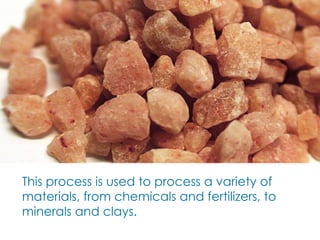

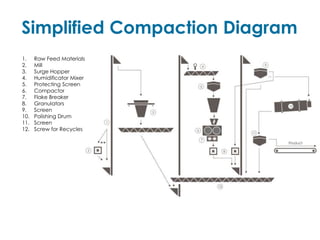

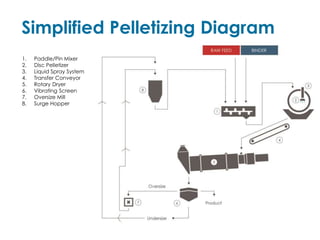

The document discusses the processes of compaction granulation and pelletizing, highlighting their differences, advantages, and disadvantages in material processing across various industries. Compaction granulation, a dry process, offers lower operating costs but requires a higher capital investment, while pelletizing, a wet process, ensures uniform pellets but has higher operational costs due to binder use and drying. Choosing between the two methods depends on factors like material characteristics, costs, and product requirements, with feasibility testing recommended when uncertainty exists.