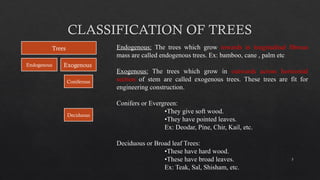

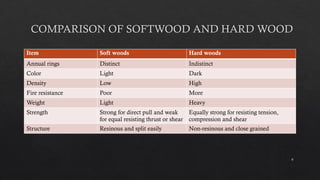

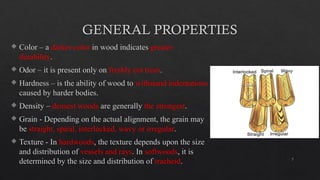

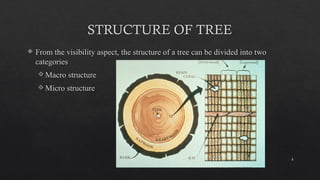

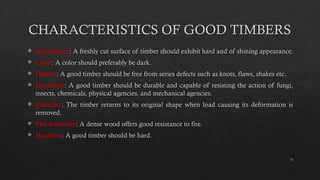

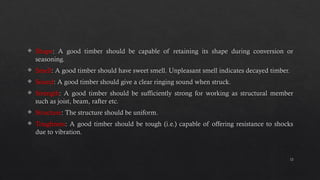

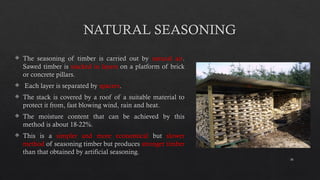

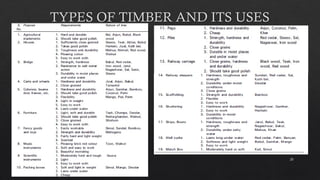

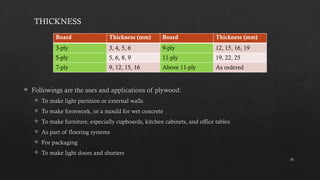

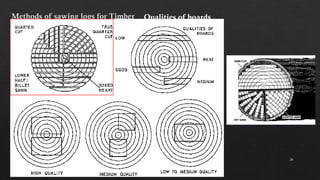

The document discusses timber, defining it as wood from trees used in construction and various applications. It covers the classification of trees, characteristics of softwood and hardwood, general properties of good timbers, and different methods of timber seasoning. Additionally, it details types of industrial timber, including veneers and plywood, and their respective uses.