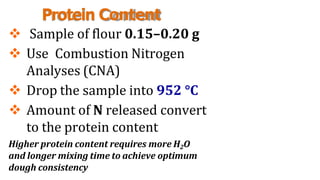

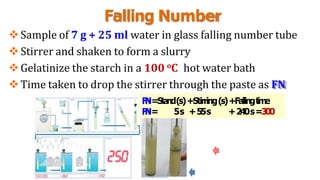

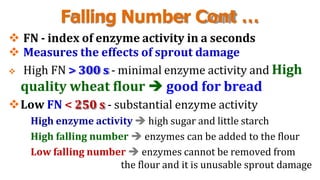

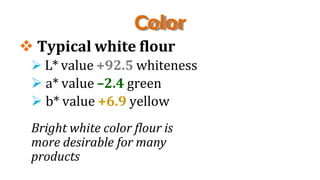

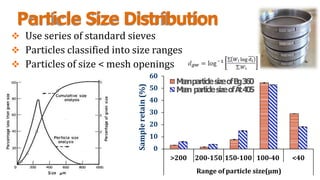

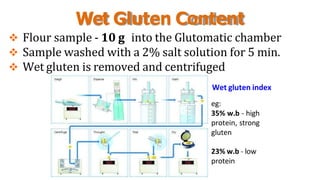

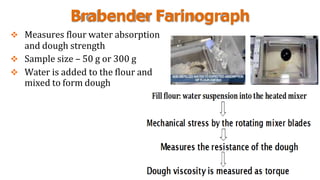

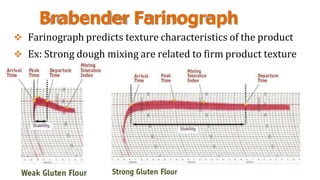

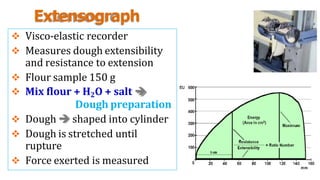

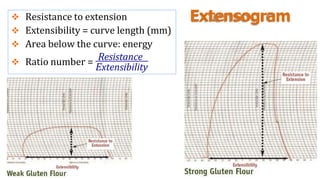

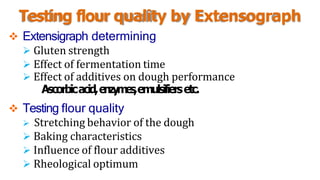

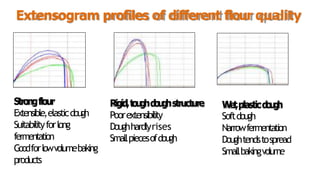

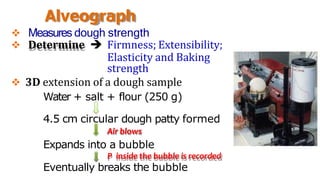

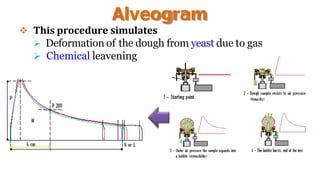

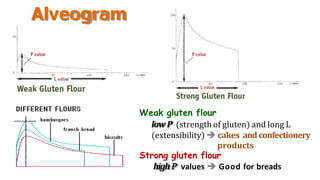

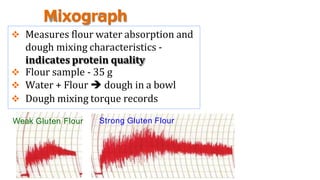

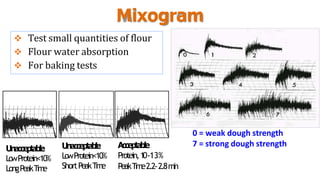

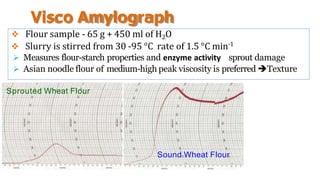

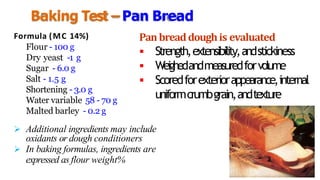

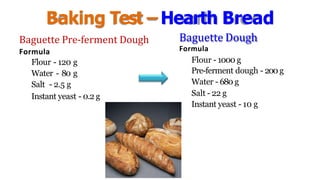

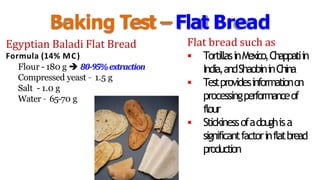

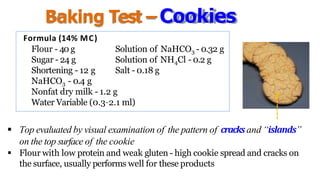

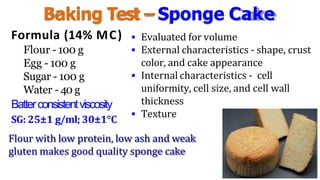

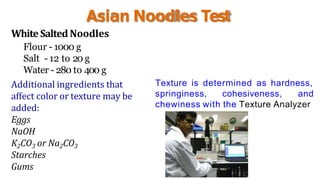

This document describes various methods for testing the quality of wheat flour, including tests for moisture content, protein content, falling number, color, particle size distribution, and wet gluten content. It also discusses laboratory tests that analyze flour properties such as water absorption and dough strength using instruments like the Farinograph, Extensograph, Alveograph, and Mixograph. Finally, it outlines several baking tests including for breads, cookies, cakes, and noodles to evaluate flour performance in different applications.