This study investigates the impact of whole-body vibrations from road roughness on drivers' health and safety, specifically on stretches of national highway 90 and county road 950. Results indicate that road roughness significantly contributes to vibration levels, with findings linking high exposure to vibrations to health issues in commercial drivers, particularly in regions with poor road conditions. The study emphasizes the need for further research and improvements in road maintenance to alleviate vibration effects on road users.

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Introduction

Apart from the direct impact road roughness and texture has on vehicles and the environ-

ment, these road characteristics are also an indirect source of the noise, infrasonic sound

and whole-body vibration that cause stress on road users. The effect of this stress/load can

be divided into the following three categories, for which criteria can be stipulated and well-

motivated limits set:

1. discomfort

2. performance ability

3. health impact

The effect on the human body depends on the type of load. It varies from individual to

individual, depending on the person’s own particular situation. Reactions can be acute (like

speech impairment), gradually increase during travel (like motion sickness) or steadily de-

velop over time (like spinal injury). The effects can be transient, as in temporary visual im-

pairment, or chronic as in kidney damage. Temporary exposure can cause stress reactions,

like a faster pulse or higher blood pressure, which in turn entails a greater stress on the

heart. Sustained exposure can tire the brain a nd produce drowsiness. Daily exposure can, in

the long run, impair health and result in long periods of sick leave or even early retirement.

Sometimes these ailments can require medical treatment, which in turn can have side ef-

fects that can substantially impair quality of life. Musculo-skeletal injury is by far the great-

est working environment problem in the Western world today.

In the mid 1970’s, the exposure of truck drivers to vibration was an issue raised at the fed-

eral government level in the USA, formulated as ”Do vibrations (as well as noise, toxic

fumes and other factors that contribute to truck “ride quality”) have a negative effect on

driver health and on highway safety?” A research programme that extended over several

years, ”Ride Quality of Commercial Motor Vehicles and the Impact on Truck Driver Per-

formance” was initiated in 1977 to answer this question. The findings were summarised in

a report published in 1982 entitled ”Truck Cab Vibrations and Highway Safety” [66]. This

report was jointly produced by leading researchers, road authorities, vehicle manufacturers,

hauliers and commercial drivers. It shows that the answer to the key question as to whether

there is any correlation between cab vibrations and road safety is YES, that there is good

reason to believe that vibrations affect drivers’ health, and that vibrations must be elimi-

nated at source through effective road maintenance rather than merely dampened. The

report concludes that if the deterioration of the road network is allowed to continue, the

result will be serious health and road safety problems.

Today, further on down the road, we can see how the American road network has been

upgraded. According to the FHWA report Life-Cycle Cost Analysis in Pavement Design,

action is nowadays initiated on federal roads before the condition reaches a level corre-

sponding to IRI 2.7 mm/m [67 ]. In the study conducted during summer on Swedish Na-

tional Highway 90, IRI1 values close to 100 mm/m have been measured3, 37 times above

the American limit. Hw 90 is known to be much rougher during the spring thaw.

At the time of writing, an EC directive stipulating limits for exposure to whole-body vibra-

tion based on health and safety criteria is in the process of being drawn up.

3 Laser/inertial Profilometers have limitated laser measuring range (MR). On the Profilometers used in Sweden MR for vertical distance

is +/ - 100 mm. Since the distance from the laser beam to the front axle of the Profilometer vehicle is close to 1 m, profile slopes (used

when calculating IRI) will begin to be underestimated when they exceed about 100 mm / 1 m = 100 mm/m in static theory case. In

practise, Profilometer pitch and roll dynamic motion reduces this range of use further.

3(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-5-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Vibration

2

(weighted acceleration [m/s ])

on stretchers, and in the case

of the bulldozer, at the

operator’s seat. Some studies indicate that

exposure to vibrations of

1.6

2

1.30-1.35 m/s for 10

1.4 minutes a day can be

harmful even for healthy

1.2

people. The journey by

1 ambulance on the rough

stretch of highway took a

0.8

little more than 15 minutes.

0.6

Clearing forest for new road construction, bulldozer

0.4 CASE 1150 C

0.2 Mobile Intensive Care Unit Ambulance

0

Emergency Ambulance

Rough road, IRI

average = 4.0 mm/m Smooth road, IRI

average = 1.2 mm/m

During a 15-minute ride on a stretch of National Highway 90, the vibration level in one

type of ambulance was high enough to pose a potential health ha zard had a healthy person

been exposed to it for as little as 10 minutes a day. It was shown that the vibration on the

ambulance stretchers was as great as at the drivers’ seat in wheel loaders loading blasted

rock, bulldozers clearing way in forests for new road construction, etc. See the figure

above. Vibration problems are even greater in the spring due to seasonal frost damage re-

lated a dditional roughness.

5(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-7-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

2 Reader instructions

The project is presented in three separate reports:

1. The first is a technical analysis of the whole-body vibrations measured in trucks and

ambulances. This report was compiled by Kjell Ahlin, Licentiate in Engineering at In-

gemansson Technology AB [64], and may be of interest for researchers etc.

2. The second analyses the impact on the human body of the vibrations measured. This

report was compiled by Professor Ronnie Lundström at the National Institute for

Working Life [65]. A summary of the conclusions is presented in Chapter 7. The report

is available (in Swedish) at SNRA as well as NIWL websites, using the following links:

http://www.vv.se/aktuellt/pressmed/2000/VVRapport.pdf or http://umetech.niwl.se/Published/.Publ.html

3. The third is the report at hand, compiled by Johan Granlund, MSc (Civil Engineering),

of the Swedish National Road Administration. This report presents the results from

collating the data collected in the annual road condition surveys with the whole-body

vibrations measured on the test stretches. It also compares the results with the ISO

limits for whole-body vibrations, and assesses the magnitude of the problem on the

state network. This report is available on the SNRA website, using the following link

for the Swedish version http://www.vv.se/publ_blank/bokhylla/miljo/2000_31/intro.htm and this link for

the English version http://www.vv.se/for_lang/english/publications/index.htm

6(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-8-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

3 Definition of terms

The definitions of the following terms are based on those in the Swedish National Enc yclopaedia [1] with its

appurtenant dictionaries [34], the Swedish Centre for Technical Terminology glossaries [9], Engineering

Mechanics [40], Handbook of Human Vibrations [11], Vägtrafikteknisk nomenklatur (Highway Engineer-

ing Terminology) [16] published by the Transport Research Institute and ASTM´s Terminology Relating to

Vehicle-Pavement Systems [20]

Accident frequency

Number of accidents at a certain intersection, stretch or unit of distance.

Differences in the accident ratio between two road networks show that one

is ”more dangerous” for an individual than the other. Differences in acci-

dent frequency between two road networks depends partially on the differ-

ence in the accident ratio, and partially on the difference in the number of

vehicles using the road networks. A simple way to reduce the accident fre-

quency on a road with heavy traffic volume is to divert certain parts of traf-

fic to other smaller roads. However, as the accident ratio is generally higher

on smaller roads, this would increase the total number of accidents. From

this perspective, the accident ratio is better than the accident frequency for

assessing how dangerous roads are. The road network in Jämtland County

(known to have low traffic volumes but poor roads) has the highest accident

ratio in Sweden.

