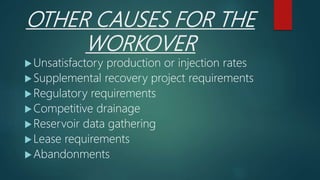

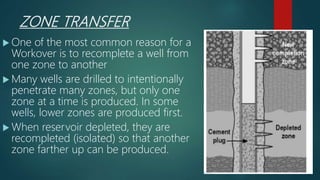

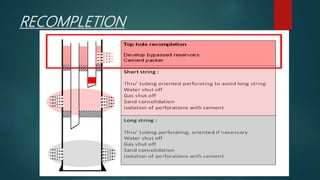

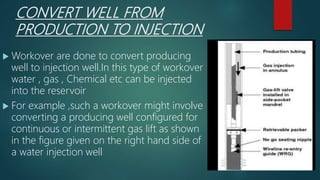

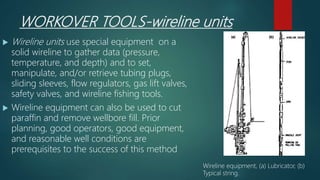

Workovers are operations done on oil and gas wells after initial completion to improve well performance and productivity. Common reasons for workovers include mechanical issues, reservoir problems, unsatisfactory production rates, and converting wells from production to injection. Workovers aim to enhance production through activities like zone transfers, recompletions, stimulation, and replacing artificial lift equipment. They can be performed using conventional rigs or non-conventional methods like wireline units, coiled tubing units, and snubbing units.