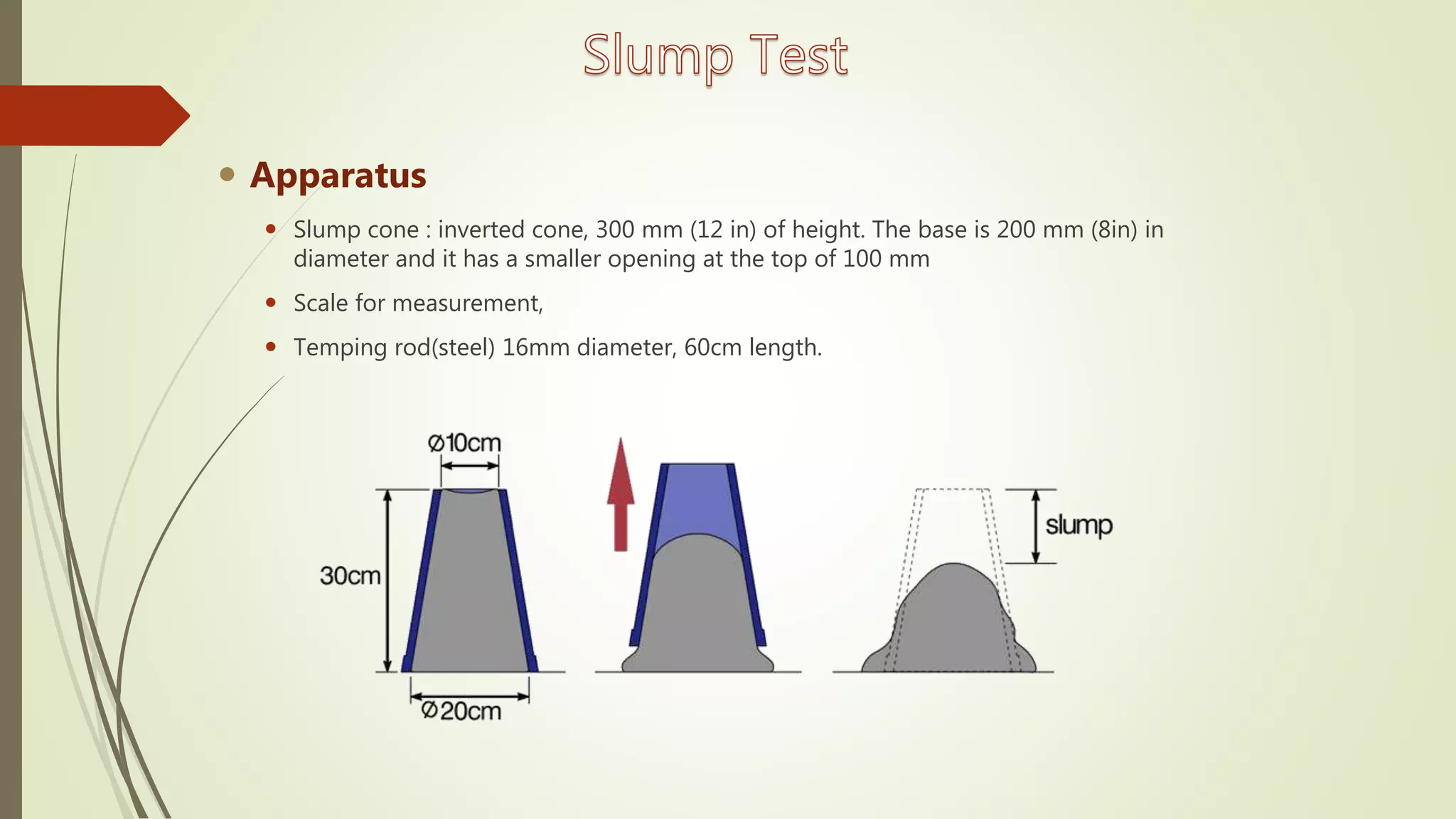

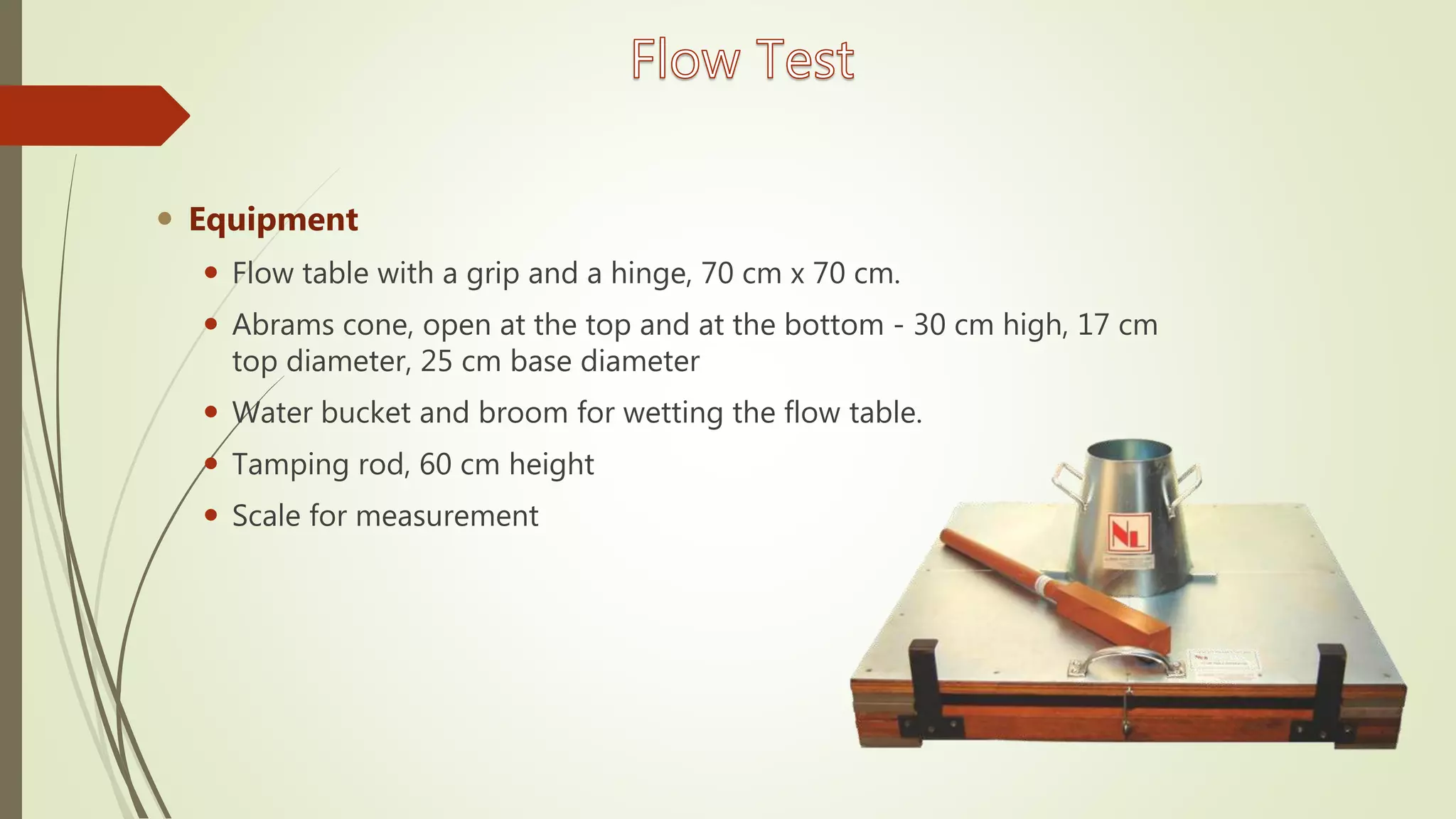

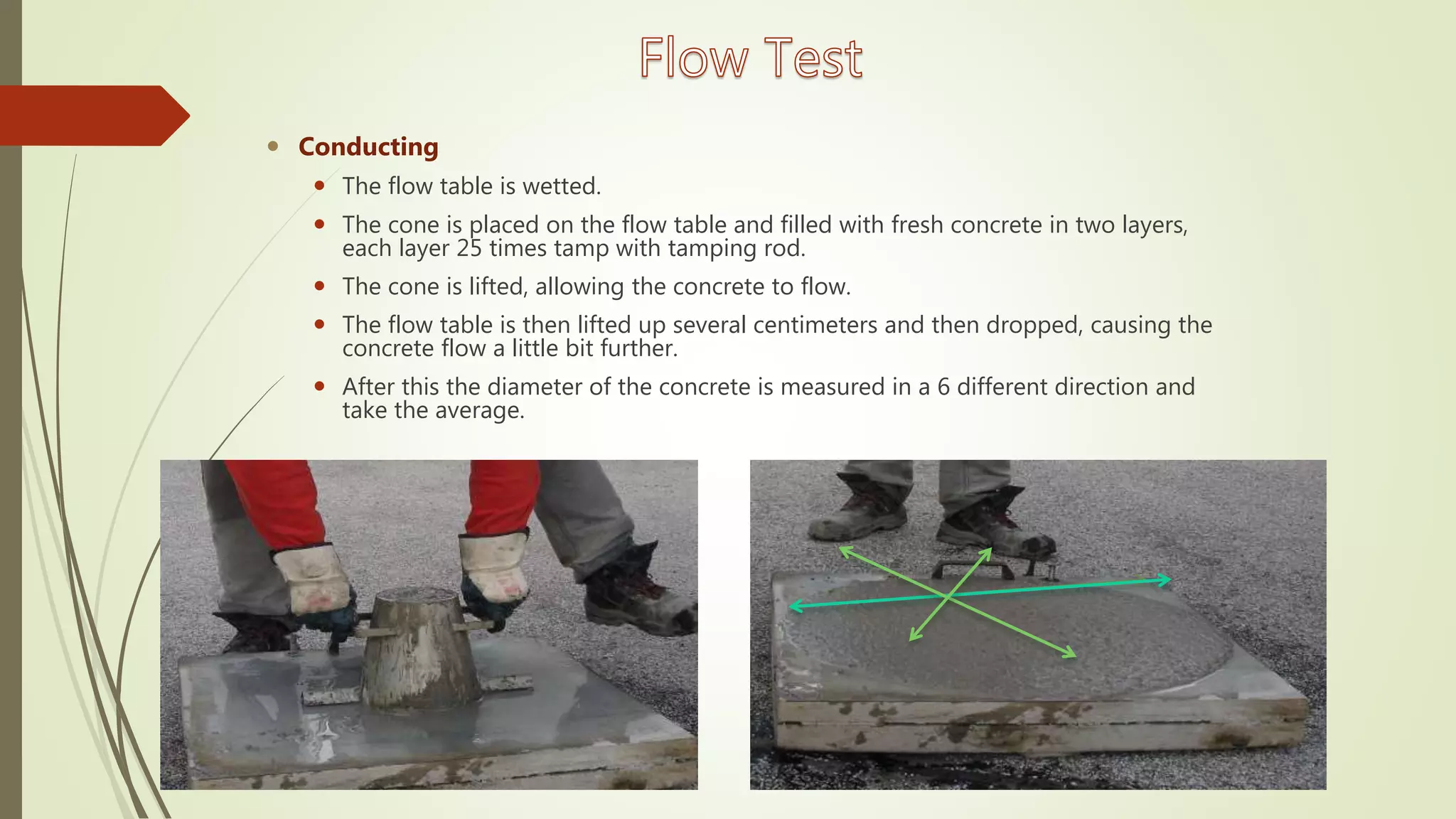

The document outlines various tests to assess the workability of concrete, including the slump test, compacting factor test, flow test, Kelly ball test, and Vebe test. Each test has specific procedures, apparatus, and definitions that assess the consistency and quality of concrete, crucial for ensuring the desired strength and performance in construction. Additionally, it discusses the implications of different slump types and the significance of proper testing methodology in evaluating concrete's readiness for use.