Accident ratio

Number of accidents related to units of measure in traffic; i.e., the term vehicle kilometres

is the unit commonly used on road stretches. At junctions the unit of measure is the num-

ber of vehicles entering the intersection.

Accuracy

The ability of the measurement instrument to give results close to the true value for the

parameter measured. The greater the accuracy, the less the error.

Alignment

The design of the road profile in space.

Amplitude

Amplitude is the maximum deviation from the mean of a signal (e.g., road roughness, or

vibration), see Figure 10.

Comfort

A subjective state of well-being or absence of mechanical disturbance in relation to the

induced environment (mechanical vibration or repetitive shock).

7(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-9-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Crest factor

The ratio between the frequency-weighted peak value and the frequency-weighted root

mean square for the parameter studied. See Figure 3.

Criteria

A criterion is a verbal description of the effect, e.g. discomfort, reduced performance ability

or physical injury that is of interest. Limits (threshold values, target values, etc.) are set to

ensure an acceptably low probability of the effect that the criterion defines. In other words,

the criteria explain the reasons for the different limits.

Crossfall

The angle between the horizontal plane and the surface of the roadway, carriageway or

shoulder, measured at a right angle to the longitudinal direction of the road.

Ergonomics

Study of the relationship between people and their work environment, especially the

equipment they use. See also [52].

Estimated vibration dose value, eVDV)

An estimation of a cumulative measure of the vibrations and shocks that a person is ex-

posed to during the period under study, based on the frequency-weighted root mean square

for the vibration. See Formula 1.

If the vibration level varies or contains shock elements, the vibration dose value

must be determined directly from the complete measurement series. This is usually

the case when the crest factor exceeds 6 – 9, which makes eVDV less useful for ride

quality assessment on the rougher roads.

eVDV = 1.4 * a rms * T1/4

Formula 1 Estimated vibration dose value during exposure time T

Fracture mechanics

The science of how solid material breaks. This is often characterised by one or more cracks

spreading throughout the mass of a structure, ultimately resulting in its splitting into two or

more parts. Cracks can increase through different mechanisms, like fatigue. An increase in

fatigue occurs in structures exposed to repeated load. The increase can be very little at any

individual load. However, major cracks can form in a very short time through exposure to

vibration. The research that laid the foundation for fracture mechanics was carried out dur-

ing the Second World War. Since the 1950’s, fracture mechanics has developed into an

important element in the mechanics of materials. Most research has been conducted in the

USA and has been motivated by safety demands, primarily within the nuclear power and

aviation industries. Fracture mechanics can be used to answer the question ”how quickly

does a small crack grow through fatigue at the load spectrum to which the structure is ex-

posed?”.

Health

A condition of complete physical, psychological and social well-being, and not only the

absence of illness or disability [World Health Organisation (WHO), 1946].

9(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-11-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Horizontal curve

The curve indicating the direction of the road alignment in the horizontal plane.

International Roughness Index

The IRI value is a substitute measure for the vertical vibration that occurs in the suspen-

sion of a model (”the Golden Car”) of a quarter of a standard passenger car during a hypo-

thetical journey at the speed of 80 km/h on the road stretch studied. The value describes

the accumulated vertical displacement between the car body and the non-suspended mass

of the wheel, divided by the distance travelled. The unit of measure for the IRI is [mm/m],

which is low when the road is smooth along the wheel track5 in which the roughness pro-

file is measured. The IRI is currently the preferred unit of roughness measure used in Swe-

den and many other countries around the world that conduct objective surveys of the road

condition.

Index notation such as IRI 400, IRI 20, IRI 1 etc is used when explaining the

length of report/averaging interval, such as 400 metre, 20 metre and 1 me-

tre. Up until now, the basic report storage interval in the SNRA PMS has

been 20 metre. (As a comparison; the sampling spatial frequency used by ve-

hicle manufacturers fatigue researchers typically must be no longer than

about 1 decimetre, not to lose information about shock that causes damage).

Jerk

The first time-derivate of acceleration. Jerk is thus a measure of how fast the magnitude of

the acceleration changes.

When assessing damage potential, the relation between load and bearing ca-

pacity is studied. The “bearing capacity” of the human body depends strongly

of the state of muscular brace, comparable to the case where a small child is

learning to stand and walk. When exposed to unexpected occasional shock,

an intensive jerk may reduce the chance for the body to suddenly increase its

“bearing capacity” through instinctive brace. This implies that among differ-

ent motions with a similar peak acceleration, motions having a more inten-

sive jerk may be more serious than those with a less intensive jerk.

5 In Sweden, the IRI value is measured in the outer wheel track as seen from the centre of the road. In some countries, it is measured

from a mean profile of the outer and inner wheel tracks instead.

10(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-12-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Macrotexture

Term for those aberrations in the road surface (compared to an ideal plane) that have cha r-

acteristic wavelength and amplitude dimensions from 0.5 mm and upwards to those that

have no effect on the interaction between tyre and roadway.

Measurement error

Difference between the measurement value a nd the true value.

Measurement results

The product of the measurement value and the unit of measure. The measurement value

can have been corrected in connection with this through calibration in order to take known

systematic errors into consideration.

Measurement value

The value for the parameter compared to the unit of measure. Can be identical with the

measurement result.

Motion sickness

A physiological reaction in people induced by vibration, where the central nervous system

is incapable of co-ordinating information obtained visually, from the balance organ in the

ear and from joints and muscles. The reaction can cause drowsiness and affect perform-

ance ability. Symptoms include greater salivation, perspiration, depression, apathy, pallor,

nausea, dizziness and vomiting. Motion sickness seldom occurs in connection with vibra-

tions with a higher frequency than 0.5 Hz. When the reaction occurs in a moving vehicle, it

is usually called ”travel sickness”.

The most renowned hypothesis for a qualitative explanation for the origin of

motion sickness is called ”the sensory conflict hypothesis”[36]. A schematic dia-

gram of this hypothesis is shown in Figure 1. Several other conflict hypotheses

are discussed in Griffins ”Handbook of Human Vibrations” [11].

12(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-14-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Stimuli Receptors Central Nervous System Responses

Active Motor

control

movement Volitional

system and reflex

move-

ment

Eyes Updates internal

Internal model

model (adaption)

Semicir- neural store of

Motion cular expected signals

stimuli canals

Otoliths Leaky Neural centre Motion

and other Compa- integ- mediating signs sickness

gravi- rator & symptoms of symptom

ration

receptors motion sickness

Passive

movement Mismatch signal Threshold

Figure 1 Schematic diagram of the sensory conflict hypothesis. This figure has

been modified by Förstberg [36], originally developed by Benson (1988).

Natural frequency

The most fundamental property of an oscillating system. Natural frequency constitutes the

free oscillation frequency of a system after having been disturbed. Every real system has

several natural frequencies, and each of these has a given pattern of movement. When a

system is subjected to an external disruptive (driving) force whose frequency is equal to a

natural frequency in the system, resonance occurs and the magnitude of the vibration in-

creases. See Figure 2.

