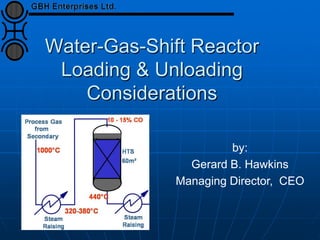

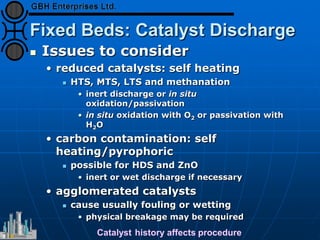

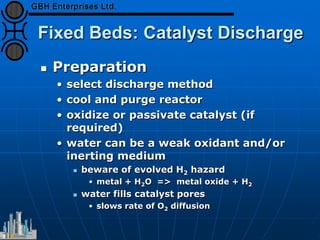

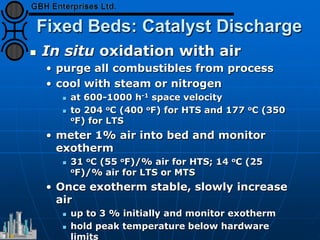

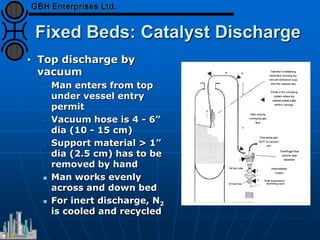

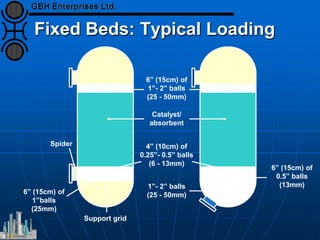

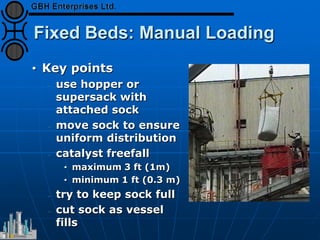

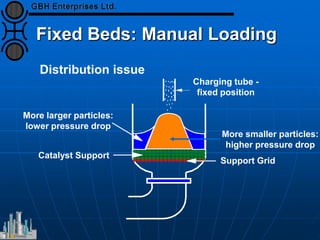

The document discusses considerations for loading and unloading catalysts in fixed bed reactors, including issues related to catalyst discharge, preparation methods, and handling techniques. Key procedures involve in situ oxidation, ensuring safety from hazards like evolved hydrogen, and managing catalyst types. Various loading methods, including manual and pneumatic techniques, are outlined to optimize catalyst distribution while minimizing damage.