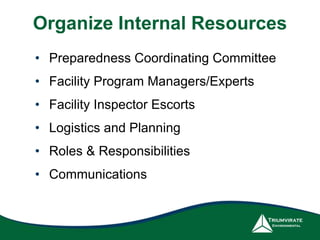

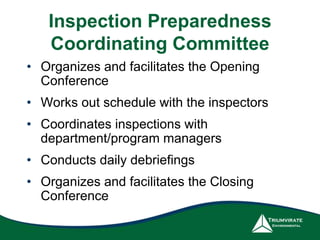

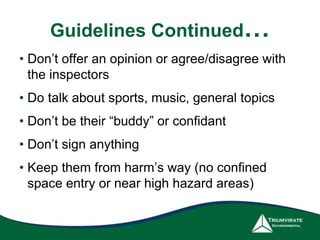

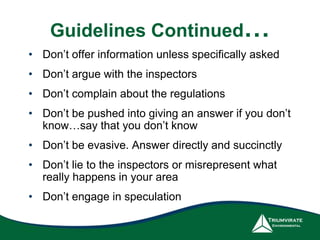

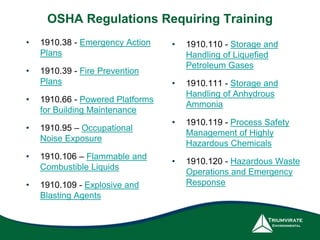

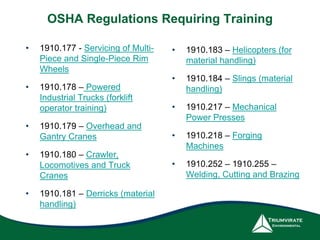

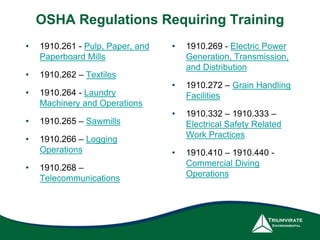

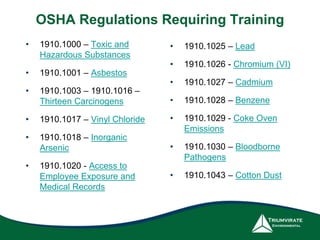

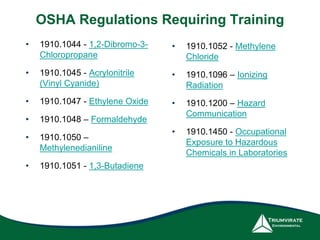

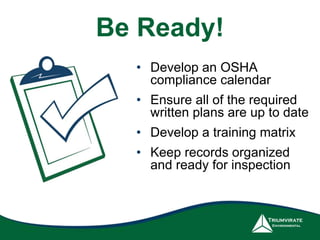

The document provides a comprehensive guide on preparing for OSHA audits, highlighting the importance of committee formation, proper documentation, and effective communication during inspections. It outlines common OSHA violations, training requirements, and strategies for successful inspection management, including maintaining comprehensive records and ensuring personnel readiness. Additionally, it emphasizes proactive compliance measures and shares success stories of organizations that improved their standing with OSHA.