The document discusses various topics related to continuous distillation processes including:

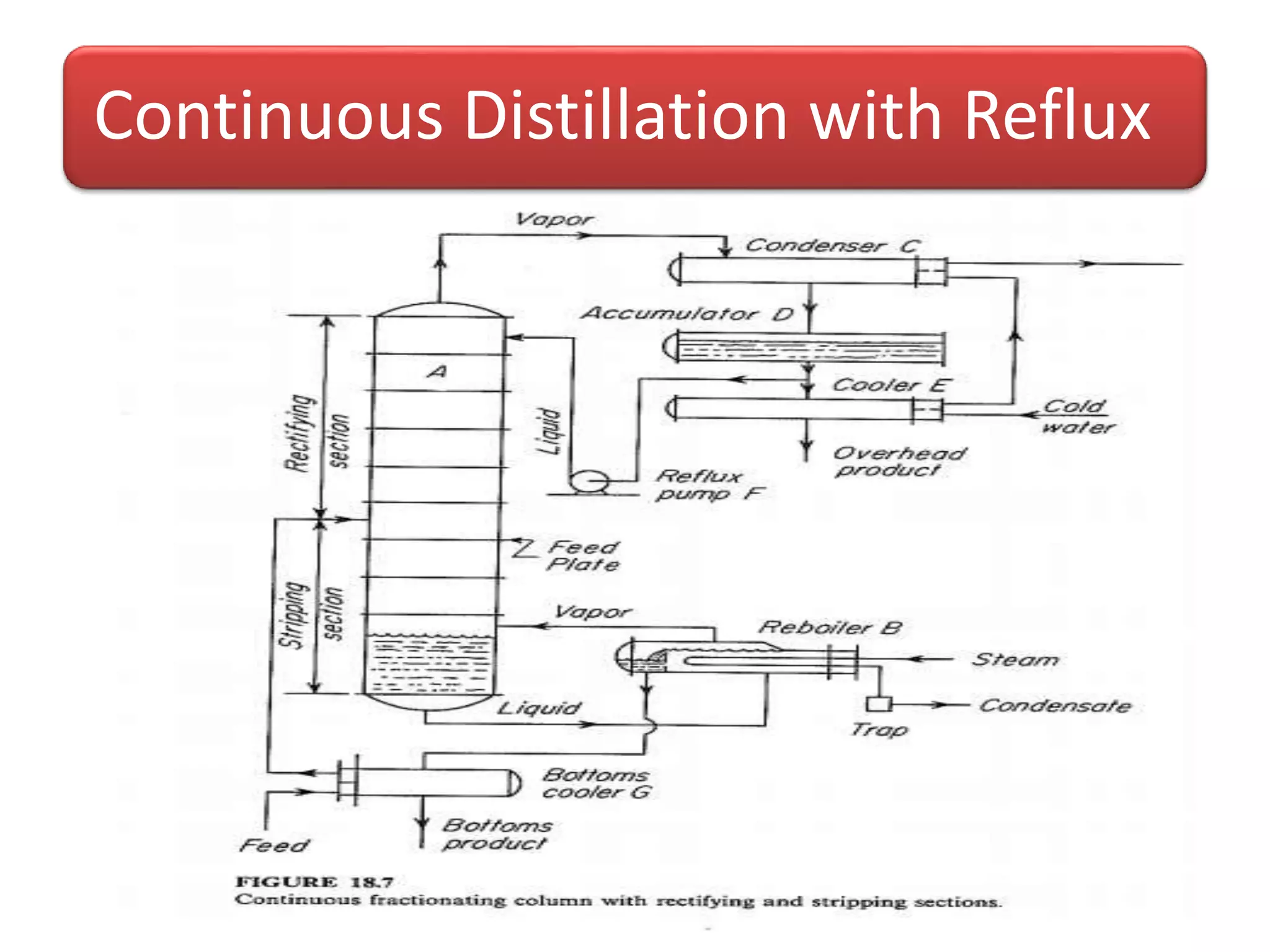

