This document discusses key concepts in reliability and safety engineering, including:

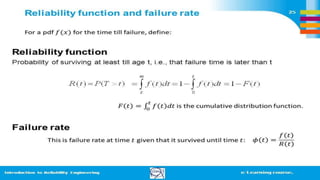

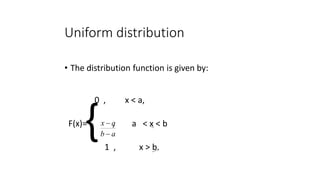

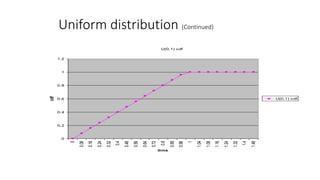

1) Defining reliability as a function of time and comparing it to other probability functions like failure distribution and survivor functions.

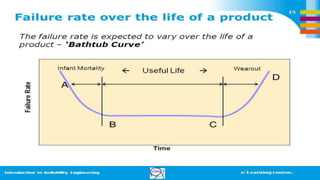

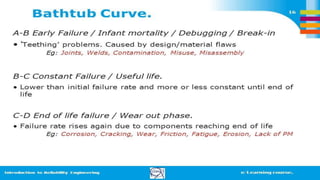

2) Explaining hazard rates and different failure rate models like Weibull and bathtub curves.

3) Describing the three phases of failure rates over time - infant mortality, steady state, and wear out - and how to model each using distributions.