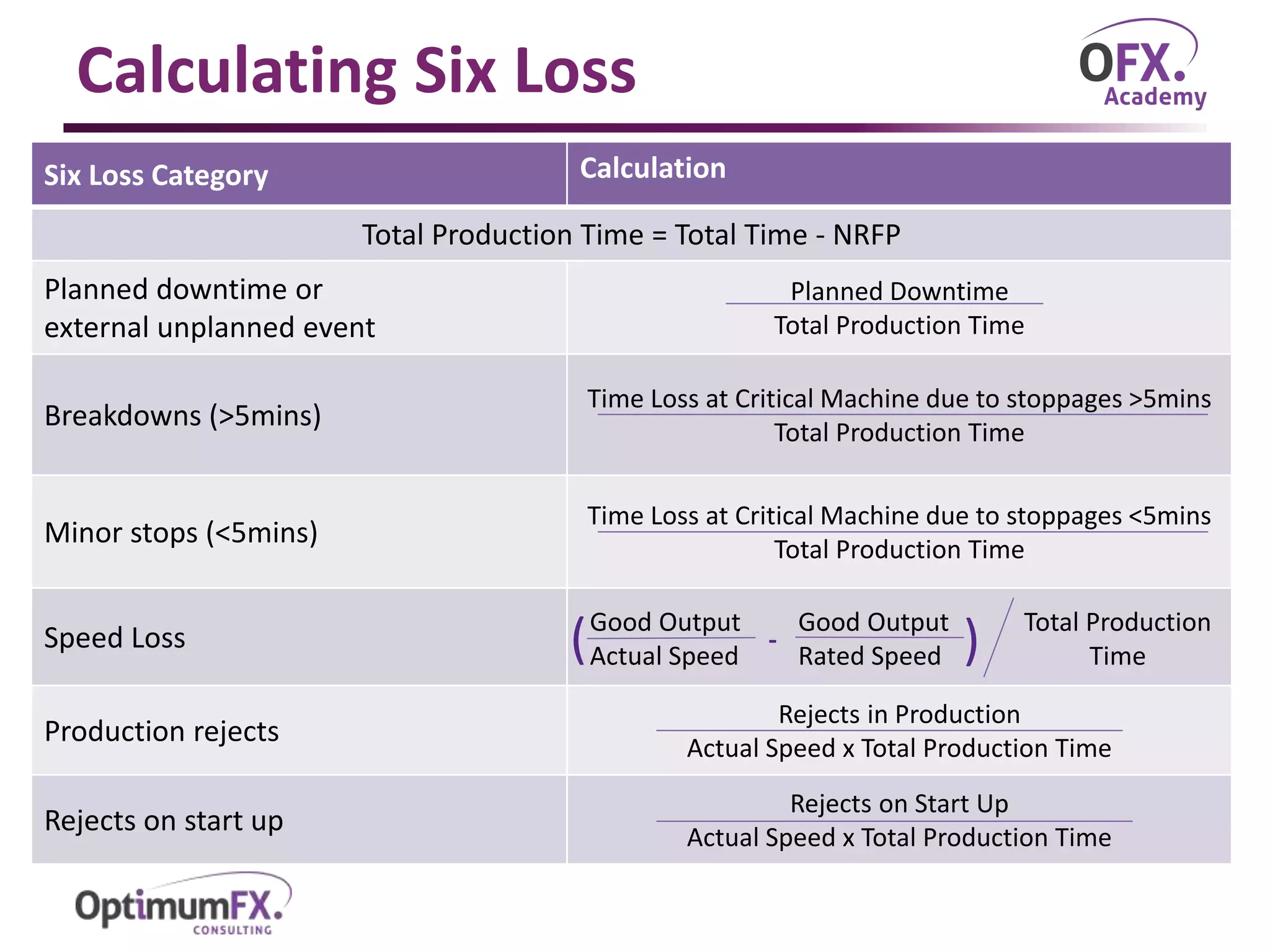

Six loss analysis provides a dashboard approach to identifying areas of loss that impact equipment performance. The six categories of loss are: planned downtime, breakdowns, minor stops, speed loss, quality loss during production, and quality loss at startup. Tracking each loss area allows companies to pinpoint where to focus improvement efforts for greatest impact on output. Regular six loss analysis combined with addressing the biggest loss areas can accelerate performance gains.