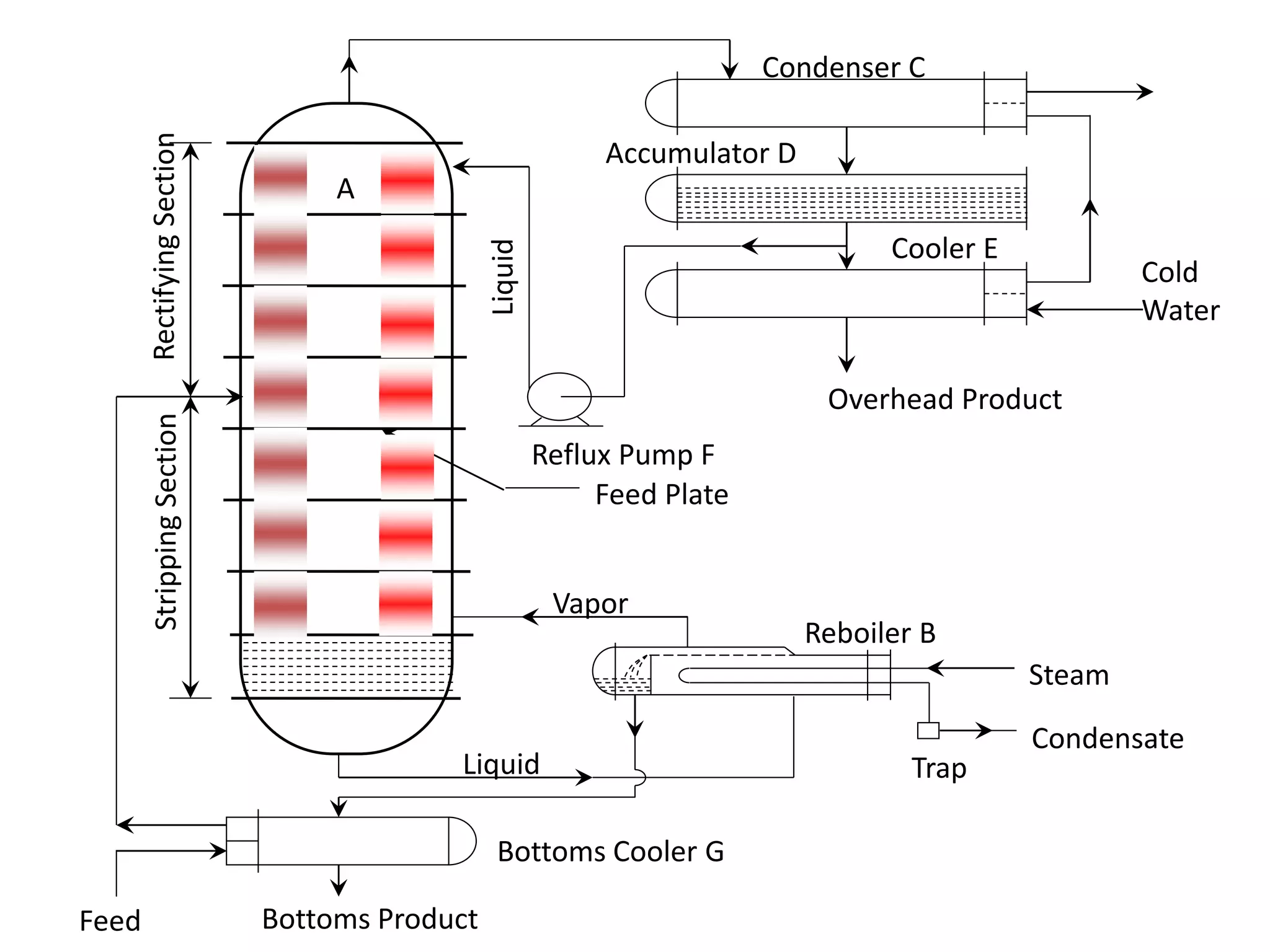

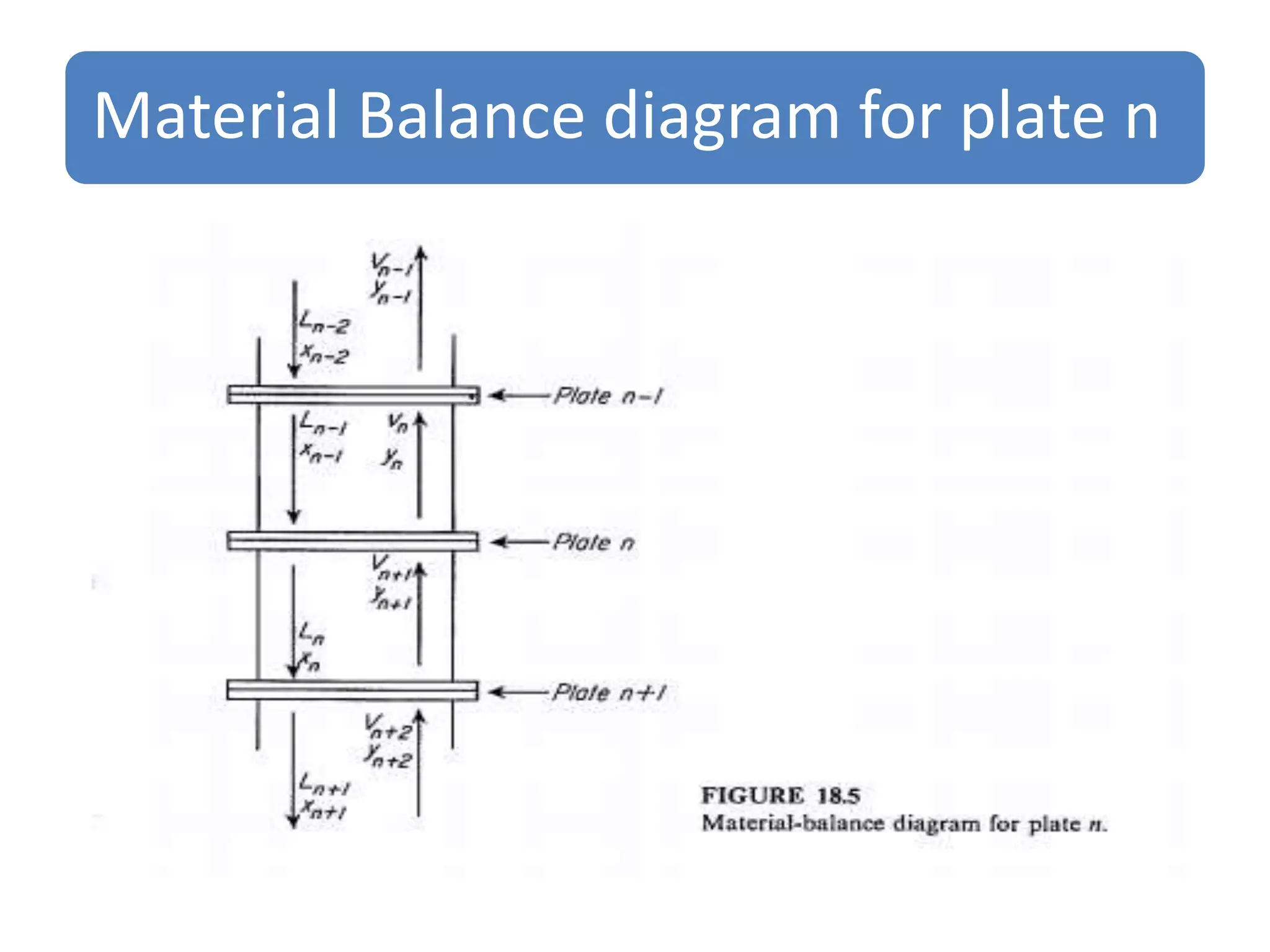

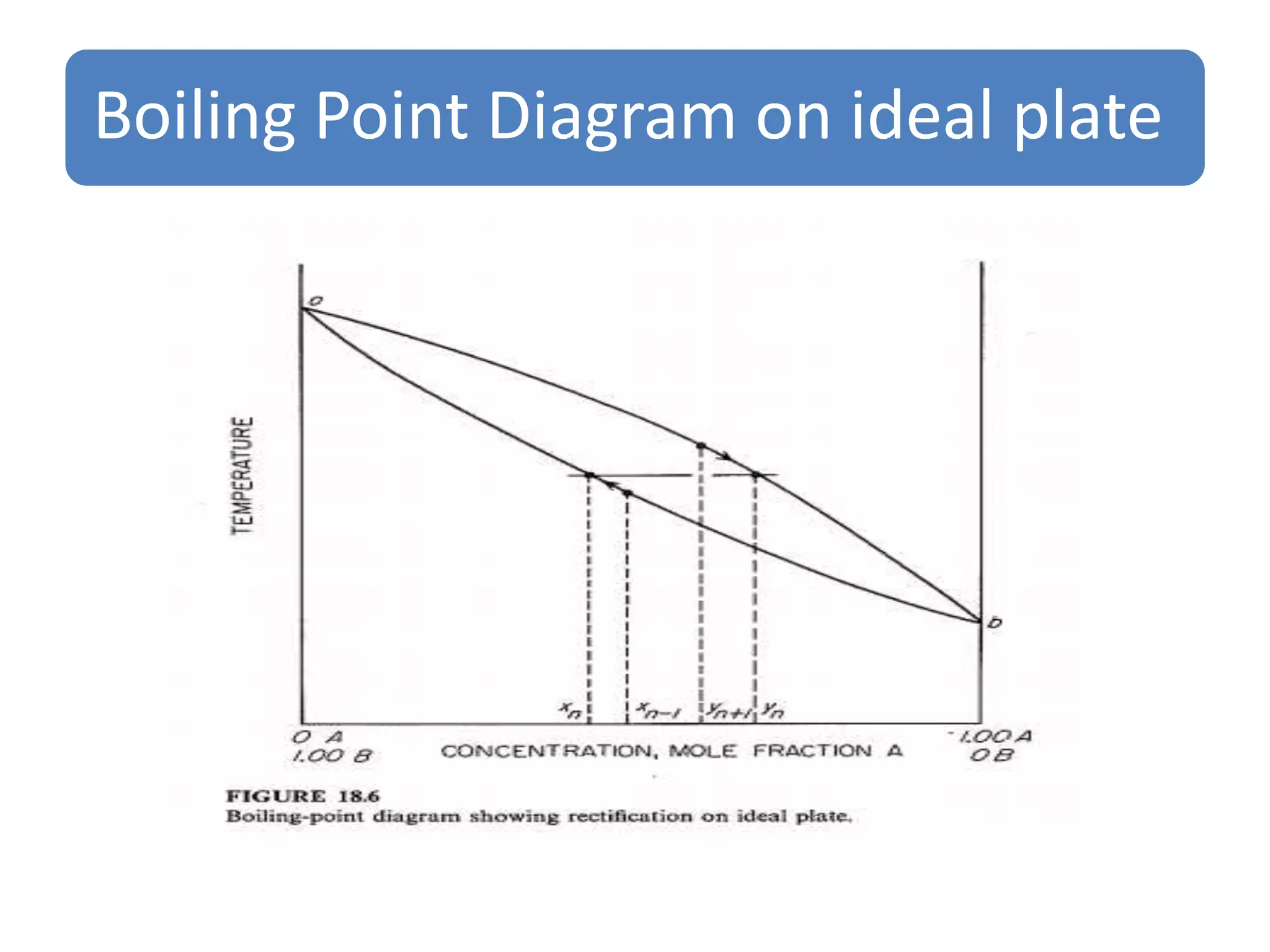

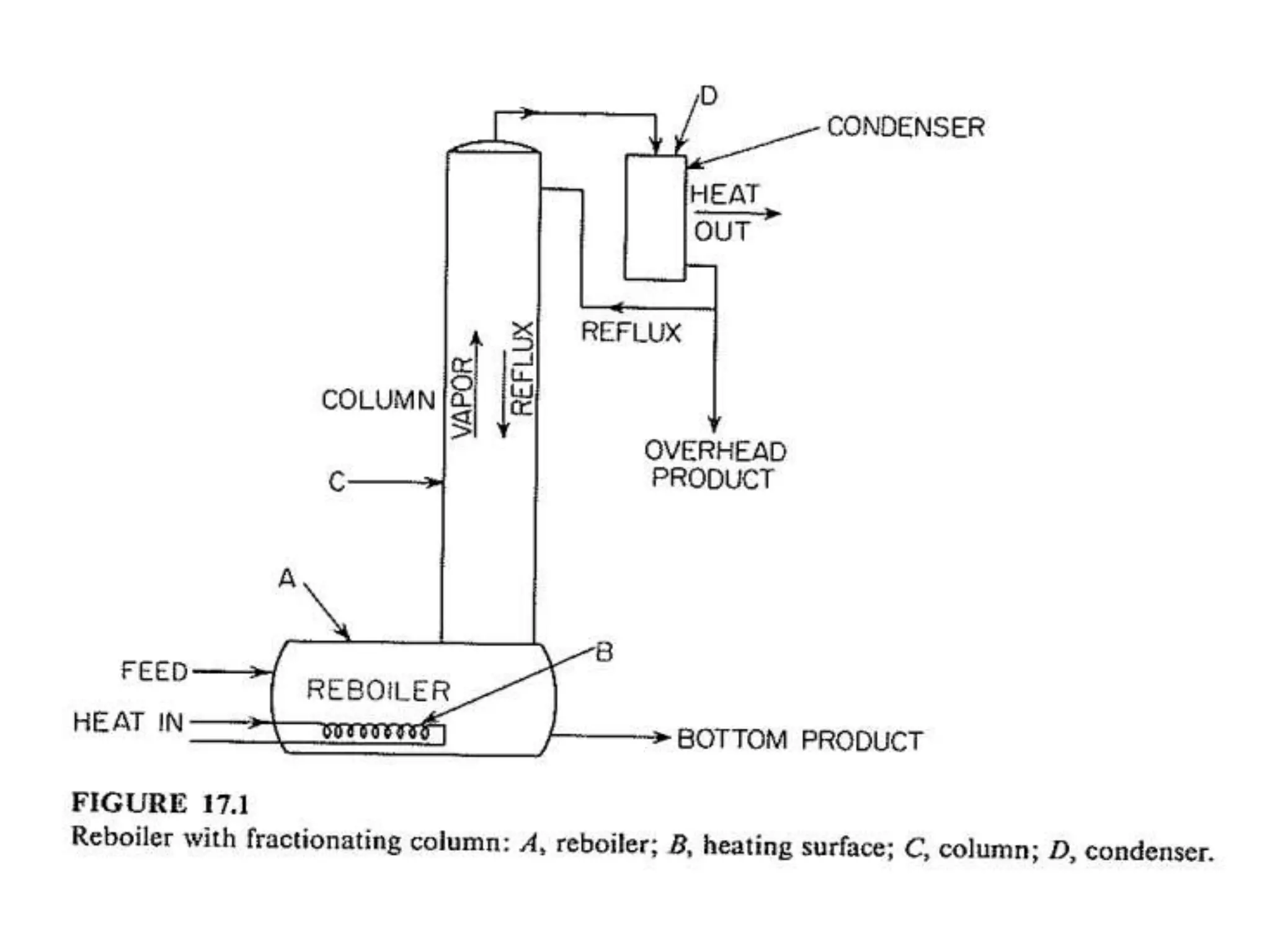

