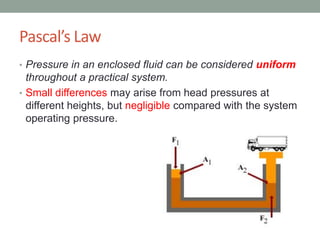

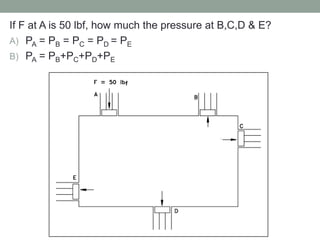

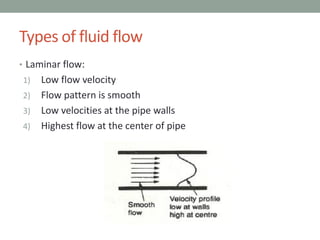

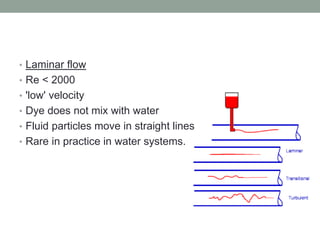

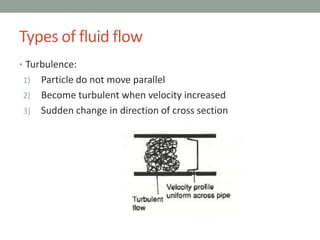

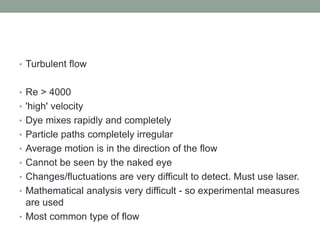

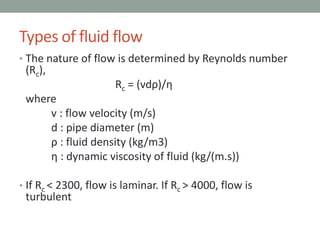

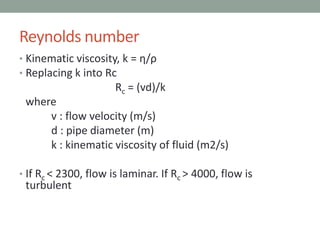

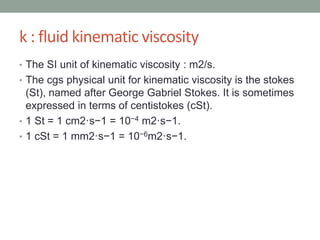

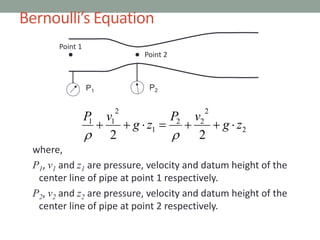

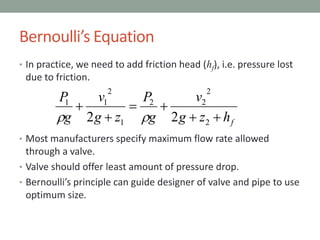

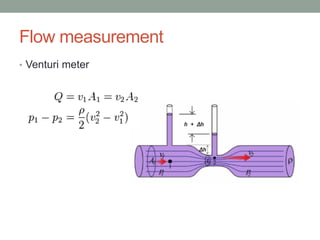

Pascal's law states that pressure applied anywhere in an enclosed incompressible fluid is transmitted equally in all directions. Reynolds number determines the type of fluid flow as either laminar or turbulent based on flow velocity, pipe diameter, fluid density, and dynamic viscosity. Bernoulli's principle states that the total energy in a fluid system is constant, relating pressure, velocity, and height according to Bernoulli's equation.