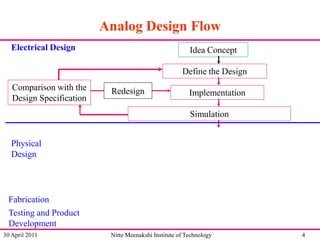

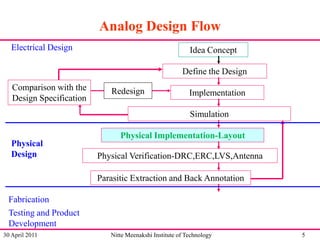

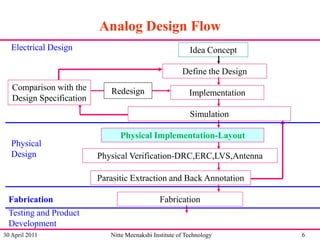

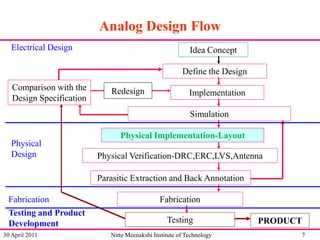

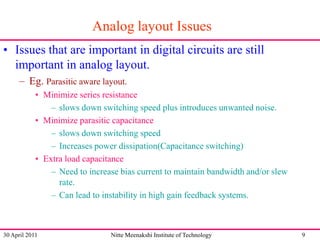

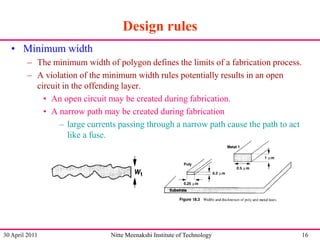

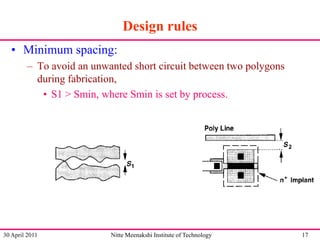

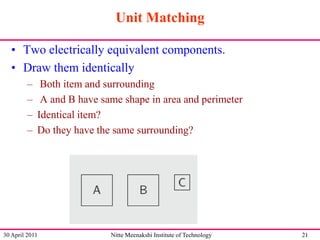

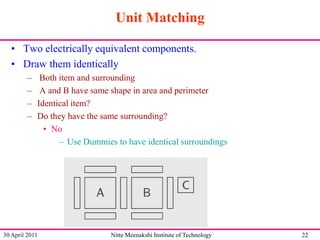

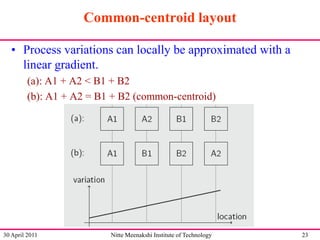

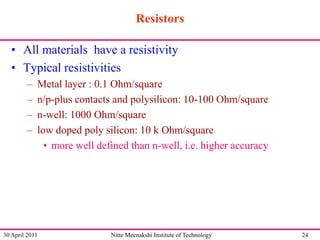

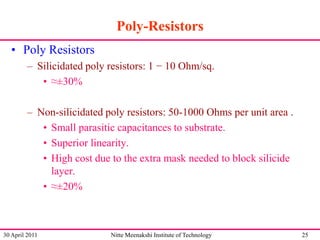

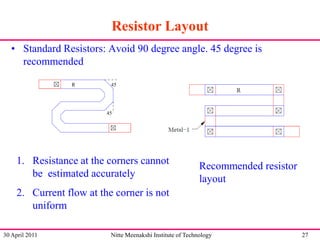

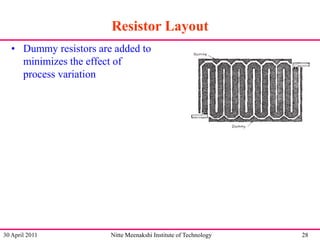

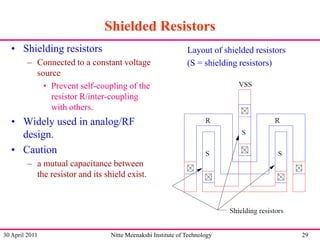

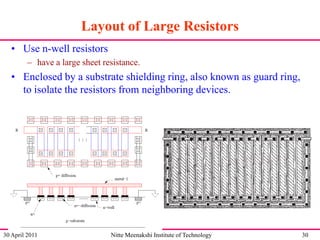

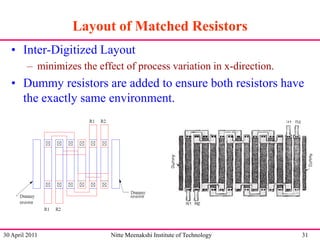

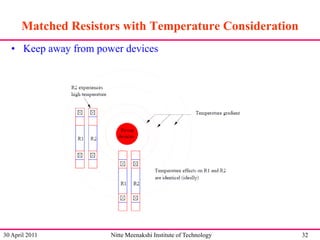

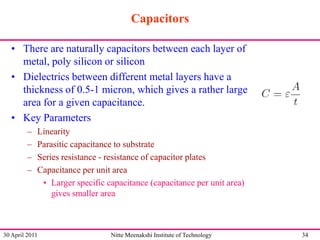

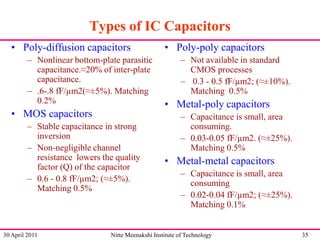

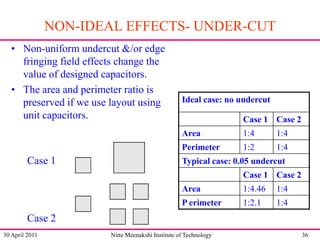

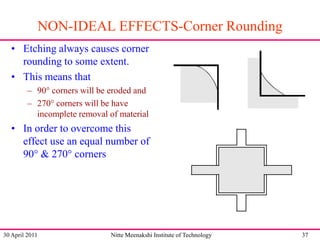

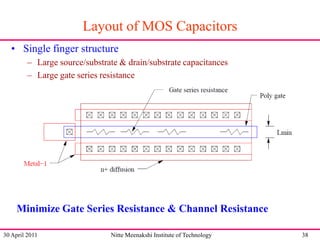

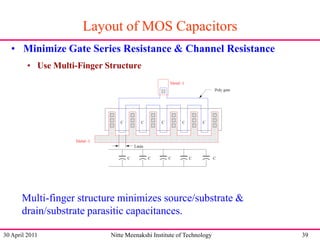

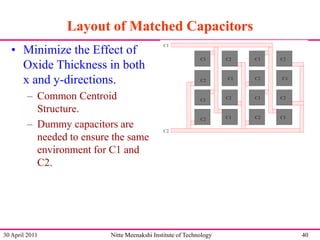

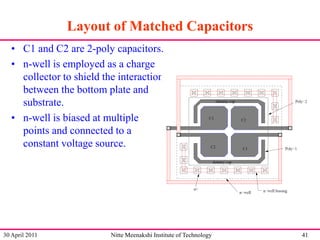

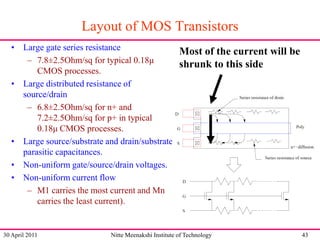

