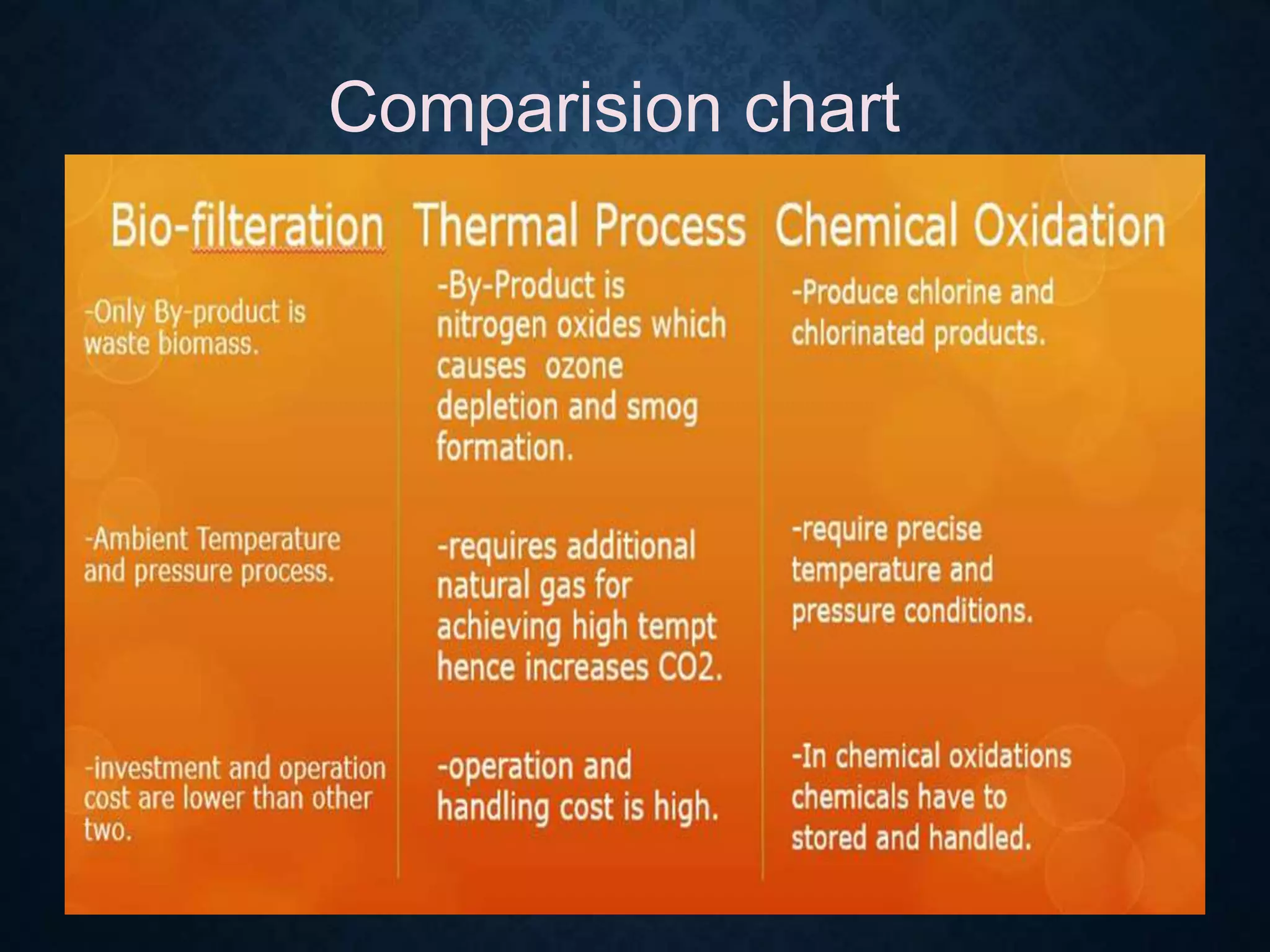

Biofiltration is a pollution control technique that uses a bioreactor containing living material to biologically degrade pollutants in waste water, surface runoff, or contaminated air. It is a green process that uses small amounts of power compared to thermal or catalytic control units. There are different types of biofilters based on layout, support media used, and shape. The biofiltration process involves contaminated air passing through a moist filter medium that provides conditions for microorganisms to absorb and degrade the contaminants into carbon dioxide through a combination of adsorption, absorption, and microbial degradation. Major considerations for the filter medium include its ability to retain moisture and microbes, provide a large surface area, retain nutrients, and allow low resistance air