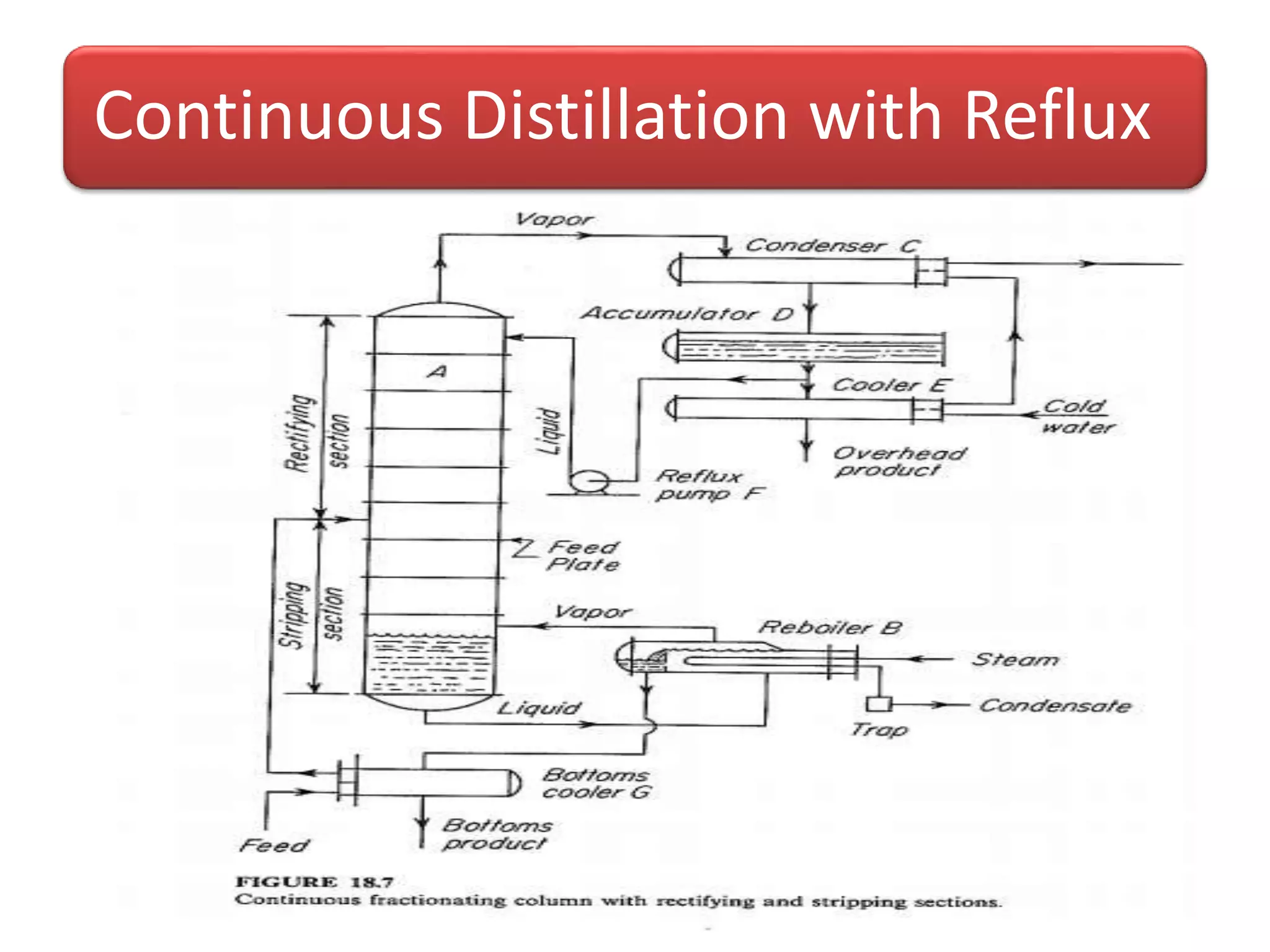

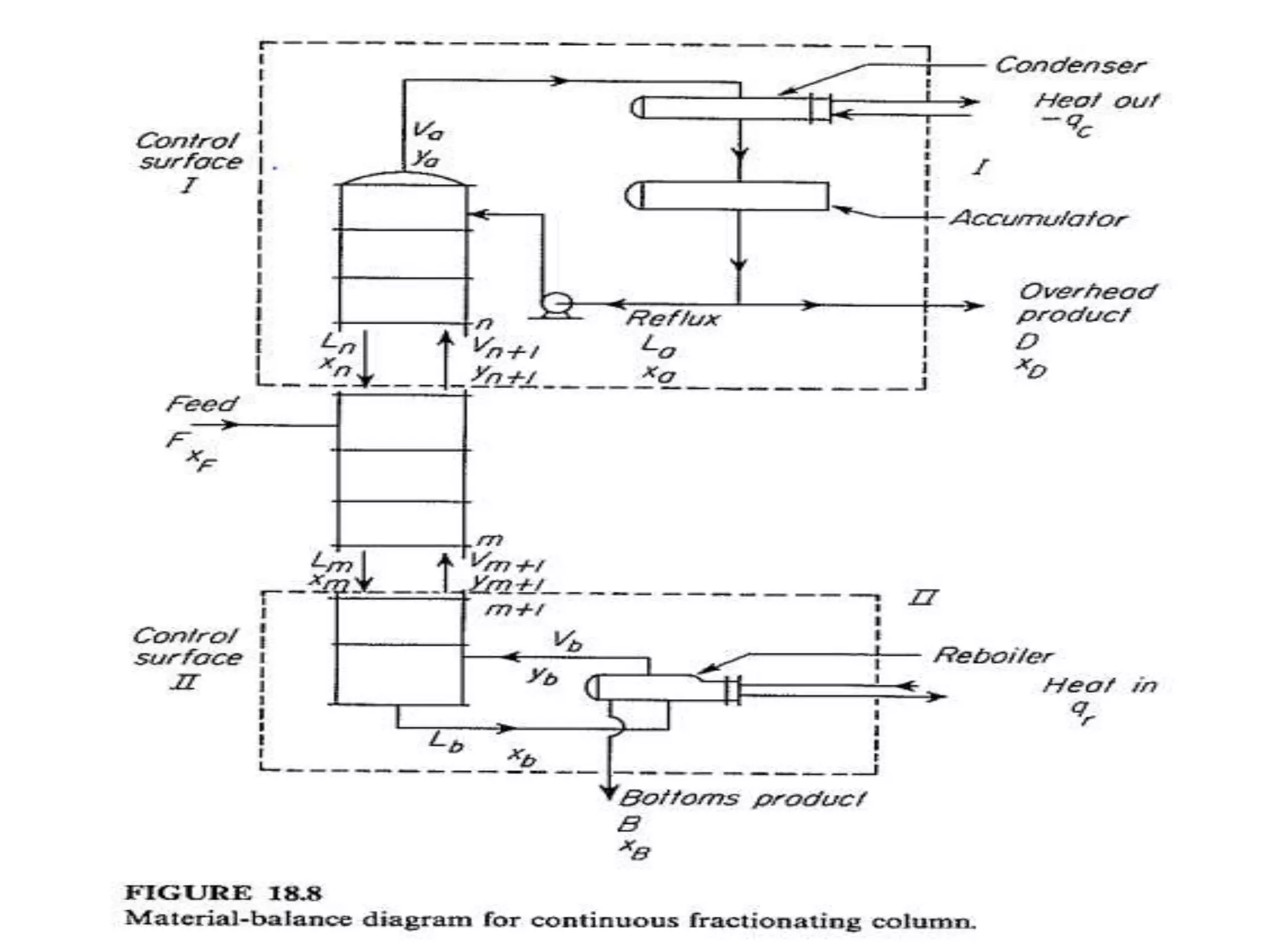

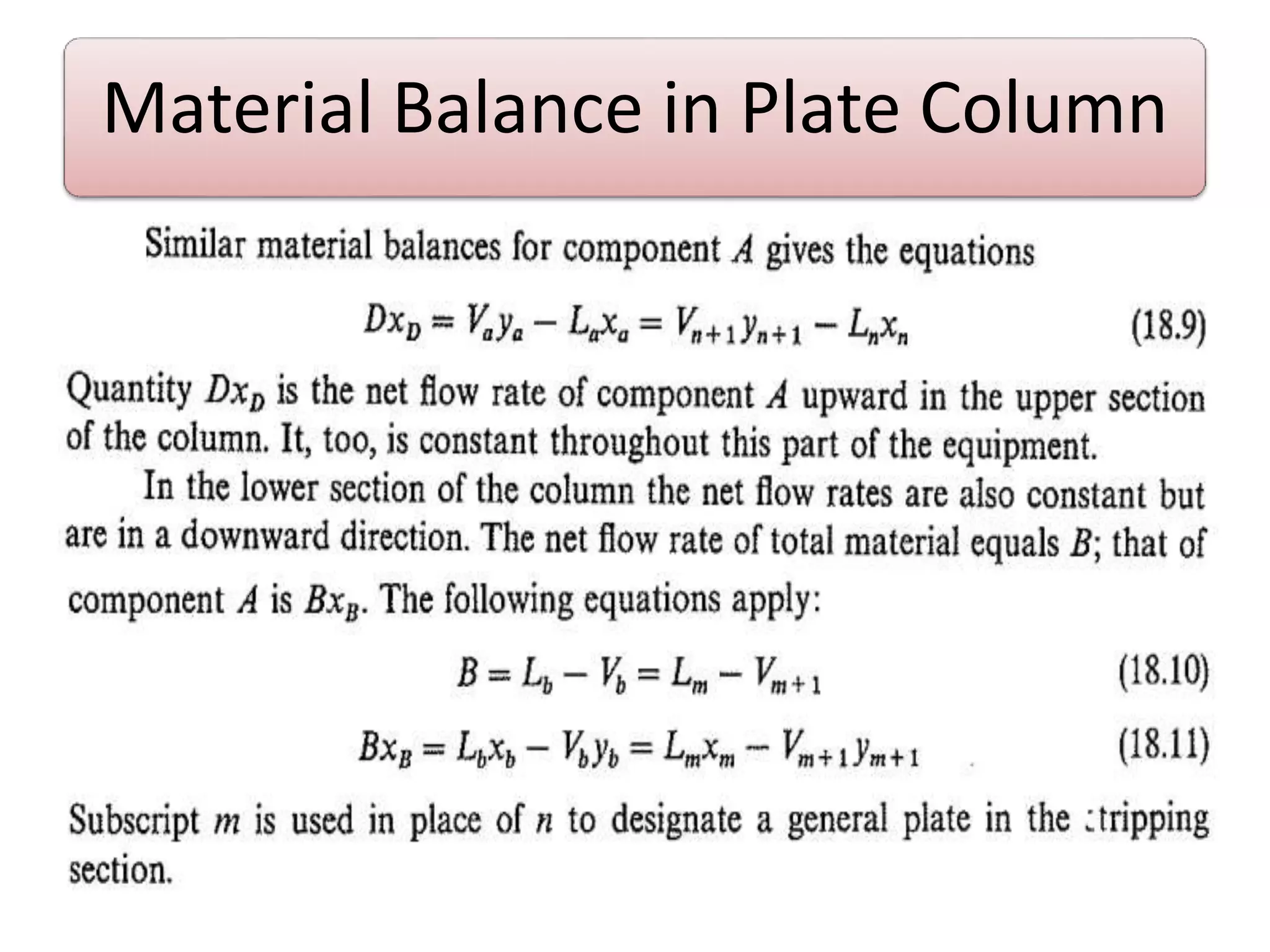

