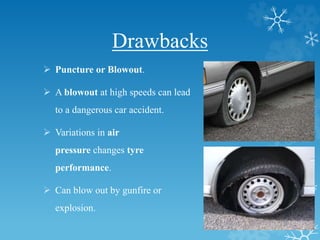

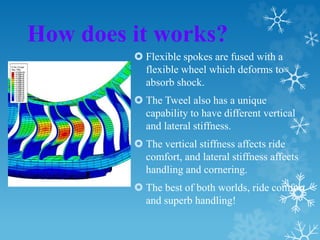

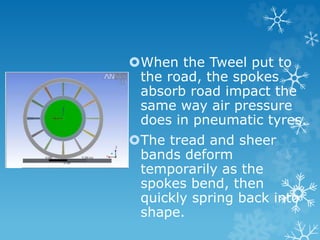

The document discusses the concept of 'tweel', an airless tyre that eliminates the drawbacks of traditional pneumatic tyres, such as punctures and blowouts. Tweels utilize a unique hub and spoke design to provide comparable performance while being more durable and environmentally friendly. Applications include small vehicles like wheelchairs and military vehicles, indicating a shift towards innovative tyre technology.

![[1].Rhyne, T. B., and Cron, S. M., “Development of a Non-Pneumatic

Wheel,” Tire Science and Technology, Volume 34, Number 3, July-

September 2006

[3]. Dr.Joshi.C.Haran, “Static analysis of airless tyres “,International

Journal of Scientific and Research Publications, Volume 3, Issue 8,

August 2013

[3]. htpps://www.michelin.com last visited on 26/03/14 at 8 am

REFERENCES](https://image.slidesharecdn.com/15705a0326-170217092610/85/Tweel-Airless-Tyres-18-320.jpg)