13(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-15-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Figure 2 Mechanical model of the human body specifying natural frequencies

for a few parts of the body [51]. Observe that the body lacks the female

bosom. The natural frequencies refer to vibrations in the axial direction of the body

parts (e.g. the spinal column)

14(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-16-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Root mean square, rms

The root mean square of a variable during the period studied. See Formula 2 and Figure 3.

When assessing ride quality, effects of occasional shock are often of great in-

terest. The running root mean square of the weighted acceleration (using in-

tegration time 1 s) is then often the preferred definition of vibration, since

this definition has been proven to correlate very closely with perceived an-

noyance [75]. To assess the risk of mechanical damage to the spine, the

weighted positive (compression phase) peak acceleration is the preferred defi-

nition.

t2

∫ a (t ) 2 dt

a rms =

t1

t 2 − t1

Formula 2 Root mean square for acceleration

Root sum of square, r.s.s.

A summation procedure for vectors in different directions. For the root mean

square, the square root is taken from the sum of the vectors squared root mean

squares.

Running rms

A filtering procedure that smoothens a very transient measurement series (as where occa-

sional shocks have occurred) that have a high crest factor.

Second Law of Newton

The acceleration of a particle is proportional to the force acting upon the particle and oc-

curs in the direction of that force. Normally expressed in dynamic analysis as F = m*a.

Stress

The physiological/hormonal reactions in the organs of the body that are triggered by

physical and mental ”stress factors”. Threatening or strenuous situations stimulate in-

creased secretions of adrenaline and noradrenaline. These hormones function such that

they increase the heart rate, blood pressure and circulation of blood to the skeletal muscles,

while decreasing the circulation of blood to other organs. Further, breathing is stimulated,

the trachea expand and the level of sugar and fatty acids in the blood increases. When peo-

ple are unable to control their own situation, the cortisol level also increases substantially.

Cortisol increases the amount of glucose in the blood, as well as the turnover of fats and

proteins. These and some 1400 other reactions to stress mean that the body, through all its

endeavours to adapt to the situation, is prepared to destroy itself after being subjected to an

all too extended or strenuous load.

Survey

A series of measures to determine the value of a parameter.

16(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-18-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Unit of measure

Reference value for a parameter; e.g., in the case of distance, a metre could be used as a

unit of measure.

Vibration

Oscillation in mechanical systems, where parts of the human body and human organs can

be included. (See Figure 2). This is governed by different kinds of force: mass, restoration,

calming and disruptive (driving, instigating) forces.

Vibration can be measured in terms of displacement, speed or acceleration.

The unit of measure used for acceleration is [m/s2]. Results are usually pre-

sented as peak values (mechanical spinal damage etc) or as a root-mean-square

or running root-mean-square (perceived ride quality etc). See Figure 3.

Peak value

Root mean square

Mean value

Mean value

Figure 3 Peak value, root mean square and mean value for a signal

Vibration dose value, VDV

A cumulative measure of the vibrations and shock elements to which a person was exposed

during the period under study. See Formula 3.

t2

VDV = 4 ∫ a w (t ) 4 dt

t1

Formula 3 Vibration dose value for acceleration

Wavelength

The shortest distance between two of the signal’s points with an equal phase. See Figure

10.

17(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-19-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

4 Background

To most people, a roadway is merely a charcoal grey surface of infinite length. They expect

it to provide safe driving conditions, a smooth and quiet ride, minimal splash and spray

when it is raining, good visibility during poor conditions and that it will last a long time (to

avoid disturbance from road works).

A closer examination of the road reveals that it has several important characteristics, such

as surface texture. Texture is needed to provide road grip, minimise spray and mist when it

is raining, and reduce the glare from high beams at night. But the texture can cause more

noise as well as reduce the life span of both roads and tyres. As the road surface ages and is

worn down by studded tyres, heavy vehicle loads and climate, road damage begins to a p-

pear. Deformation (or road roughness), which is one type of damage, can limit both

shorten the life span of a road as well as reduce the quality of the ride. Roughness, primar-

ily longitudinal, can also be built into the road from the outset due to poor geometric de-

sign/construction.

Roughness is the source of many kinds of irritation that road users encounter; flickering

headlight reflections, deep pools of water, the dynamic forces that increase pavement stress

and damage to vehicles and cargo, and poor ride quality. Most road users are very sensitive

to ride quality, making this a prime criterion when setting road maintenance priorities [68].

Road roughness can mean reduced travel speeds. This has led many to believe that rough

roads are safer than smooth ones, since speed is generally acknowledged as dangerous.

However, after collating databases with information on accidents, road surface condition,

climate, road geometry, speed, etc at VTI (Swedish Road & Transport Research Institute),

it was concluded that ”the accident ratio increases with an increase in the roughness” and

”roughness has a major impact” [18]. A strong correlation between road roughness and the

accident ratio on the paved part of the state road network in Sweden has thus been ascer-

tained, implying that the idea of rough roads being safer is probably a serious misconcep-

tion.

However, such a statistical correlation is not clearly tantamount to the accident risk actually

being caused by roughness. For instance, it is likely that the vehicles on the roads in rural

areas, where roughness is worst, are older and less roadworthy than those found on the

smoother roads in and between the larger cities. It is therefore necessary to verify a statisti-

cal correlation through experiments that provide information about possible mechanisms

for an actual cause and effect relationship. This could include the effect of roughness

through mechanical interference on the steering and braking properties of road vehicles,

the effect on winter road maintenance and on drivers’ performance ability.

4.1 From past to present

The mechanisation of human transport on roads has taken place in a very short time. Peo-

ple were still basically travelling on the backs of animals or on foot in the 18th century,

despite the fact that the invention of the wheel 3 500 years before Christ had made the

development of animal-drawn carts possible. The reason was that roads were often almost

entirely impassable, which explains why the carts were primarily used to transport goods,

and even then only at average speeds up to about 10 km/h. This meant that travellers usu-

18(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-20-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

ally experienced more discomfort from dirt than from vibrations. On the narrow streets of

Stockholm, the upper class avoided the dirt by being carried on palanquins. A tariff for this

was laid down in 1726 [58].

Through Carl Snoilsky’s classical poem on Stenbock’s courier, generations of Swedish stu-

dents have learned about how Captain Henrik Hammarberg, who was sent off by General

Magnus Stenbock from Helsingborg with a message to the king and government in Stock-

holm on February 28th 1710, rode so hard that ”a horse collapsed behind him at every

station”. Modern historians maintain, however, that the courier, who covered the journey

of 900 kilometres at an average speed of 18 km/h, probably did not ride on horseback at

all. Verification ”Folio 2282” in the 1710 treasury records (preserved in the National Ar-

chives) for Hammarberg’s travelling-expenses account clearly shows that he travelled by a

carriage drawn by a team of horses from station to station. It is believed that he suffered

from travel sickness during the journey; ”this coach is swaying so frightfully on these terri-

ble roads” [59].

The bicycle could enter the scene at the turn of this century, as a result of the soft non-

bituminous roads, which could be evened out by simple means as needed. Bicycles were

crowded further and further out to the periphery as motoring became more widespread. In

the past 130 years, mobility for people in Sweden has grown a thousand fold. See Figur 4.

