1. The document discusses the Single Minute Exchange of Dies (SMED) concept for reducing changeover times in manufacturing. SMED aims to classify changeover tasks as either internal or external to standardize and simplify the changeover process.

2. The document reviews literature on SMED and its applications in various industries. It describes implementing SMED on a CNC machine by redesigning fixtures to reduce internal setup activities.

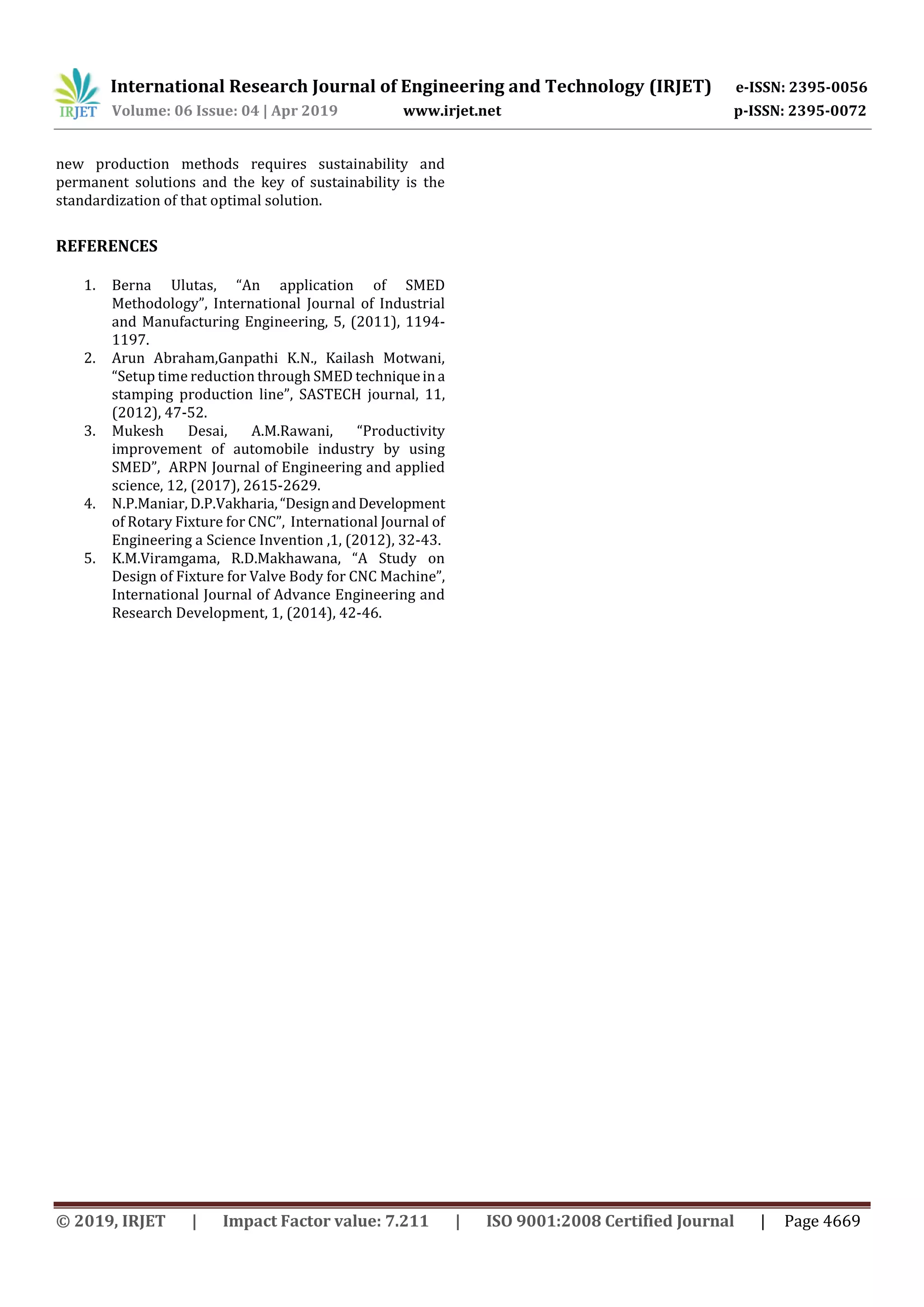

3. The key aspects of SMED covered include separating internal and external tasks, streamlining processes, training workers, and standardizing changeovers. Implementing SMED can optimize equipment usage and enable smaller batch sizes to improve flexibility.