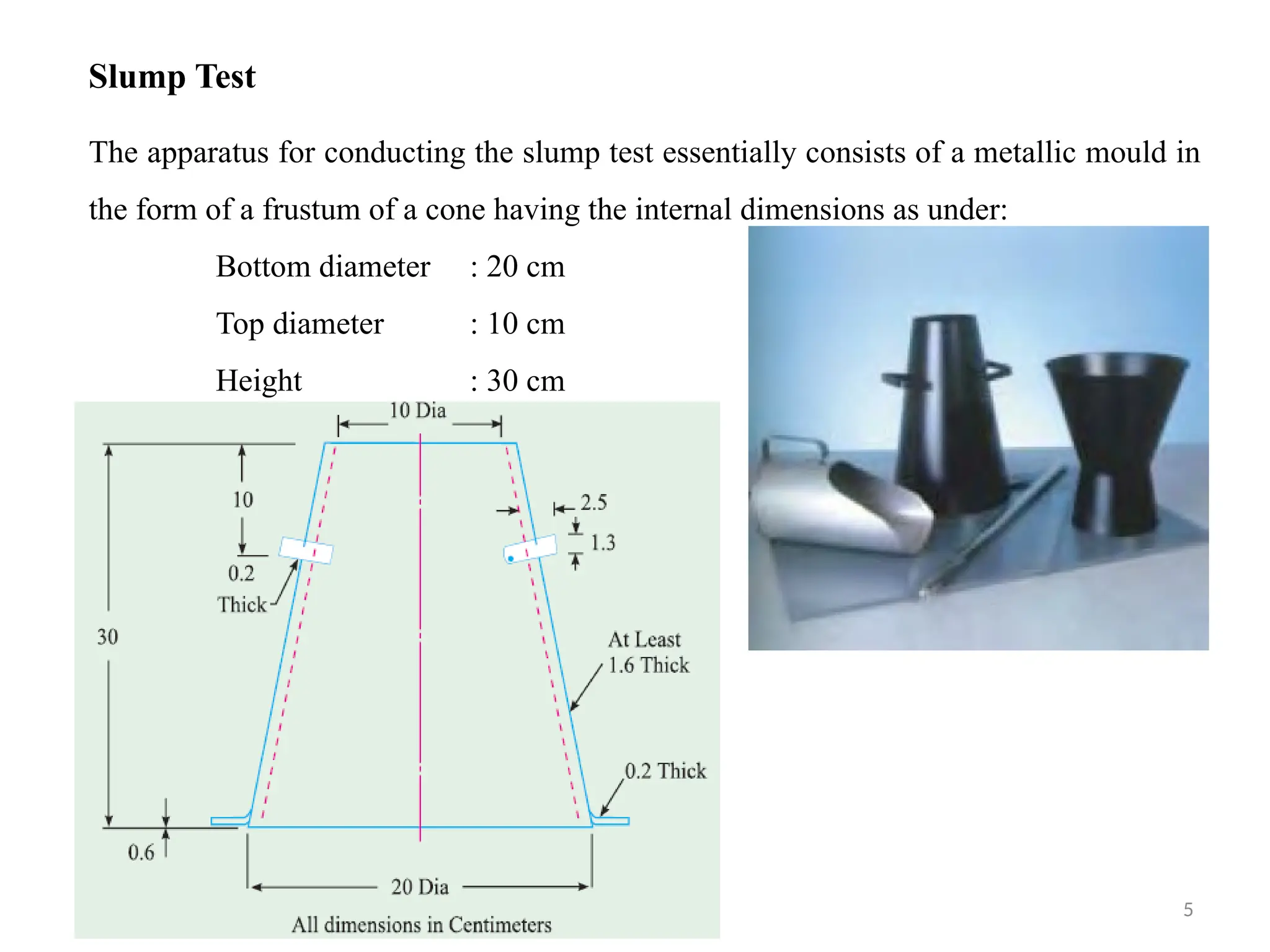

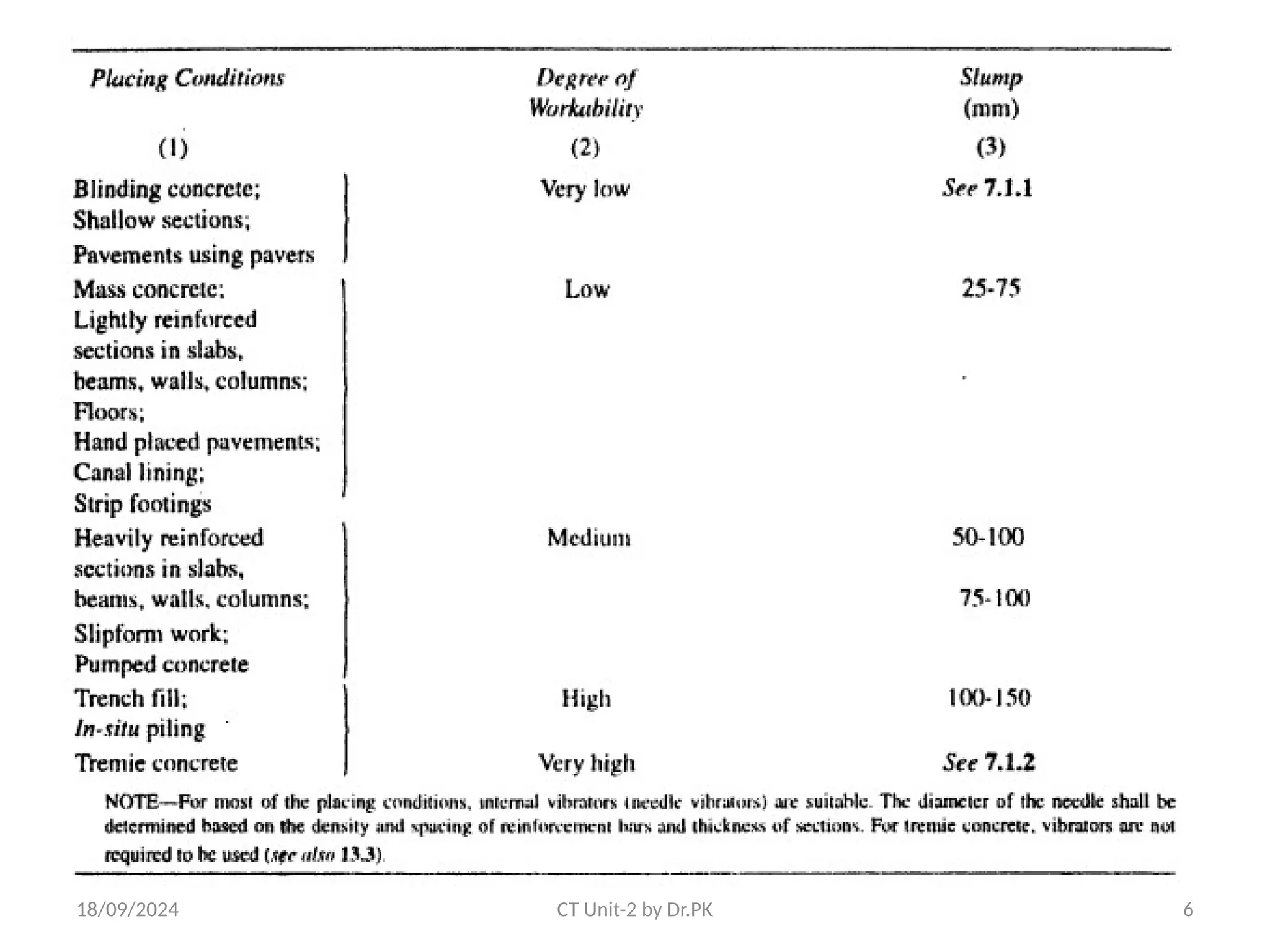

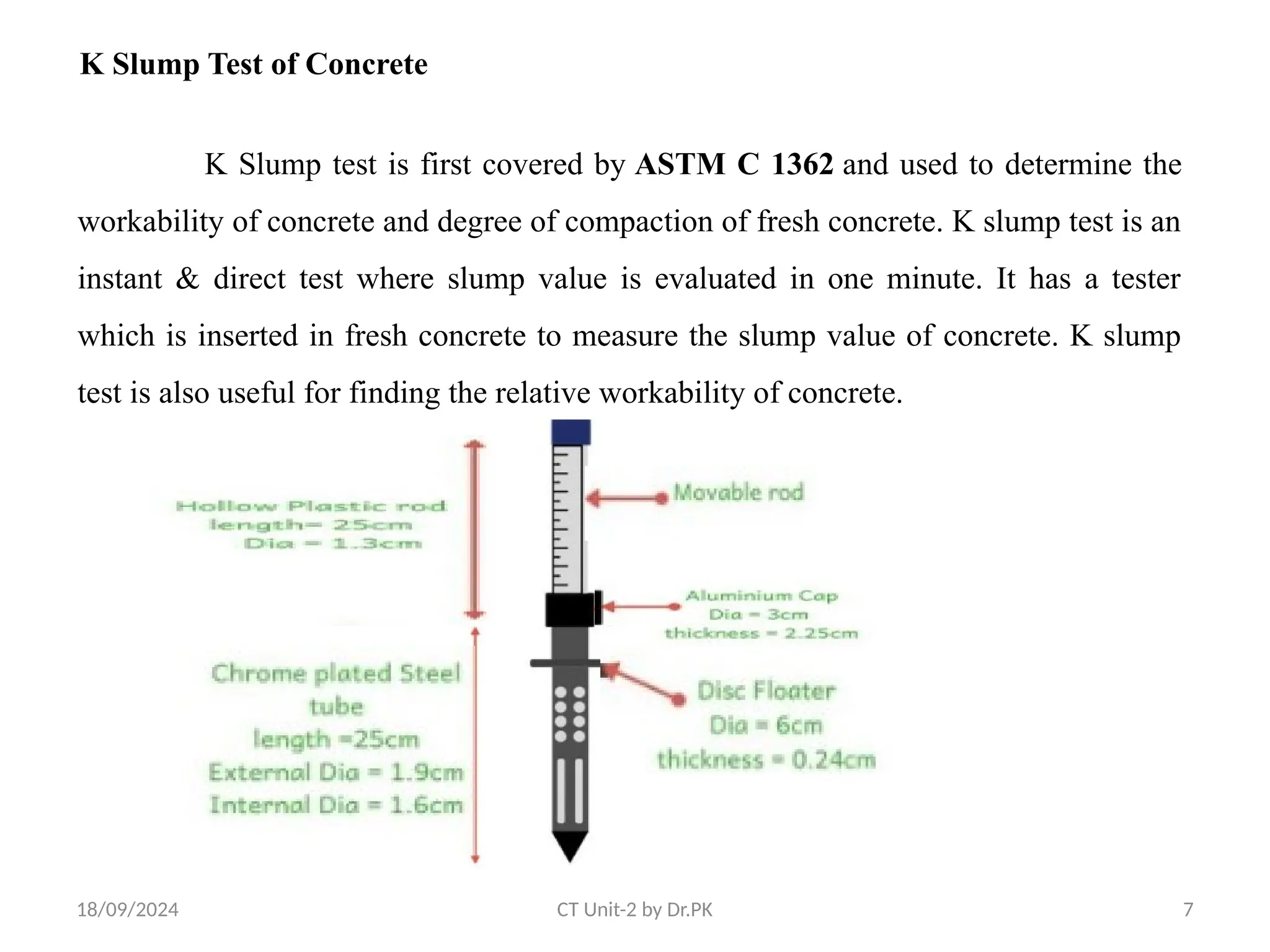

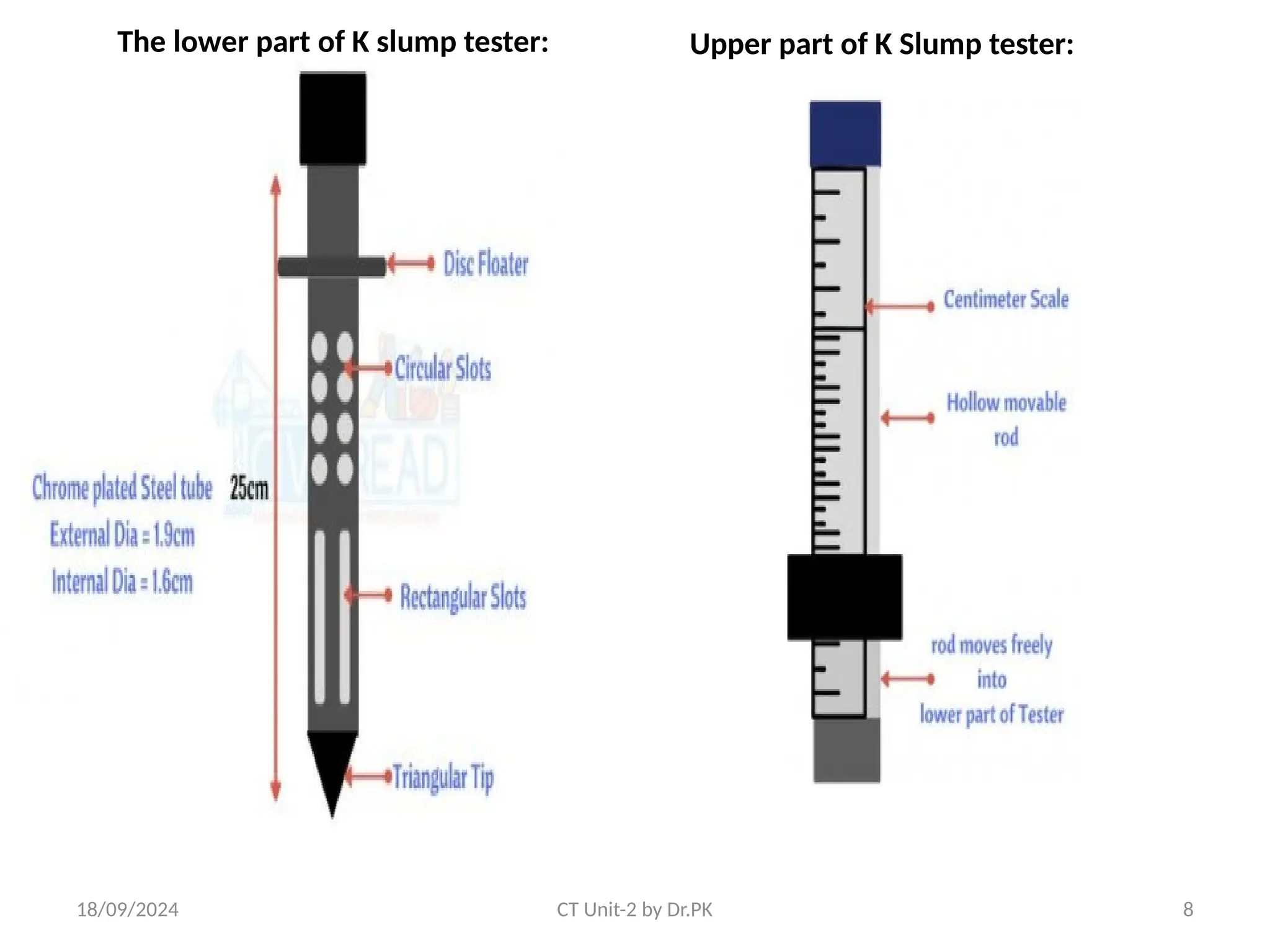