Mobility trend in Sweden, 1850 - 1990

50000

45000

40000

Decade Travelled distance [m] 35000

1850 40 30000

1870 200 25000

1890 350 20000

1910 900 15000

1930 3000 10000

1960 20000 5000

1980 40000 0

1850 1870 1890 1910 1930 1950 1970 1990

Decade

Figur 4 The average daily distance travelled by vehicle by adults in Sweden

from the 1850’s to the 1990’s. Data in the tables extracted from [61], supple-

mented in the figure with data from [62].

Roads became steadily harder throughout the years, necessitating more sophisticated care

and maintenance routines. The long distances covered at the high speeds that characterise

modern road traffic, mean an exposure to vibration and shock that, in the presence of sig-

nificant road roughness, can mean people being exposed to mechanical energy that is sub-

stantially higher than at any other time in history. According to the second law of Newton,

the magnitude of this mechanical load can be estimated through measuring the acceleration

of whole-body vibration.

19(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-21-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

The mental stress is more difficult to measure. At the macro level, it has been shown that

the risk for certain types of cardio-vascular disease in Sweden is more than three times

higher for commercial drivers than for the average worker. Mental stress under certain

driving conditions is considered to explain the raised level of stress hormones found in

commercial drivers, and is believed to cause the problem [69, 70].

Amongst older commercial drivers, musculo-skeletal problems and cardiovascular diseases

are the primary reasons for changing their occupation [71].

20(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-22-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

4.2 Road roughness in brief

Road roughness can result from faulty basecourse adjustment (usually through insufficient

repair of crossfall variations or longwave deformations); incorrect initial construction; post-

compaction of added layers; subgrade settlement; material abrasion -- primarily by studded

tyres -- or through uneven frost heave during the spring thaw.

A general rule, based on laboratory tests, is that drained road structures can stand being

driven on by trucks six to seven times more than those without drainage before unaccept-

able deformation occurs in the unbound layers. Ditching is thus a very effective mainte-

nance measure for preventing roughness, if it is executed so that the gradient of the inner

embankment is not steeper than 1:3 (otherwise there is the risk of edge deformations due

to insufficient lateral counterstay). A drained road structure is also a prerequisite for avoid-

ing frost-related roughness in winter.

The binder stiffness affects the ability of the asphalt to distribute the load and thus the risk

of deformation in underlying layers. Temperature is a key factor for this stiffness, which

means that dark asphalt roads become rough faster than those with a light surface.

The mechanical properties of vehicles can also increase roughness. As early as in the

1930’s, a large-scale experiment showed a substantial increase in roughness on gravel roads

when the test vehicles had high-pressure tyres, while there was not even enough roughness

to measure when low-pressure tyres were used (the roadway had actually been smoothed

out). Speed and suspension were also shown to be major factors affecting roughness [56].

These conclusions could even be valid today for roads with a thin surface, like single sur-

face treatment (Y1G), which is very similar to the dust abatement measures undertaken on

the old gravel road.

8,00

7,00

6,00

5,00

IRI [mm/m]

4,00

3,00

2,00

1,00

0,00

01

01

-01

-01

-01

-01

-01

-01

-01

-01

-01

-01

1-

0-

-12

-03

-06

-09

-04

-07

-02

-05

-08

-11

-0

-1

00

00

00

00

00

00

00

00

00

00

00

00

Tid på året

Figure 5 Conceivable variation in roughness per month, on a specific road sec-

tion

21(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-23-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Road roughness varies throughout the year, which often is more noticeable than the annual

deterioration in the road condition. An estimation of what the variation might be like over

the year on a road that is not treated with salt de-icer and that is slightly frost-damaged is

shown in Figure 5. Variable weather conditions in addition to winter maintenance measures

accounts for the greater variation shown in the graph for the winter months, while the ex-

tremes in the spring are explained by the thaw. While there is a high rate of steadily increas-

ing deterioration on roads with deficient bearing capacity and/or problems related to fro-

zen ground conditions, the deterioration on well-constructed roads is minor and disappears

in time (except during the late stage when surface abrasion occurs if no preventive meas-

ures are undertaken). Roughness can be eliminated through appropriate periodic mainte-

nance. Road strengthening serves to reduce roughness immediately, while also retarding its

future speed of increase. Needless to say, this applies regardless of whether the improved

bearing capacity has meant a change in the administrative bearing capacity class of the road.

For microtexture, as well as that part of the macrotexture with wavelengths shorter than ca

25 mm, it is important that the road roughness amplitudes are neither too large nor too

small. To a certain extent, this kind of roughness produces desirable effects; like friction,

noise reduction, a certain amount of drainage, etc. Some effects are undesirable, like greater

wear and tear on tyres [2].

All roughness with wavelengths above ca 25 mm increases transport costs [2]. It is possible

to correct roughness with amplitudes under ca 15 - 30 mm and with wavelengths up to

about 10 metres simply through a new wearing course. Roughness with larger amplitudes,

or of a more longwave nature, is remedied through milling or more fill works. Frost-related

roughness normally demands highly extensive and expensive measures, such as deep drain-

age and extensive material replacement. The maintenance and repair budget (per square

metre road surface) must therefore be several times higher for roads damaged by frost than

for roads damaged by traffic.

22(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-24-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

4.3 Monitoring of the road condition at the SNRA

Roads with an IRI > 5 mm/m

14%

12%

10%

Northern Region

Central Region

8%

Stockholm Region

Western Region

6% Mälardalen Region

South-Eastern Region

Skåne Region

4%

2%

0%

95 96 97 98 99

Year

Figure 6 Development of severe roughness on the paved state road network,

expressed as time series of IRI 20 > 5 mm/m per road management re-

gion. A lower percentage indicates fewer very rough stretches on the road network.

4.3.1 Road roughness measurements

The SNRA regularly measures roughness on paved state roads using high technology sur-

vey vehicles. European and National Highways are surveyed annually, and other roads at

least every third year. Up until now, the parameters that have been of greatest interest are

ruts, crossfall and roughness. The IRI value [mm/m] is the most important measure of

roughness, and is calculated from the road roughness profile measured. The IRI value can

be said to describe the vertical vibrations in the suspension of a mathematically simulated

passenger car driving at a speed of 80 km/h, and is affected primarily by roughness with

wavelengths between about 1 and 30 metres. IRI is very similar to the measures of rough-

ness used in the USA as early as the 1920’s when roughness began to be measured using

simple vehicles. These roughness measures were successfully used to stimulate competition

among civil engineers and contractors to achieve better ride quality through their being

officially published as objective comparisons of different road projects [54].

Today’s survey results are analysed and interpreted as the basis for budget discussions, set-

ting priorities, research projects, evaluating performance contracts, etc [8]. Figure 6 shows

the percentage of roads with excessive roughness (very high IRI values) in all road man-

agement regions. Signs of improvement can be seen, particularly up to 1999.

