This presentation summarizes the DRI (Direct Reduced Iron) plant process. Key points include:

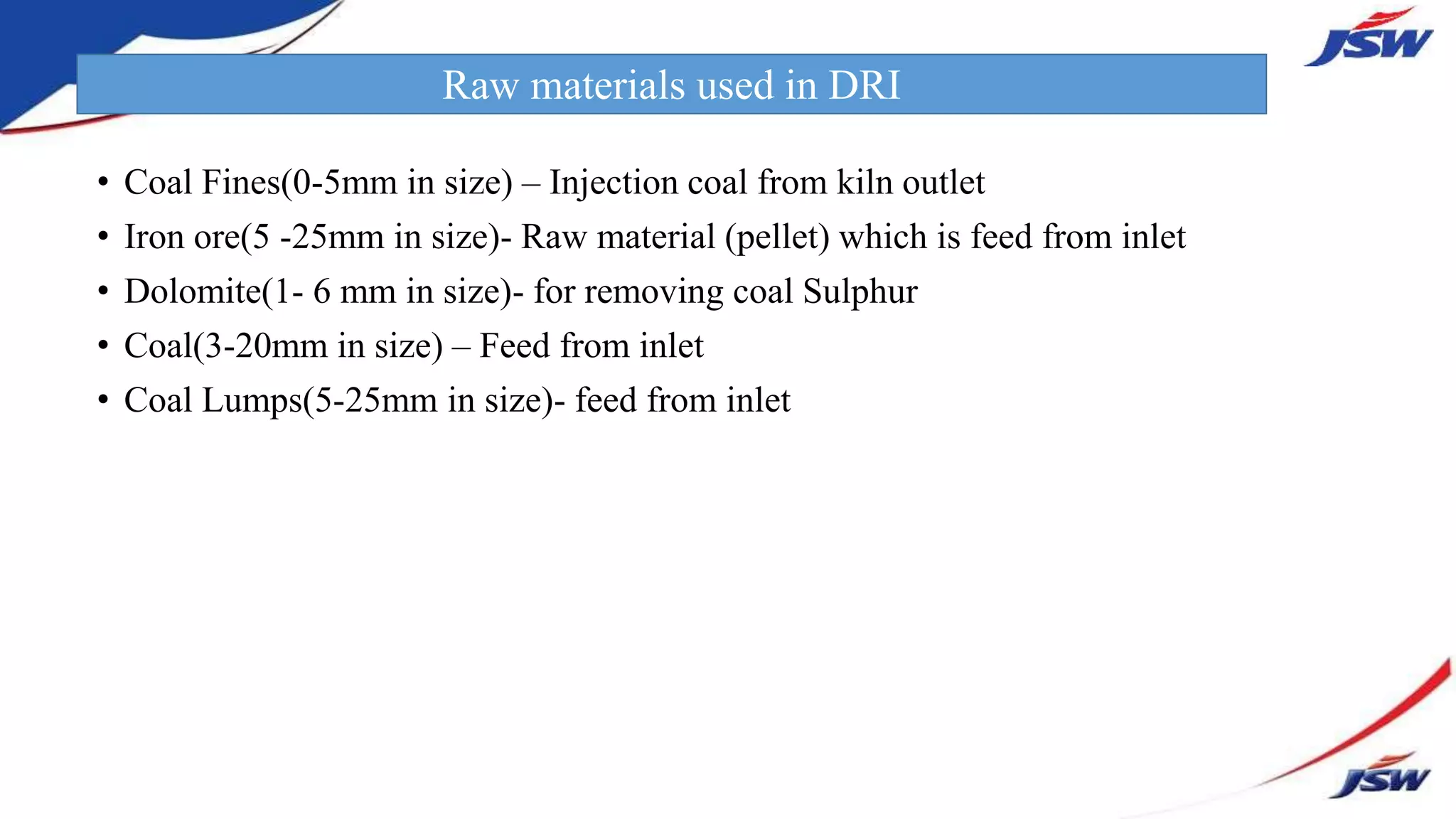

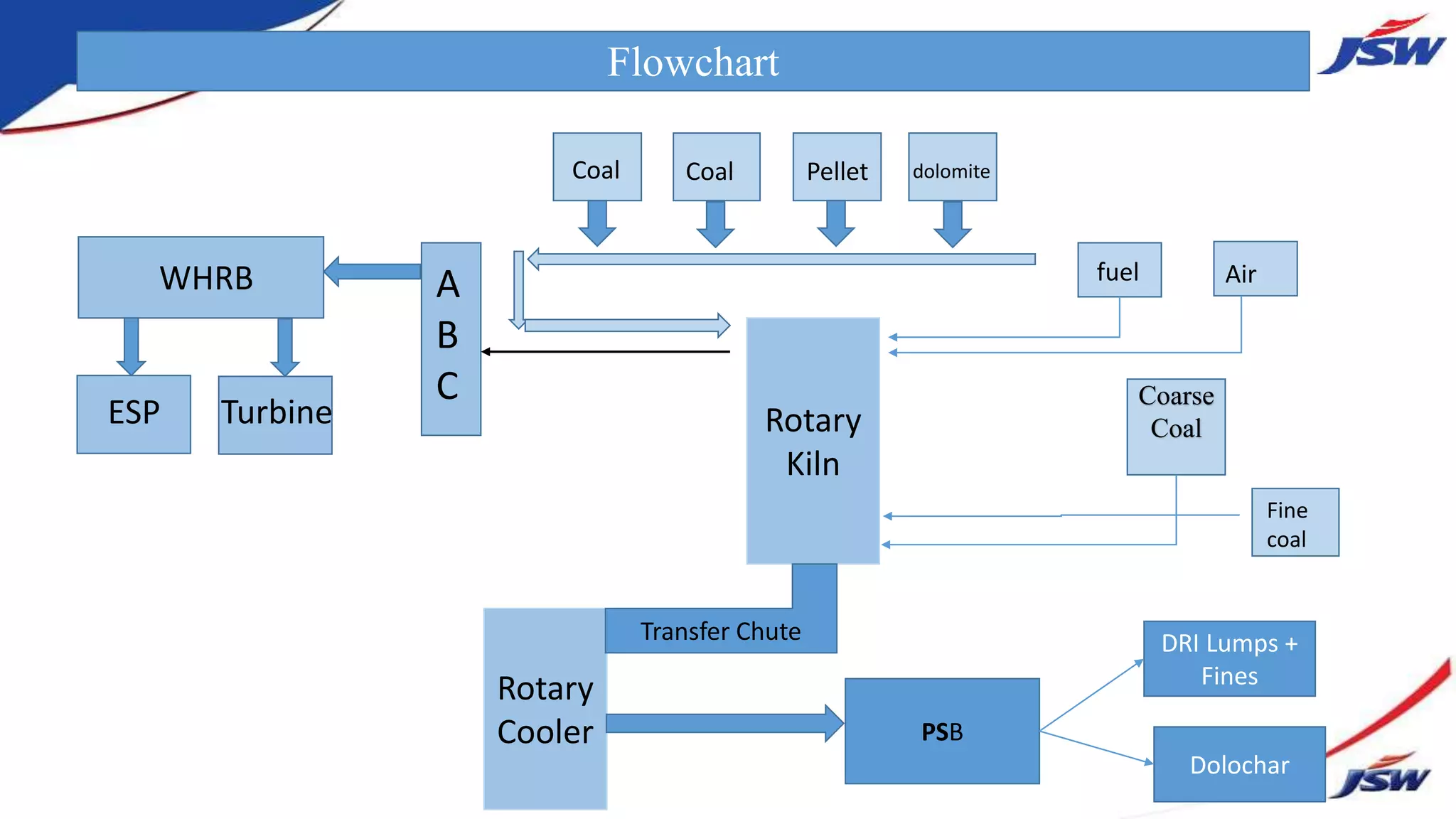