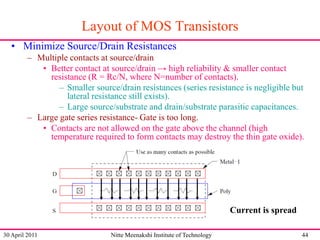

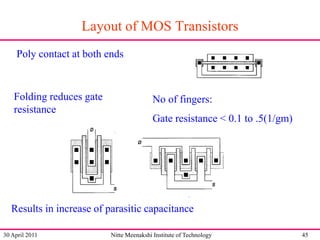

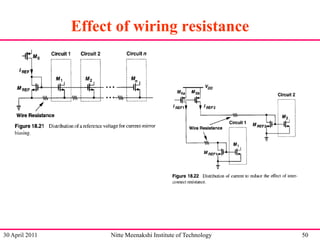

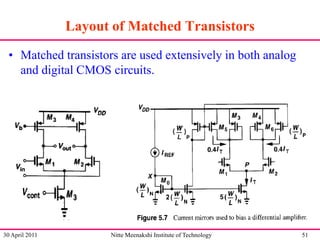

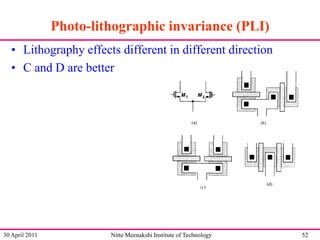

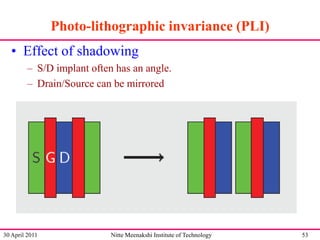

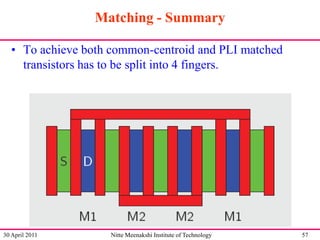

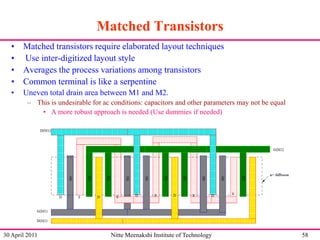

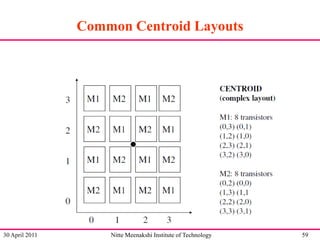

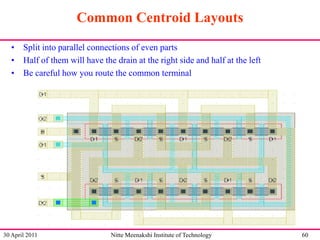

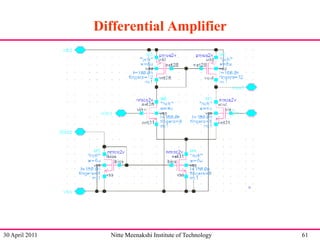

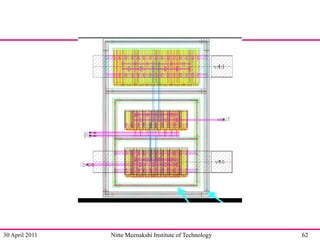

The document provides an overview of analog layout design. It discusses that analog circuits require careful attention to geometry during layout due to process variations. The analog design flow includes electrical design, physical design involving layout, and fabrication/testing. Key considerations for analog layout include minimizing parasitic resistances and capacitances, reducing noise, and ensuring matching between identical components using techniques like common-centroid layout. Resistors and capacitors must be carefully laid out to minimize non-ideal effects and provide accurate values.