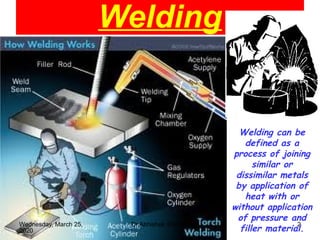

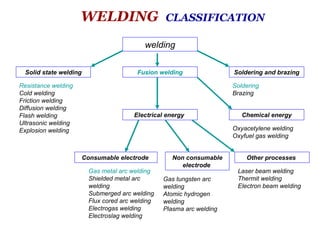

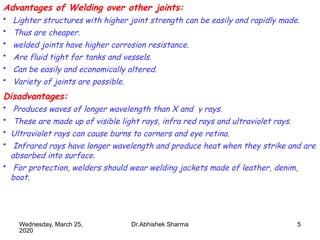

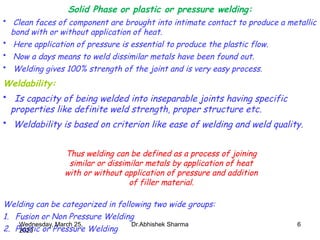

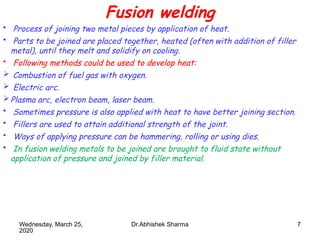

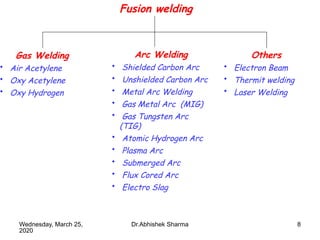

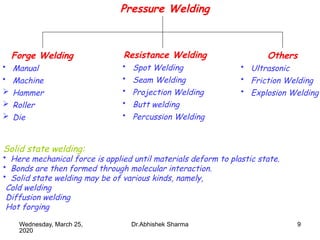

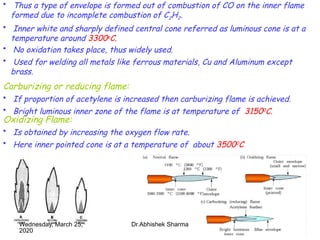

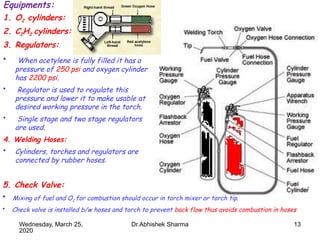

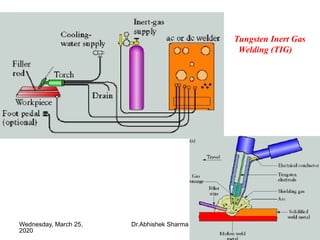

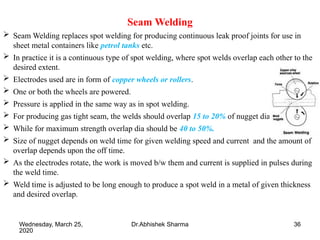

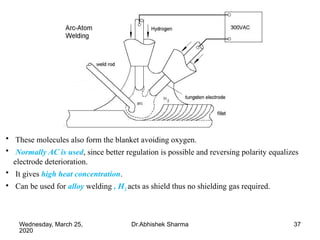

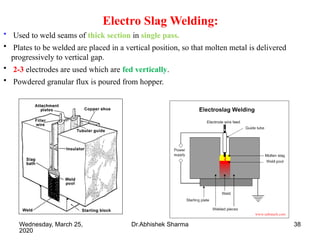

This document discusses different types of welding processes. It begins by defining welding as a process of joining similar or dissimilar metals through the application of heat, with or without pressure and the addition of filler material. It then provides a brief history of welding technology and describes some modern welding techniques. The document goes on to classify welding into two main categories: fusion welding, which joins metals through melting; and pressure welding, which joins metals in their solid state through applied pressure. It provides details on specific fusion and pressure welding methods.