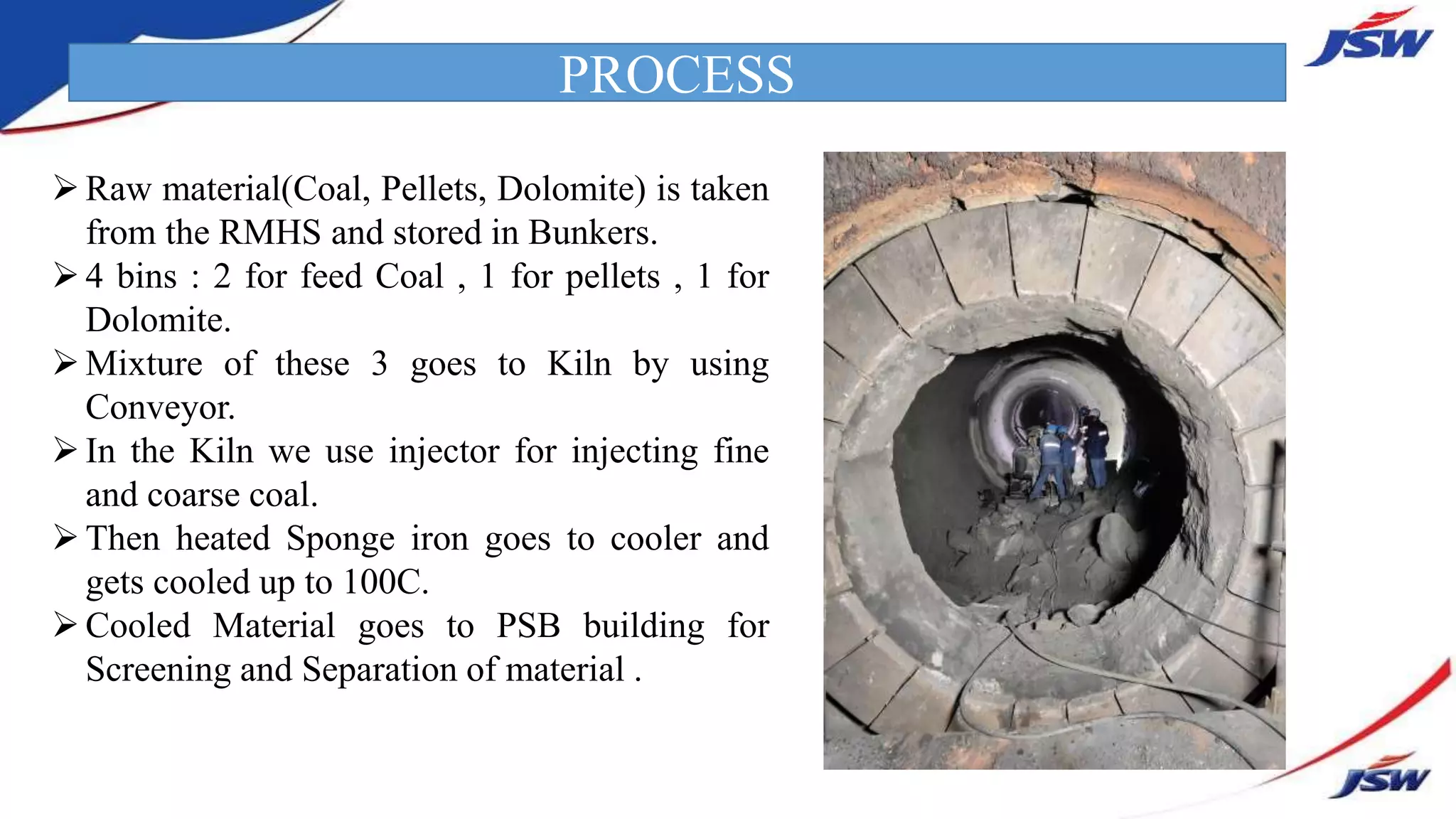

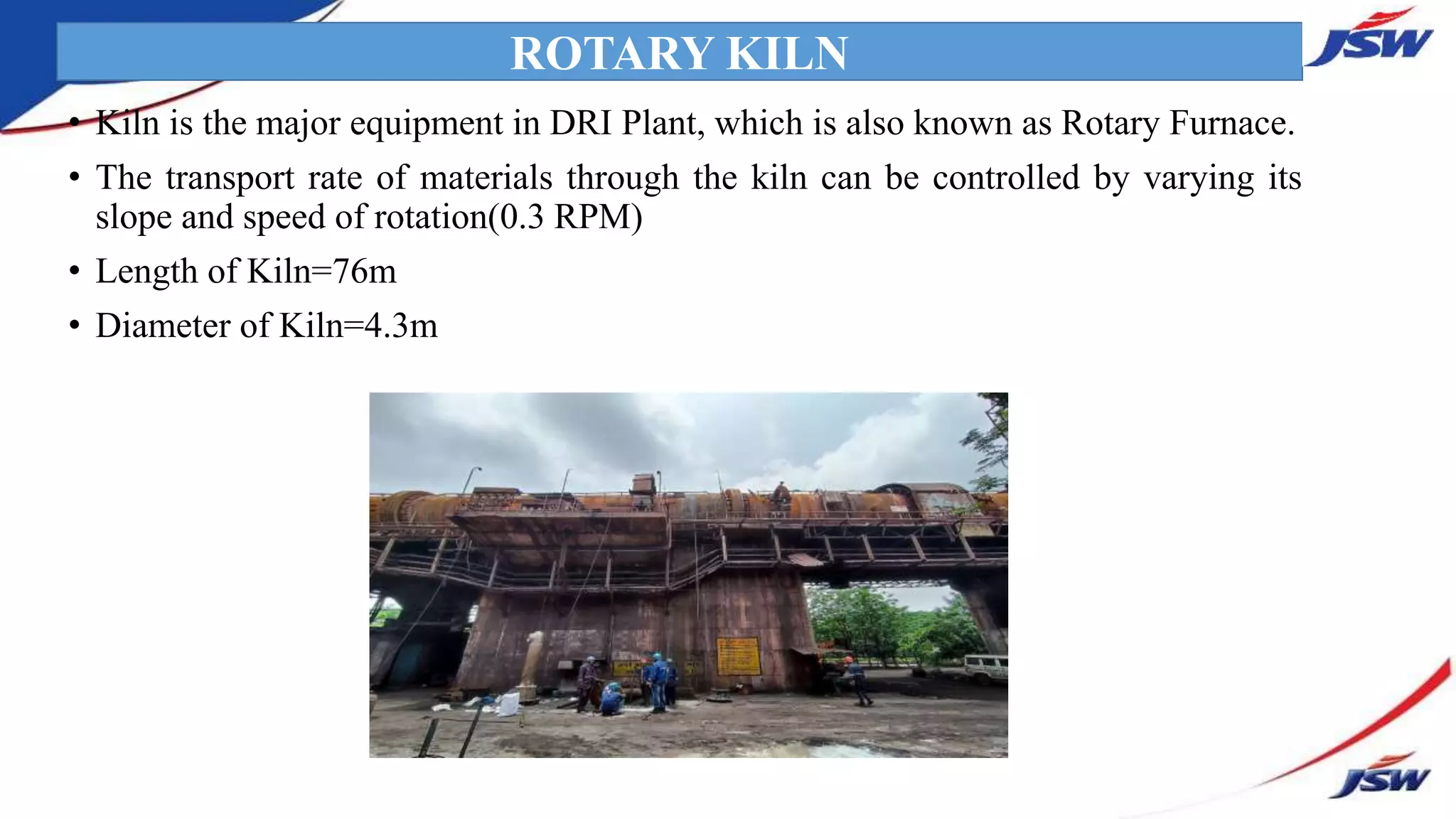

