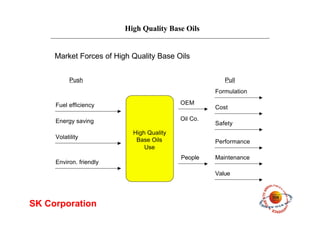

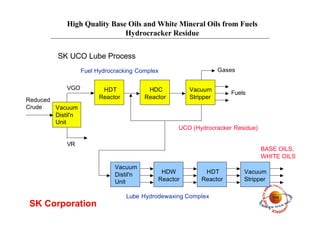

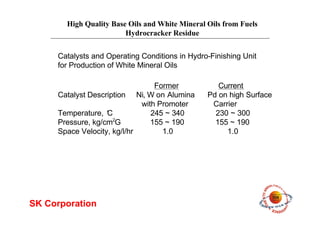

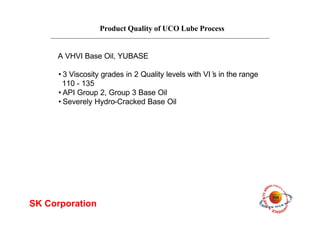

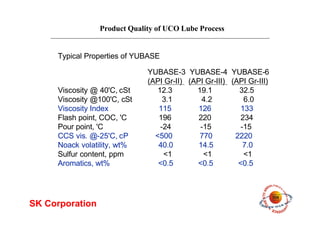

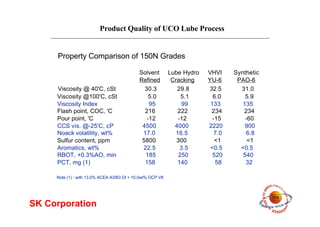

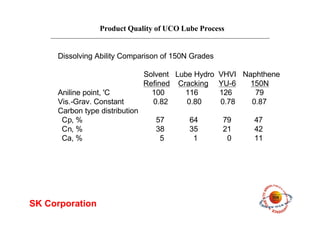

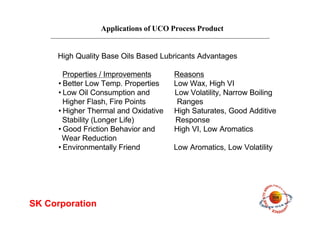

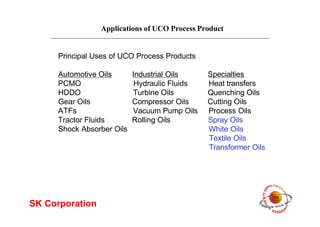

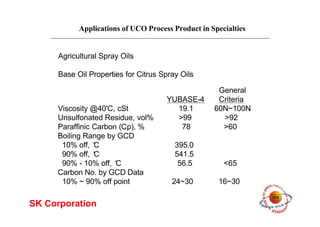

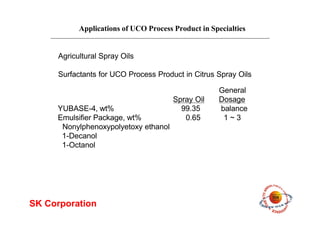

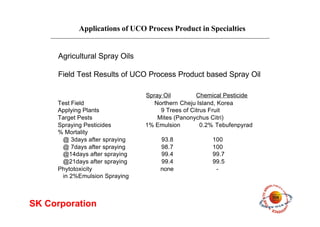

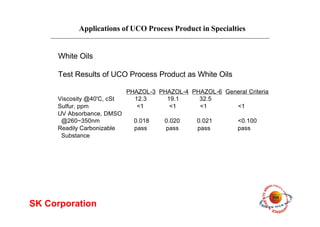

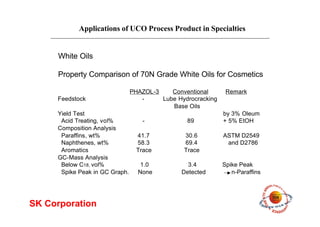

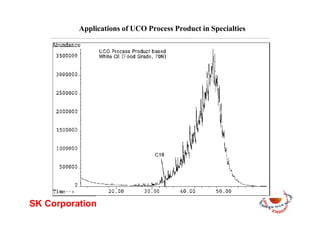

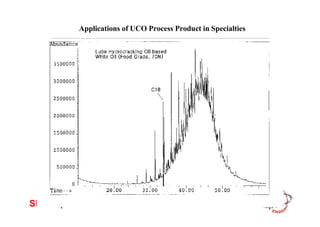

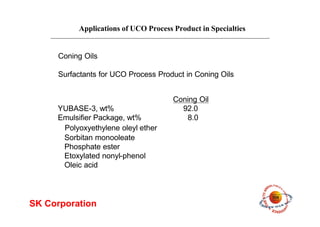

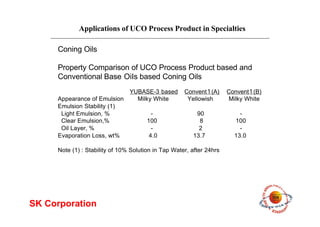

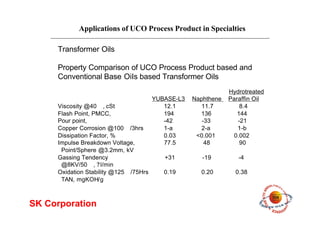

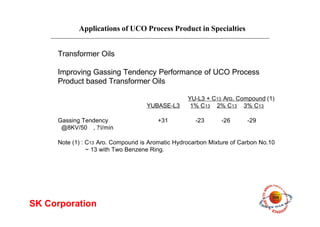

This document discusses the application of high quality base oils from SK Corporation's UCO lube process to specialty lubricants. It summarizes that the UCO process produces base oils from severely hydrocracked fuels hydrocracker residue that have properties similar to synthetic PAO oils, including high viscosity index, oxidation stability, and low volatility. These base oils can be used in automotive, industrial, and specialty applications like agricultural spray oils, white oils, coning oils, and transformer oils where they provide benefits like improved low-temperature properties and thermal stability compared to conventional base oils. Their main limitation is lower dissolving ability which can be addressed through additive selection or blending with aromatic compounds.