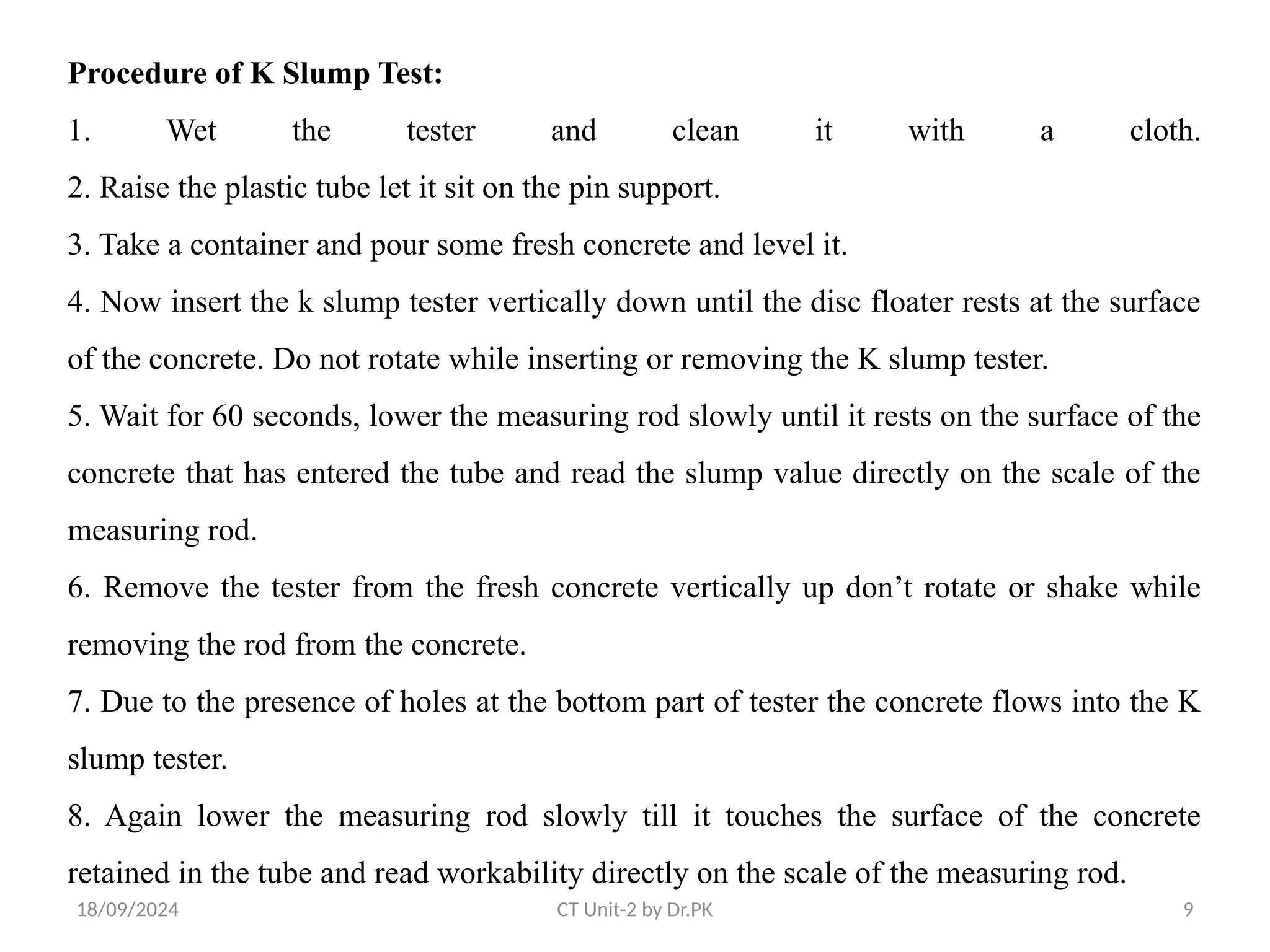

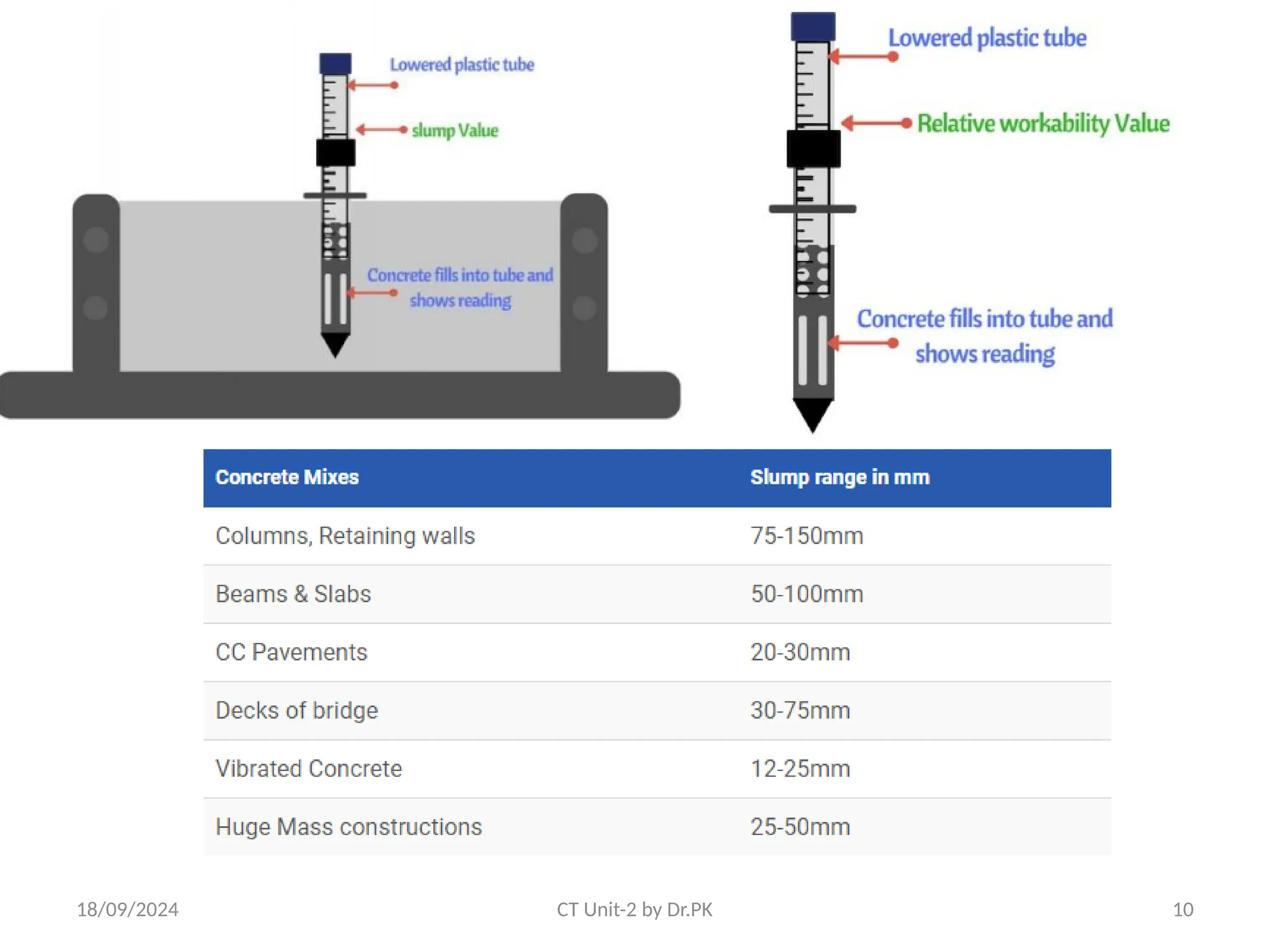

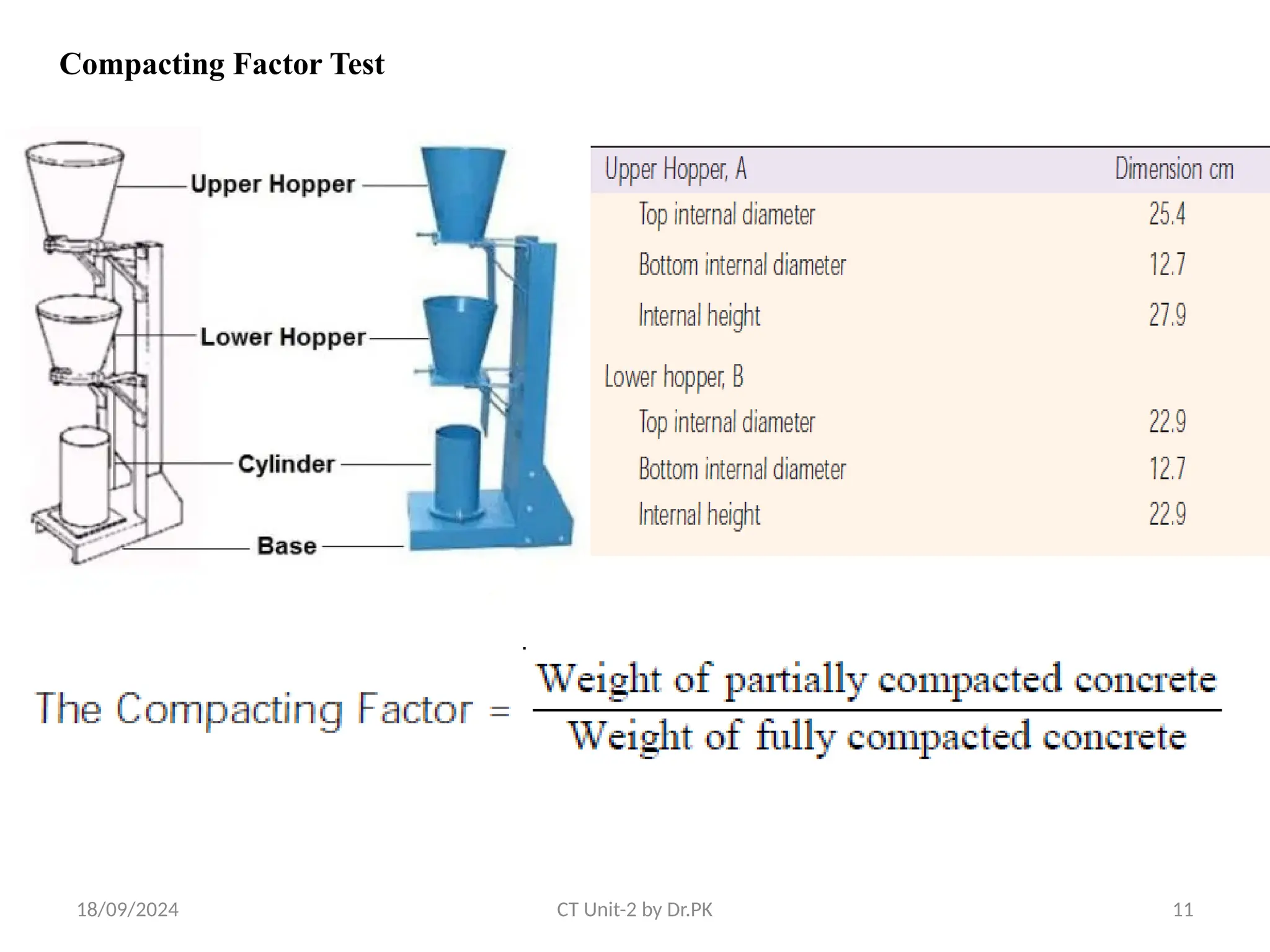

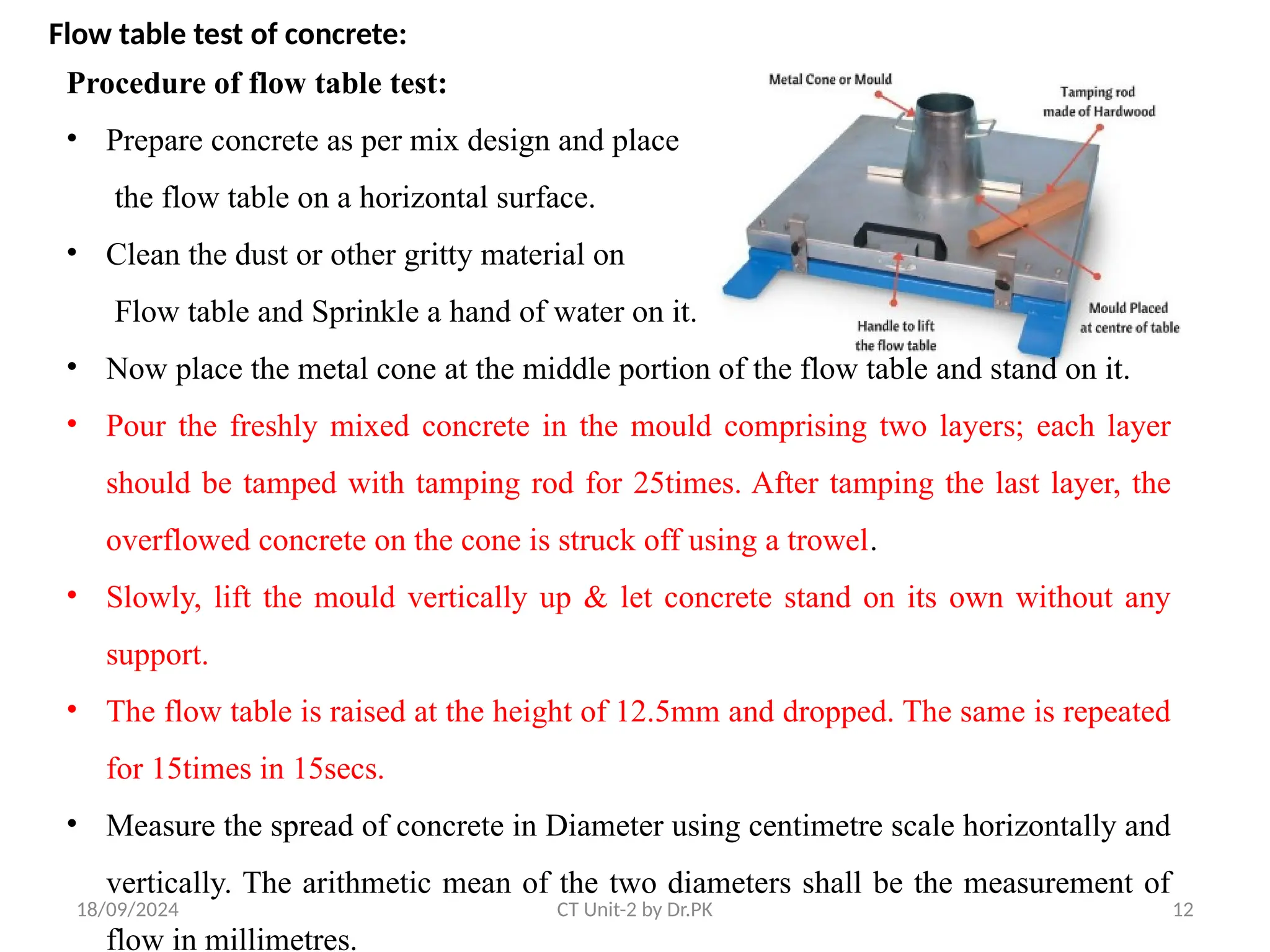

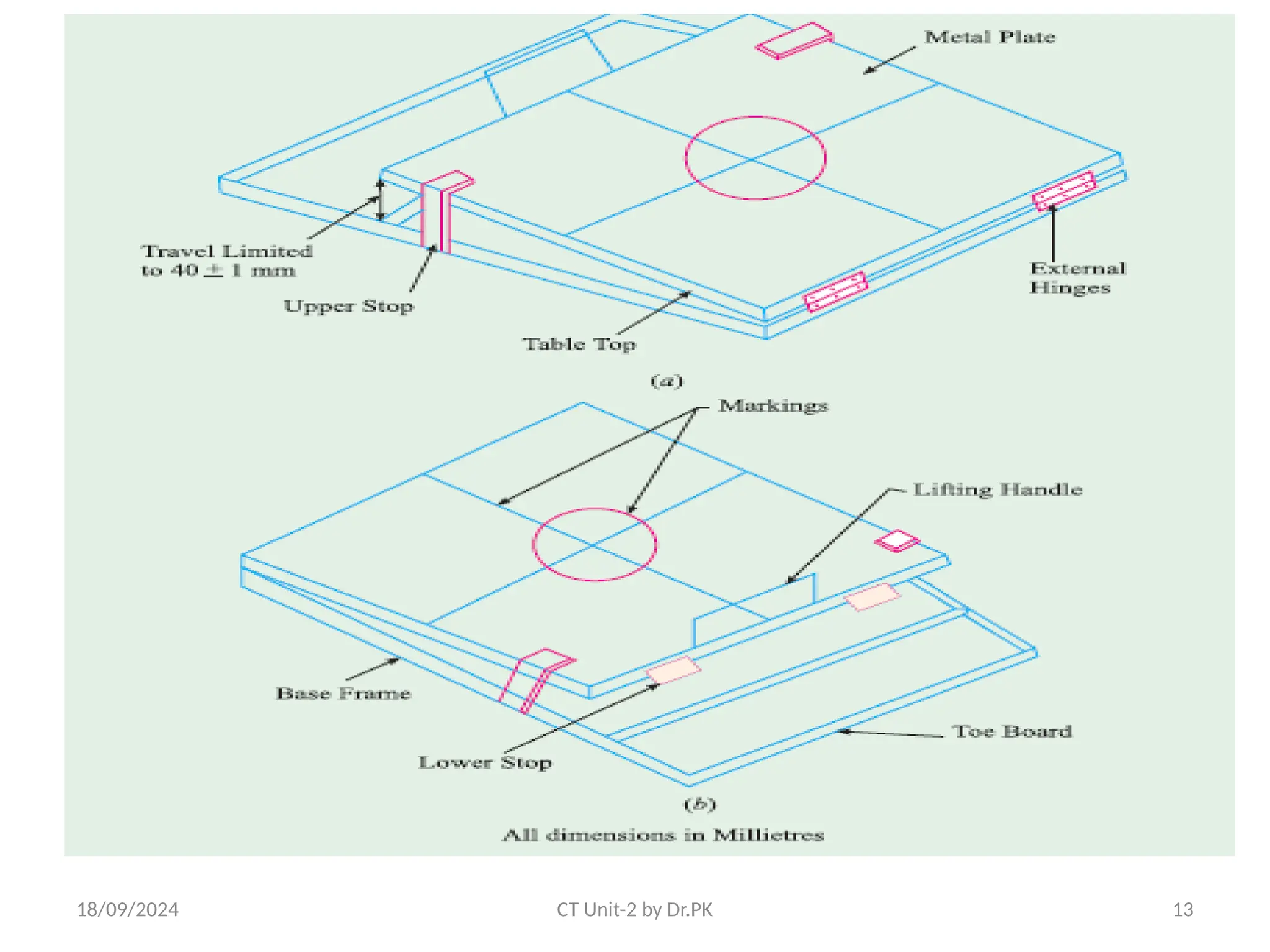