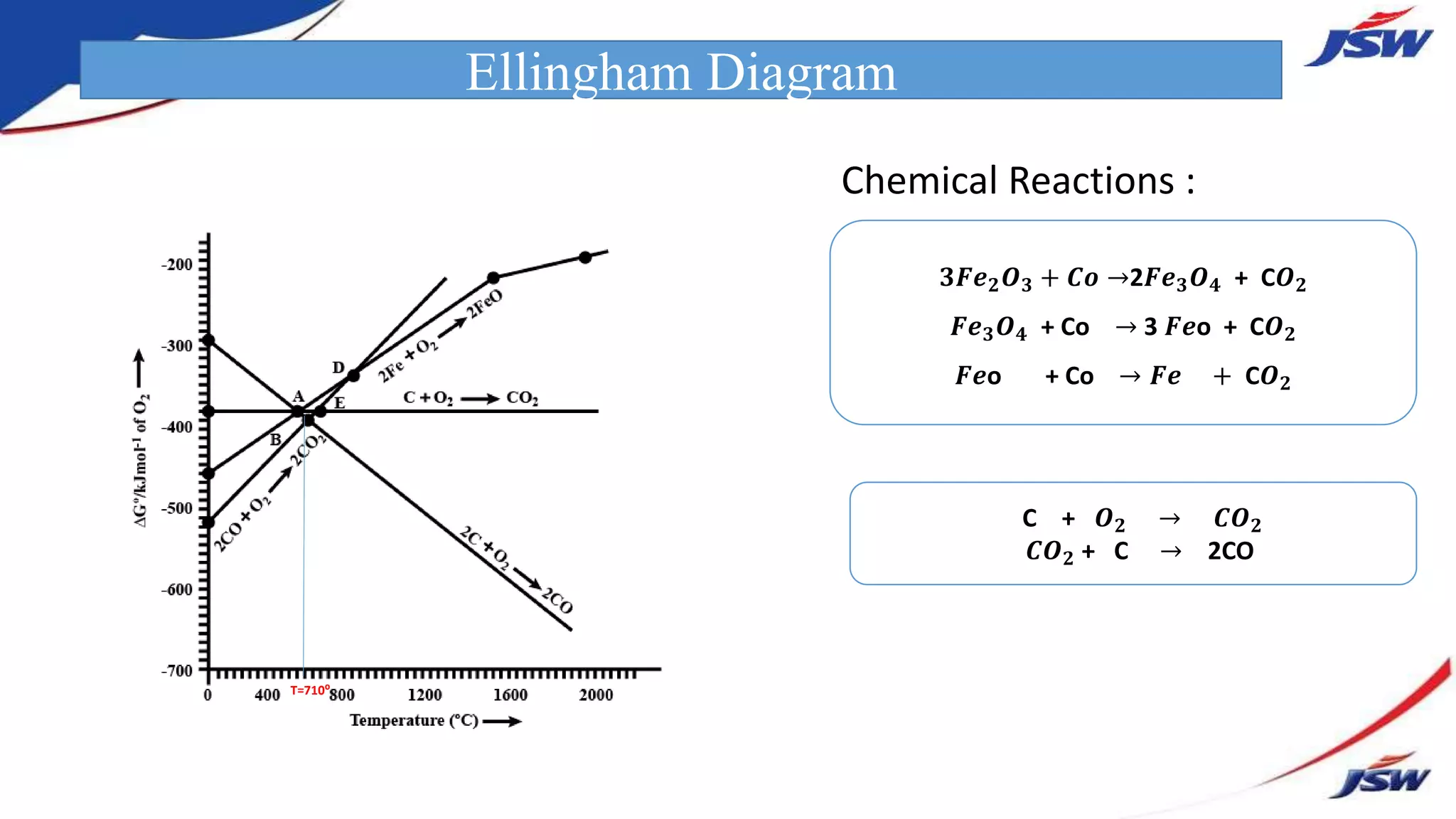

- The DRI plant uses iron ore, coal, and dolomite as raw materials which are fed into a rotary kiln and reduced to sponge iron through chemical reactions.

