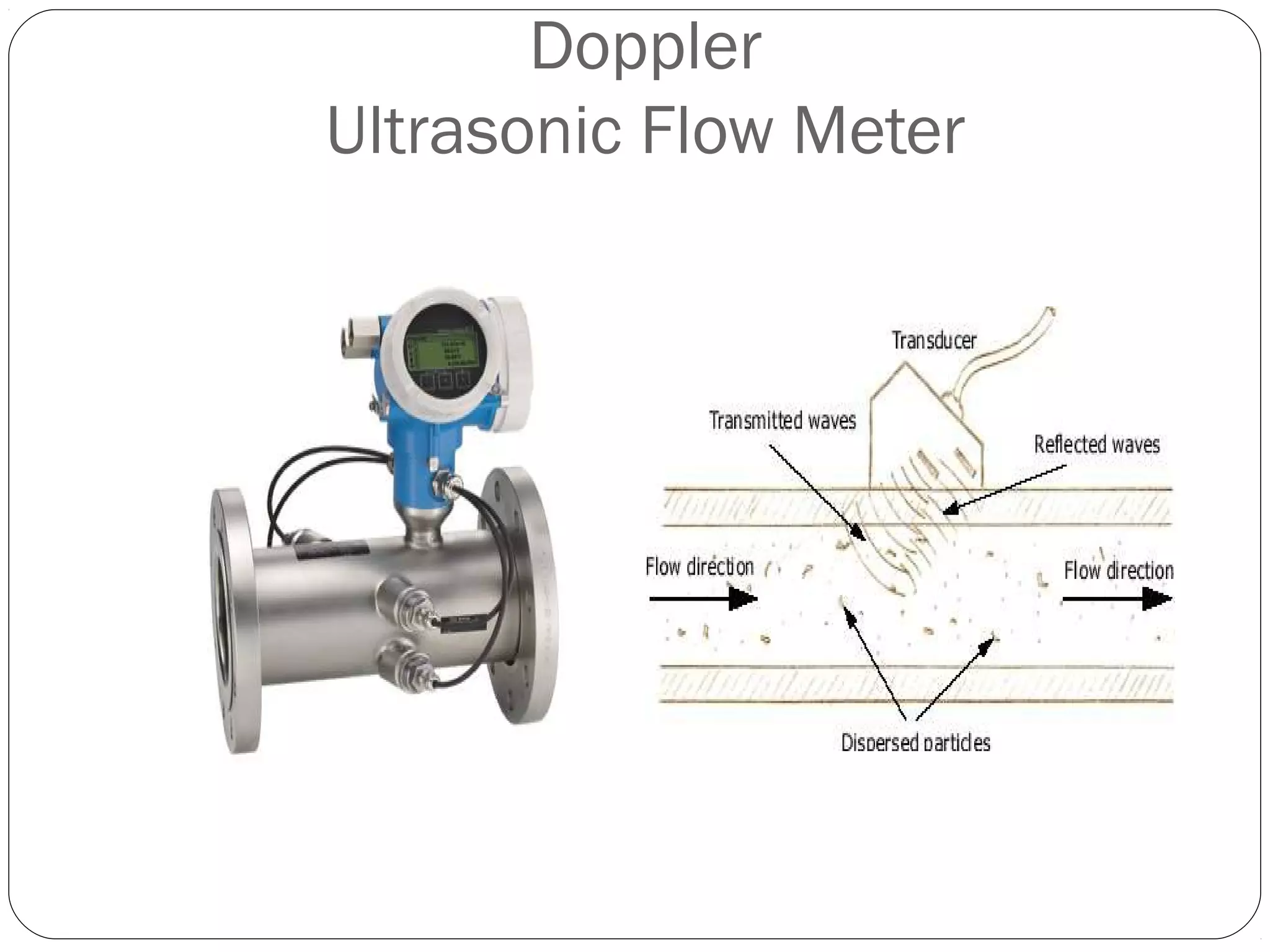

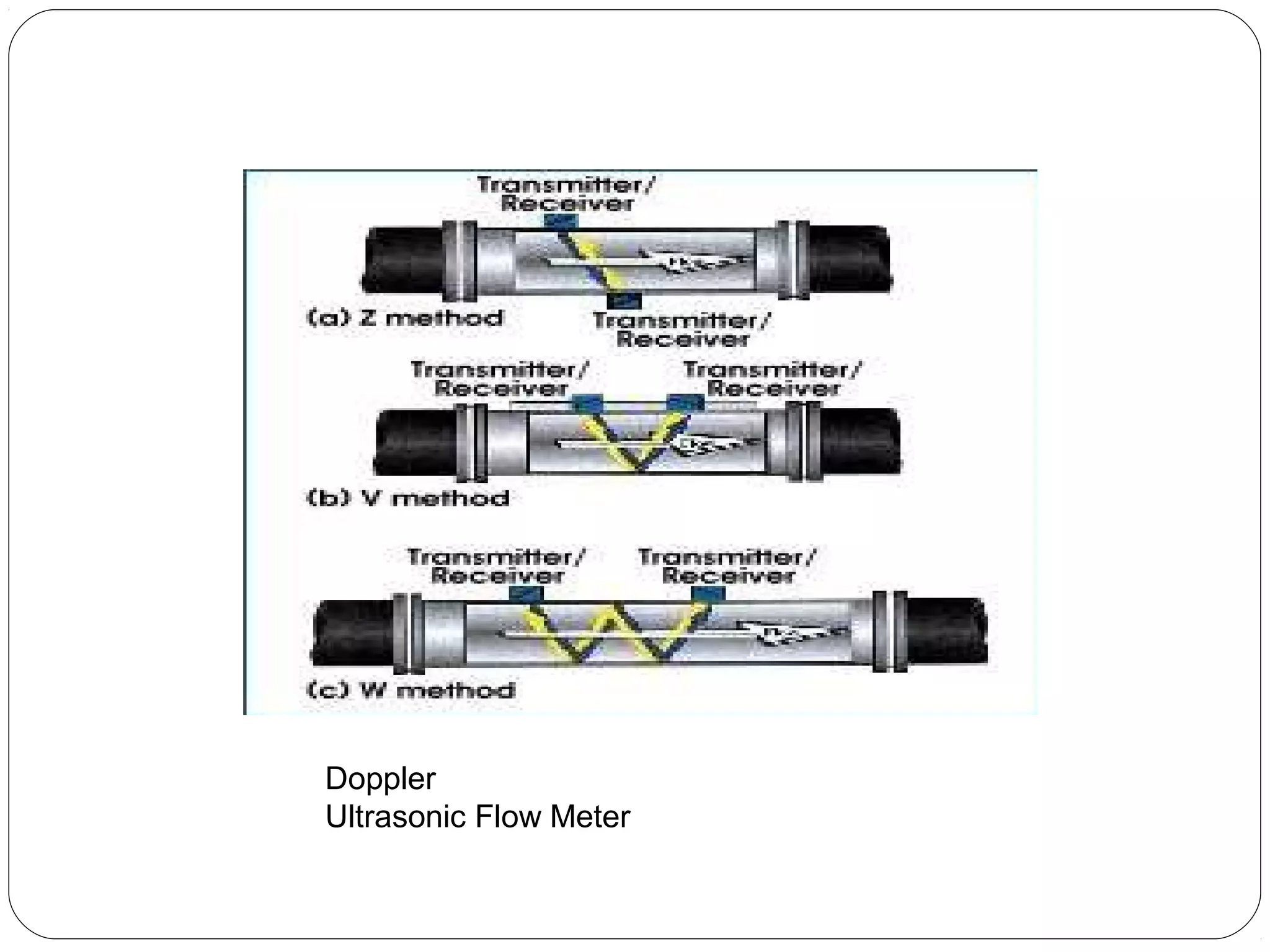

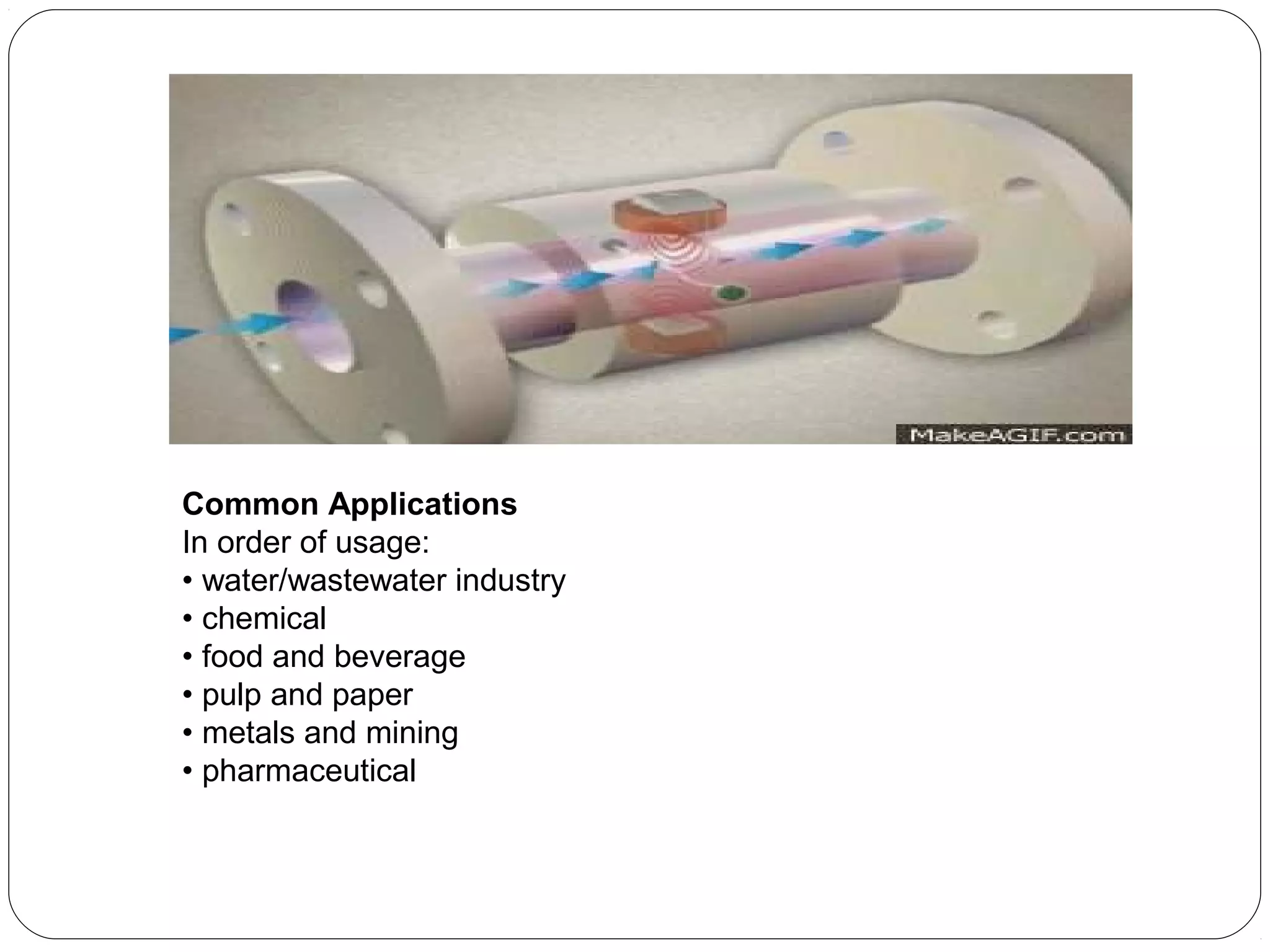

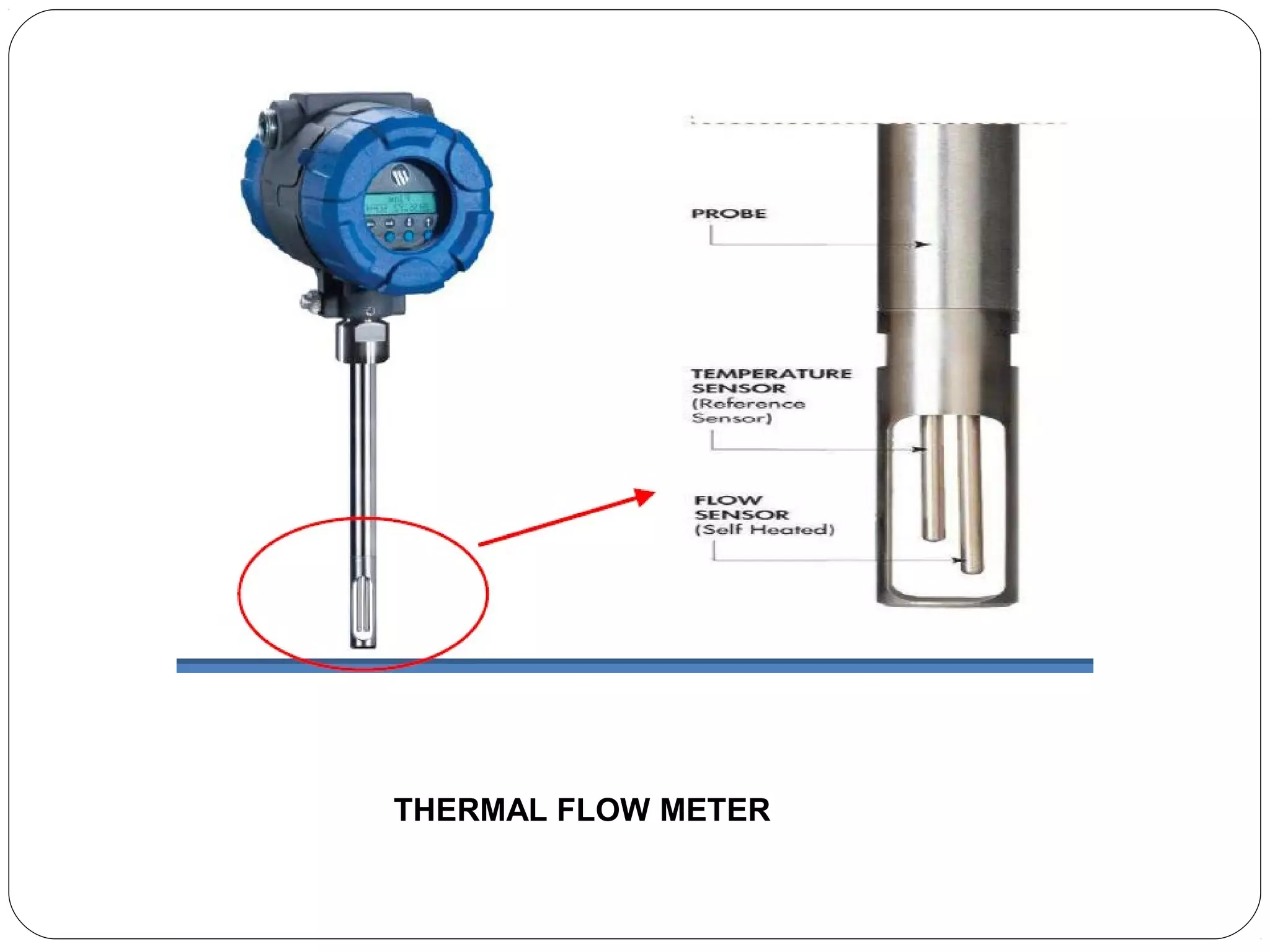

Flow can be defined as the quantity of fluid passing a point per unit time. Flow rate is affected by properties like fluid velocity, pipe size, friction, viscosity, and specific gravity. Ultrasonic flow meters use ultrasound to measure flow velocity and calculate volumetric flow rate. They work well for clean liquids and are unaffected by temperature, density, or viscosity changes. Electromagnetic flow meters use Faraday's law of induction - the voltage induced across a conductor moving through a magnetic field is proportional to its velocity. Thermal flow meters are based on conductive and convective heat transfer - a heated wire in fluid flow measures mass velocity according to King's law. They are mainly used for low pressure gas flow measurement.