This document provides details on the planning, design, and analysis of a reinforced concrete box culvert. It includes the following key information:

- The box culvert dimensions are 3m x 3m with a total cushion height of 5m above the top slab.

- Load calculations are presented for dead loads, live loads, earth pressures, and base pressure. Moments are then calculated.

- Distribution factors and moment distribution are determined for the fixed end moments on the top and bottom slabs and walls.

- The box culvert design is analyzed using STAAD Pro and drawings are created using AutoCAD.

![ PLAN OF BOX CULVERT

size of box culvert is 3mx3m.For box[1/3 x

3/0]and[1/3 x 3/5]

DESIGN OF BOX CULVERT

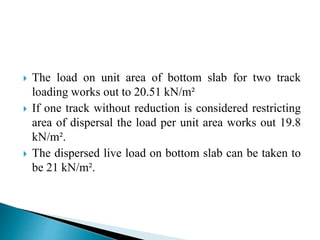

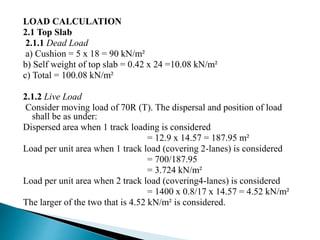

Load calculation

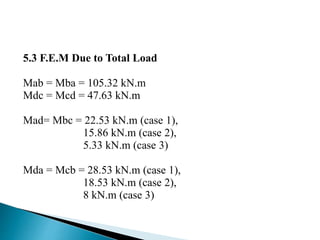

Moment calculation

Distribution factor

Moment distribution

Design of section](https://image.slidesharecdn.com/rccboxculvert-200209121543/85/Rcc-box-culvert-12-320.jpg)

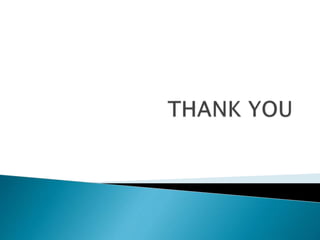

![4.1 RCC BOX CULVERT, SPECIFICATION:

[1/3 x 3/0]

Design a box culvert size of [1/3 x 3/0] , except

the cushion which is 5.0 m total height above top

slab which is constructed in embankment which

come in the way of natural flow of storm water and

refer the given data below.

SPECIFICATION

Clear span = 3 m

Concrete grade M25 = 25 Mpa

Clear height = 3 m](https://image.slidesharecdn.com/rccboxculvert-200209121543/85/Rcc-box-culvert-15-320.jpg)

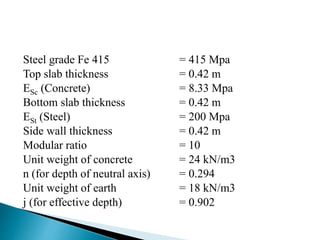

![Design a box culvert size of [1/3 x 3/5] ,except the

cushion which is 5.0 m total height above top slab which is

constructed in embankment which come in the way of

natural flow of storm water and refer the given data below.

SPECIFICATION

Clear span = 3 m

Concrete grade M25 = 25 Mpa

Clear height = 3 m

Steel grade Fe 415 = 415 Mpa

Top slab thickness = 0.42 m

ESc (Concrete) = 8.33 Mpa

Bottom slab thickness = 0.42 m](https://image.slidesharecdn.com/rccboxculvert-200209121543/85/Rcc-box-culvert-48-320.jpg)

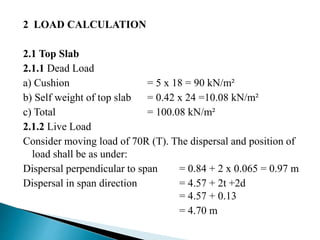

![6.1 Top Slab

Maximum moment support/mid span = 83.0 kN.m

Depth required =274 mm ,

provided =362mm

(420-50-8=362) is ok

Ast =1271mm²

CHECK FOR SHEAR

Shear force at d eff from face of wall113.80 kN

Shear stress =0.3144 N/mm²

Permissible shear stress =0.2623 N/mm²

% of steel =0.351

[Refer IRC : 21:2000 Table 12 B]](https://image.slidesharecdn.com/rccboxculvert-200209121543/85/Rcc-box-culvert-70-320.jpg)