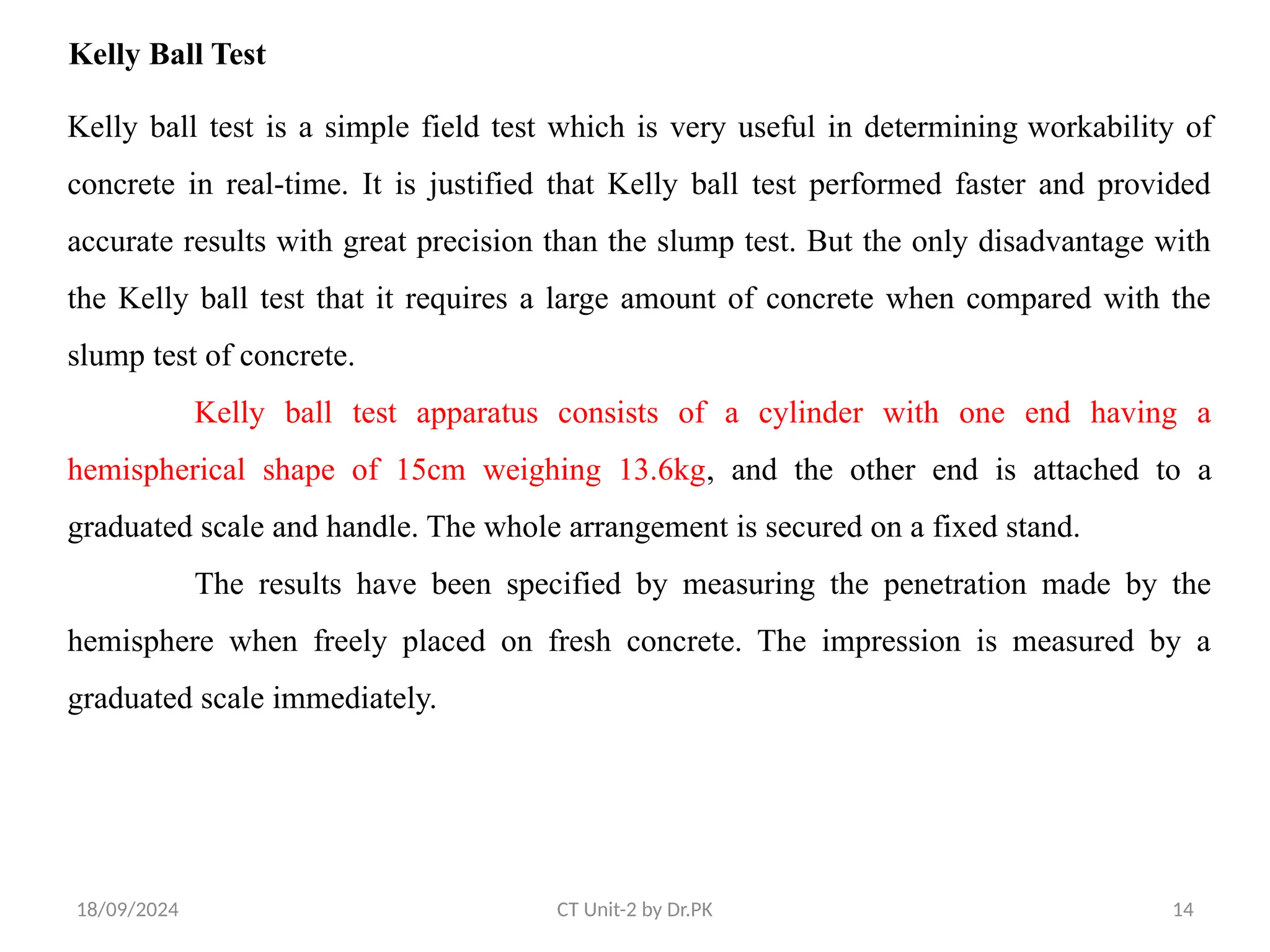

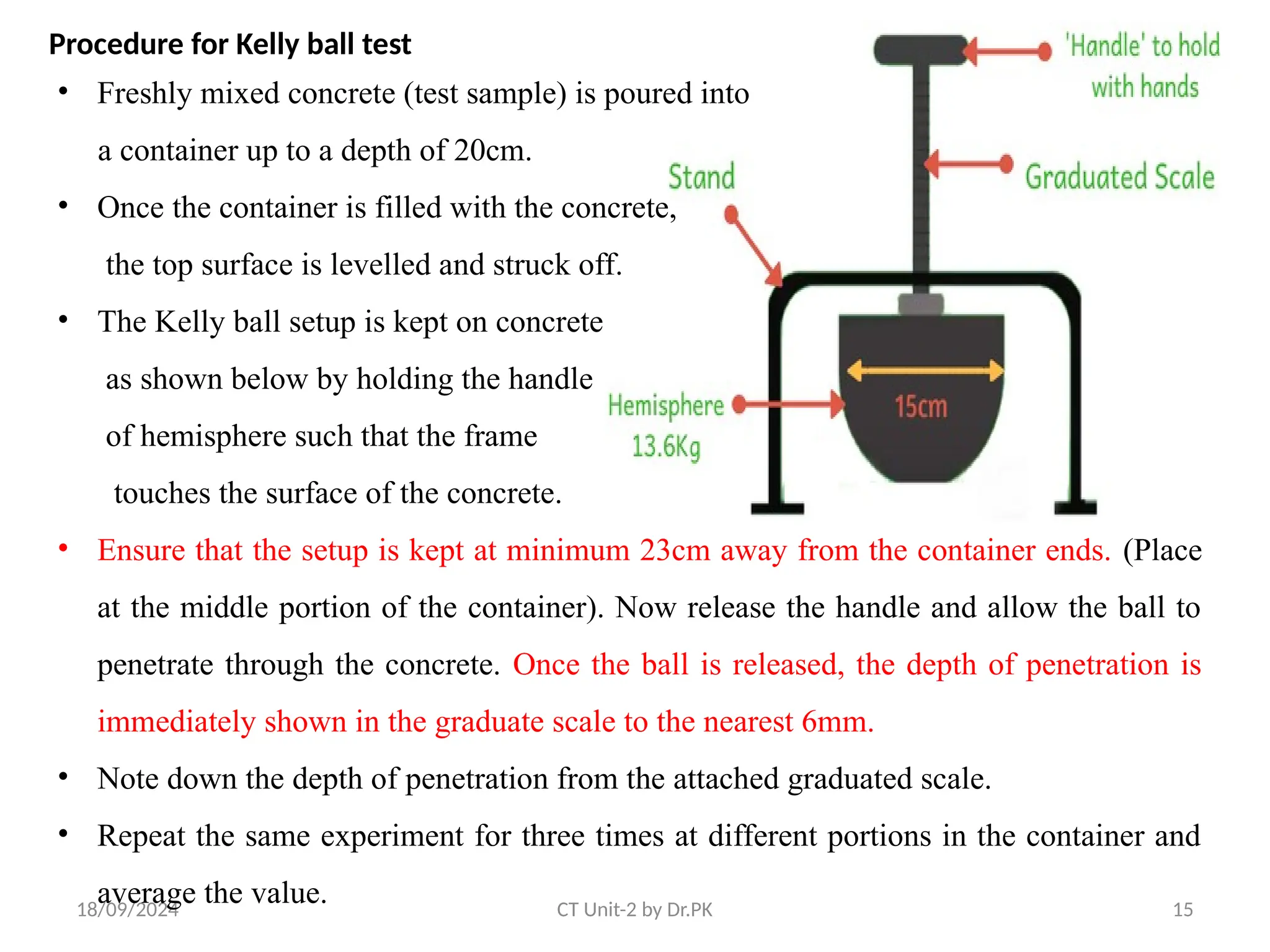

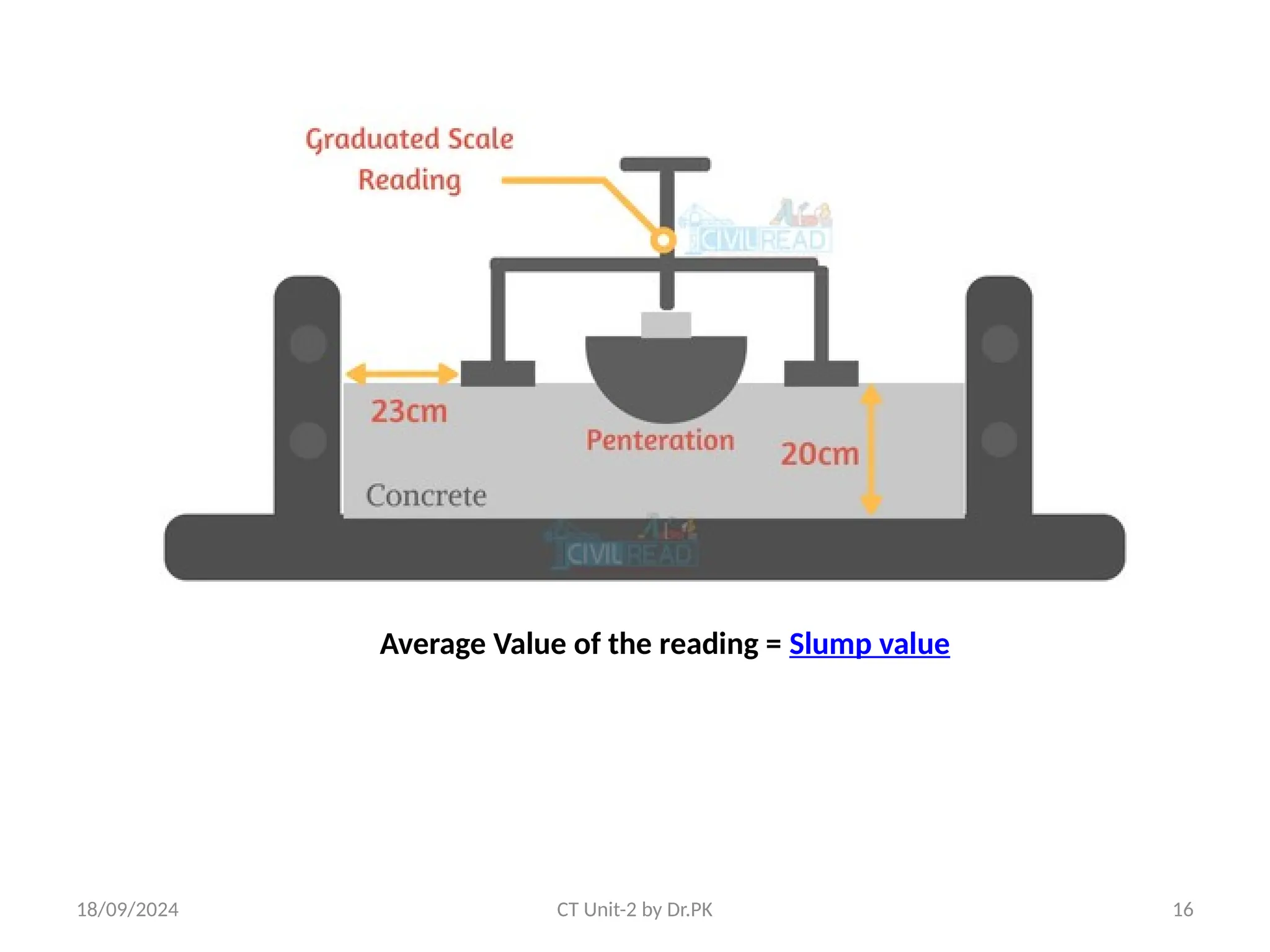

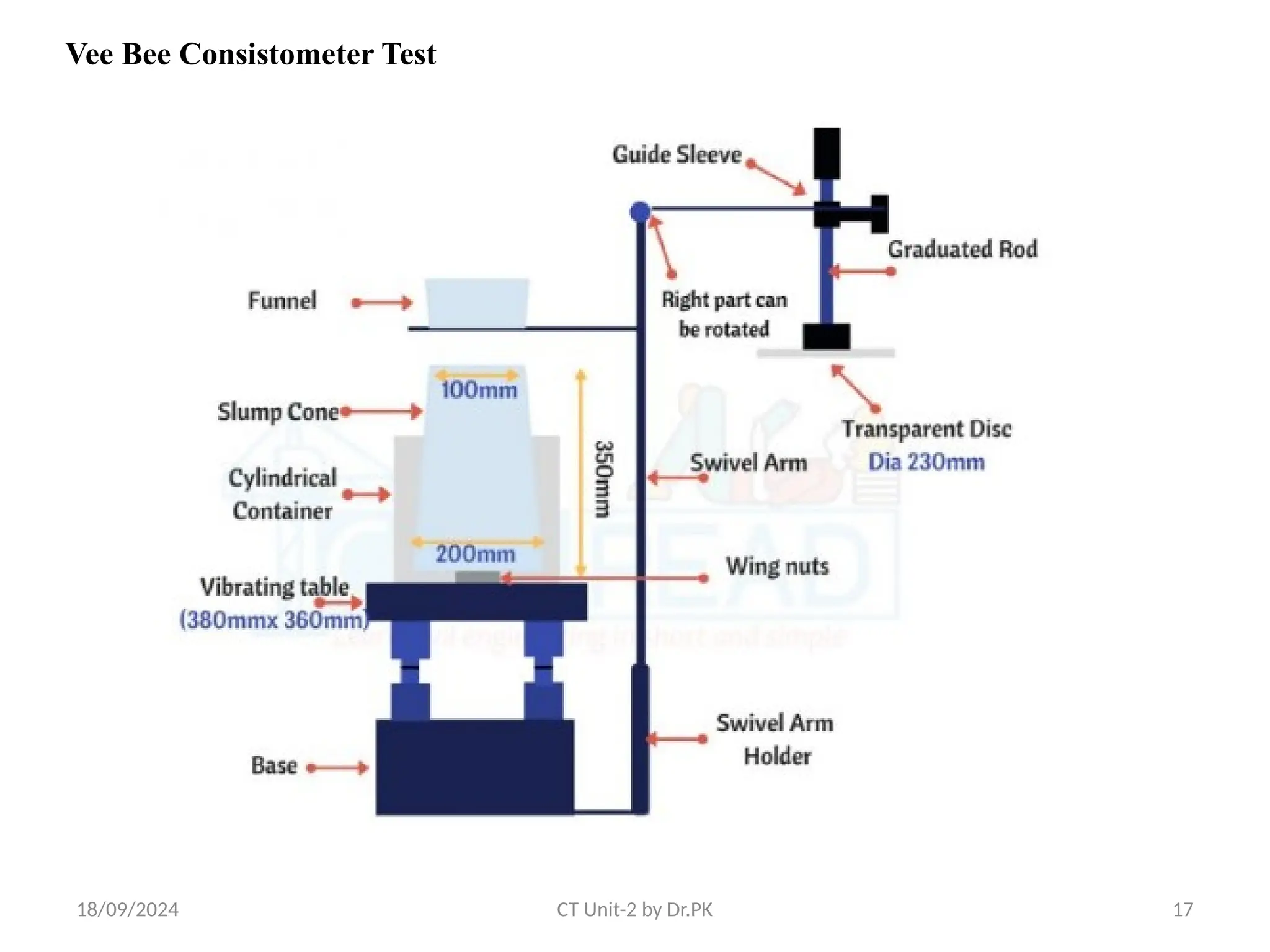

