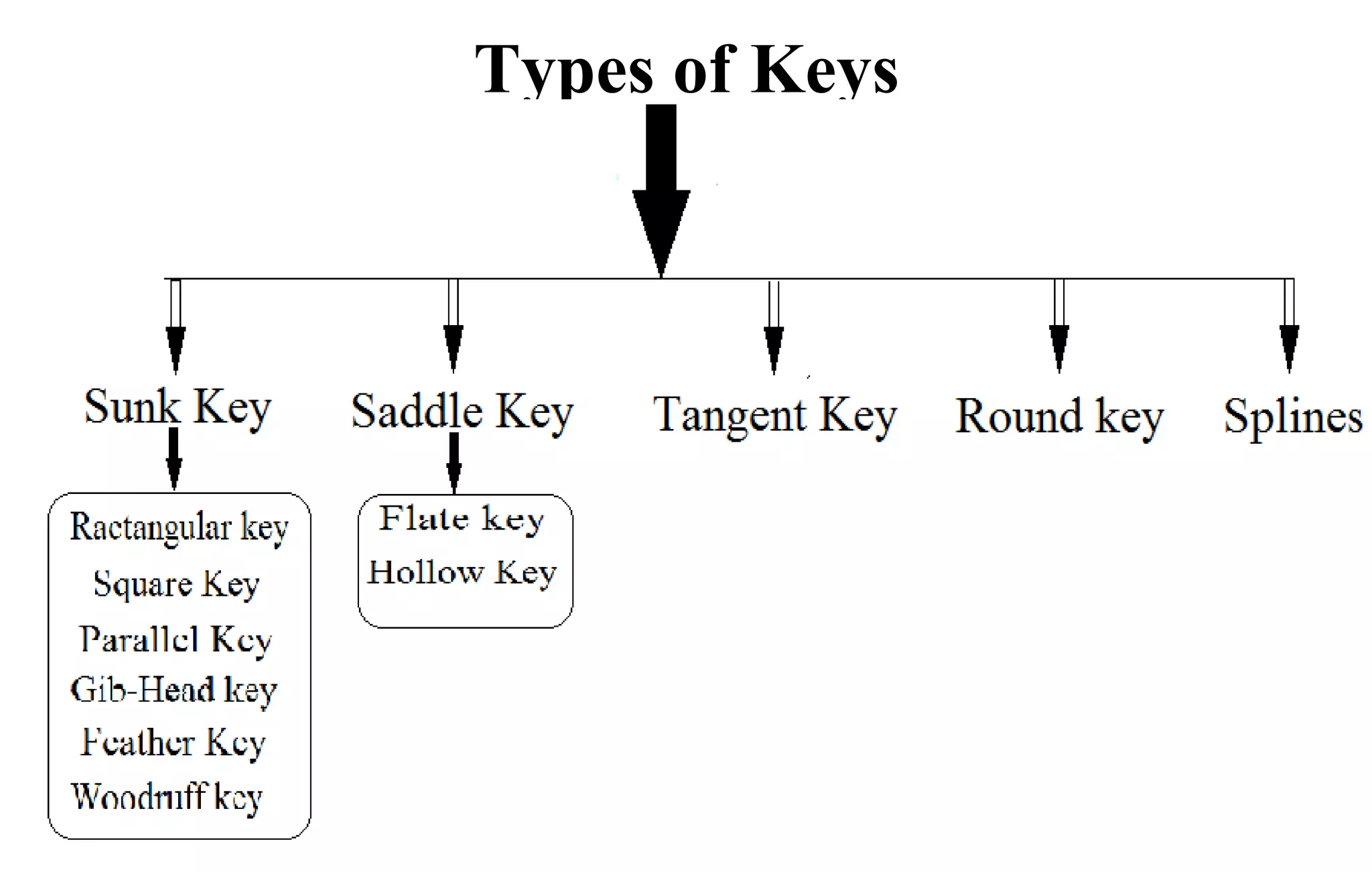

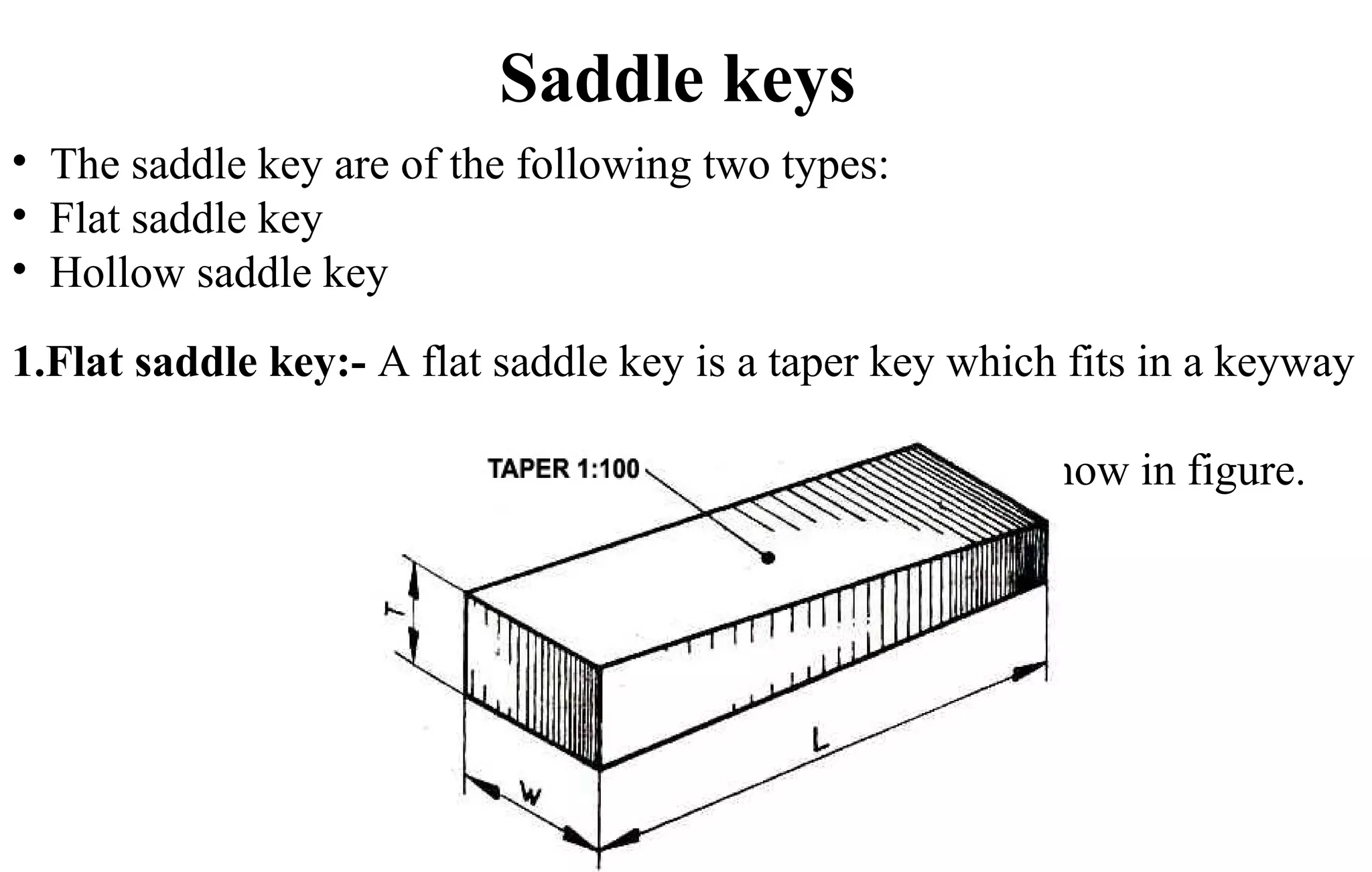

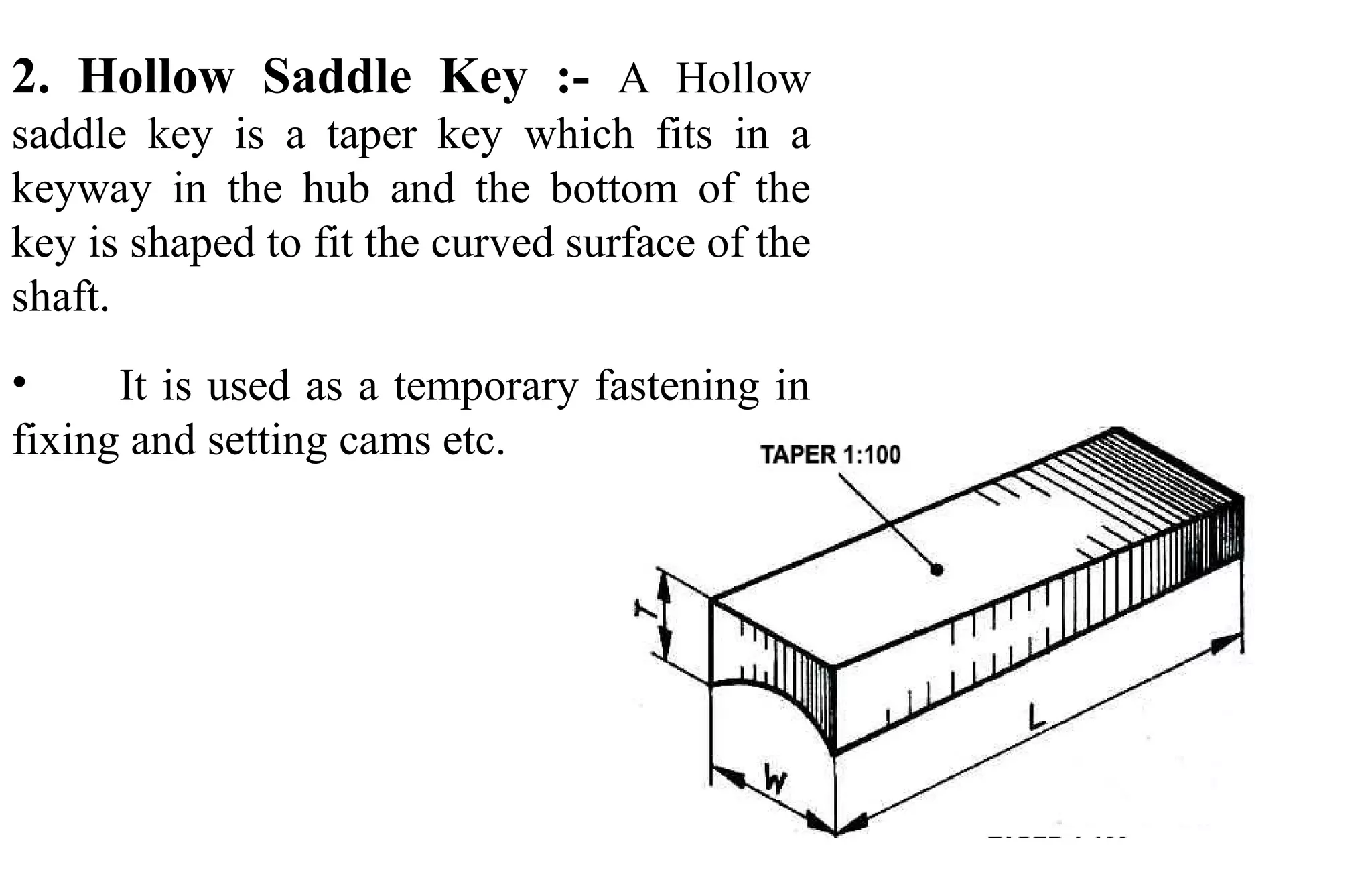

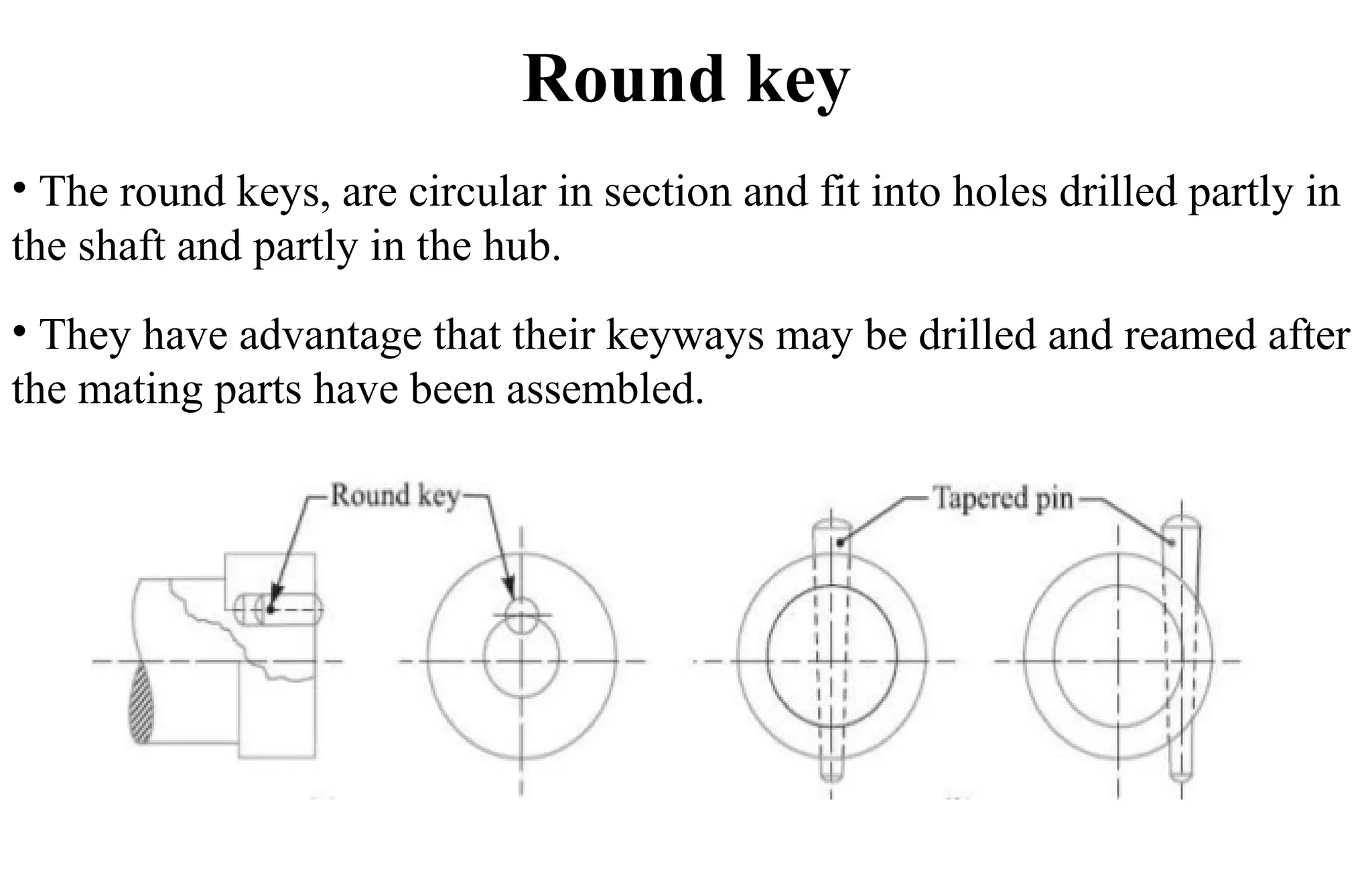

This document discusses different types of keys used to connect rotating machine elements to shafts. It describes sunk keys like rectangular, square, parallel, gib-head, and feather keys. It also discusses saddle keys, tangent keys, round keys, and splines. The main types of keys covered are sunk keys like rectangular, square, parallel, gib-head, and feather keys which are partially inserted in the shaft and hub keyways. It provides details on the purpose and design of each key type.