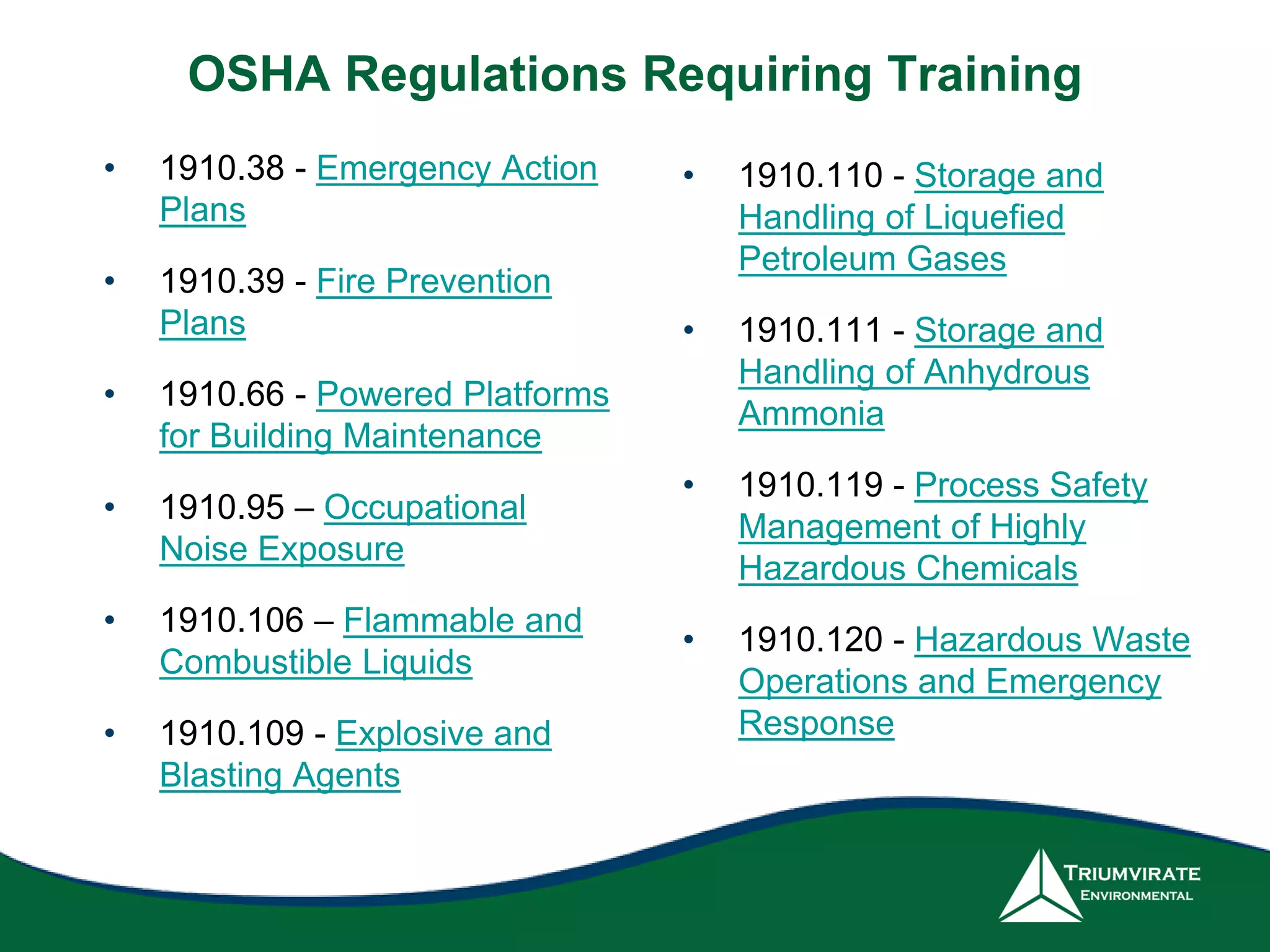

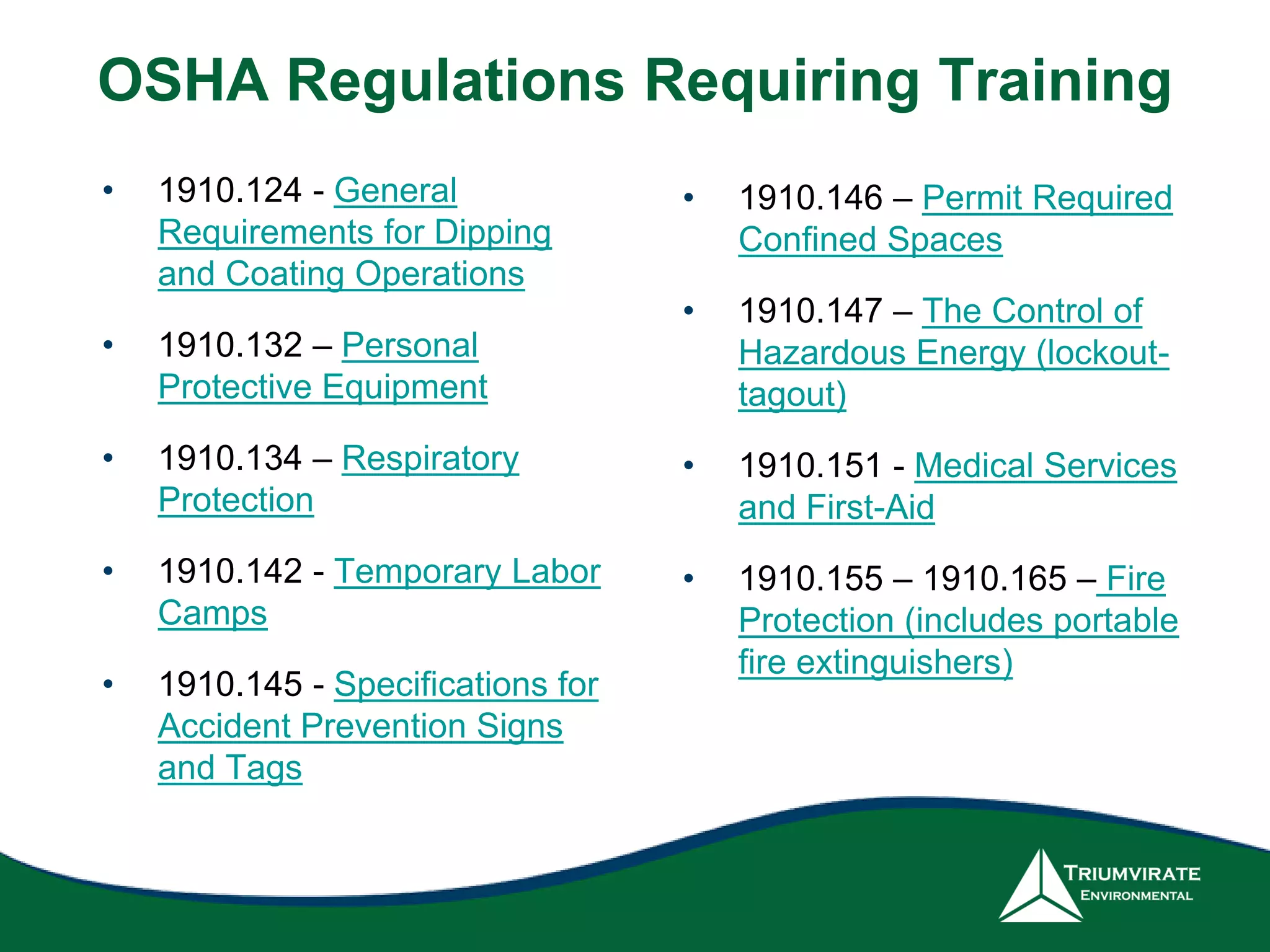

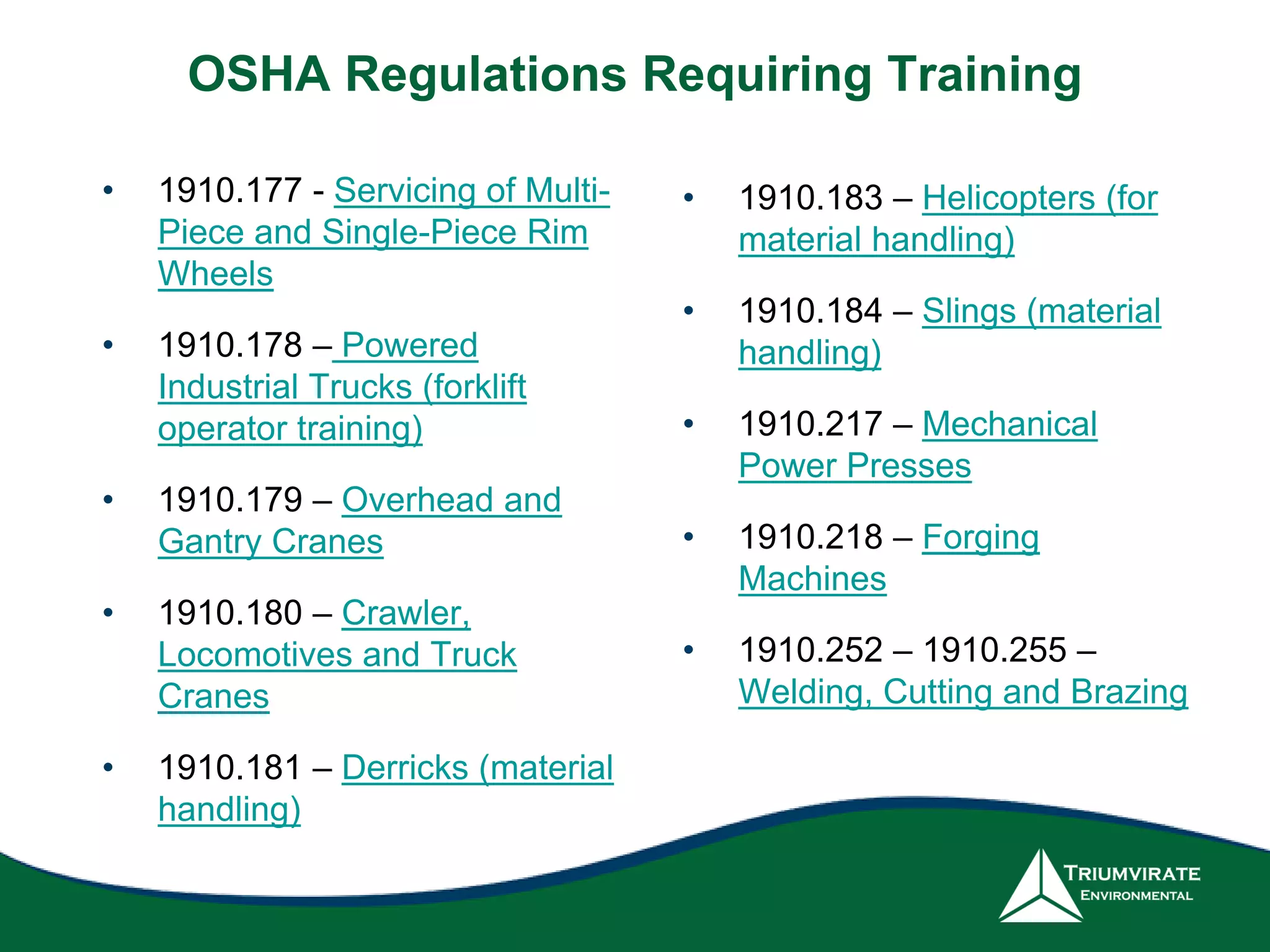

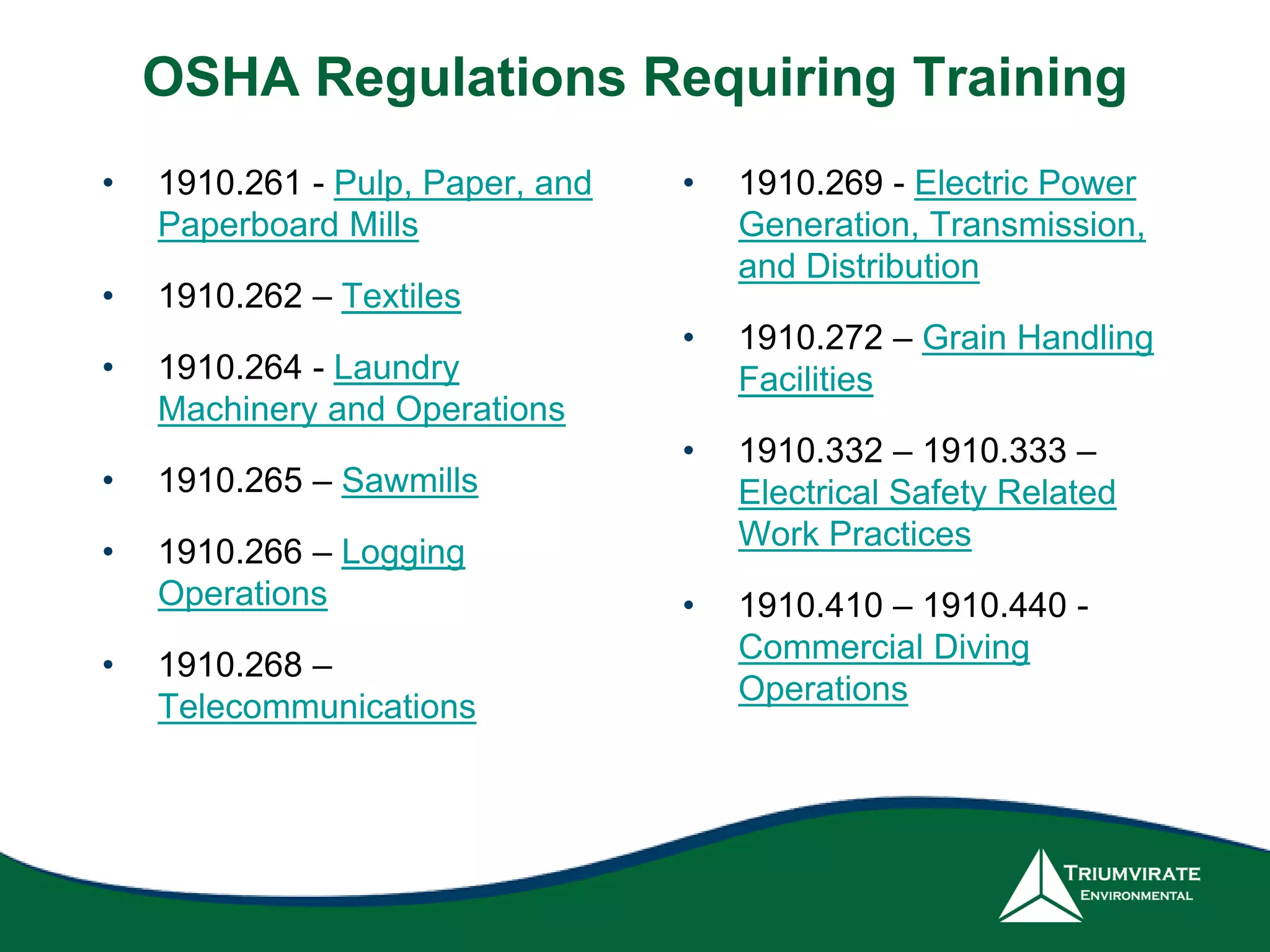

