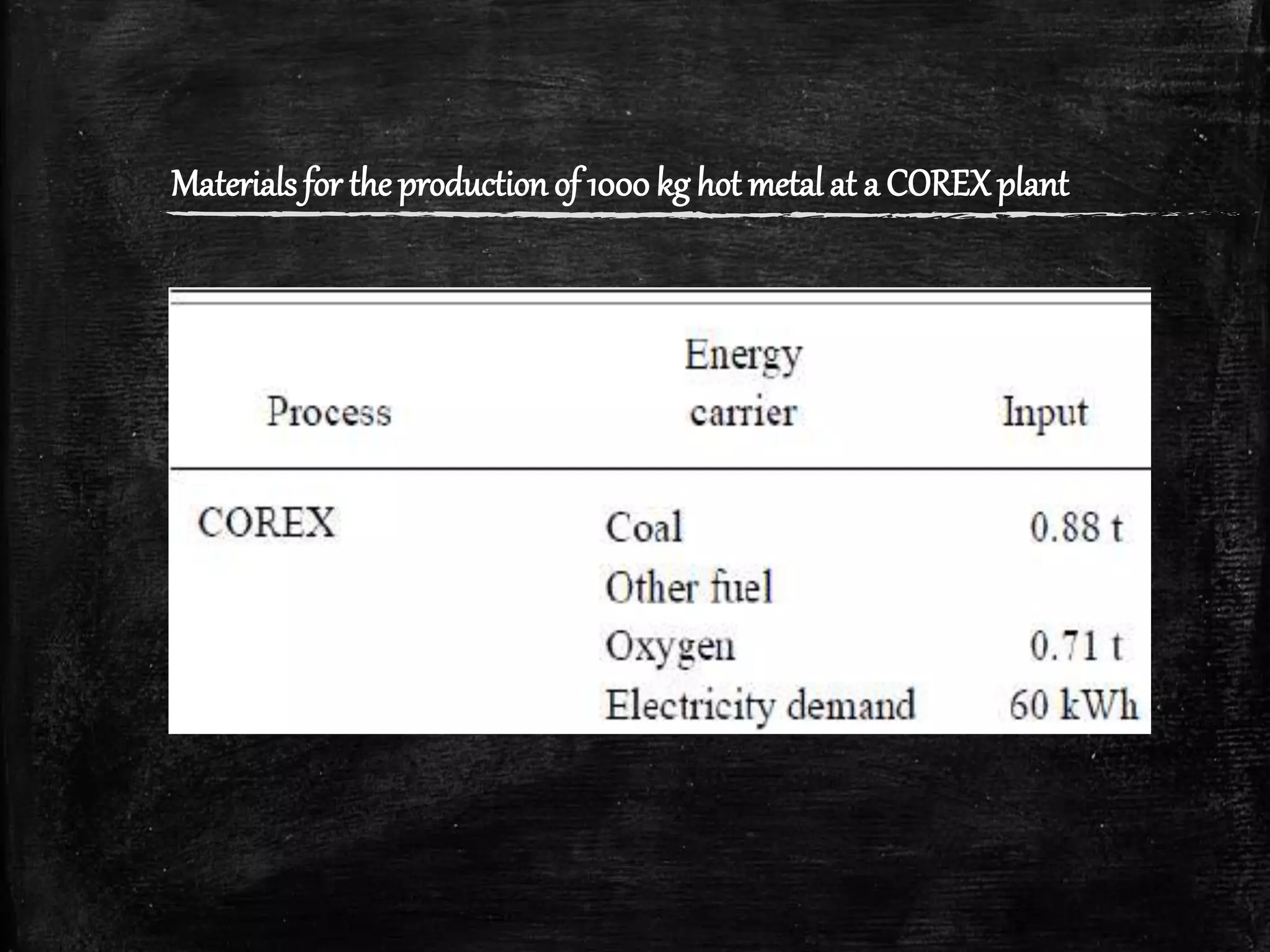

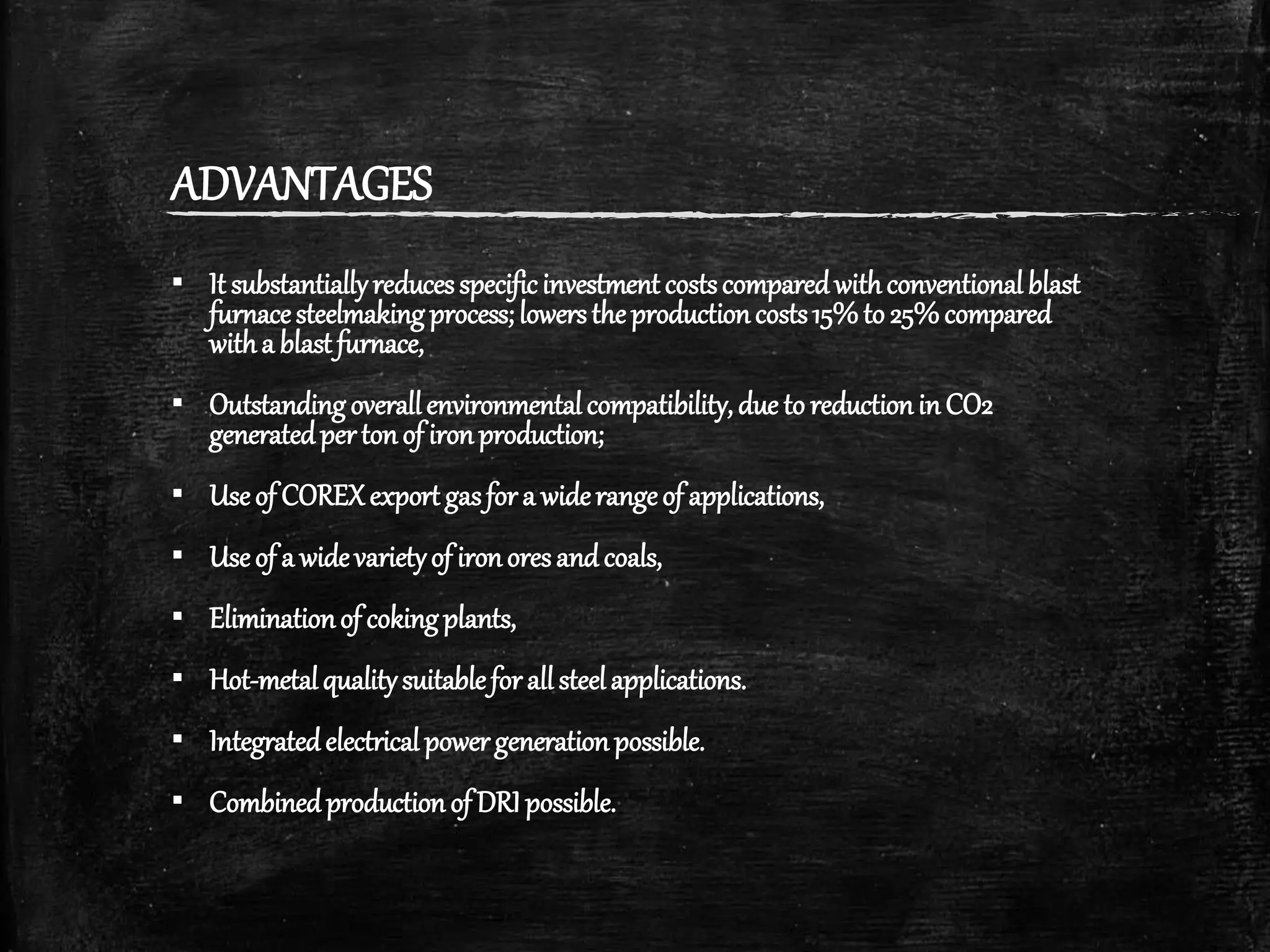

The Corex process is an alternative ironmaking technology to the blast furnace that uses non-coking coal, iron ore, and oxygen instead of coke and hot blast. It consists of a reduction shaft and a melter-gasifier that work in countercurrent to reduce iron ore to hot metal. The Corex process offers advantages over traditional blast furnaces such as using coal and lump ore without sintering, producing hot metal with suitable quality for all steel applications, and having outstanding environmental compatibility through reduced CO2 emissions per ton of iron produced. Some commercial Corex units are operated by companies such as POSCO, JSW Steel, and ArcelorMittal.