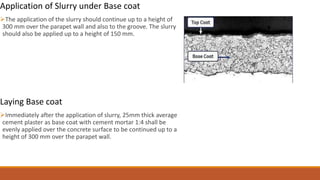

This document discusses various types of terrace waterproofing methods, including brick bat coba, bituminous coating, membrane types like torch seal and self-adhesive, polyurethane liquid membrane, EPDM membrane, and liquid roofing with bitumen coating. It provides steps for preparing the surface, applying slurry and base coats, placing brick bats, and applying a final cement plaster coat with waterproofing compound to achieve a smooth, crack-resistant finish. Proper curing for at least 21 days is recommended.