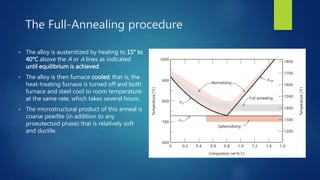

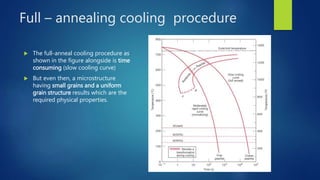

The document explains the process of annealing, a heat treatment that involves heating a material to a high temperature, holding it, and then cooling it slowly to relieve stresses and enhance material properties. Full annealing is specifically used for low and medium carbon steels, producing a microstructure of coarse pearlite that is soft and ductile. The procedure includes heating above specific temperature lines, furnace cooling, and requires careful control of time and temperature.