23(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-25-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

However, an entirely different, negative trend was found when reviewing road users’ opin-

ions on ride quality. See Section 4.3.2. The discrepancy between the results from the road

condition and road user surveys can perhaps be attributed to the fact that people are travel-

ling more (which can increase the exposure to vibration even if the road roughness is un-

changed) and that the annual road condition surveys are only performed when there is no

ground frost, for reasons of measurement precision. Roughness on frozen roads can be

much worse than on non-frozen roads, and ground frost conditions vary substantially from

year to year. Much higher local IRI values have been measured on frost-damaged roads,

than what has been registered in the routine surveys in the summer months.

During the quality a ssurance of road condition surveys, it was observed how the vehicle

operators found it much more difficult on rough roads to follow the driving instruction

requirements. In other words, roughness has a strong adverse effect on driver performance

[private comment made by Kerstin Svartling, administrator for the SNRA’s road condition

surveys].

The significance of different types of roughness and different speeds can be studied in

Figure 7.

24(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-26-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Figure 7 Typical vertical motions at the rear axle and in the car body when driv-

ing at different speeds on different road roughness [12]

4.3.2 Road user opinion polls

The road user opinion polls conducted by the SNRA between 1995 and 1998 included 30

000 people. The questions cover new roads, care and maintenance. On the whole, the find-

ings were not too negative. The majority of the interviewees were satisfied in most respects,

with one major exception being road roughness.

The smoothest roads in Sweden are found in Skåne Region (southern Sweden). Despite

this, the percentage of commercial drivers in Skåne who are satisfied with ride quality on

the national road network is as low as 30 – 35 percent. The percentage of satisfied road

users is much lower in other parts of the country and with respect to other types of road.

25(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-27-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Dissatisfaction is greatest and growing most rapidly in the northern half of the country. For

example, it is expected that 0% (none) of the commercial truck drivers in the counties of

Västernorrland, Jämtland, Gävleborg and Dalarna (the Central Road Management Region,

being part of “northern Sweden”) will be satisfied with the ride quality on regional thor-

oughfares in the winter of 1999. See Figure 8.

SNRA Central Region

(Västernorrlands, Jämtlands, Gävleborgs och Dalarnas counties)

Marks given by commercial drivers for the ride quality on regional roads

Results 1996 Results 1997

8%

18%

82%

92%

Percentage dissatisfied

Results 1998 Percentage satisfied Prognosis 1999

0%

5%

95%

100%

Figure 8 Commercial drivers’ marks for ride quality on regional roads. Väs-

ternorrland, Jämtland, Gävleborg and Dalarna Counties [6].

At the national level, the percentage of commercial truck drivers who are satisfied with the

quality of the ride is about half that of passenger car drivers. However, even the percentage

of passenger car drivers who are satisfied in this respect is low [6][37].

Factors that are known to influence people’s sense of discomfort are shown in Figure 9.

26(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-28-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Texture Vibrations Vibration-

Roughness related discomfort

Alignment Jerky ride Vision disor-

ders

Megatexture Shock Difficulties in

Roughness handling

Noise and Sleeping disor-

Roughness Infrasound ders

Texture Visually Variance between Noisiness

Roughness

individuals

Road signs Information Speech diffi-

Road markings culties

The individual Ride quality

Rest areas Food / beverages Sweating / (sum of discomfort)

freezing

? Odours Air quality

Variance for

the individual

? Temperature Glaring

lights

? Body posture Uncomfortable

posture

? Privacy Social discom-

fort

Disruptive Other Other

road works

Figure 9 Factors associated with road management that produce discomfort in

connection with road transport. The figure has been modified on the basis of

[11]. The figure also helps us understand for example that faulty, irregular crossfall,

unsuitable texture and major road roughness cause many different kinds of discom-

fort. Road damage, along with recurrent disruptive road works, thus results in poor

ride quality.

27(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-29-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

4.4 Analysis of road roughness

The deviation of the road surface from a horizontal plane can be described by the wave-

lengths and amplitudes of the roughness, see Figure 10. The very shortest roughness wave-

lengths are classed as microtexture, which is determined by the properties of the aggregate

and binder in the surface. Somewhat longer wavelengths are classed as macrotexture,

which is determined by such things as the shape of the aggregate and the particle size dis-

tribution. Longwave deviations are quite simply designated as roughness [2], often caused

by more or less extensive settlement, frost heave or ice lenses in or under the road struc-

ture in the winter.

λ A

λ/2

A

Figure 10 Wavelength (λ) and amplitude (A). Above at corrugation, below at a

pothole.

The basic relationship between travel speed (velocity) v [m/s], wavelength λ [m] and verti-

cal vibration frequency f [s-1] is shown in Formula 5. Depending on the travel speed and

type of vehicle, vehicle properties are a key factor where the wavelengths are up to 25 - 50

m. Where the wavelengths are longer (or more to the point, at lower frequencies) the

dampening property of the vehicle is insignificant [11]. The equation should therefore pro-

vide a reasonable estimation of the vibration frequencies where the roughness is of longer

wavelength. Vibrations with a frequency of 0.1 Hz are caused by roughness (unevenness)

with wavelengths of about 85 m at a travel speed of 30 km/h (8.3 m/s) and wavelengths of

about 360 m at 130 km/h (36.1 m/s). A vibration frequency of 0.5 Hz is caused by rough-

ness with wavelengths of some 15 - 20 m at a speed of 30 km/h and 70 m at 130 km/h.

λ = v/f

Formula 5 The basic relationship between roughness wavelength, travel speed

and vertical vibration frequency (one wheel, no suspension).

28(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-30-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

4.5 Transmission of vibrations through the vehicle

The magnitude of the vibration transmitted to vehicle occupants through the vehicle de-

pends on the road roughness and the speed of travel, as shown clearly in Figure 7. This is

accentuated by the mechanical properties of the vehicle. For instance, those riding in

higher vehicles are exposed to a greater amount of pitch and roll than those in low vehicles

[13].

Two-axle cars, are said to have three natural frequencies for vertical vibrations: one that is

related to the car body bouncing on its suspension, one that is connected to the wheel axle

hop between the body suspension and the tyre suspension, and one that originates from

the rocking of the car seat. The car body has a natural frequency of about 1 Hz, and vibra-

tions close to this frequency are amplified by a factor of 1.5 – 3.0. The wheel axles of a car

have a natural frequency of 10 – 15 Hz, which means that at this frequency they tend to

vibrate more than what the car body and tyres together with the road surface would di-

rectly cause [13][14].

Formula 5 indicates that a vibration frequency of 1 Hz when travelling at 90 km/h is

caused by roughness with wavelengths of about 25 metres. Vibration frequencies of 10 –

15 Hz at 90 km/h seem to be caused by roughness with wavelengths of about 2 - 3 metres.

Multi-axle vehicles that are both heavy and long may have considerably different mechani-

cal behaviour than normal cars, particularly if they are towing heavy trailers. Moreover, the

properties of heavy vehicles are changed substantially by the actual weight of the payload.

Some types of heavy-duty vehicles lack suspension altogether.

The natural frequency of the roll of heavy vehicles is less than 3 Hz. Since roll motions at

frequencies under 5 Hz are not common when driving on roads with ”normal”(?) rough-

ness and at normal speeds, it is not usually considered to be of any greater significance.

