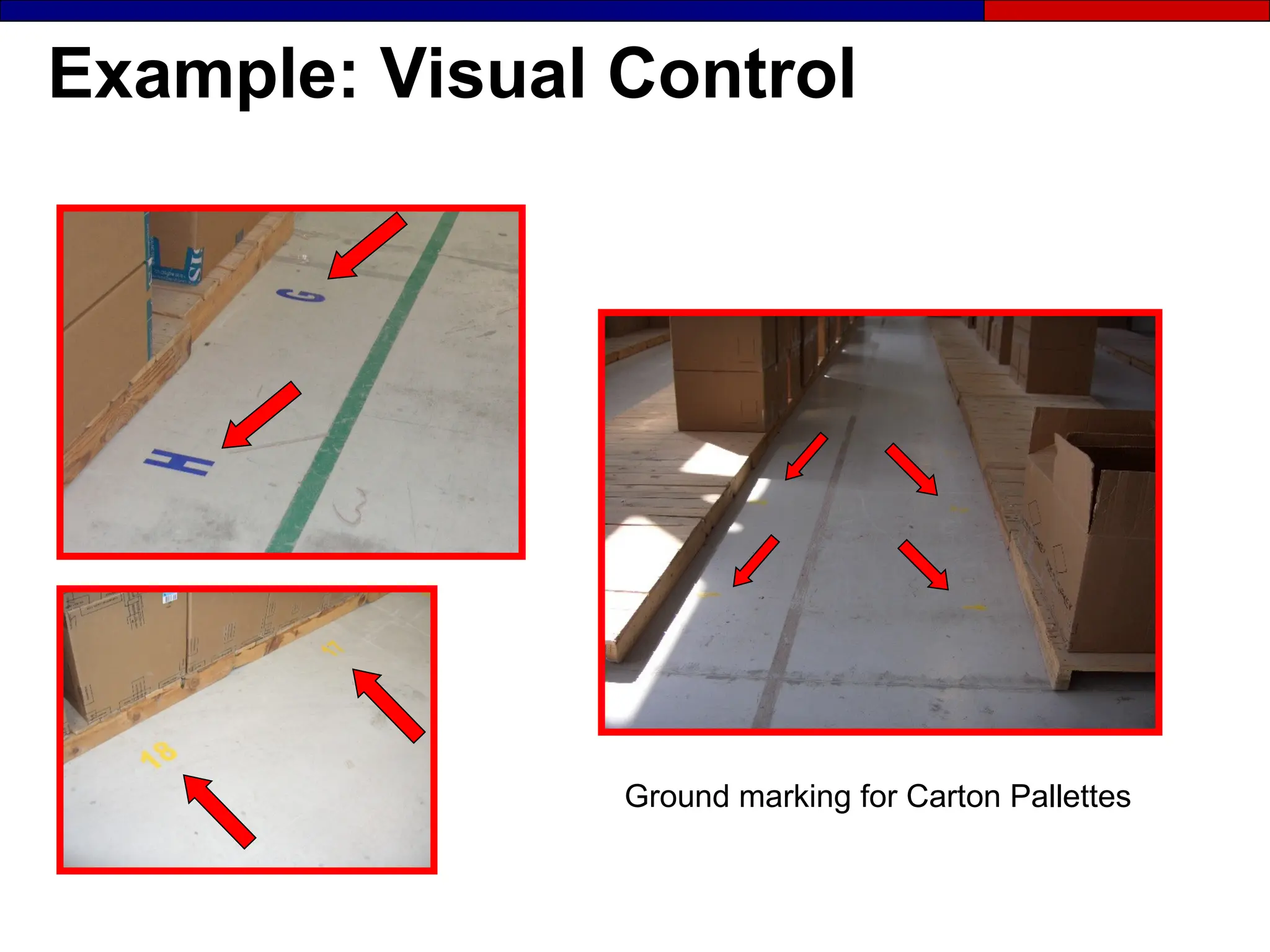

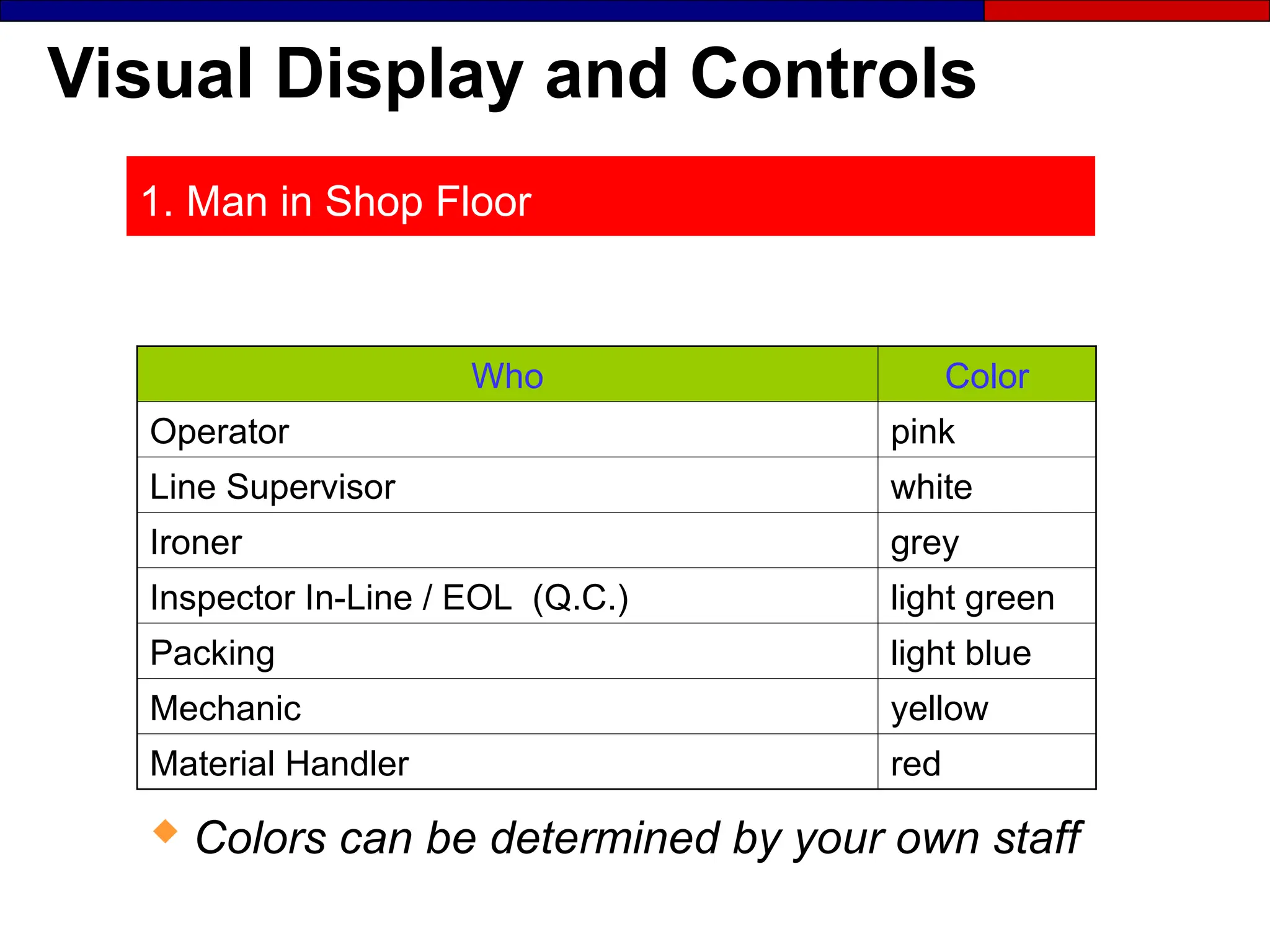

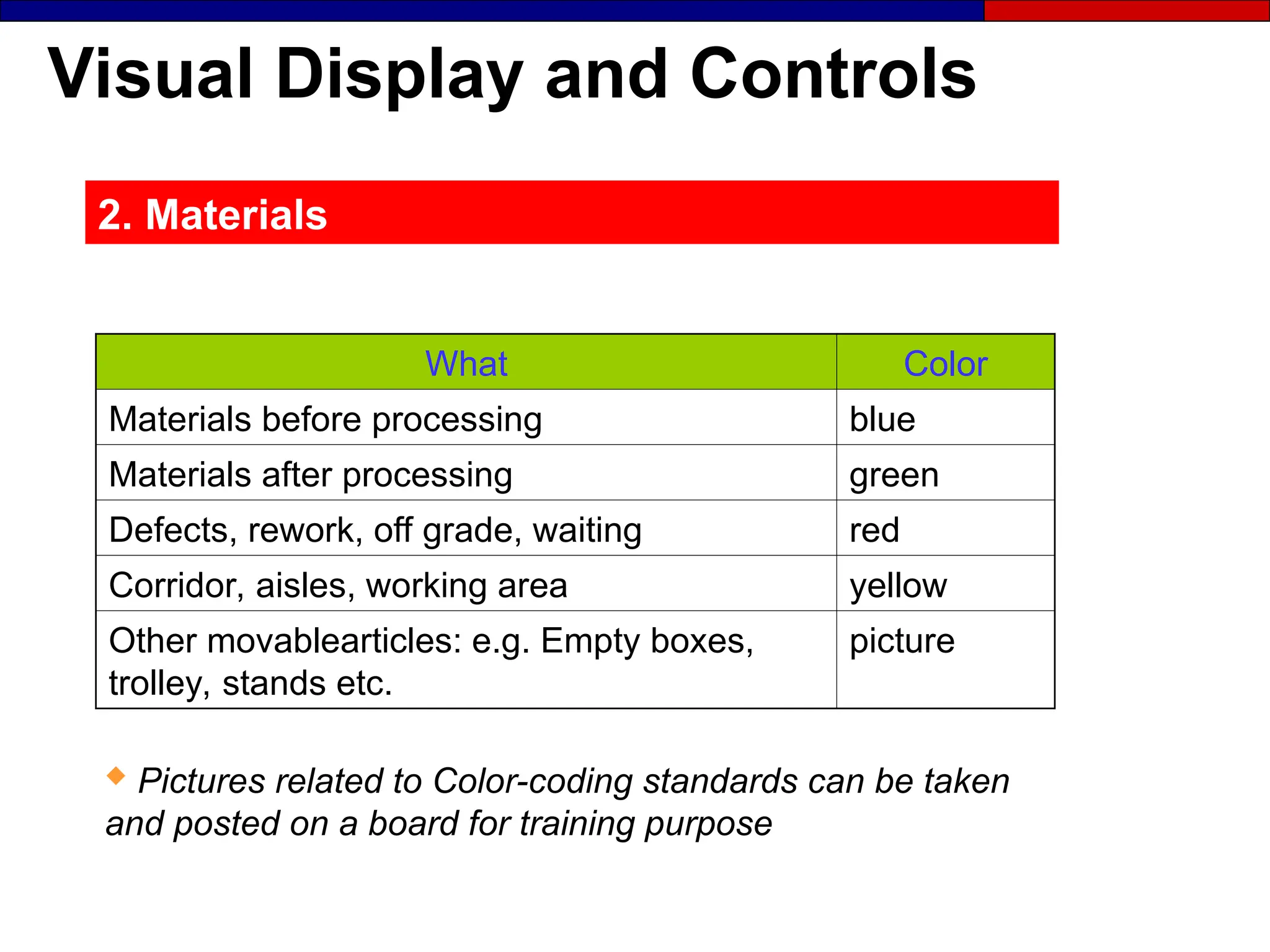

The document outlines the 6S methodology, which includes Sort, Set in Order, Shine, Standardize, Sustain, and Safety to improve workplace organization and productivity. It emphasizes the importance of visual management and clear standards to maintain a safe and efficient work environment while driving continuous improvement. The document also discusses the implementation of these principles through team engagement and training to ensure lasting changes.