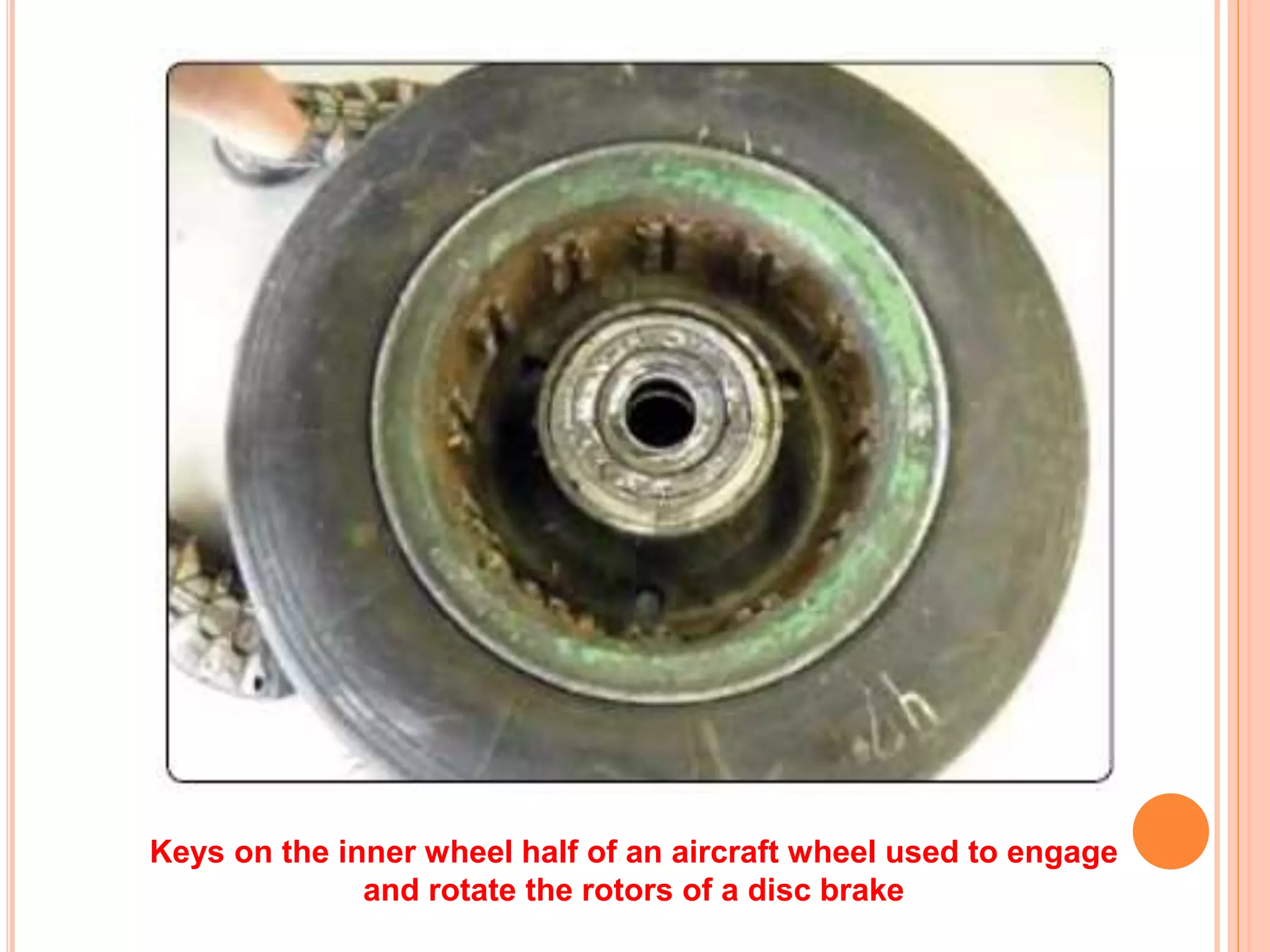

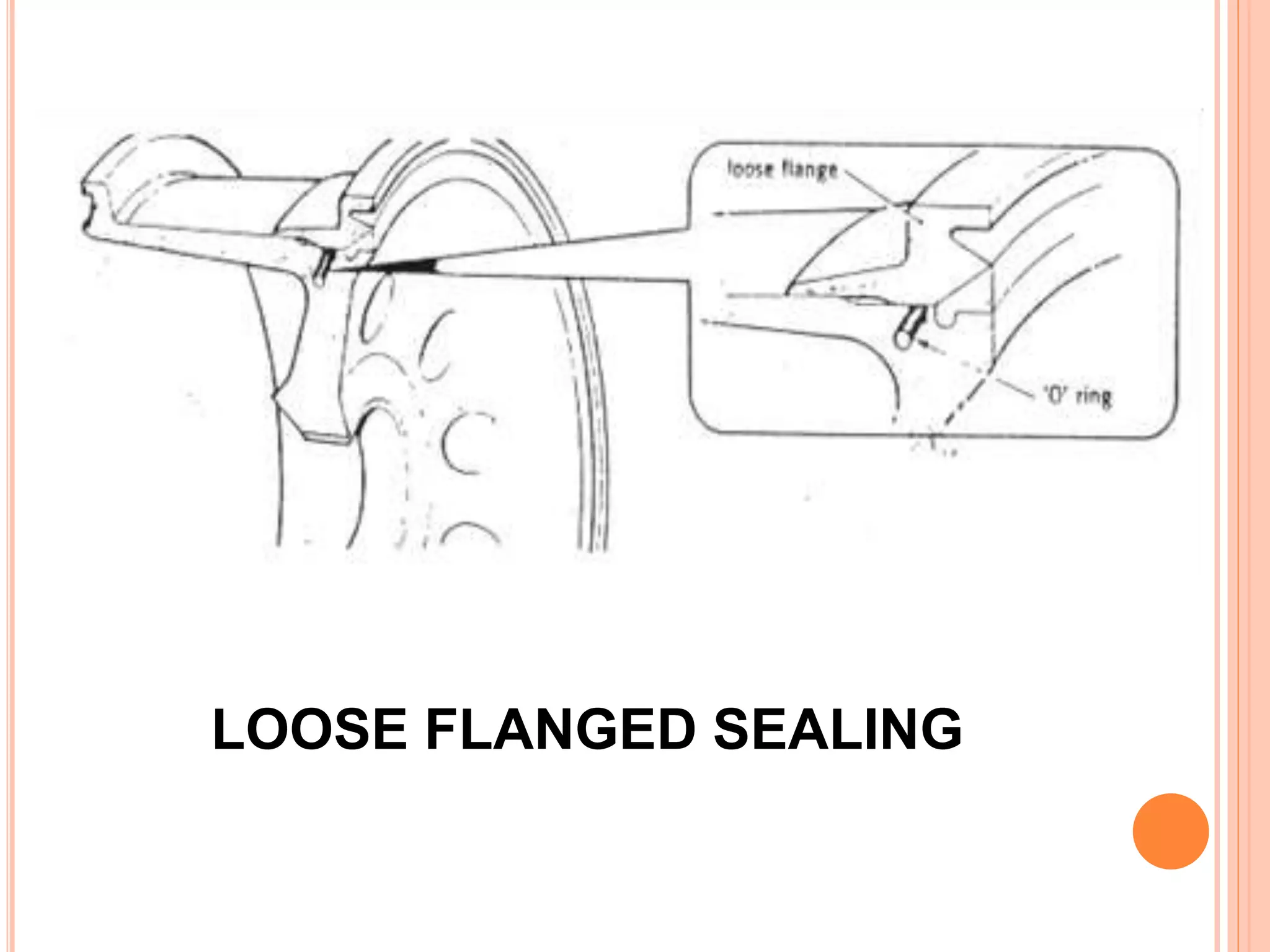

Aircraft wheels are an important component of the landing gear system that support the weight of the aircraft during taxi, takeoff, and landing. Modern aircraft wheels are typically constructed of two lightweight yet strong aluminum alloy halves bolted together, with the inboard half fitted with keyways to engage the brake discs. The two-piece wheel construction allows for tubeless tires, which are sealed between the wheel halves. Aircraft tires experience tremendous loads and temperatures compared to automobile tires, requiring specialized construction and nitrogen inflation for optimal performance.