[55]. This item will be under further discussion later in the report.

The current European trend towards fewer and more specialised hospitals is resulting in a

greater percentage6 of ambulance transports having to cover longer distances while simul-

taneously administering intensive care. To manage this, more -- and heavier -- medical

equipment is required on board. Ambulances must then have a greater load capacity than

before, which means that large vehicles (”container ambulances”) designed similarly to

trucks are needed. See Figure 11. An effective load capacity of more than a tonne is not

unusual.

In many cases it has been shown how even slight road roughness can, through vibration

and dynamic weight transfer, cause the wheel load to temporarily exceed twice the static

load and then revert just as suddenly to 0 (zero!) during the ride. See Figure 12. A feeling

for how dynamic loads can originate can be created by bouncing a little on the bathroom

scales. That the road grip varies between the wheels – and moreover is occasionally non-

existent – involves a major risk of skidding when hitting the brakes in an emergency. [3].

Dynamic loads have been proven to be a large problem when weighing vehicles in motion,

even on very smooth road stretches [48].

6Today, there already are some 850 000 ambulance transports per year in Sweden. Of these, about 200 000

are emergencies [29, 17].

29(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-31-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Figure 11 Well-equipped “Mobile Intensive Care Unit” type of ambulance. The

effective load capacity of the vehicle in the picture is 1.44 tonnes. Notice the heavy-

duty wheels, which are even mounted in pairs at the rear.

Wheel load

Wheel axle hop

Road roughness profile

Figure 12 Dynamic change in the wheel load when driving on a rough road [57].

The static wheel load is designated as ”p” in the figure. As seen here, the actual

wheel load -- which determines the road grip and thereby the risk of skidding when

braking -- varies between 0 (zero!) and twice the static load as roughness in the road

profile causes vibrations and weight transfer in the vehicle.

30(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-32-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

4.6 Whole-body vibration

Describing the consequences of shaking the whole human body -- a complex, active, intel-

ligent structure -- is not a completely simple matter. The National Board of Occupational

Safety and Health has compiled the known effects of humans being over-exposed to

whole-body vibration. A few of the conclusions were: ”It can be assumed without a doubt

that the human being is negatively affected by whole-body vibration, from both a subjec-

tive and objective perspective” and ”It would obviously be desirable from everyone’s point

of view if vibrations could be totally eliminated” [51].

Needless to say, there are also vibrations that are positive. For instance, vibrations that

inform drivers about the movement of their vehicle, [11, 66], that they are driving over a

zebra crossing or that the right front wheel ha s a puncture. For safety reasons, such vibra-

tions -- ”a sense of the road” -- should not be dampened.

Like auditory stimuli, sensory impulses impart strong impressions. These should therefore

be used sparingly, since they partially block or suppress other sources of information. [57].

For instance, unlike operators of forestry machinery working out in the woods, those driv-

ing on public roads find it completely reasonable to expect the underlying surface to be

smooth enough that any vibration generated would be insignificant. In an upcoming EC

directive for limiting exposure to whole-body vibration, it is stipulated that ”the risks aris-

ing from exposure to mechanical vibration shall be eliminated at source or reduced to a

minimum [with the aim of reducing exposure to below the threshold level].”

The survey conducted by the National Board of Occupational Safety and Health on the

effects of overexposure to whole-body vibration showed that although this primarily causes

fatigue, it also gives rise to visual acuity disorders, motion sickness, dizziness,

back/abdomen/face pain, headaches and a frequent need to urinate [51].

That very extreme acceleration causes bodily injury is a factor that has set limits on the

manoeuvrability of manned fighter aircraft. Based on fracture mechanics, it is not unlikely

that even the substantially less intensive forces (but at higher frequencies) that cause more

”normal” whole-body vibrations can cause physical injury in connection with long-term

exposure.

When being subjected to vibration, human body reflexes try to protect organs that are sen-

sitive to resonance through a tightening of the muscles (this is only successful for very

short periods - seconds) [38]. Lengthy exposure to vibration therefore often results in high

muscular tonicity [15], which is dangerous to health on many accounts.

A governmental working committee on public health has estimated that the cost to society

for back problems, which is the primary reason for people reporting in sick and for early

disability retirement in Sweden, exceeds SEK 20 billion per year (1991). In its report, the

committee also ascertained that whole-body vibrations are of ”key importance” as a source

of back problems [53]. However, in the general health statistics, the concept of whole-body

vibration is lacking. ”Vibration injuries” primarily refers to hand/arm vibrations [33]. In

England a direct relationship has been found between the frequency of back problems and

the distance travelled per year [60].

31(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-33-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

The findings of a recent review of epidemiologic studies conducted between 1986 and 1997

on the relationship between exposure to vibration and problems in the lumbar part of the

back provided ”clear evidence for an increased risk for LBP disorders in occupations with

exposure to WBV. Biodynamic and physiological experiments have shown that seated

WBV exposure can affect the spine by mechanical overloading and excessive muscular

fatigue, supporting the epidemiologic findings of a possible causal role of WBV in the de-

velopment of (low) back troubles”. The review also mentions that it is estimated that 4-7%

of the working population in the EU is exposed to potentially harmful whole-body vibra-

tion [74].

Surveys have shown that truck drivers are exposed to considerably greater vibrations than

most other categories of road user. The exposure often exceeds the recommendations and

limits in the International Vibration Standards [10, 7], as well as the limits proposed by the

EU.

Sensitivity to vibration differs substantially between men and women. Women (and the

foetus) are particularly sensitive during pregnancy [30].

Those who are most sensitive to vibration are injured, sick or disabled people who often

require ambulance transportation. The National Swedish Institute for Working Life has

compared the noise and vibration properties in traditional ambulances and the increasingly

more common larger MICU container ambulances. A major difference was found. The rms

for vertical vibration (0,5 – 80 Hz) at the driver’s seat in a large ambulance amounted to as

much as 1.44 m/s2. Interpretations of the findings indicate that levels above 0.5 m/s2 entail

an excessive risk for any normally healthy person sitting behind the wheel 6 hours a day.

The surveys also showed that the vibrations in an infant incubator on board are often even

greater than at the driver’s seat. On one occasion, the rms for the vertical vibration in the

incubator was ranked as a 5 (very uncomfortable) on a six-grade scale of discomfort in the

ISO 2631-1 “Evaluation of human exposure to whole-body vibration” standard. [17, 29].

According to ambulance orderlies, acute motion sickness is a common problem for staff

and patients alike.

More can be learned about the effects of whole-body vibration in the report by Prof.

Ronnie Lundström [65]. Additional information – including the effect of such loads as low

frequency noise and infrasound – can be found in other reference literature compiled in

Chapter 8 as well as from such sources as the National Board of Occupational Safety and

Health, the National Swedish Institute for Working Life’s Vibration Committee [31], Upp-

sala Academic Hospital [15] and the Swedish Road and Transport Research Institute.

4.6.1 Natural frequencies and resonance in the human body

All material bodies have a natural frequency, which to some extent can be compared to the

natural frequency of a swinging pendulum. When a body is exposed to a frequency vibra-

tion that coincides with its own natural frequency, it will vibrate strongly.