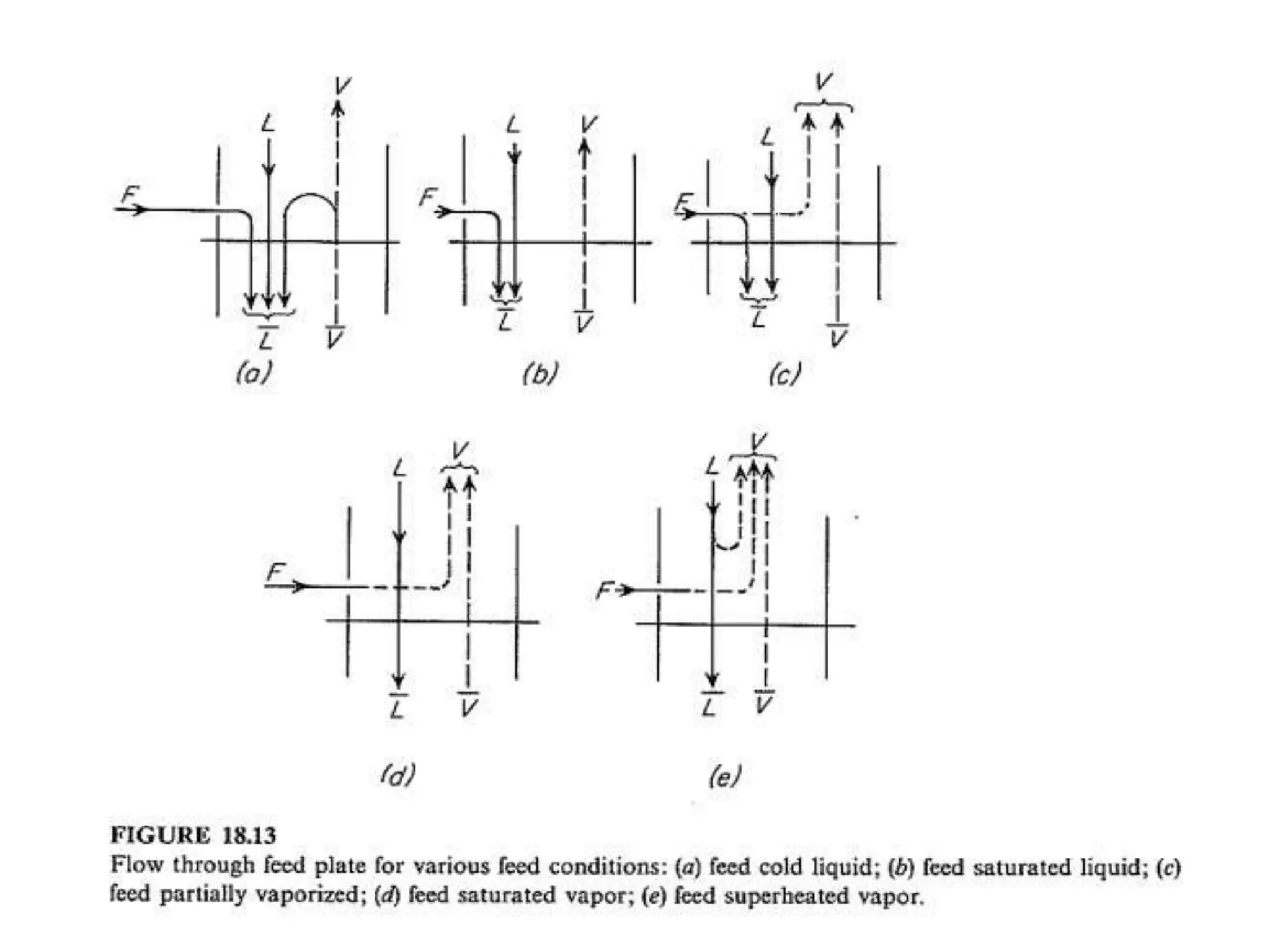

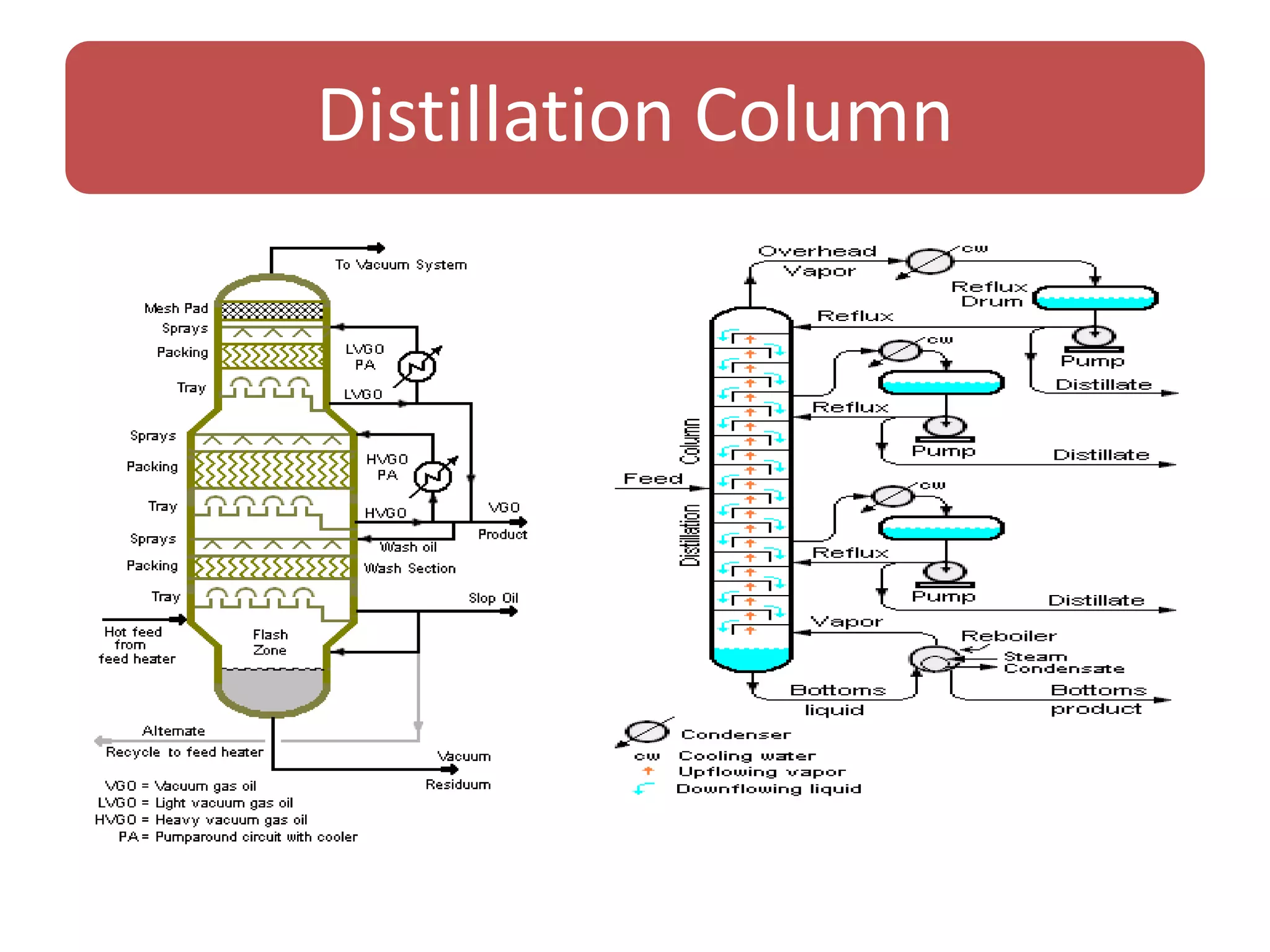

1) Material balance diagrams for continuous distillation columns and individual plates within the column. Different sections of the column like the rectifying and stripping sections are identified.