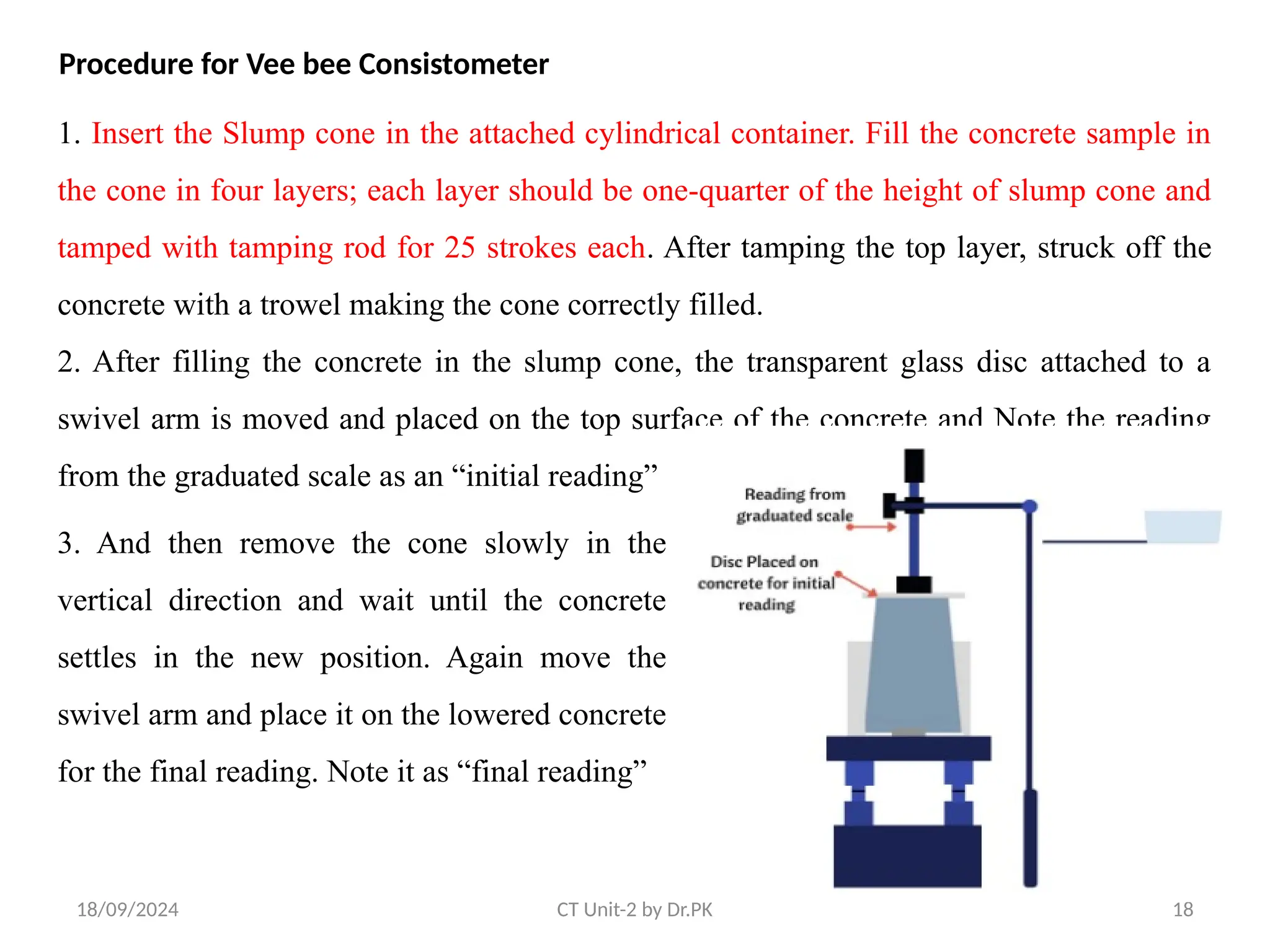

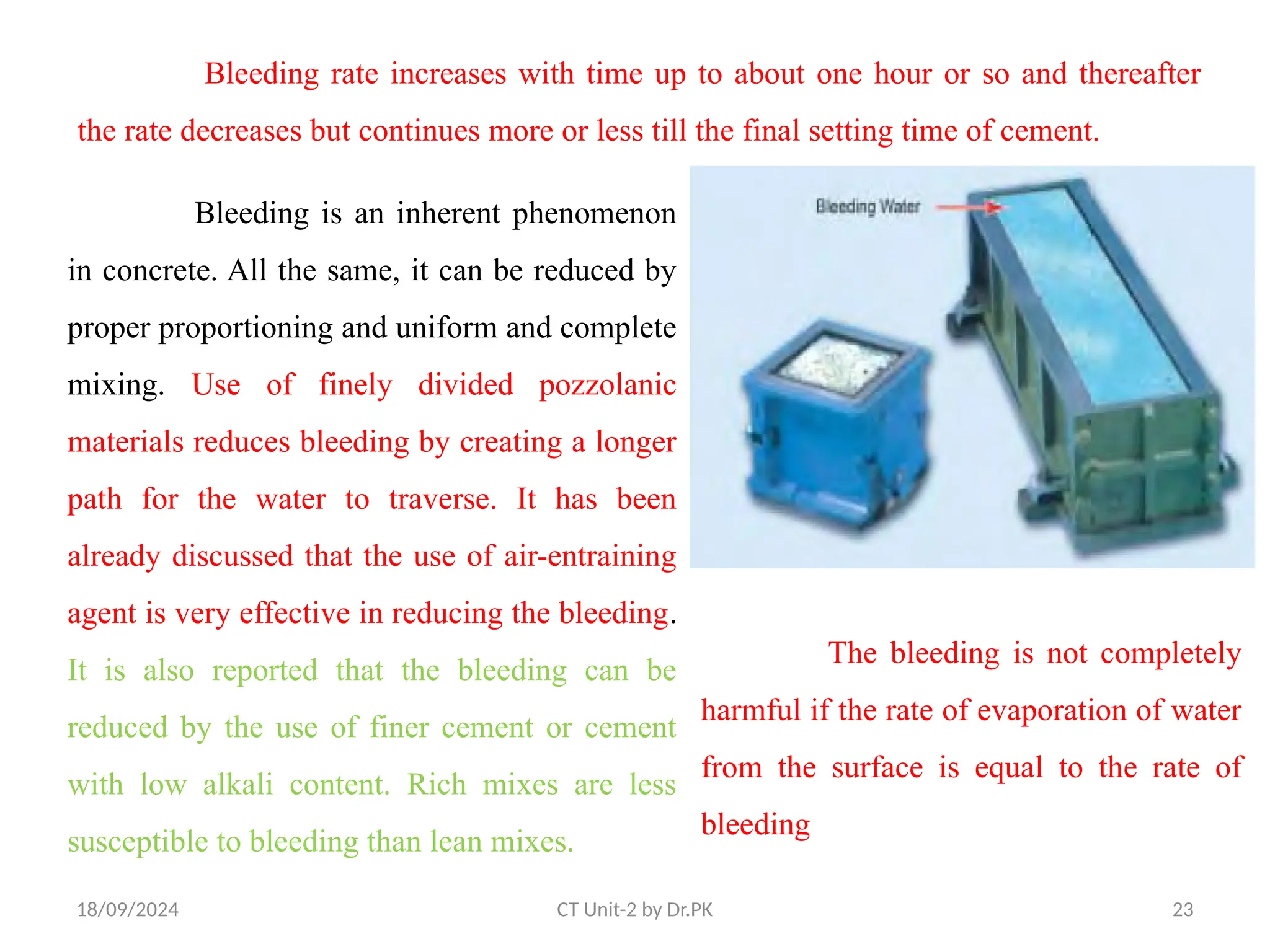

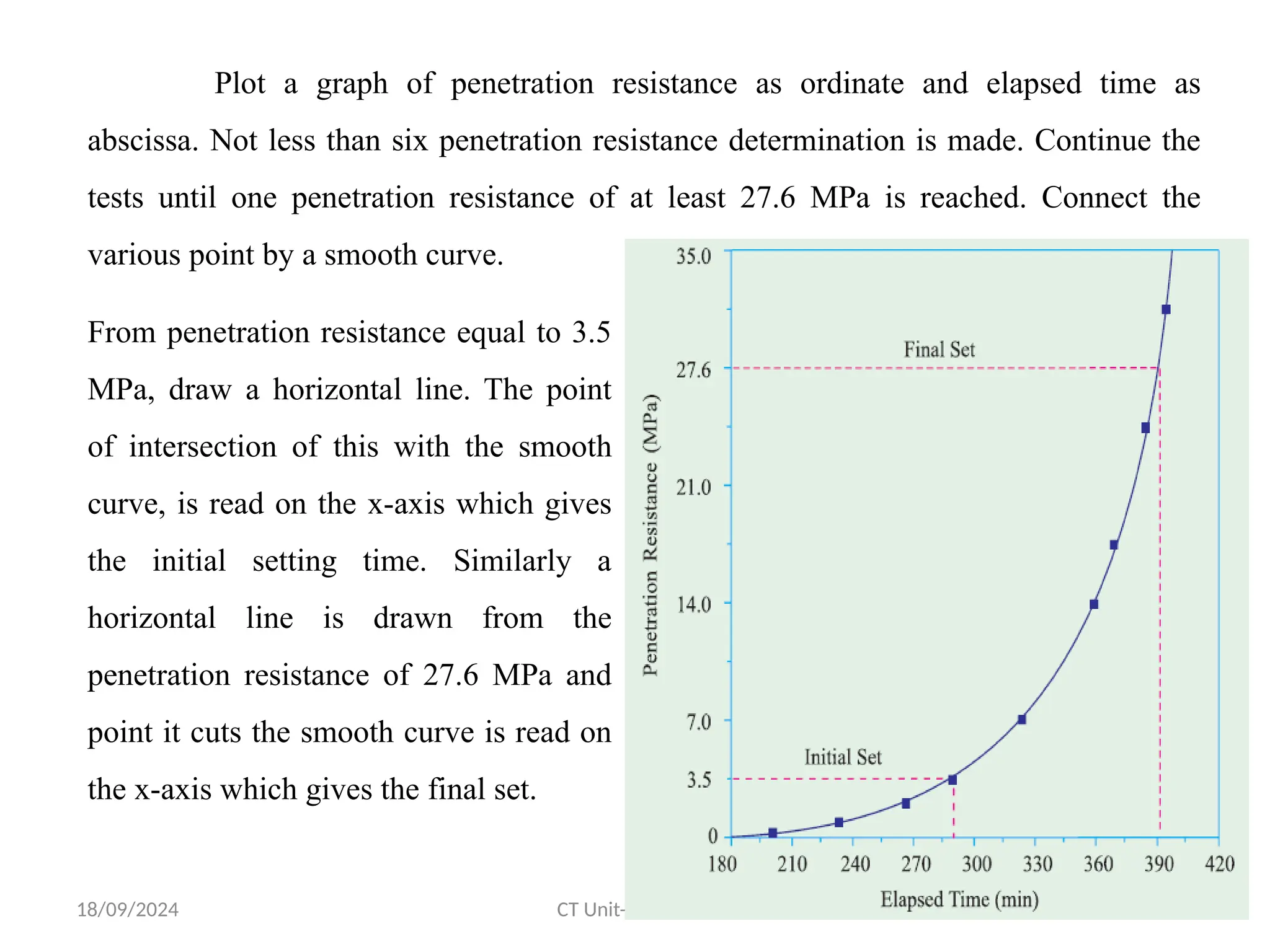

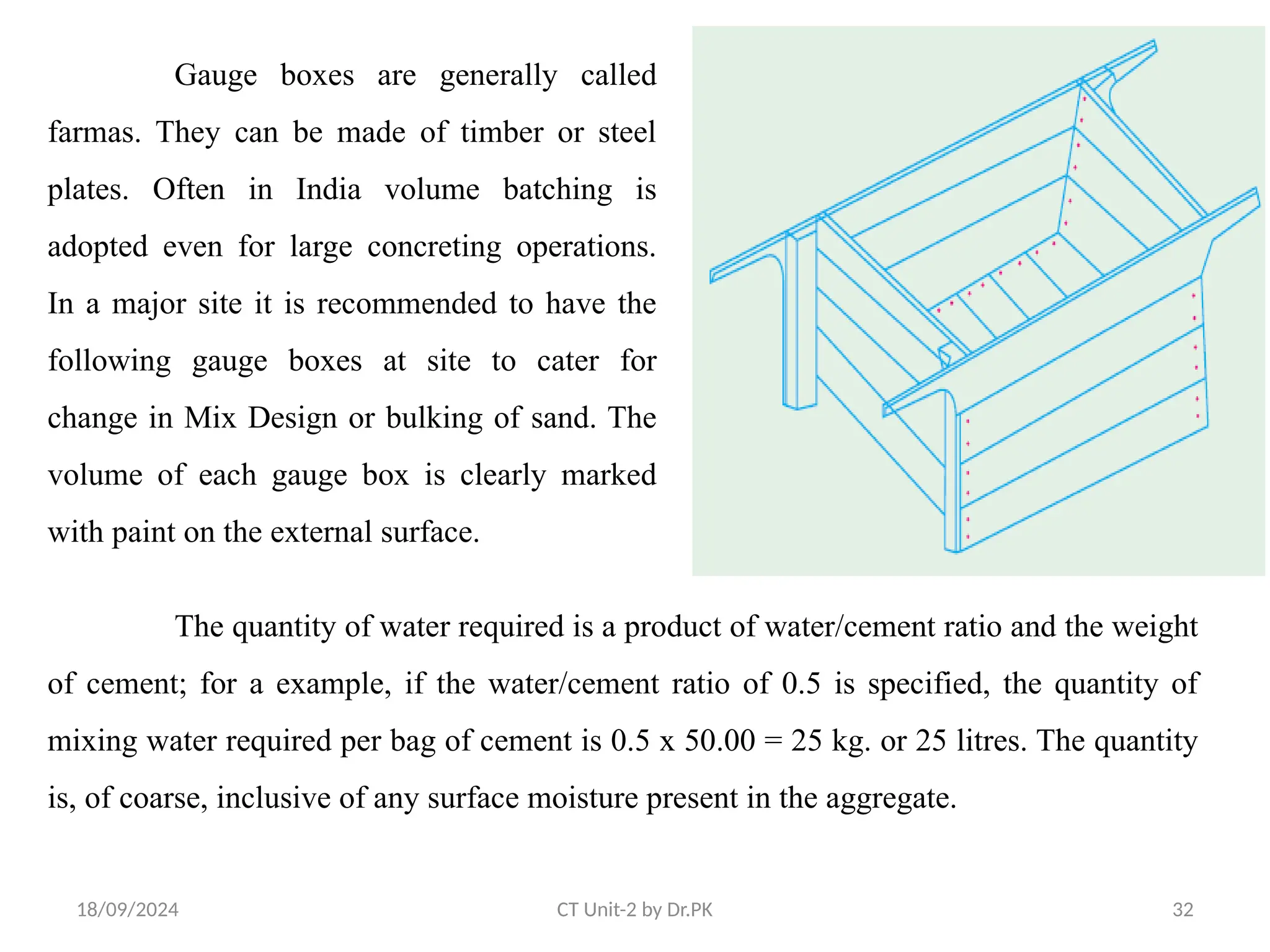