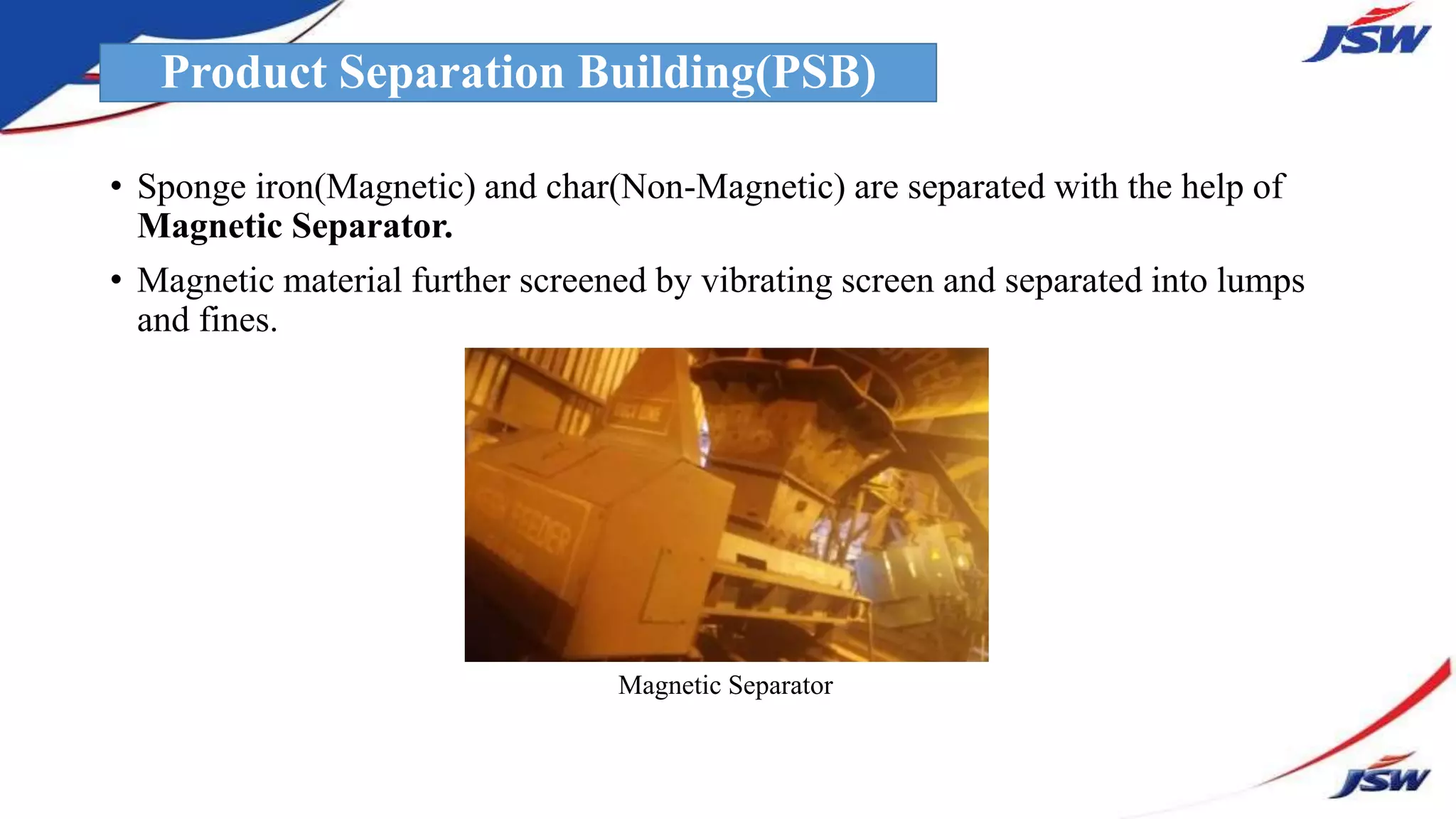

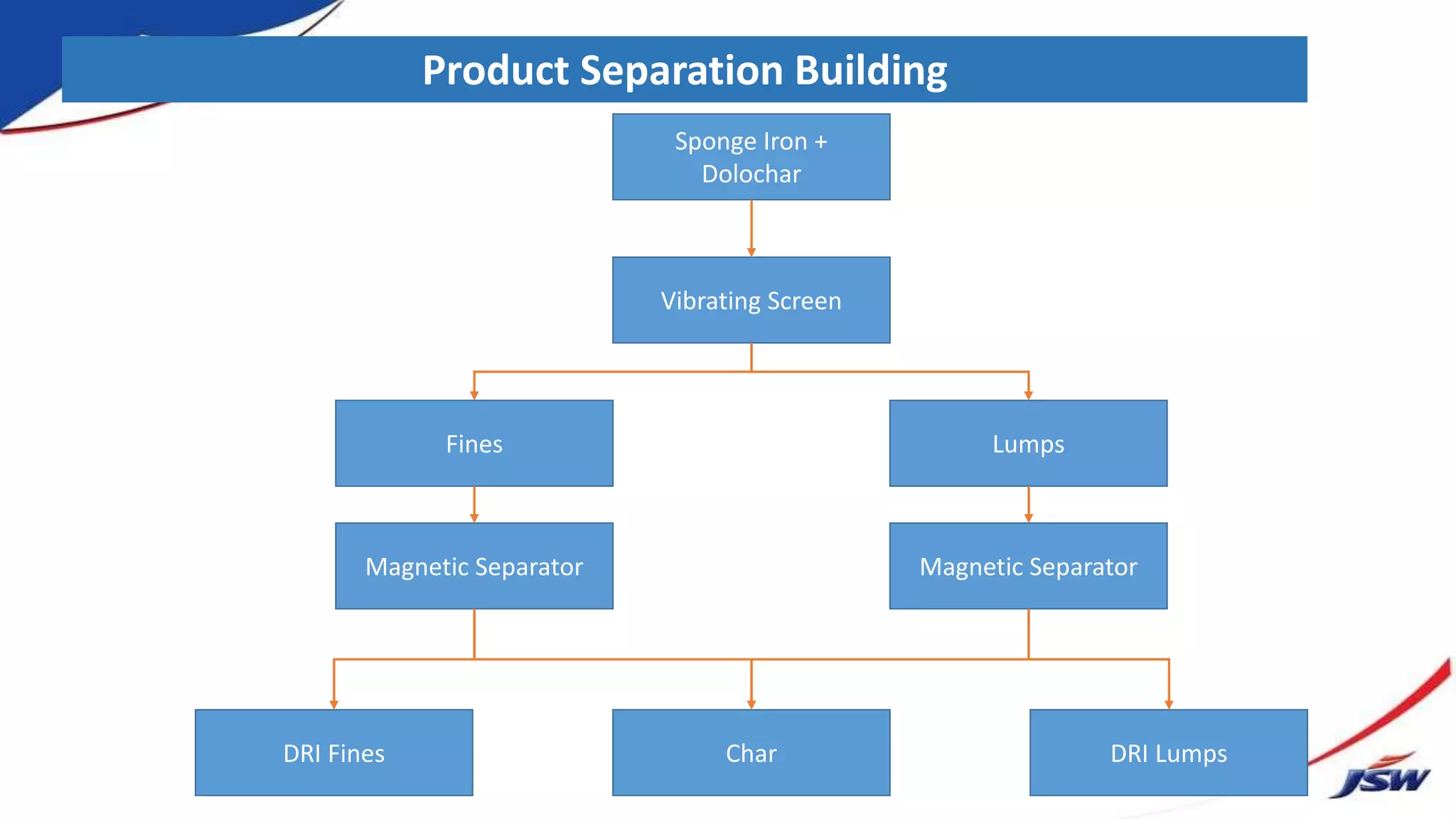

- The sponge iron is then cooled in a rotary cooler before being separated into lumps and fines in the Product Separation Building using magnetic separation and screening.

