This document discusses ship rudders, including:

- Rudders are fitted at the aft end of ships to provide directional control and derive benefit from increased water velocity from the propeller.

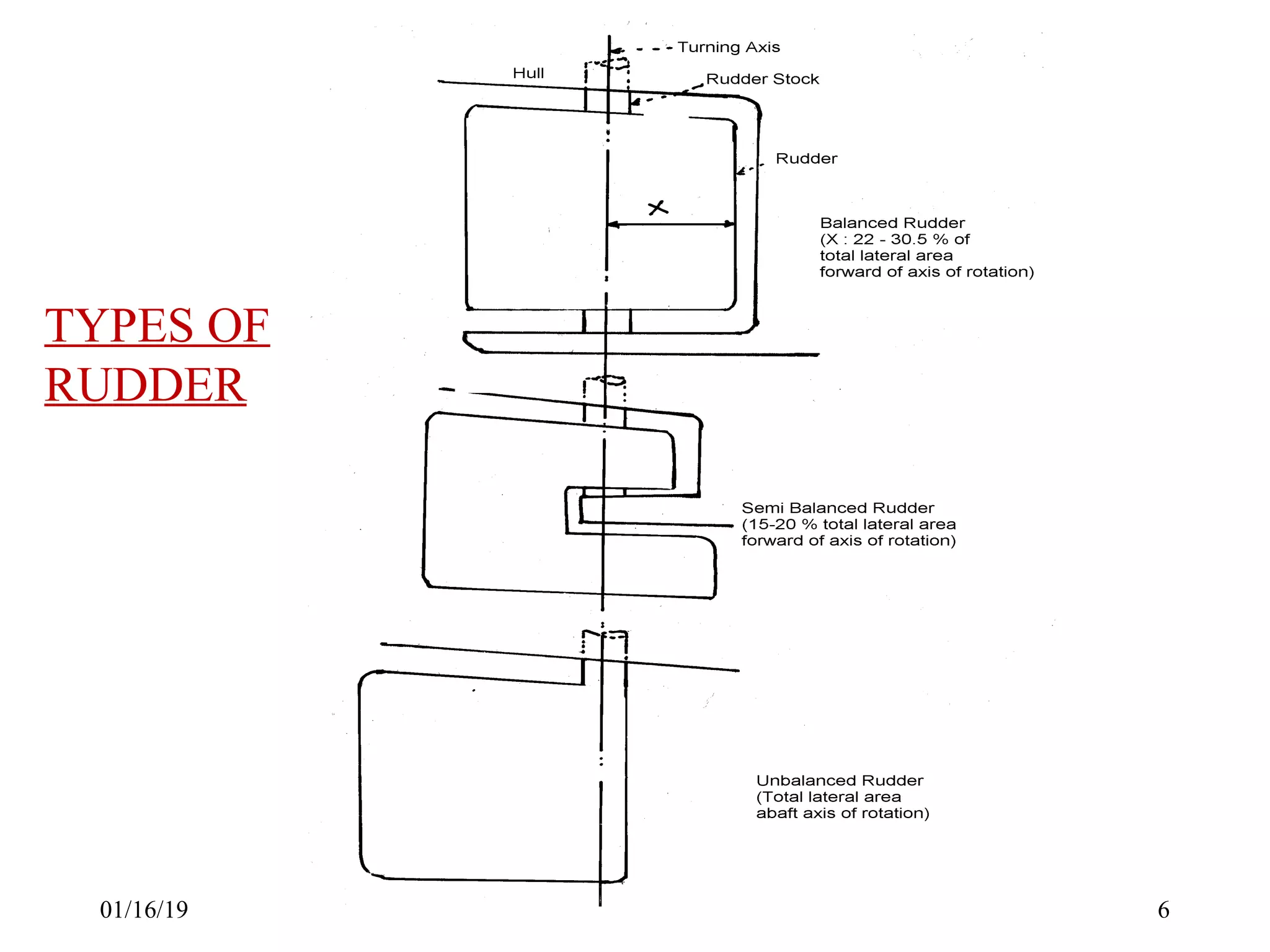

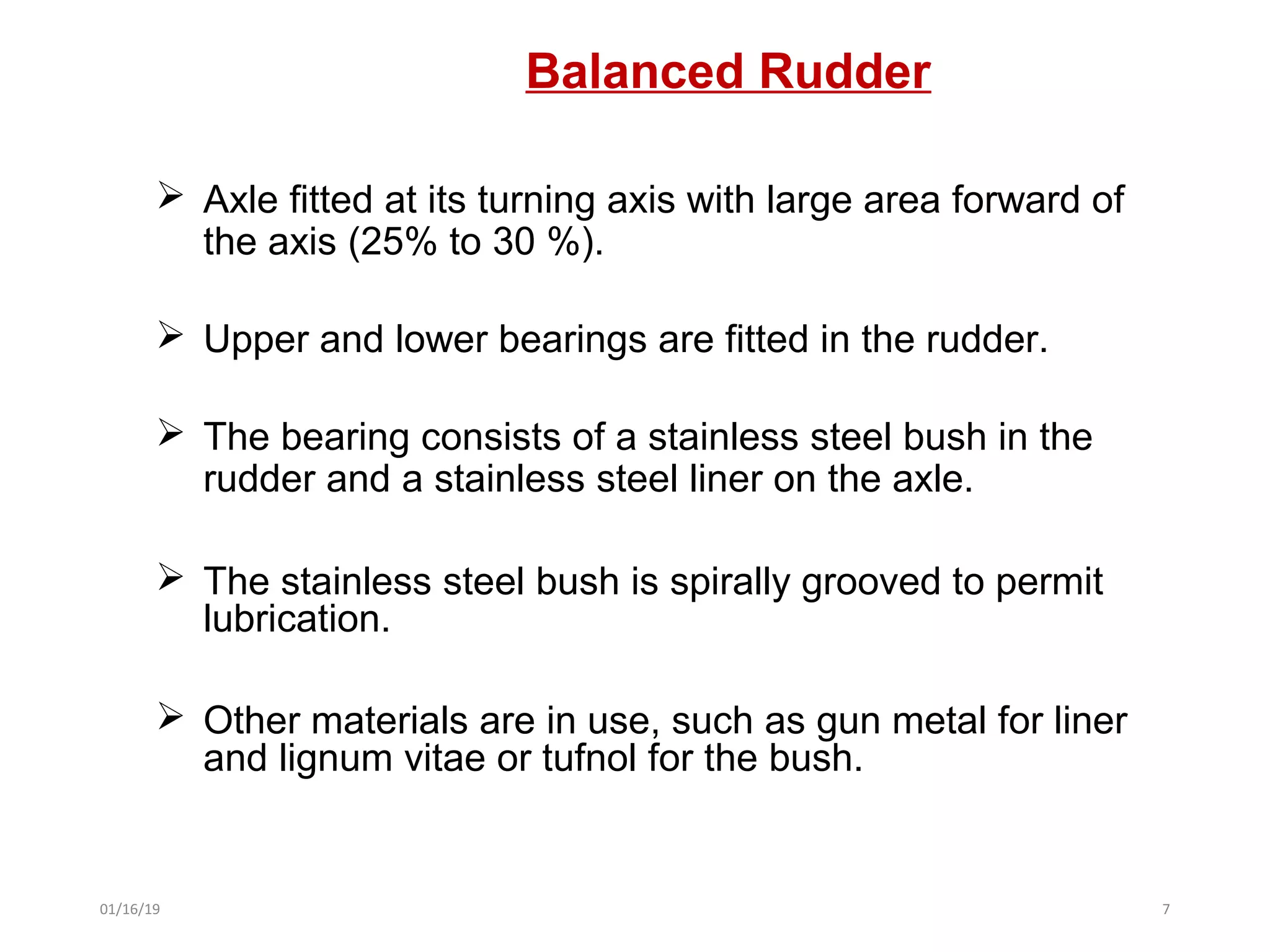

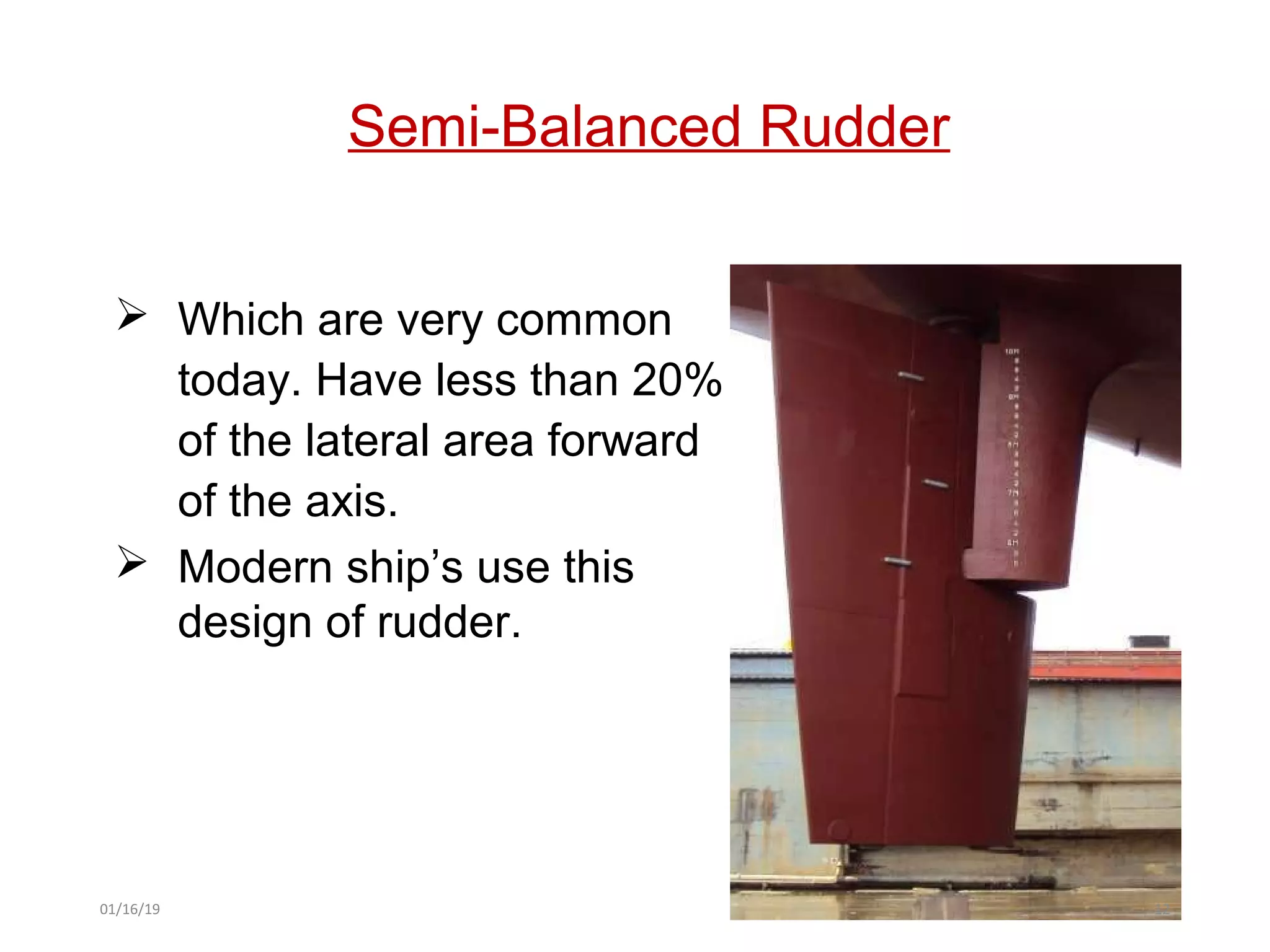

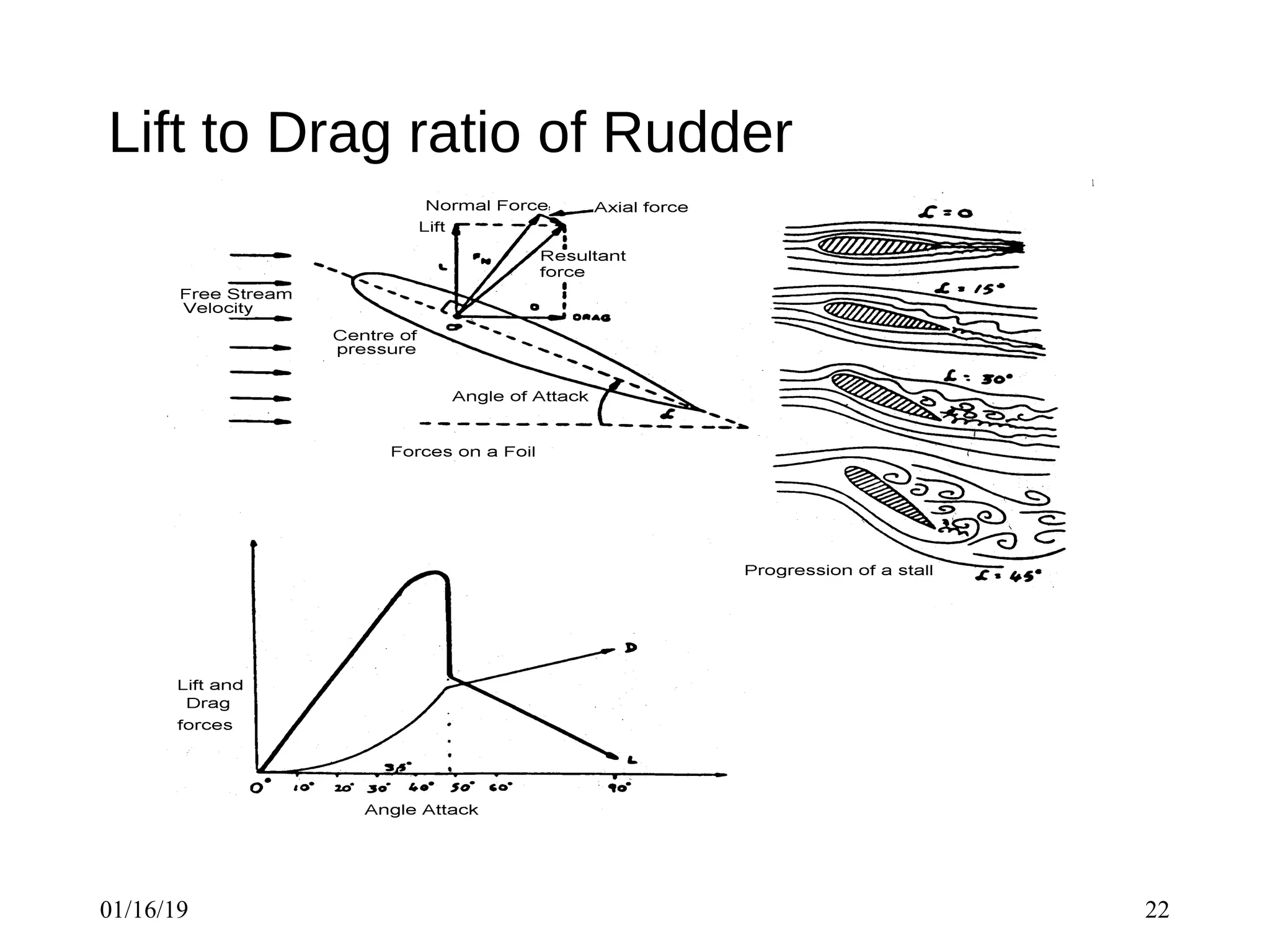

- There are three main types of rudders - balanced, unbalanced, and semi-balanced. Balanced rudders have a portion of blade area forward of the stock to reduce torque on the steering gear.

- Size, shape, and type of rudder is governed by the ship's stern shape, required rudder area, steering gear capacity, and service conditions.

