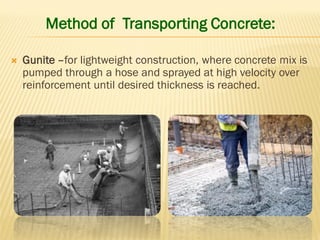

This document discusses concrete, its composition, properties, and testing methods. It highlights concrete's advantages, workability, and issues such as segregation and bleeding, alongside essential tests like the slump test to determine consistency. Additionally, it delves into factors affecting concrete quality and presents the importance of proper mix proportions and handling for optimal strength and durability.