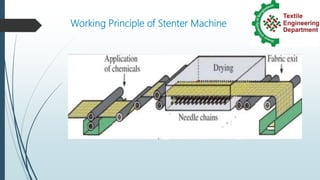

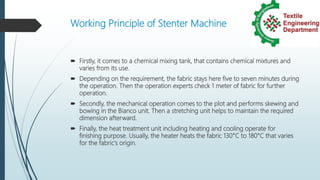

The presentation discusses the stenter machine, a crucial electrical device in the textile industry used for stretching and finishing fabrics to desired dimensions. It outlines the machine's functions, including drying, chemical application, and moisture control, along with its key components such as cooling drums and burners. The working principle involves chemical treatment, mechanical operations for dimension maintenance, and heat treatment for finishing the fabric.