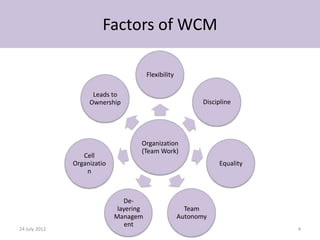

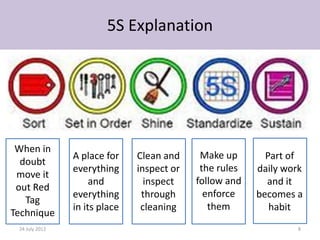

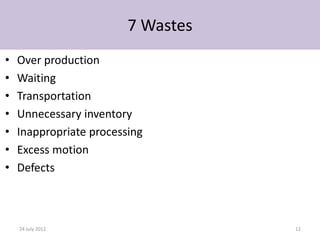

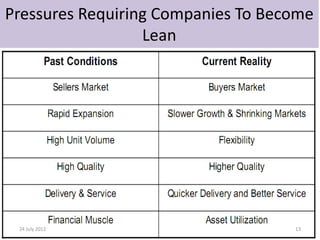

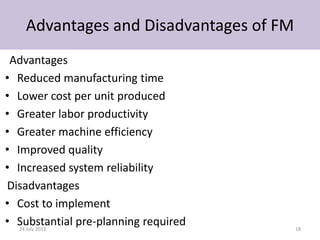

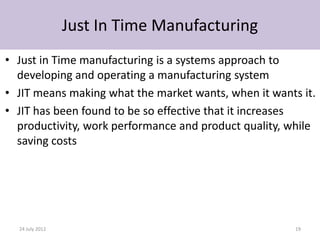

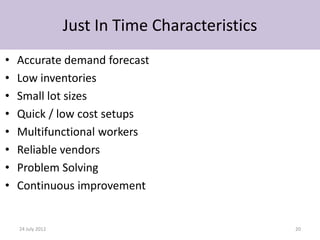

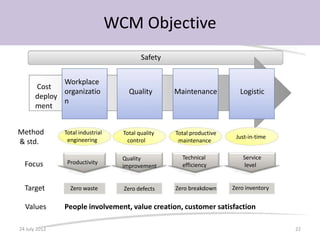

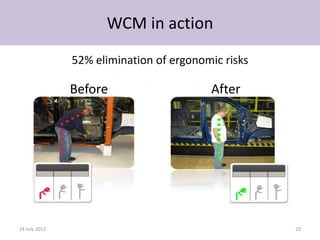

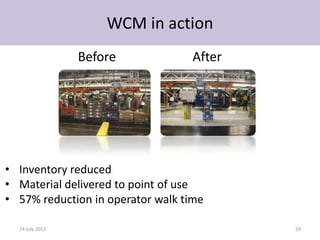

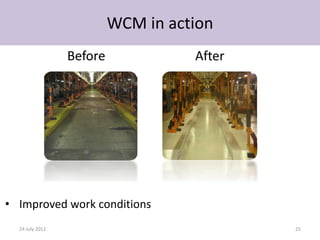

This document discusses world class manufacturing. It defines world class manufacturing as aiming to compete globally through quality and becoming a leader in international manufacturing excellence. It discusses factors like continuous improvement, zero defects, just-in-time production, and total quality management. It also summarizes various concepts, principles, and techniques used in world class manufacturing and provides examples of their implementation from Indian companies.