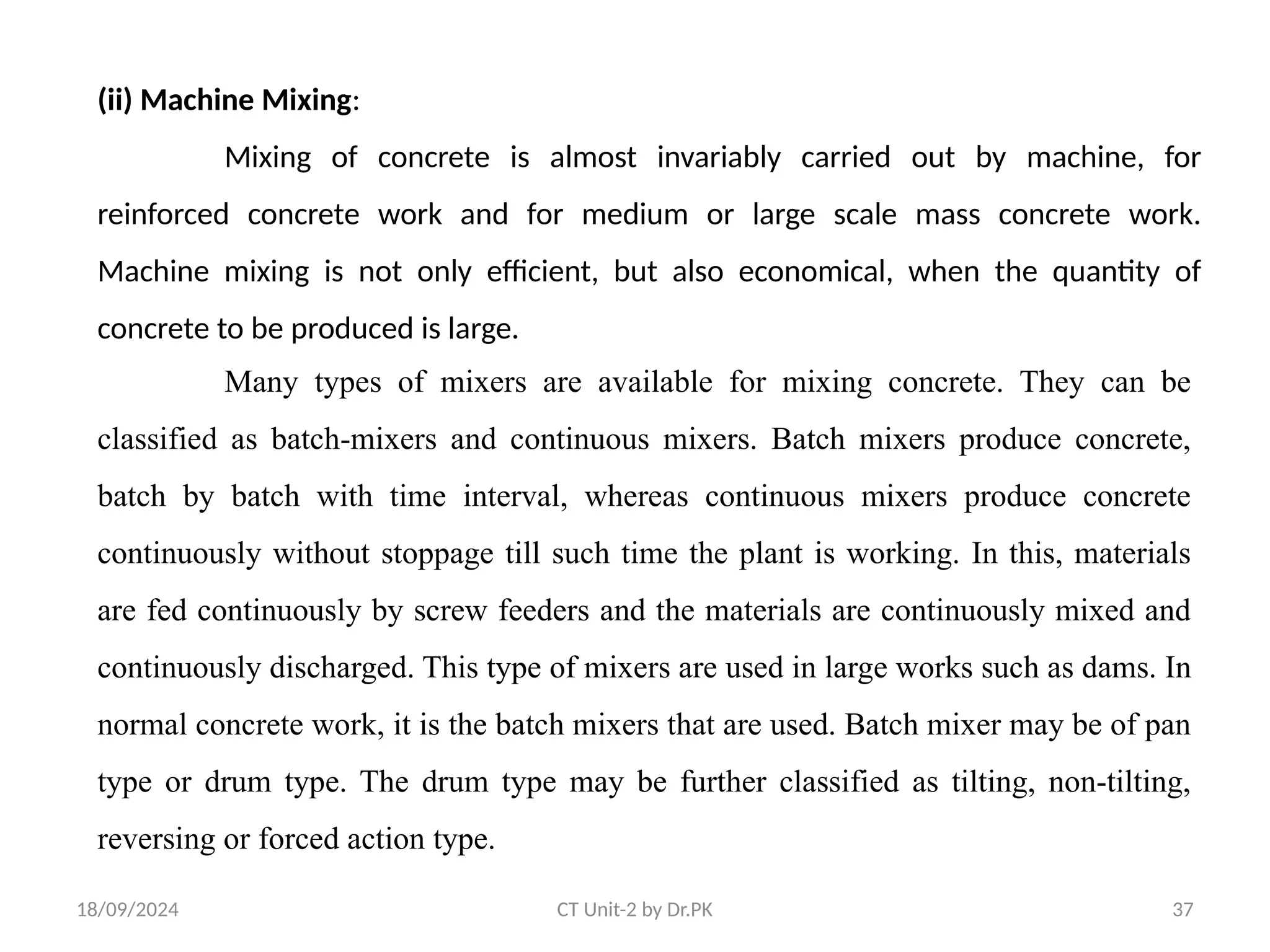

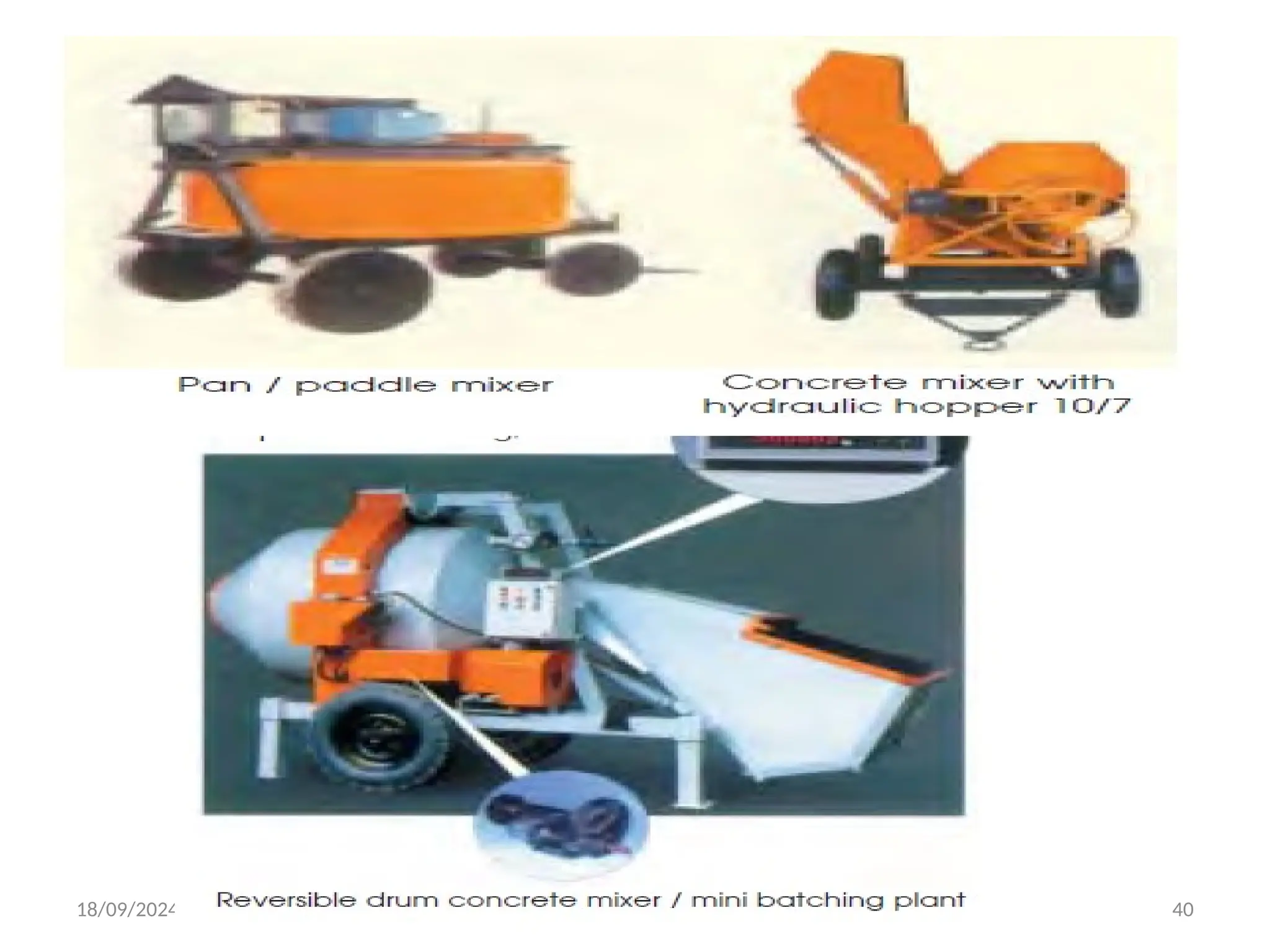

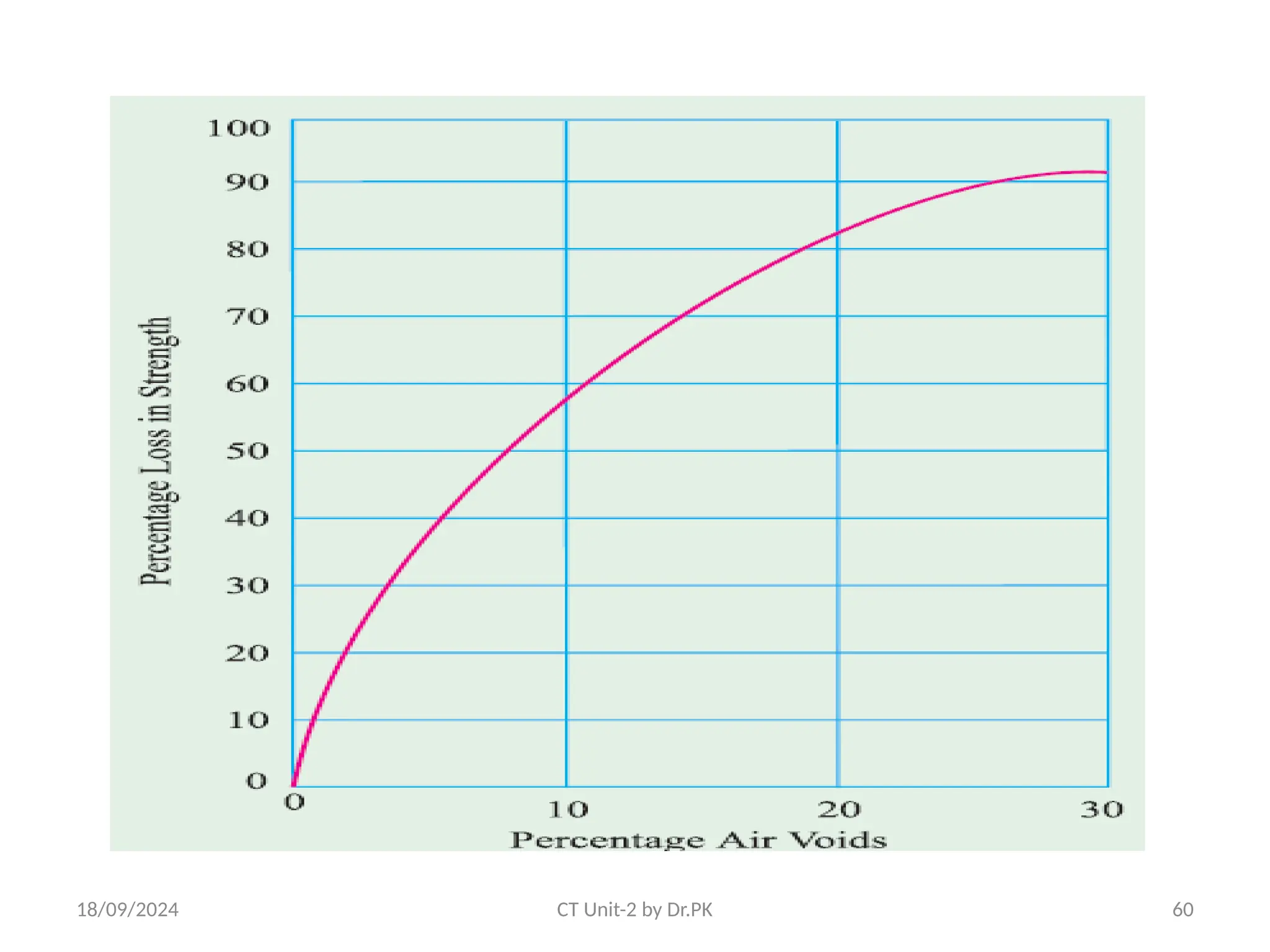

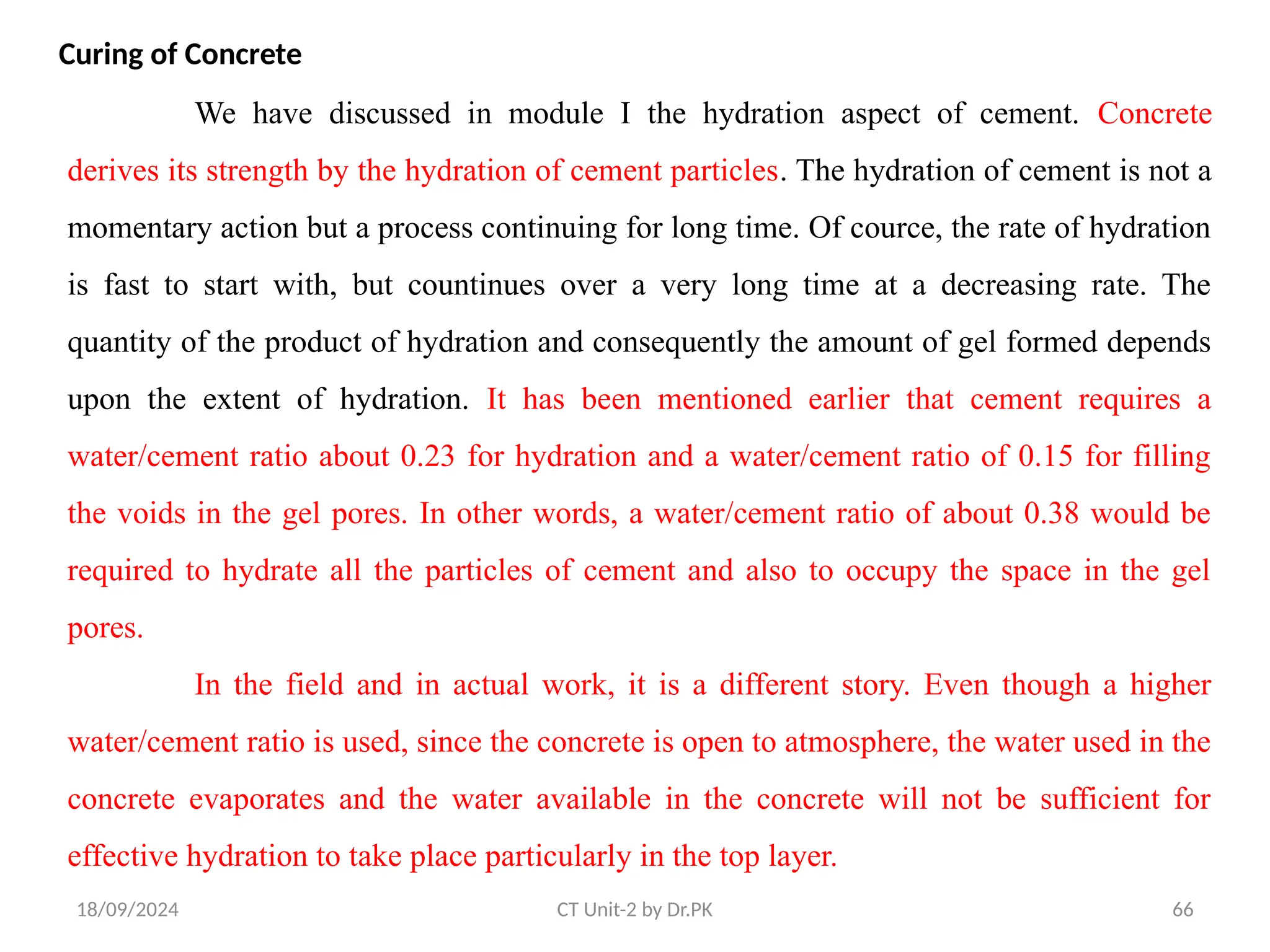

The document discusses the properties, workability, and various tests for fresh concrete, emphasizing the importance of the water/cement ratio, factors influencing workability, and methods to evaluate it. Different tests such as the slump test, compacting factor test, Kelly ball test, and Vee Bee consistometer test are detailed, each illustrating how to assess the consistency and segregation of concrete. Additionally, the document addresses issues like bleeding and setting times, highlighting the significance of careful manufacturing processes to ensure high-quality concrete.