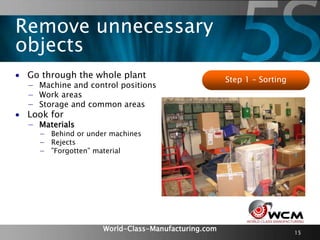

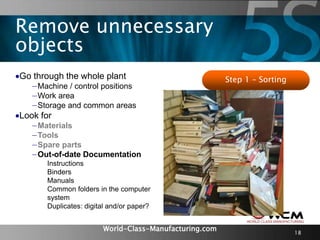

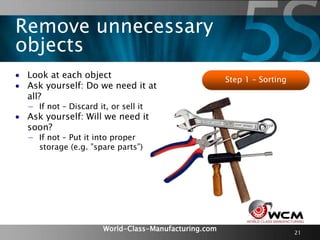

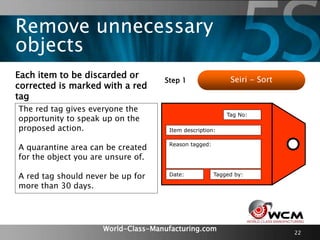

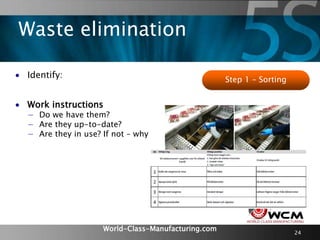

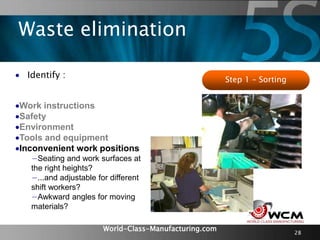

The document outlines the 5S methodology designed to improve workplace safety and efficiency through a systematic approach that includes sorting, organizing, cleaning, standardizing, and sustaining practices. It emphasizes the benefits of implementing 5S, such as reduced breakdowns, better work environments, and lower environmental impact. The document also details the steps to effectively implement 5S, encouraging team participation in identifying and eliminating waste.