The various parts and organs of the human body have different natural frequencies. This

means that the body does not vibrate uniformly, but rather that the different parts behave

like individual, albeit interlinked, material bodies in this respect. (See Figure 2). External

vibrations with frequencies of about 6 Hz are amplified through resonance in the abdomen

by up to 200%. Certain vibrations are amplified in the spine by up to 240%. The head has a

32(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-34-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

natural frequency of about 25 Hz, which means that vibrations with frequencies around

this are amplified by up to 350% [41][42]. The resonance phenomenon leads to a greater

load on the body and thereby a greater risk of injury.

4.6.2 Examples of the effect of whole-body vibration in the 0.5-80 Hz range

Shortwave road roughness produces vibrations with a frequency content that among other

things includes the 0.5 - 80 Hz band.

According to the ISO 2631-1 standard, vibrations with frequencies between 0.5 - 80 Hz

could probably cause a greater risk of injury to the vertebrae in the lumbar region and the

nerves connected to these segments. Exaggerated mechanical strain can be a factor in the

deterioration of the lumbar segments. Vibrations are reported as affecting the body

through causing deformation of the spine (spondylosis deformans), damaging the cartilage

between the vertebrae (osteochondrosis intervertebralis), and by producing chronic pro-

gressive change in the cartilage and bone tissue (arthrosis deformans). Exposure to whole-

body vibration can also exacerbate certain endogenous pathological disorders of the spine.

It is not considered unlikely that the digestive system, the urinary and sexual organs and the

female reproductive organs are affected. Health impairment caused by whole-body vibra-

tion normally only occurs after several years of exposure [10]. Spontaneous abortion is an

exception.

4.6.3 Examples of the effect of extremely low frequency whole-body vibrations

Longwave road roughness produces low frequency vibrations. Vibrations with greater am-

plitudes within the 0.1 – 0.63 Hz frequency band have a particularly strong effect on peo-

ple.

According to the ISO 2631-3 standard, these vibrations cause various degrees of motion

sickness, ”travel sickness”, even after only short exposure. Motion sickness can affect peo-

ple for hours, and even up to days after an arduous trip. It has been observed that motion

sickness lowers performance ability and reduces alertness.

A survey conducted amongst 300 students revealed that about 58% had felt nauseous dur-

ing car rides. Some 33% could remember actually having vomited during car trips before

the age of 12 [11].

A nationwide questionnaire revealed that motion sickness is a frequent working environ-

ment problem amongst ambulance orderlies. 23% replied that they easily felt nauseous

during the ride. [27]. Orderlies in Sollefteå Municipality reported having observed palpable

travel sickness symptoms in patients (in the worst case vomiting, uncontrollable bowel

movements, etc) in 20-25% of the most acute (high speed) transport situations. In the care

unit of the vehicle, it is impossible to watch the horizon.

Vehicle manufacturers are aware that the suspension properties affect the risk of passen-

gers developing motion sickness. A sports car type of suspension is recommended for

people who easily get car sick. It cannot be ruled out that ”comfort suspension” -- by

American standards -- can mean that the high frequency vibrations caused by road surface

damage are converted to an exceptionally high degree into that very type of low frequency

vertical vibration that is known to cause motion sickness. It is also known that rotation

vibrations are a factor in motion sickness. Perhaps even the differences in roll-stability be-

33(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-35-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

tween different vehicles has a major impact? Added to the ”motion sickness vibrations”

created by the ride are the low frequency vibrations that ensue from the billowing align-

ment that roads originally built for horse drawn carriages often have.

4.6.4 Origin of whole-body vibration

According to the Academy of Engineering Sciences (IVA) road roughness is a much

greater cause of vibration in road vehicles than in-vehicle factors (wheel imbalance, drive-

line, etc.). IVA has also ascertained that vibrations have a major impact on the steering and

braking properties of the vehicle, and on the working environment, ride quality, health and

possibly even performance ability of vehicle occupants [19].

Whole-body vibrations originate from two different types of force. A random and sudden

force designated as shock. When the wheel hits a bump or sinks into a pothole, shock oc-

curs. If this shock is strong enough, passengers without a safety belt can be thrown from

their seat. They could also be hit by a loose-flying object. Shock can also cause severe spi-

nal injury [32], such as in several Scandinavian cases due to riding in buses over traffic

calming road humps. Less sudden displacements and forces occur during a normal ride on

more or less rough roads. See Figure 13 - Figure 15. These are the most common motion

induced forces that we experience during a normal day [42]. The second law of Newton

can be used to calculate the dynamic forces that vibrations transfer to human organs.

Certain types of vibration are known to cause car sickness. These include extremely low

frequency vertical vibrations (0.1 – 0.63 Hz) and roll (often in combination with lateral

displacement). The low frequency vertical vibrations are caused by exceedingly longwave

roughness (up to 350 m), but can also occur when a vehicle with worn or poorly designed

wheel suspension transforms high frequency vibrations to low frequencies. Roll occurs

when there is an unfavourable variation in the gradient between the wheel tracks (crossfall);

this often is caused by roadway deformations and all too sharp curves in the alignment.

The limits for whole-body vibration in the ISO 2631-3 Standard can be converted into

standard specifications for the road roughness profile. See Figure 16. On roads where there

is substantial roll (caused for example by sharp curves or deformed edges) the acceptable

longwave road roughness must be reduced by 25%.

Major vertical

motion

Figure 13 Origin of vertical vibrations on roads where the roughness wavelength

coincides with the distance between the vehicle axles. Adapted from [66]

34(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-36-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Major pitch and thus

major longitudinal

vibration

Little vertical

movement

Figure 14 Vibrations in the direction of travel occur when the wavelength of

the road roughness does not coincide with the distance between the vehicle axles.

Adapted from [66].

Major roll and thus

substantial lateral vibration

Figure 15 Origin of lateral vibrations on a road with deformed edges

35(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-37-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

2.00

1.80

1.60

1.40

1.20

1.00

0.80

0.60

0.40

0.20

0.00

153 122 95 76 61 49 38 31 24

Length of the hollow or ridge

(i.e., half the roughness wavelength), [m]

Figure 16 Limits for longwave roughness at a speed of 110 km/h, set with respect

to the criterion for decreased performance ability. The values are derived

from the vibration limits in the ISO 2631-3 standard. The corresponding limits with

respect to the discomfort criterion are considerably stricter. The limits assume no

surface defects at all (aggregate stripping, potholes, etc) or damage that cause rota-

tion vibration (unevenness at culverts, edge deformation, etc).

4.6.5 Measurement of whole-body vibration

The measurement of whole-body vibration must comply with ISO 2631 “Evaluation of

human exposure to whole-body vibration” (1997). The equipment consists of acceleration

sensors, arranged as shown in Figure 17 and Figure 18.

The reaction time for the sense of motion has been found to be 0.24 – 0.80 s, with a mean

value of 0.72 seconds [57]. This is one of the reasons why comfort-related measurements

are normally done through integration over 1-second intervals. A vehicle travels 20 m in a

second, at the speed of 72 km/h. This means that vibration data measured in compliance

with ISO 2631 at rural highway speeds on sub-stretches are fairly comparable in length to

road roughness data in the SNRA road surface condition database, which after sampling at

the mm-level was ultimately averaged over 20 m intervals.

