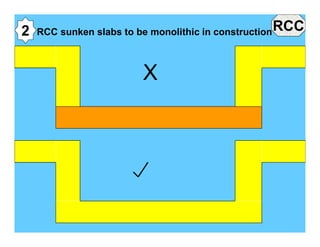

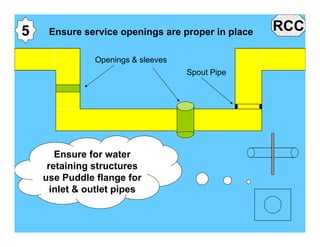

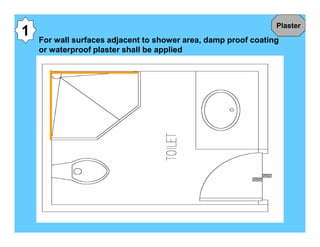

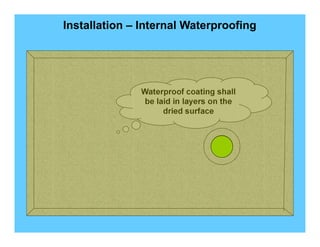

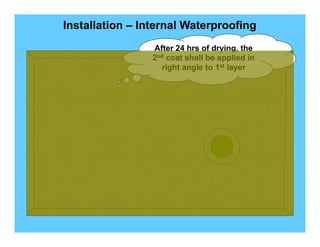

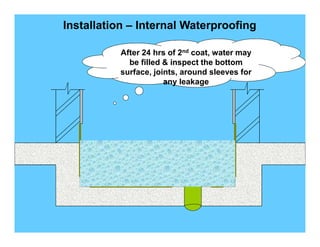

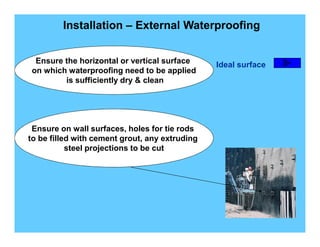

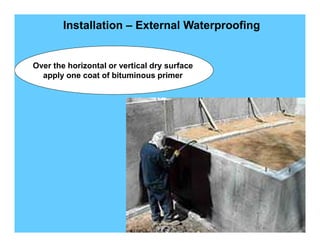

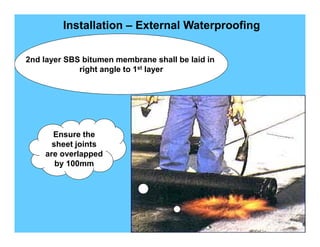

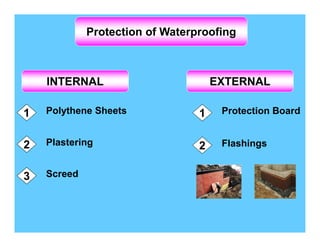

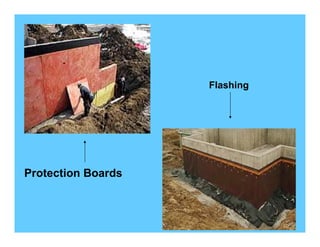

This document summarizes waterproofing methodologies for various areas and structures. It discusses the types of waterproofing, including liquid, sheet, and geotextile membranes. Precautions are outlined for proper installation of waterproofing on concrete, masonry, and plaster surfaces. The stages of internal and external liquid and sheet waterproofing installation are described, including surface preparation, application of primer and membrane layers, and protection methods.