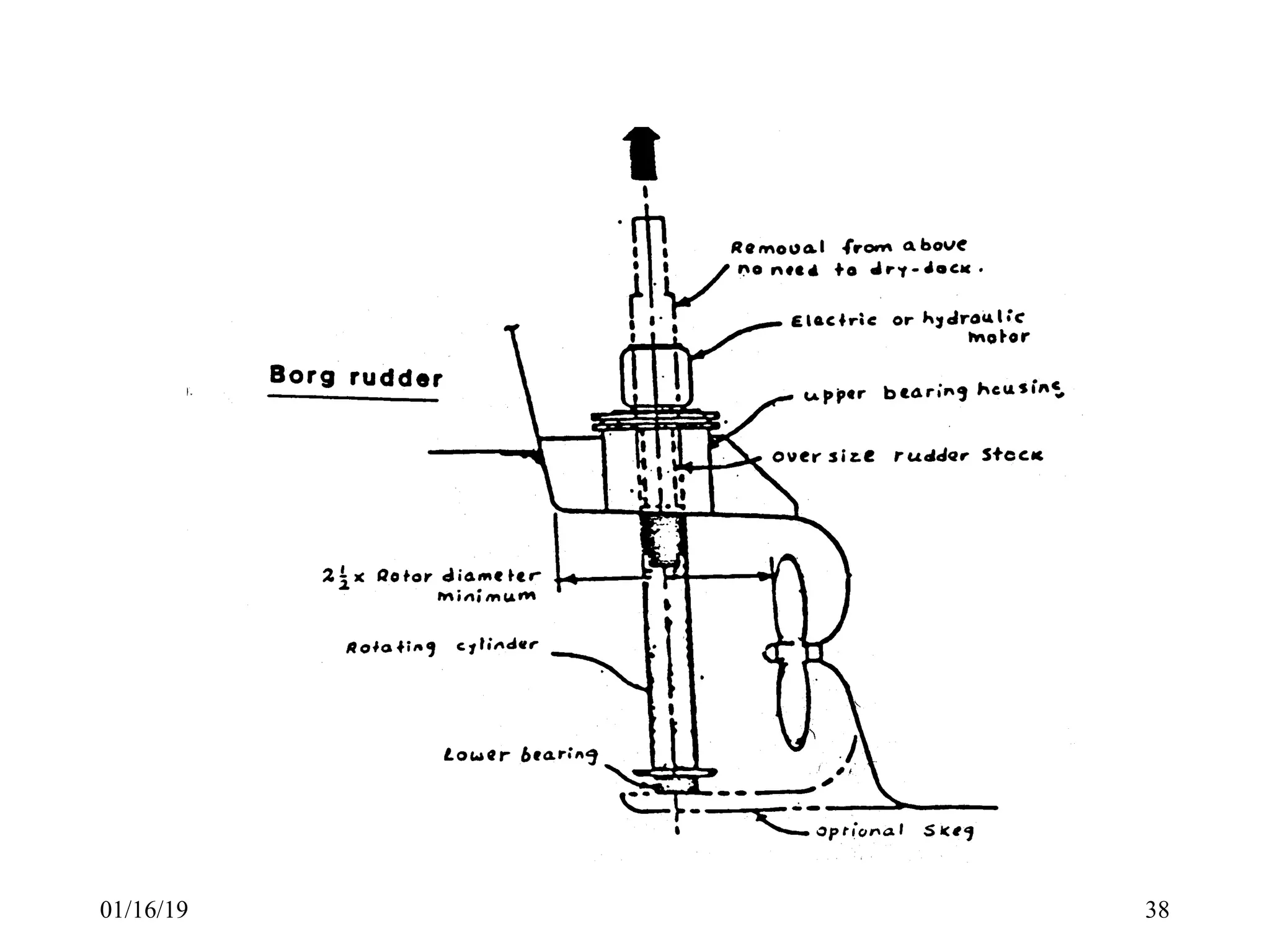

- Special rudders like spade rudders, Flettner/Becker rudders, Borg