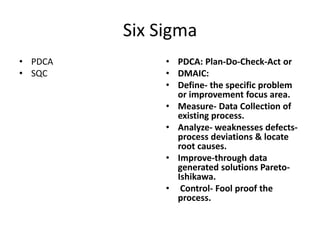

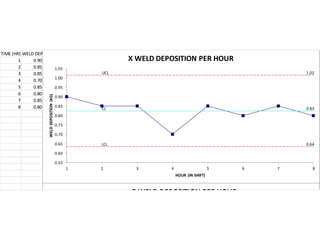

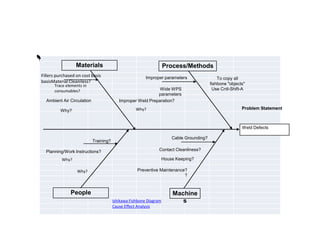

The document discusses process optimization through Lean Six Sigma implementation in a fabrication environment. It states that Lean focuses on processing efficiency by eliminating waste, while Six Sigma focuses on reducing product variation. Implementing these strategies can increase performance and profitability by lowering costs and allowing companies to better compete globally. Specific Lean and Six Sigma tools are described, such as value stream mapping to reduce delays, control charts to monitor processes, and root cause analysis to address defects and deviations. Overall, the document advocates using a Lean Six Sigma approach to data-driven problem solving in order to improve productivity and cost-effectiveness.