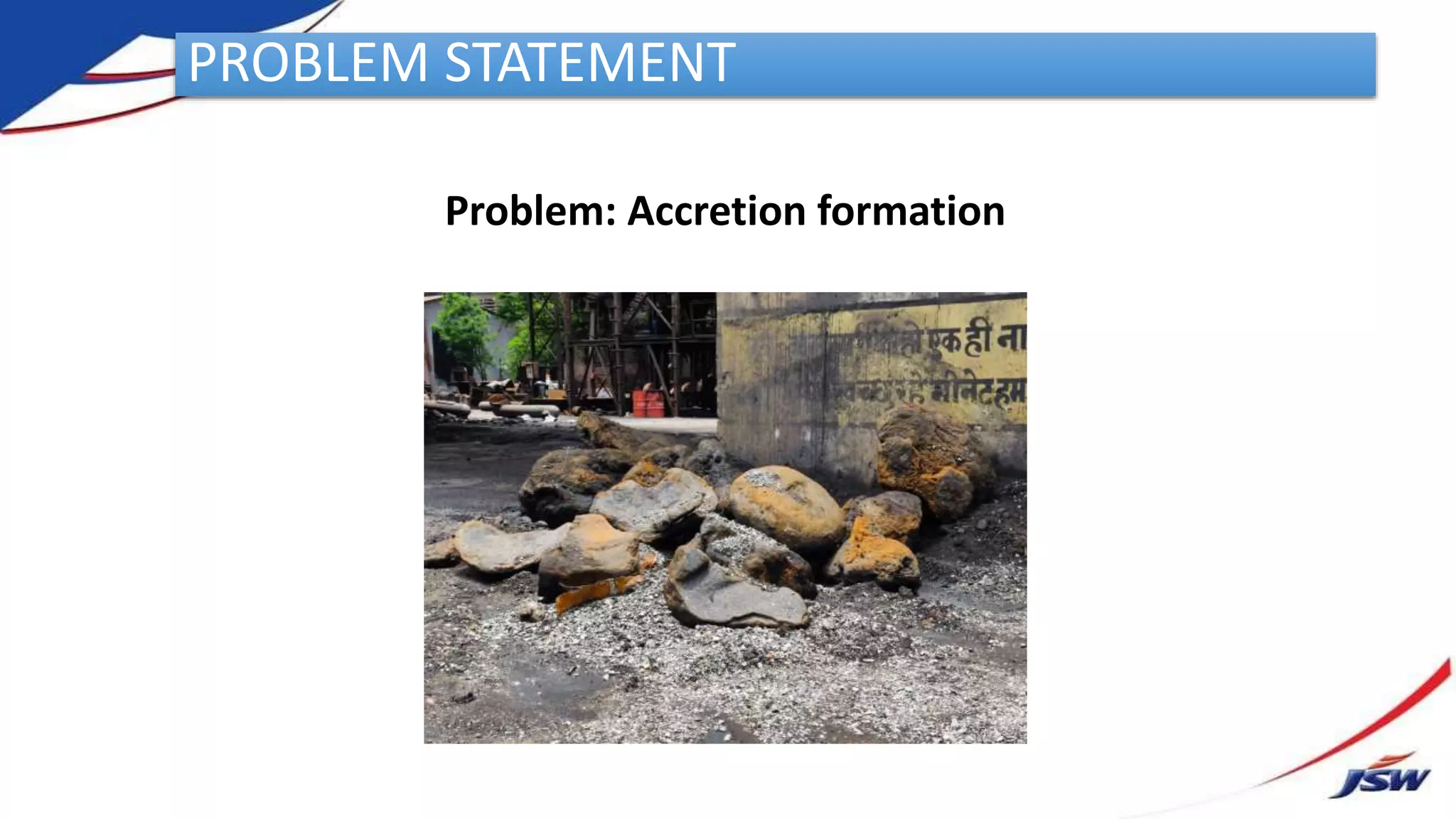

- Common problems addressed include gear issues in the rotary cooler and accretion formation, which can be addressed through maintenance and using higher quality raw materials.