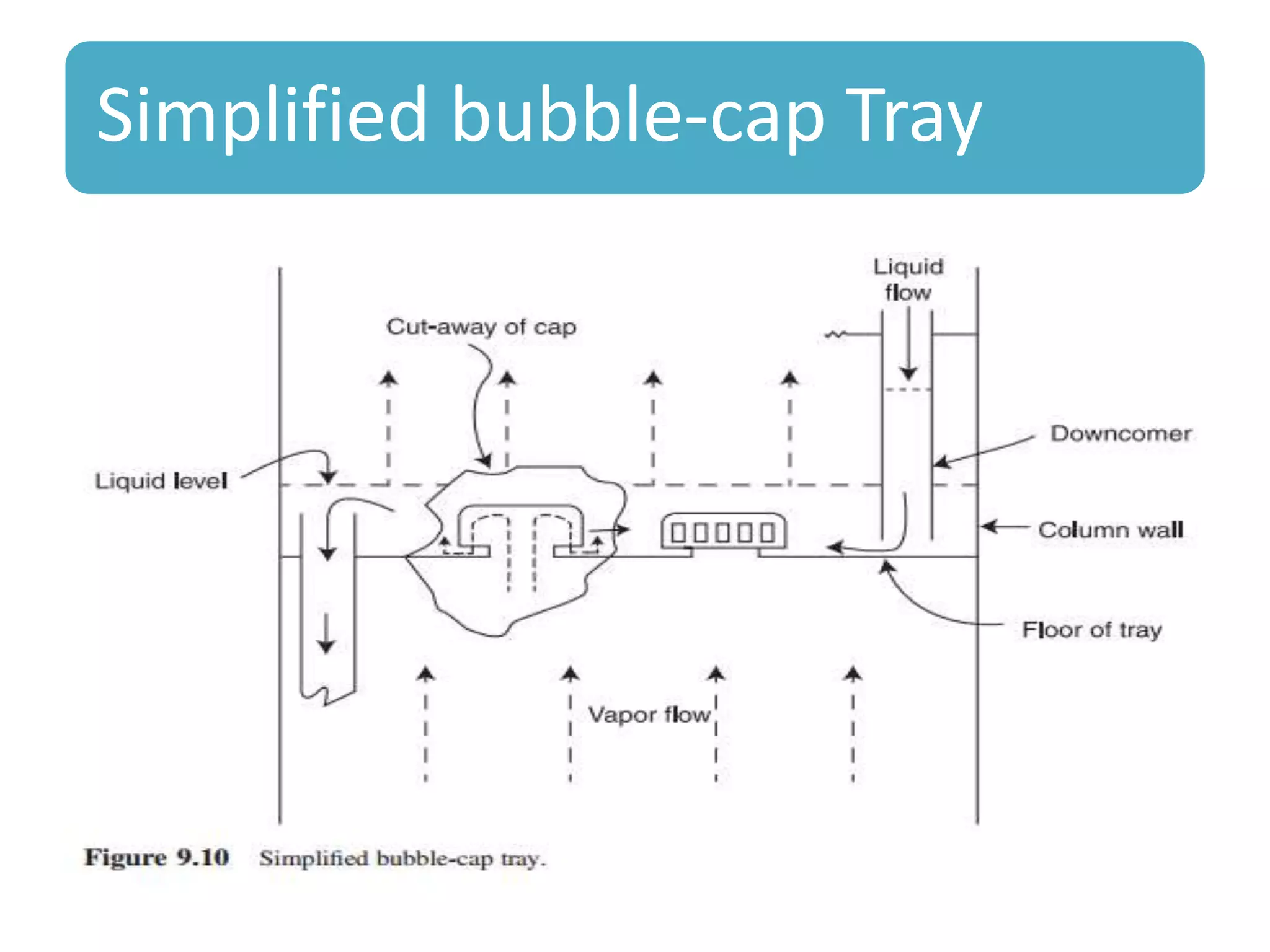

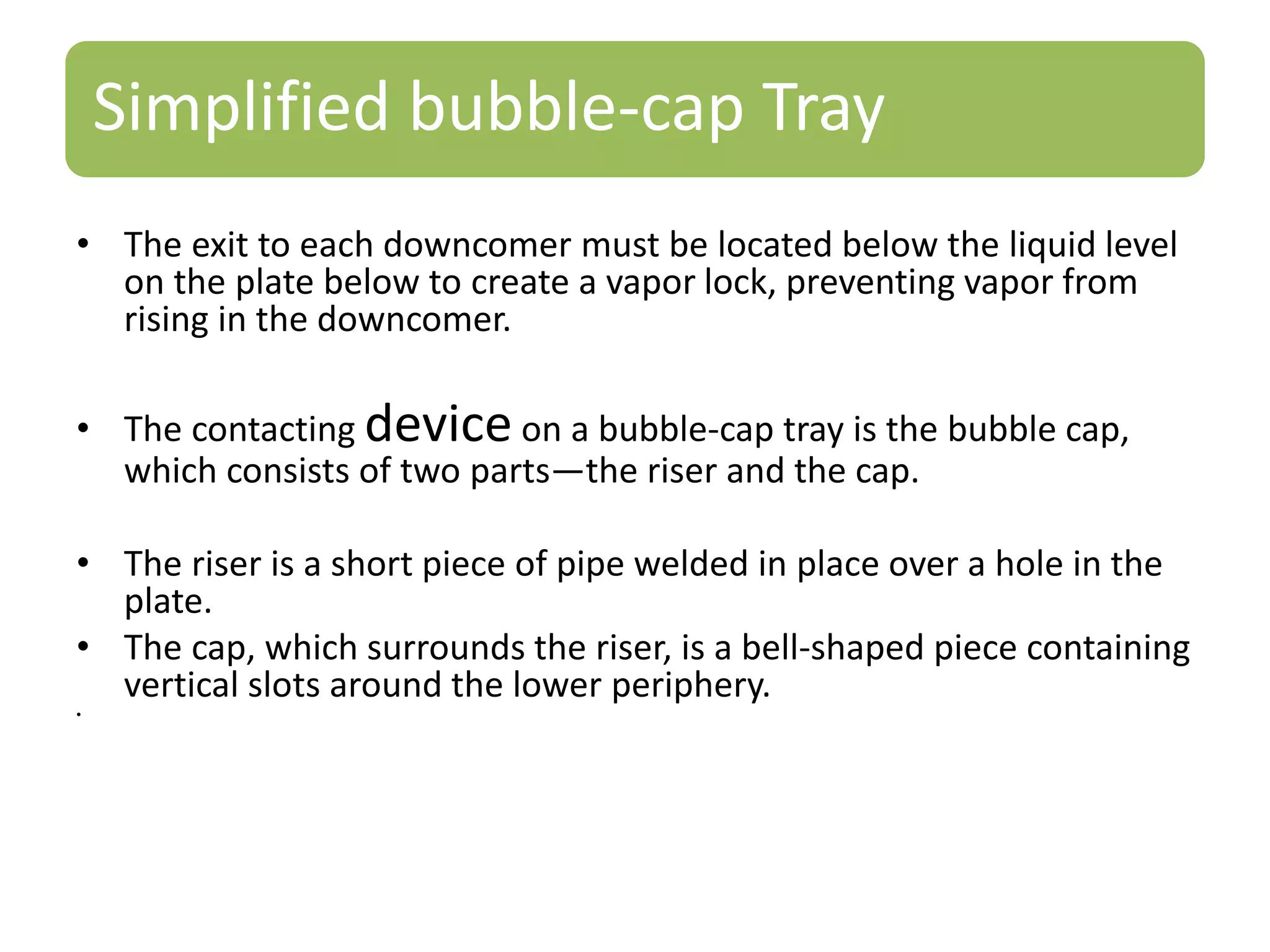

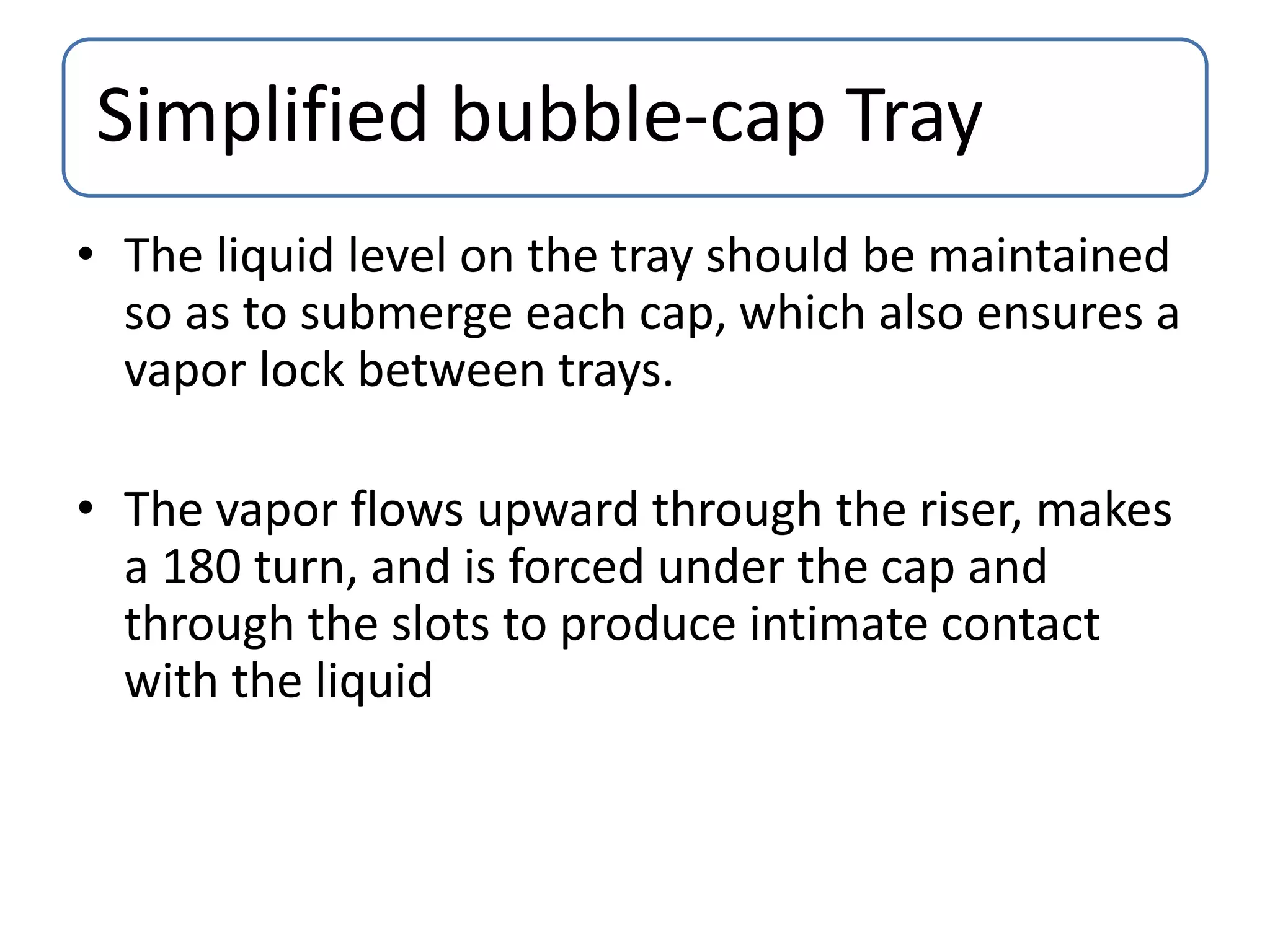

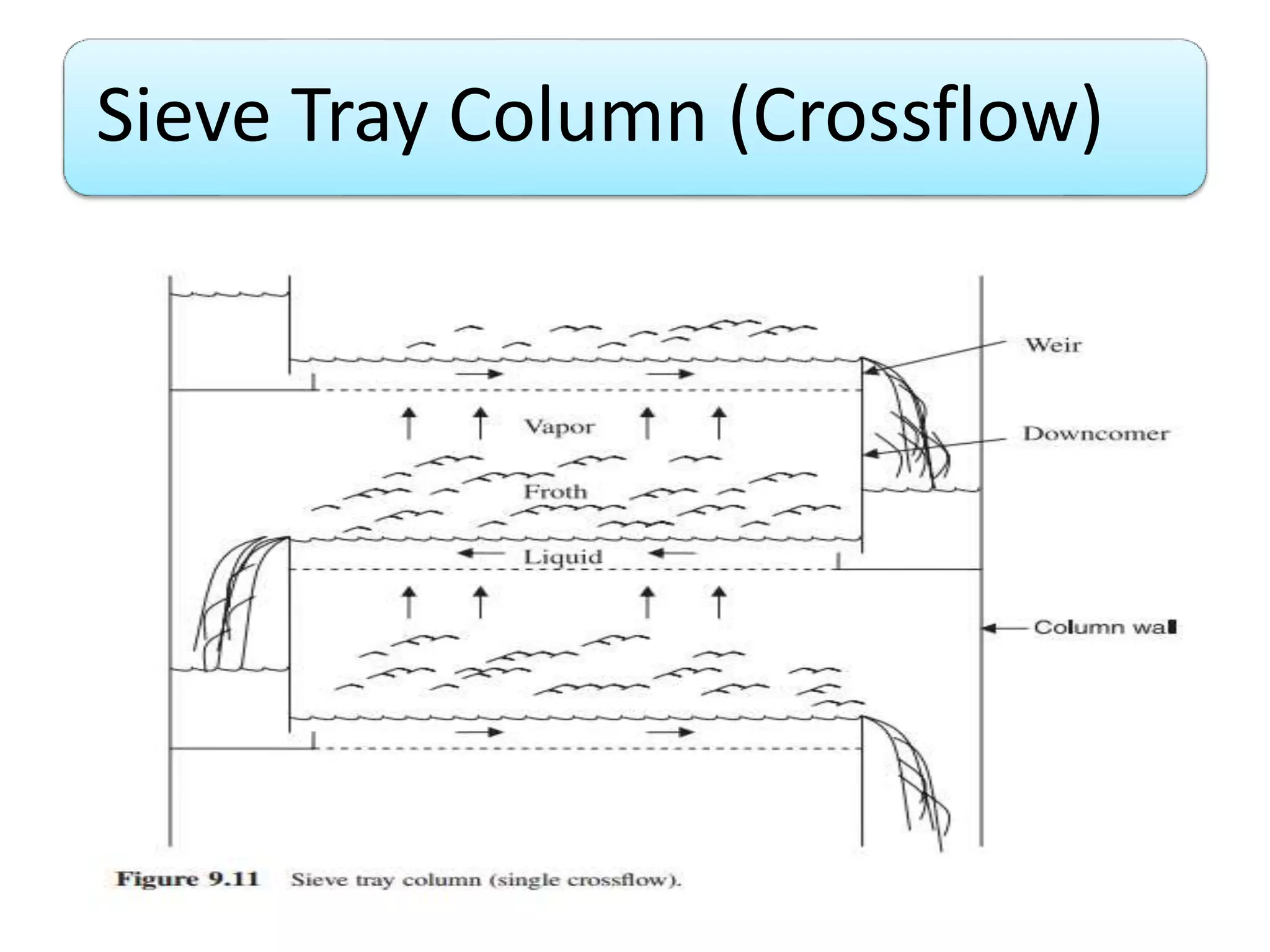

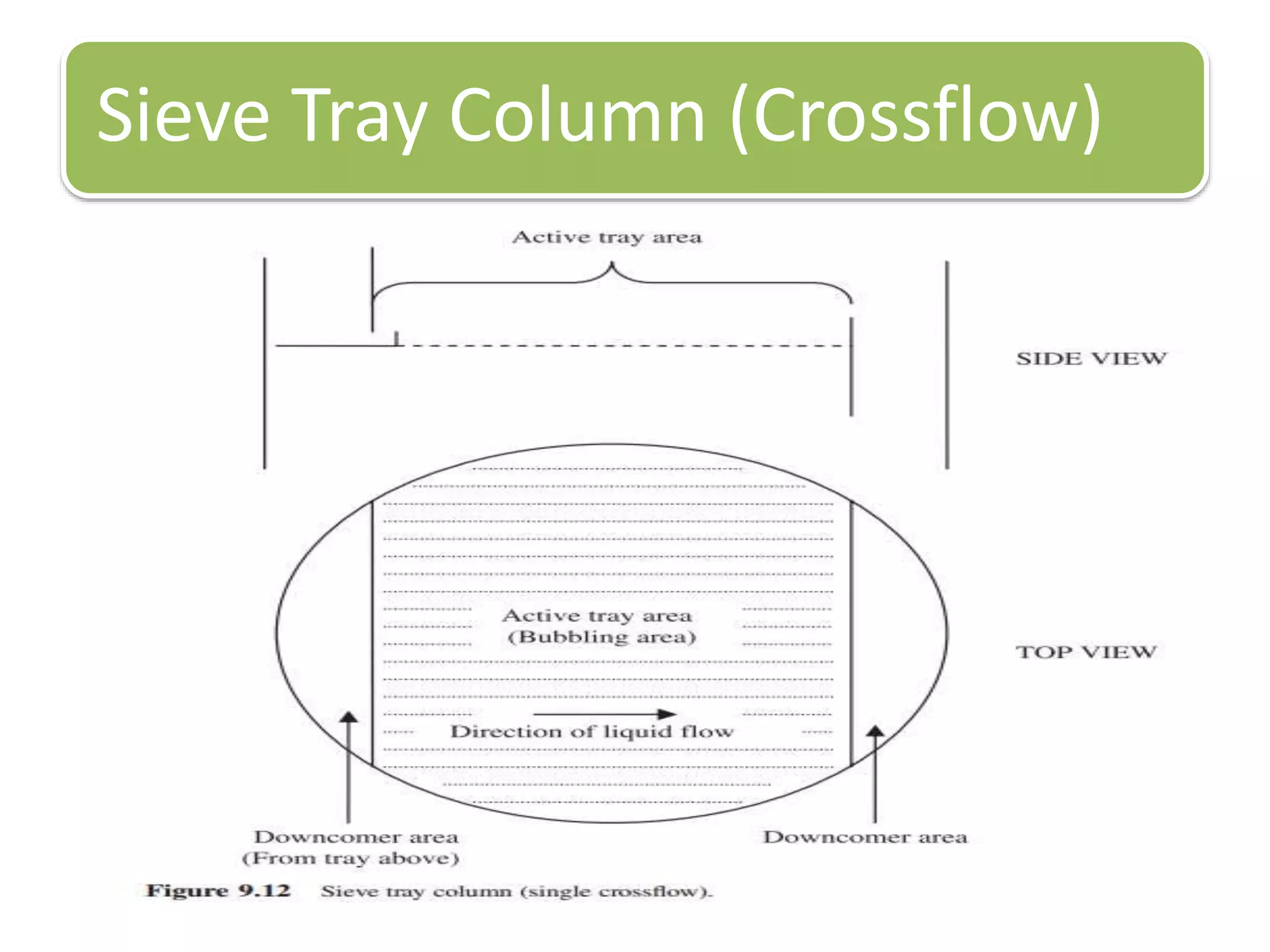

