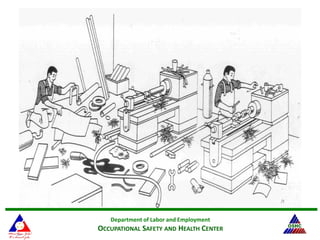

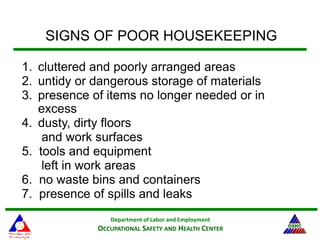

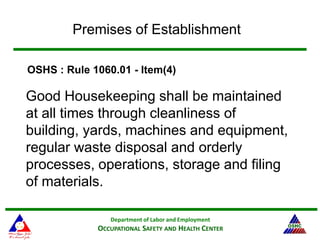

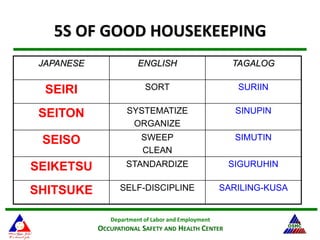

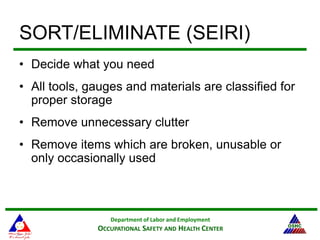

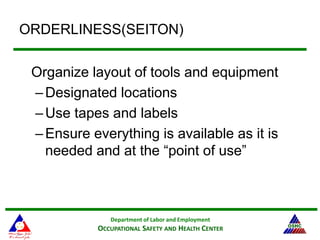

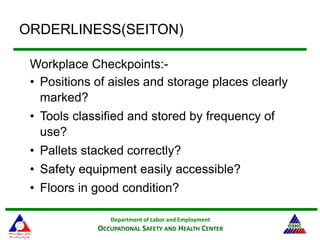

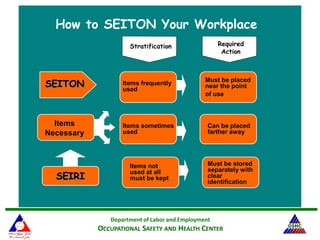

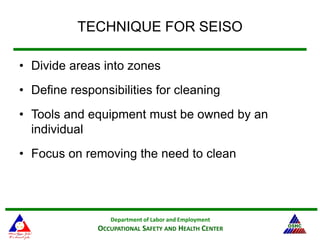

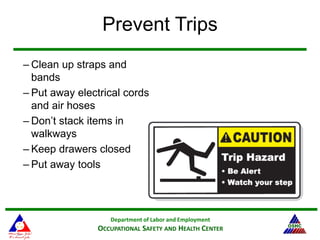

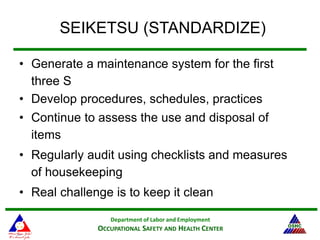

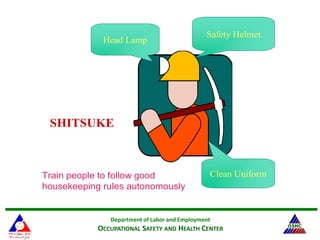

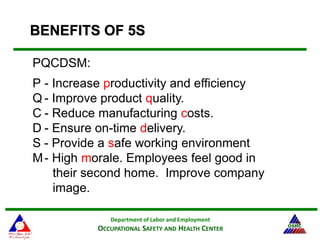

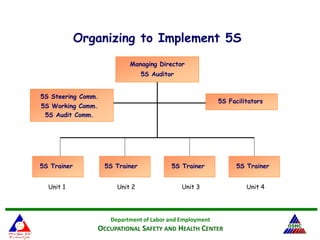

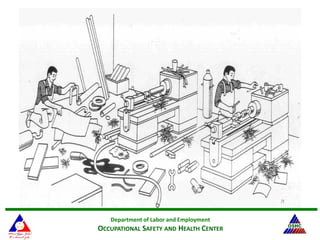

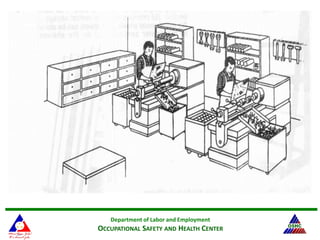

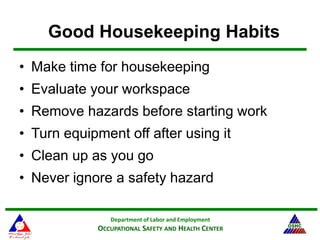

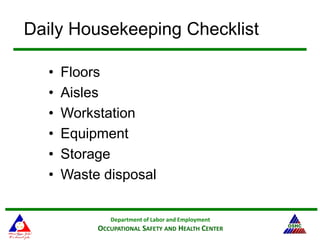

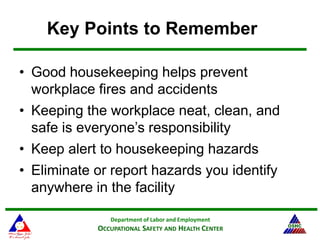

The document discusses the importance of good workplace housekeeping. It explains that practicing good housekeeping through the 5S methodology (Sort, Set in Order, Shine, Standardize, and Sustain) can help reduce accidents, maintain a safe work environment, and improve productivity. The 5S approach provides a systematic process for organizing a workspace and establishing procedures to keep it clean and well-maintained. Management, supervisors, and employees all have responsibilities to continuously implement good housekeeping practices.