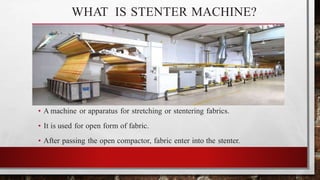

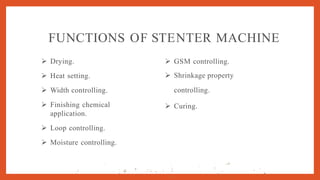

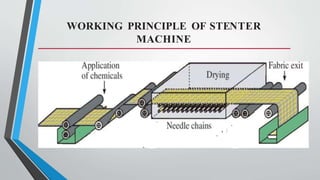

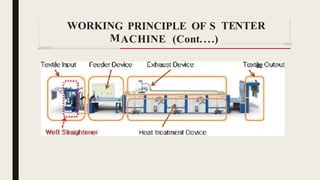

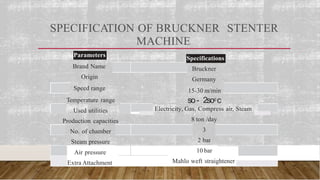

This document discusses a stenter machine used in textile manufacturing. It defines a stenter machine as a machine used for stretching fabrics after weaving. The key functions of a stenter machine are drying, heat setting, width and shrinkage controlling. It describes the working principle which involves passing fabric through padders and chambers with burners and filters to apply heat and stretch the fabric. Specifications of a Bruckner stenter machine are provided, including a speed range of 15-30 m/min and temperature range of 50-250°C.