2) Common tray designs for distillation columns including bubble cap trays and sieve trays. Operation of these trays and factors influencing liquid-vapor contact are explained.

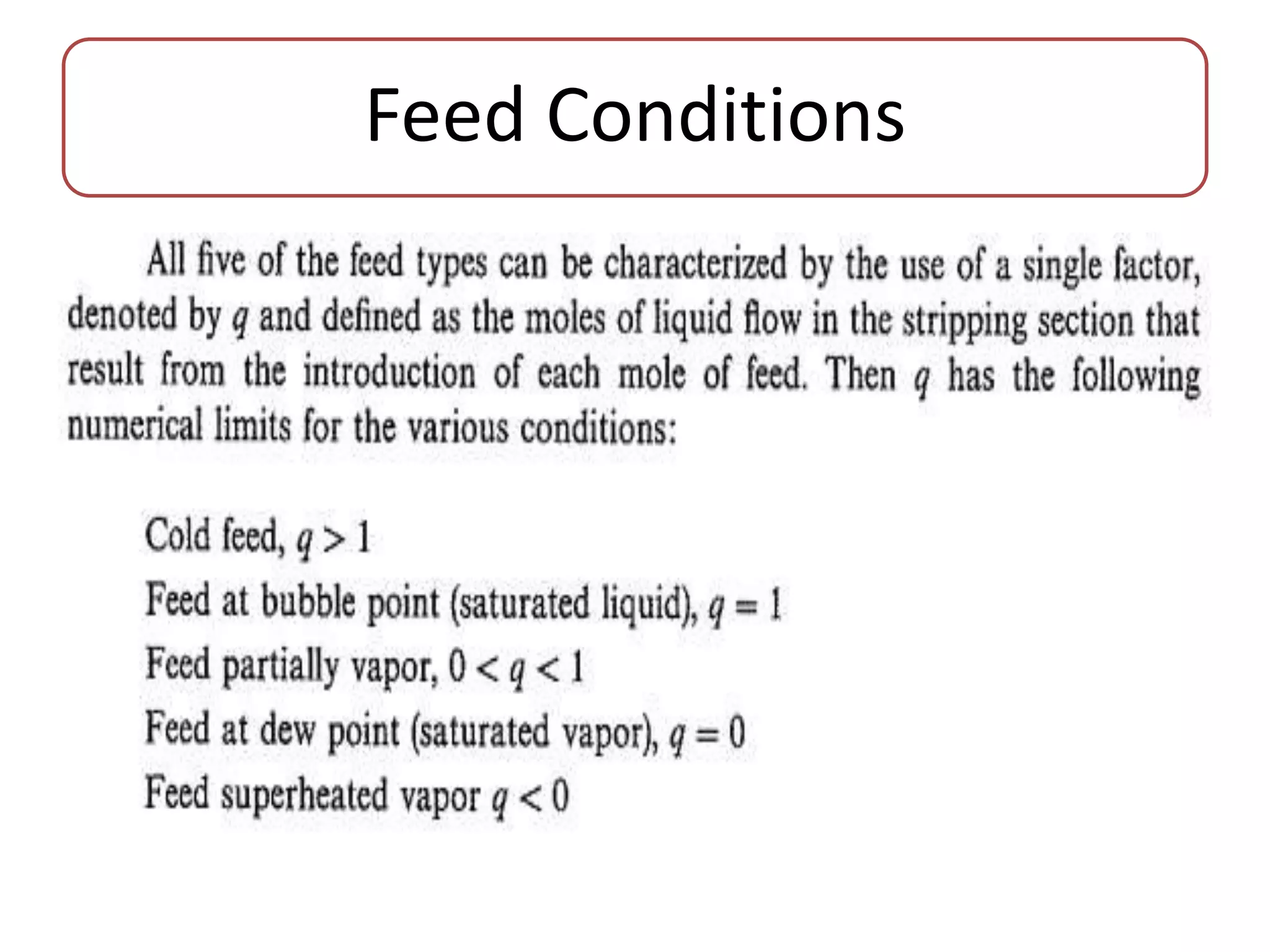

3) Operating parameters that can impact column performance are reviewed such as feed conditions, pressure drop across the column, flooding, weeping, entrainment, reboiler temperature control and vacuum maintenance. Column diameter is also noted as an important design factor.