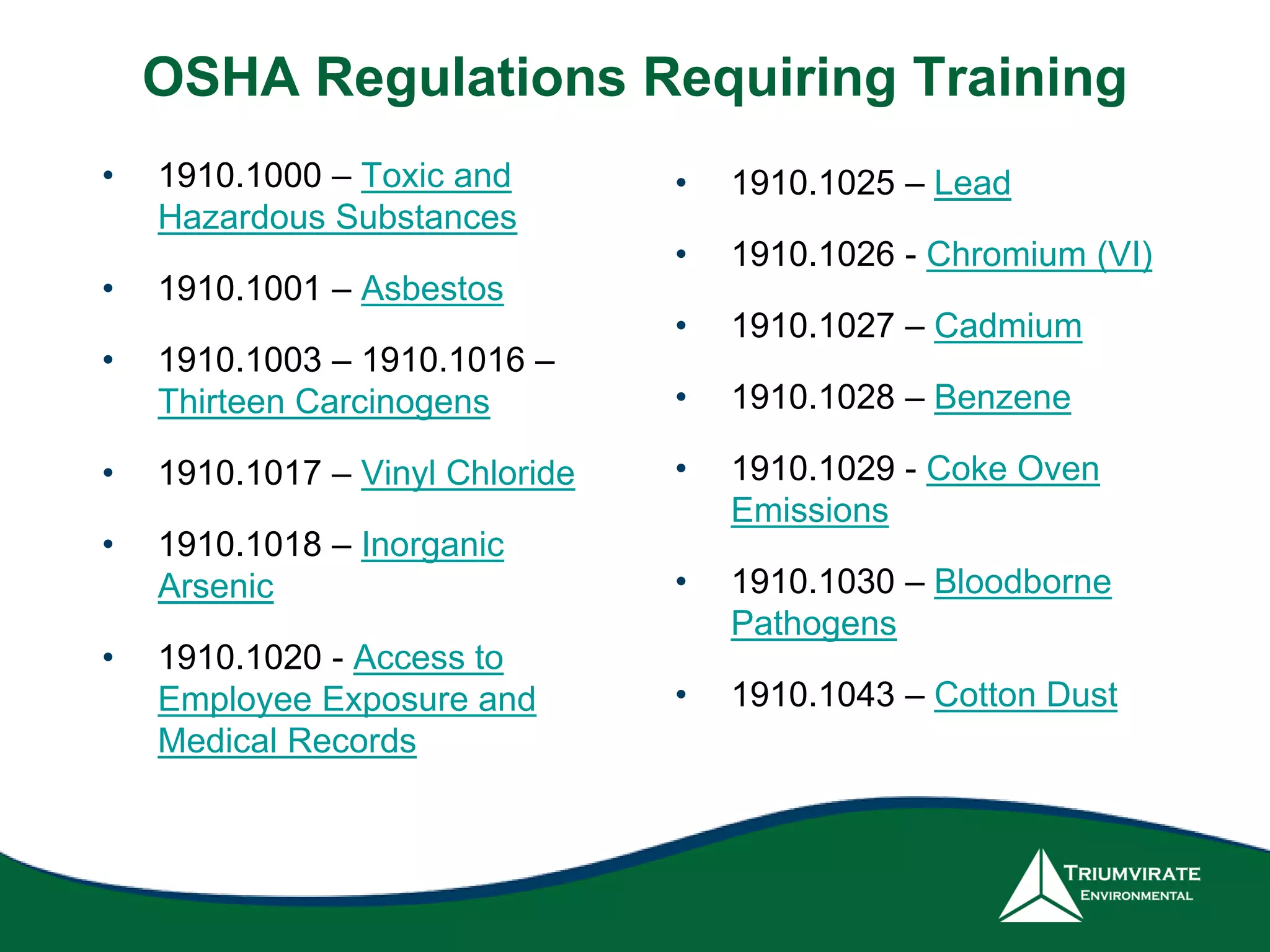

This document provides guidance on preparing for an OSHA audit. It outlines common OSHA violations, tips for organizing inspection resources like forming a preparedness committee and escort roles. Key steps include being prepared with updated plans and records, coordinating logistics like an opening conference, and ensuring issues found are addressed. Training requirements across many OSHA regulations are also listed to ensure compliance. The overall message is that preparation, organization, and addressing any potential violations are essential to successfully navigating an OSHA inspection.