36(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-38-320.jpg)

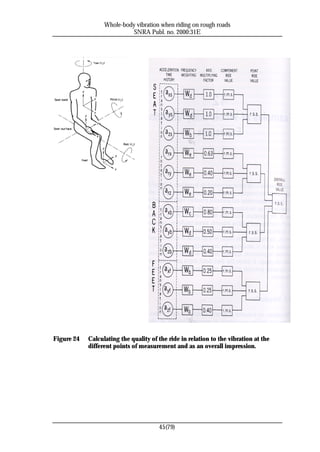

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

5.3 Measurement and analysis of whole-body vibrations

The measurements and analysis were conducted by Kjell Ahlin, Licentiate in Engineering

of Ingemansson Technology AB and are detailed in a report [64]. The analysis in principle

is shown in Figure 23 and Figure 24.

5.3.1 Variables

• Vertical and horizontal whole-body vibration, and both roll and yaw rotations ob-

tained through synchronised measurement on the floor and at the driver and pas-

senger seats. Frequency range 0.5 - 80 Hz in compliance with ISO 2631-1 (revised

1997).

• Vertical measurements at a frequency range of 0.1 - 0.63 Hz in compliance with

ISO 2631-3 (1985).

The plans contained two methods (redundancy) for registering real travel speed and current

position along the road to enable collation with existing road surface condition data. One

involved a mounted measuring wheel with a pulse transducer, and the other GPS. Ar-

rangements had been made to borrow the measuring wheel from the Swedish Armed

Forces. Unfortunately, it arrived too late and could not be used. The GPS receiver broke

due to severe shocks during the first run. A video film was taped simultaneously. This film,

with its time indicator, was later used as an aid during the data collation.

Figure 23 Flow chart for measurement and analysis of whole-body vibrations

44(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-46-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

5.4 Expert analysis of the effect of vibration on the human body

An expert analysis of the effect on the human body of the vibrations measured was con-

ducted at the National Institute for Working Life. The findings are presented in a separate

report [65]. See also chapter 7.

5.5 Collation between the vibration data and the data from the road

condition surveys

The aim was to develop a correlation model for the translation vibrations as a function of

IRI, based on values measured on National Highway 90.

Since the real speed varied somewhat during the runs, the analysis was initiated by dis-

criminating individual measurement values (both IRI values and vibration values) to keep

the distance synchronisation of the measurement series from ”getting out of hand”. The

analysis was then based on the mean values on 100 m long stretches. After having studied

descriptive statistics for data in a computer environment (histogram, distribution, etc.), it

was found suitable to classify the material according to IRI100 values. Classes 0 < IRI100 < 3

mm/m, 3 < IRI100 < 5 mm/m, and IRI100 > 5 mm/m were chosen for the Mercedes ambu-

lance driving at low speed. In all the other cases, classes 0 < IRI100 < 3 mm/m and IRI100 >

3 mm/m were chosen. This was followed by a regression analysis, whereby a linear regres-

sion model was found to give the best results. The results are presented in Chapter 6.

5.5.1 Effect of emergency action, ”the devil’s choice”, on National Highway 90

The road condition data that was collated with the vibration data was collected during the

summer of 1999. In the autumn of 1999 spot emergency actions was taken to reduce

roughness on the stretch at hand. See Figure 25. This meant correcting steep deformations

(amplitude ca 50 – 300 mm) with crushed gravel, which was then provisionally covered

with a bitumen mix.

46(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-48-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

Figure 25 Emergency repair on National Highway 90 between Skarped and

Näsåker

Vehicular roll motions drastically reduces where spot actions had been taken, particularly

when the repair was close to the edge of the road. This also facilitates effective road main-

tenance during the winter ahead, of course very positive with a view to road safety. How-

ever, spot repair often means a heterogeneous road texture, which leads to split friction

between the wheels, especially when the moisture on the road begins to freeze. In connec-

tion with moisture/freezing, even colour differences are a significant factor, as this affects

the absorption of solar heat.

Split friction considerably increases the risk of skidding. For cars, there is a greater risk of

skidding when braking sharply on bare roads than on winter roads. This is due to fact that

the load on the rear axle is lightened through vehicle pitch in the first case, reducing the

road grip of the rear wheels. On the other hand, steering control is lost faster on winter

road surfaces than on bare roads. It becomes difficult to avoid rear wheel skid in situations

where the rear wheels have less road grip than the front wheels when braking [3].

Hence, split friction means a much greater risk of skidding when having to brake sharply,

or it can cause the ”jack-knife” phenomenon for a truck with a semi-trailer, making it im-

possible for the driver to maintain control of the vehicle. For this reason, spot repairs

should be done so that the texture is the same as on the surrounding surface. It is advisable

that the repair cover the entire lane width. There is always somewhat of a height discrep-

ancy on the road surface at all temporary patching. This can significantly reduce the dy-

namic contact between the tyres and the roadway, which is an obvious safety hazard.

Action similar to that shown in Figure 25 can be described as the ”devil’s choice”, the least

bad alternative where maintenance budgets are all too constricted.

47(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-49-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

6 Results

When first driving in a large, comfortable 1999 car model on the ”rough” test stretch of

Highway 90, those taking part in the vibration survey wondered why the Swedish National

Road Administration had not chosen a road in poorer condition. During the subsequent

runs inside the trucks, the same people commented that ”this is not much different than

driving through the forest in an army tank”.

During the survey, they occasionally found it hard to speak because of the vibrations.

While riding in the care unit of the ambulance, members of both the survey team and the

”patient” experienced clear signs of motion sickness -- perspiration, pallor, nausea and diz-

ziness -- when there was little opportunity to keep their eyes on the horizon. Before start-

ing, and at the end of each run, they had to get out of the ambulance for some fresh air.

They also found eating difficult on their lunch break.

Both road authority employees and the survey team had back pain for about ten days after

the intensive round of test driving.

A full account of the measurements and analysis results is contained in a separate report

[64].

The expert analysis of the impact of the vibrations on the human body, conducted at the

National Institute for Working Life, is presented in a separate report [65]. A summary of

the conclusions is compiled here in Chapter 7.

The following are extracts from the SNRA’s current data on the road surface condition and

the results from collating this data with the vibrations measured inside vehicles.

49(79)](https://image.slidesharecdn.com/skakstudieengelsk-13369415317251-phpapp02-120513154534-phpapp02/85/Whole-Body-Vibrations-When-Riding-on-Rough-Roads-51-320.jpg)

![Whole-body vibration when riding on rough roads

SNRA Publ. no. 2000:31E

6.1 Road surface condition as per the SNRA’s ”PMS” database

6.1.1 Roughness expressed as International Roughness Index

Rv 90: Fördelning av mätsträckornas ojämnheter (IRI-värde)

60

50

Jämn: Skarped - Remsle

Ojämn: Näsåker - Skarped

40

Antal observationer

30

20

10

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

IRI-värde [mm/m]