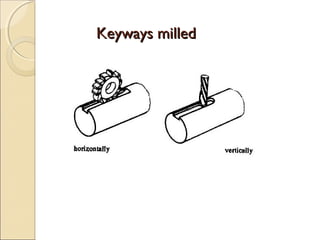

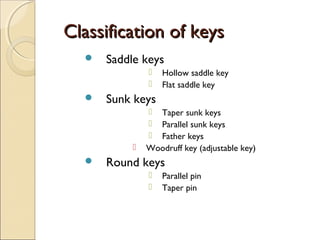

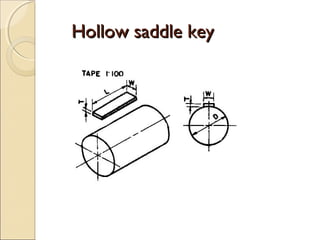

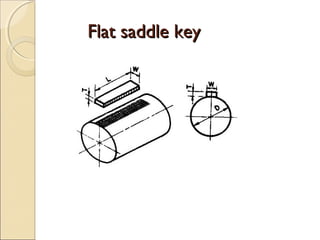

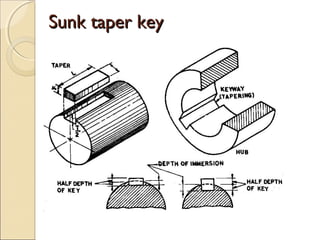

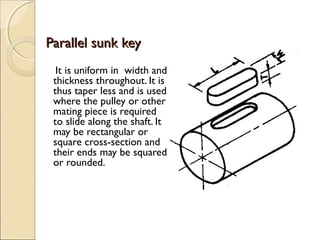

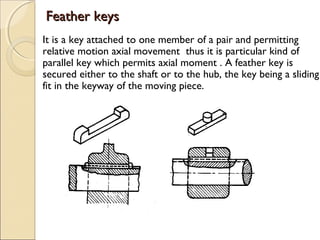

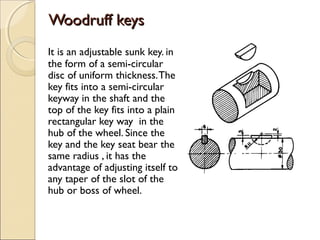

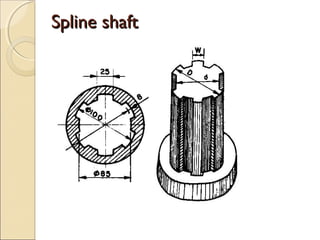

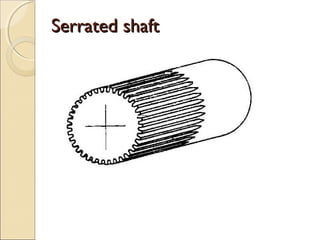

Mechanical keys are used to connect a shaft to a hub to allow power transmission while preventing relative rotation. There are several types of keys including saddle keys, sunk keys, feather keys, and Woodruff keys. Saddle keys rely only on friction to transmit torque and are used for light duty applications. Sunk keys are tapered or parallel and are sunk into both the shaft and hub for heavier duty use. Feather keys allow for axial movement along the shaft. Woodruff keys provide an adjustable connection between the shaft and hub. Splines and serrations can also be used to connect shafts and hubs while enabling axial movement.